$38

Terex Crane RT555 Tier 4i & Export Operator’s Manual 12261-270 – PDF DOWNLOAD

Terex Crane RT555 Tier 4i & Export Operator’s Manual 12261-270 – PDF DOWNLOAD

FILE DETAILS:

Terex Crane RT555 Tier 4i & Export Operator’s Manual 12261-270 – PDF DOWNLOAD

Language : English

Pages : 316

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crane RT555 Tier 4i & Export Operator’s Manual 12261-270 – PDF DOWNLOAD

Introduction 6

Construction and Industrial Equipment Product Safety 6

Nomenclature 8

Intended Use 9

Bulletin Distribution and Compliance 10

Contacting Manufacturer 11

Transfer of Machine Ownership 12

Safety 14

Safety Introduction 14

Alert System 15

General Safety 20

Safety Sign Maintenance 20

Safety Sign Locations 21

Workplace Safety 33

Effects of Wind Conditions 41

Lightning Storm 43

Temporary Interruption of Crane Operations 44

Resuming Crane Operations 47

Ending Crane Operations 48

Turning/Driving in Reverse 49

Parking the Vehicle 50

Lock Out & Tag Out 51

Access/Egress 53

Personal Safety 58

Seat Belts 59

Temperature Effects on Telescope and Boom Hoist Cylinders 60

Assembly 64

Step Installation 64

Spooling Wire Rope on Drums 65

Hoist-Line Reeving 69

Cable Reeving 72

Side Stow Jib 73

Description Of Machine and Controls 78

Universal Symbol Identification 78

Upper Controls and Instruments 82

Inspection 92

Pre-Start Inspection 92

Wire Rope Inspection Record 97

Crane Boom 98

Mobile Crane Load Test Inspection 100

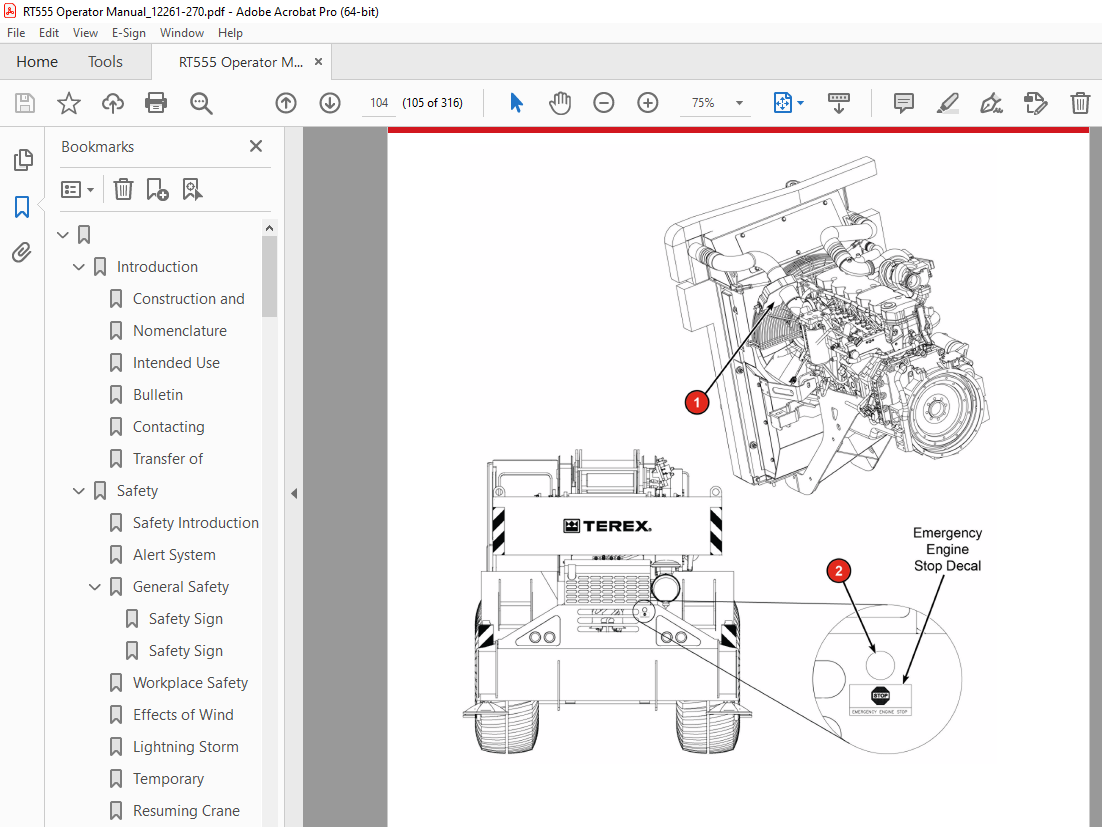

Operating Instructions 104

Emergency Engine Shutdown 104

General Operational Issues 106

Operator Shutoff Devices 106

Operating the Unit 107

Starting the Engine 107

Cold Weather Starting 108

Jump-Starting an Engine with Booster Cables 109

Operating the Engine 110

Making a Typical Lift 111

Arm and Hand Signals 118

Load Rating Chart Interpretation 120

“On-Tires” Lift 129

Unusual Operating Conditions 131

Moving the Unit 135

Vehicular Operation 135

Traveling around the Jobsite 138

Disassembly 140

Side Stow Jib Stowage 140

Transportation 142

Transporting the Crane 142

Maintenance 144

Lubrication Chart 144

