$38

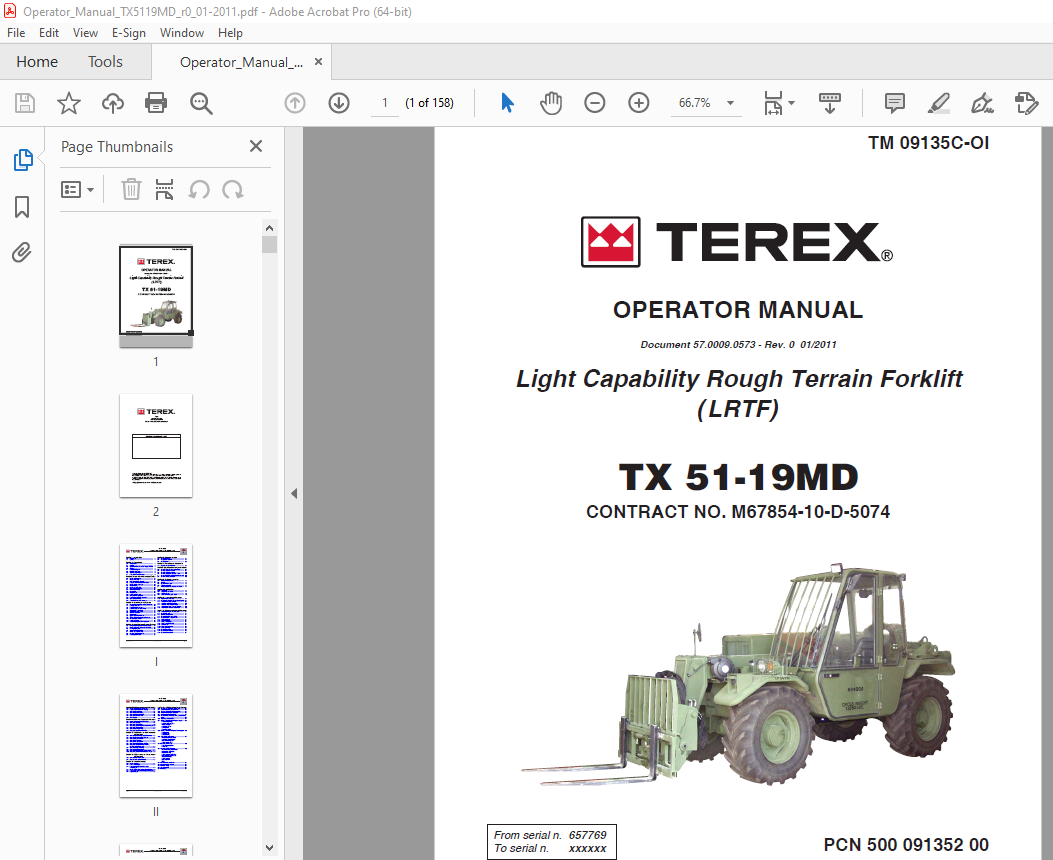

Terex Crane TX 51-19MD Rough Terrain Forklift Operator Manual – PDF DOWNLOAD

Terex Crane TX 51-19MD Rough Terrain Forklift Operator Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Crane TX 51-19MD Rough Terrain Forklift Operator Manual – PDF DOWNLOAD

Language : English

Pages : 158

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crane TX 51-19MD Rough Terrain Forklift Operator Manual – PDF DOWNLOAD

