$38

Terex Crane RT600 Tier 3 Export & RТб00-1 Tier 4i Operator’s Manual 12261-262 – PDF DOWNLOAD

Terex Crane RT600 Tier 3 Export & RТб00-1 Tier 4i Operator’s Manual 12261-262 – PDF DOWNLOAD

FILE DETAILS:

Terex Crane RT600 Tier 3 Export & RТб00-1 Tier 4i Operator’s Manual 12261-262 – PDF DOWNLOAD

Language : English

Pages : 385

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crane RT600 Tier 3 Export & RТб00-1 Tier 4i Operator’s Manual 12261-262 – PDF DOWNLOAD

Introduction 6

Construction and Industrial Equipment Product Safety 6

Alert System 8

Nomenclature 9

Safety 10

Safety Introduction 10

General Safety 11

Safety Sign Maintenance 11

Safety Sign Locations 12

Workplace Safety 23

Personal Safety 30

Assembly 32

Step Installation 32

Spooling Wire Rope on Drums 33

Hoist-Line Reeving 37

Cable Reeving 40

Side Stow Jib 41

Description Of Machine and Controls 46

Upper Controls and Instruments 46

Upper Controls and Instruments-Tier 4i 57

Universal Symbol Identification 62

Inspection 66

Pre-Start Inspection 66

Wire Rope Inspection Record 70

Crane Boom 71

Operating Instructions 74

Cummins Tier 4i Engine-Overview of Operation 0

Aftertreatment Regeneration Lamp Behaviors 74

DPF Lamp Functionality 77

DPF Regeneration 79

HEST Lamp Functionality 80

Regeneration Modes 81

Manual Regeneration Procedure 82

Aftertreatment Switch 84

Safety Hazards during Regeneration 85

Engine Idle Speed Increase 87

General Operational Issues 88

Safety Devices 88

Rated Capacity Indicator 89

Operating the Unit 131

Starting the Engine 131

Cold Weather Starting 132

Jump-Starting an Engine with Booster Cables 133

Operating the Engine 134

Making a Typical Lift 135

Arm and Hand Signals 141

Load Rating Chart Interpretation 143

Unusual Operating Conditions 152

Moving the Unit 156

Vehicular Operation 156

Traveling around the Jobsite 159

Transportation 160

Transporting the Crane 160

Maintenance 162

Cold Weather Package Specifications 162

Cold Weather Package Recommendations 167

Lubrication Chart 171