Exhaust Spark Arrestor Muffler 145

Cold Weather Package Specifications 147

Cold Weather Package Recommendations 152

Maintenance Introduction 156

Machine Maintenance Checklist 157

Engine Maintenance 160

Engine Radiator Maintenance 162

Transmission Maintenance 163

Axle Maintenance 165

Tire Maintenance 167

Wheel Removal & Installation Procedure 171

Air System Maintenance 173

Brake System 175

Brake Bleeding Procedure 178

Turntable and Swing Pinion 182

Swing Reducer 184

Hydraulic System Maintenance 185

Hydraulic Hoses 190

Hydraulic Oil Requirements 193

Cable Lubrication Methods 196

Electrical System Battery Check 200

Electrical System Collector Ring 204

Wire Rope and reeving 205

Air Dryer 207

Slider Pads 208

Storage 209

Machine Storage 209

Engine Storage 211

Transmission Storage 214

Restoration to Service 215

Restoring Engine to Service 216

Restoring Transmission to Service 217

Chrome Cylinder Rod Storage 218

Specifications 220

Wire Rope Specifications 220

Troubleshooting 222

General Procedure 222

Hydraulic – General 223

Operator Controls 224

Axles 225

Steering Circuit 226

Alternator 230

Starter 231

Brakes 232

Parking Brake 233

Air Pressure 234

Swing Circuit 235

Boom Hoist Circuit 236

Boom Telescope Circuit 237

Winch Circuit 238

Outrigger Circuit 240

Pumps 241

Control Valves 245

Relief Valves 246

Fluid Motor 247

Cylinders 248

Cylinder Leakage 249

Excessive Heating of Oil In Circuit 251

Electrical Controls 252

Propane Heater 253

Maintenance Free Battery Testing 256

Anti Two Block System 258

Service / Parts 260

Valve Adjustments 260

Outrigger Position Sensors 266

Swing Relief Valve Adjustment 268

Rotary Manifold 269

Steering Priority Valve Adjustment 272

Boom Alignment and Adjustment 274

Boom Chain Adjustment 278

Axle Lockout System 282

Swing Brake Control Adjustment 284

Ring Gear Bolting Sequence 287

Torque Wrench Extensions 289

Welding Instructions 290

Hydraulic Cylinders 292

Wire rope and reeving 297

Cable Sockets 302

Appendix 306

Conversion Tables 306

Average Weight of Materials 310

Torque Specs -SAE & Metric 312

Greer Element VGA Operator’s Manual 314