Section 1 – Introduction

1 0 Introduction 3

1 1 Symbols 4

Section 2 – Safety Rules

2 0 Safety Rules 7

2 1 General 7

2 2 Operators Maintenance Staff Responsibilities 7

2 3 Clothing 7

2 4 Personal Equipment 8

2 5 Safety Precautions 8

2 6 Getting Ready to Work 8

2 7 During Work or Maintenance 8

Section 3 – General Information and Specification

3 0 Machine References 13

3 1 Machine Position 13

3 2 Labels and Warning Decals 14

3 3 Explanation of the Different Symbols 19

3 4 Machine Model and Type 20

3 5 Manufacturer 20

3 6 Machine Identification 20

3 7 Chassis Serial Number 21

3 8 Identification Plates 21

3 9 Allowed Use 21

3 10 Improper Use 21

3 11 Applicable Standards 22

3 12 List of Main Components 22

3 13 Description of Main Components 23

3 14 Optional Accessories 23

3 15 Technical Data and Performance 24

Section 4 – Controls and Instruments

4 0 Preoparation, Inspection and Adjustments 29

4 1 Adjusting the Seat 29

4 2 Fastening the Seat Belts 30

4 3 Adjusting the Rear View Mirrors 30

4 4 Controls and Operations 32

4 5 Controls and Instruments 33

4 6 Control Description 34

4 7 Control Lever 43

4 8 Operating the Control Lever 44

4 9 Tilting the Forks Forward and Rearward 45

4 10 Side Shifting the Forks 46

4 11 Rotating the Forks 47

4 12 Quick-Coupling the Fork Attachment 48

Section 5 – Pre-operation Inspection and Adjustment

5 0 Pre-operation Inspection and Adjustment 51

5 1 Pre-Operation Inspection and Check List 51

5 2 Starting the Engine 51

5 3 Jump-Starting the Engine 52

5 4 Battery Disconnect Switch 52

5 5 Stopping / Parking Machine 52

5 6 Refueling the Machine 53

Section 6 – Using the Handler

6 0 Using the Handler 57

6 1 Using the Load Chart 57

6 2 Handling Loads 58

Section 7 – Replacing the Attachments

7 0 Replacing the Attachments 63

Section 8 – Operation Under Adverse Conditions

8 0 Operation Under Adverse Conditions 67

8 1 Operation in Extreme Cold 67

8 2 Operation in Extreme Heat 68

8 3 Operation in Dusty and Sandy Areas 68

8 4 Operation in High Humidity or Salt Water Areas 69

8 5 Operation at High Altitudes 69

Section 9 – Towing the Machine

9 0 Transporting the Machine 73

9 1 Towing 73

9 2 Road or Site Transfer 73

9 3 Lifting the Machine 73