Maintenance Introduction 172

Machine Maintenance Checklist 173

Engine Maintenance 176

Engine Radiator Maintenance 178

Transmission Maintenance 180

Axle Maintenance 182

Tire Maintenance 184

Wheel Removal & Installation Procedure 188

Air System Maintenance 190

Brake System 192

Turntable and Swing Pinion 195

Swing Reducers 197

Hydraulic System Maintenance 198

Hydraulic Oil Requirements 203

Cable Lubrication Methods 210

Electrical System Battery Check 214

Electrical System Collector Ring 218

Wire Rope and reeving 219

Air Dryer 221

Slider Pads 222

Storage 223

Machine Storage 223

Engine Storage 225

Transmission Storage 228

Restoration to Service 229

Restoring Engine to Service 230

Restoring Transmission to Service 231

Chrome Cylinder Rod Storage 232

Specifications 234

Wire Rope Specifications 234

Troubleshooting 236

General Procedure 236

Hydraulic – General 237

Operator Controls 238

Axles 239

Steering Circuit 240

Alternator 244

Starter 245

Brakes 246

Parking Brake 247

Air Pressure 248

Swing Circuit 249

Boom Hoist Circuit 250

Boom Telescope Circuit 251

Winch Circuit 252

Outrigger Circuit 254

Pumps 255

Control Valves 259

Relief Valves 260

Fluid Motor 261

Cylinders 262

Cylinder Leakage 263

Excessive Heating of Oil In Circuit 265

Electrical Controls 266

Propane Heater 267

Maintenance Free Battery Testing 270

Anti Two Block System 272

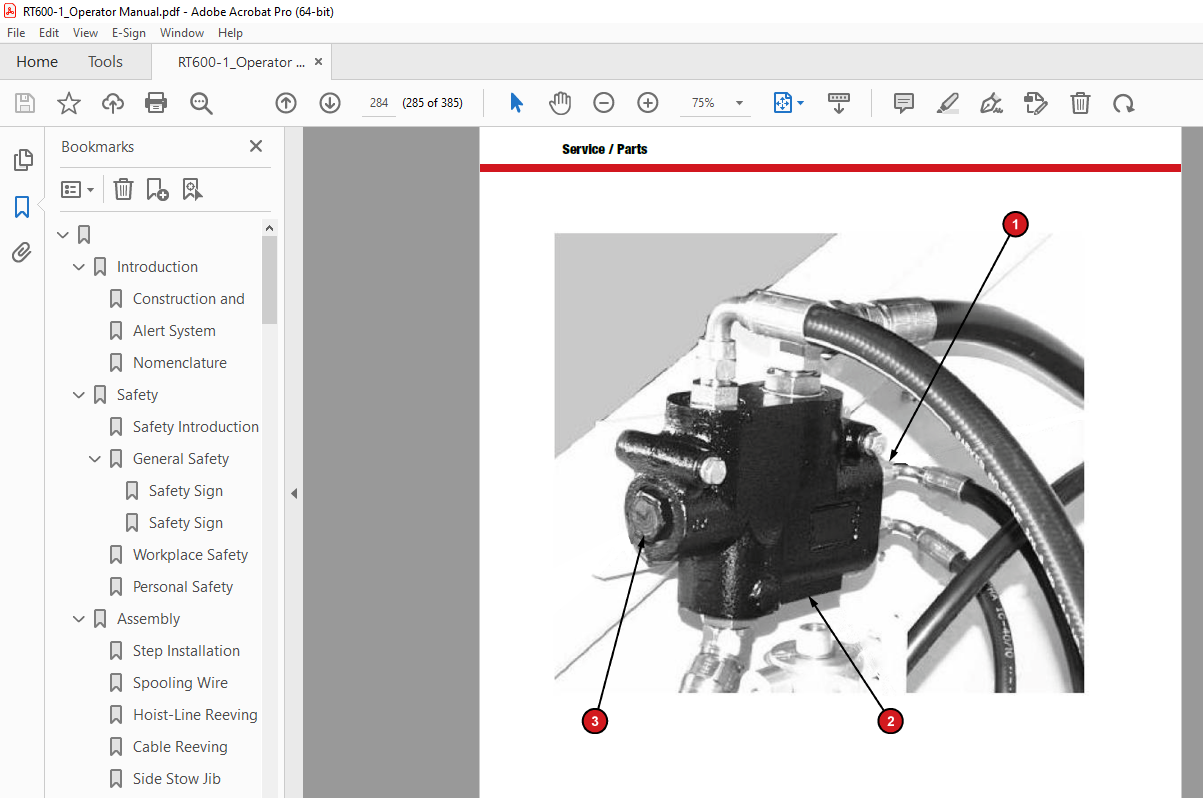

Service / Parts 274

Valve Adjustments 274

Swing Relief Valve Adjustment 280

Rotary Manifold 281

Steering Priority Valve Adjustment 284

Boom Alignment and Adjustment 286

Boom Chain Adjustment 290

Axle Lockout System 294

Swing Brake Control Adjustment 296

Ring Gear Bolting Sequence 299

Torque Wrench Extensions 301

Welding Instructions 302

Hydraulic Cylinders 304

Wire rope and reeving 309

Cable Sockets 314

Applicable Standards / Regulations 316

Wire Rope Users Manual 316

Appendix 376

Conversion Tables 376

Average Weight of Materials 380

Suggested Torque ratings 383