9 4 Transporting Machine on other Vehicles 74

Section 10 – Lubrication

10 0 Lubrication 77

10 1 Lubricant Specification 77

10 2 Lubricant Chart 78

10 3 Lube and Fluid Capacity Chart 79

Section 11 – Preventive Maintenance

11 0 Preventive Maintenance 83

11 1 Using the Suggested Schedule Check Sheets 83

11 2 50 Hours or Weekly Services 85

11 3 250 Hours or Monthly Services 86

11 4 500 Hours or Quarterly Services 87

11 5 1000 Hours or Semi-Annually Services 88

11 6 3000 Hours or Three Years Services 89

Section 12 – 50 Hours or Weekly Maintenance

12 0 50 Hours Or Weekly Maintenance 93

12 1 Check Engine Oil 93

12 2 Drain Engine Fuel Filter 93

12 3 Check Hydraulic Reservoir Oil 94

12 4 Check Brake Oil Reservoir Level 94

12 5 Lube Boom Pads 94

12 6 Lube Drive Shaft 95

12 7 Lube Axle King Pins 95

12 8 Lube Axle Rear Pivot Pin 95

12 9 Lube Cylinder 95

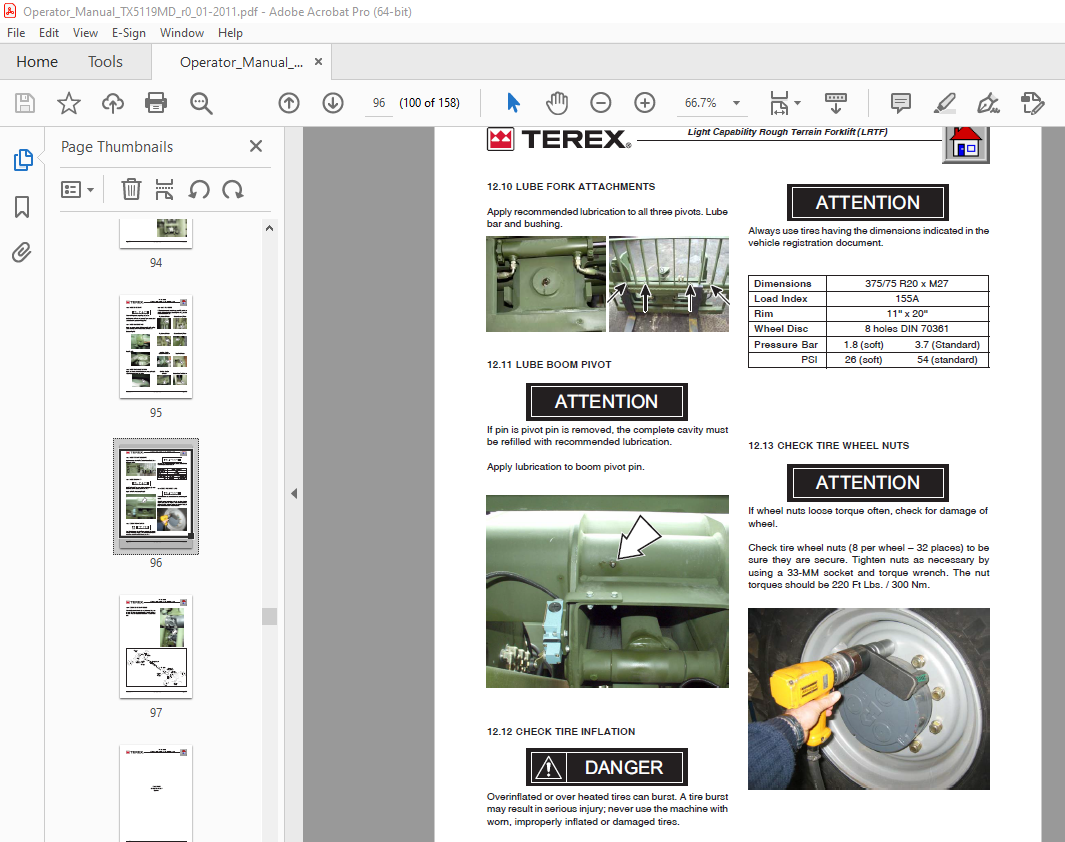

12 10 Lube Fork Attachment 96

12 11 Lube Boom Pivot 96

12 12 Check Tire Inflation 96

12 13 Check Tire Wheel Nuts 96

12 14 Check Drive Shaft Bolt 97

TX 51-19MD

Light Capability Rough Terrain Forklift (LRTF)

Page II TX51-19MD-1-OM 57 0009 0573

Section 13 – 250 Hours or Monthly Maintenance

13 0 250 Hours Or Monthly Maintenance 101

13 1 Engine and Hydraulic Oil Sampling 101

13 2 Check Engine Air Filter 101

13 3 Check Engine Drive Belts 102

13 4 Check Axle Wheel Ends Oil 102

13 5 Check Axle Differential Oil 103

13 6 Check Battery 103

Section 14 – 500 Hours or Quarterly Maintenance

14 0 500 Hours or Quarterly Maintenance 107

14 1 Change Engine Oil 107

14 2 Change Engine Oil Filter 108

14 3 Change Engine Air Filter (external cartridge) 109

14 4 Change Engine Fuel Filter 110

14 5 Check Engine Glow Plugs 111

14 6 Change Hydraulic Reservoir Filter 111

Section 15 – 1000 Hours or Semi-Annually

Maintenance

15 0 1000 Hours or Semi-Annually Maintenance 115

15 1 Check Engine Valve Tip Clearance 115

15 2 Check Electrical Alternator 115

15 3 Check Electrical Starter 115

15 4 Check Electrical System 116

15 5 Check Hydraulic Hoses and Fitting 116

15 6 Change Hydraulic Reservoir Oil Filter,

Cleaning Hydraulic Magnet 116

15 7 Change Axle Wheel End Oil 117

15 8 Change Axle Differential Oil 117

15 9 Check Accumulator Pre-charge Pressure 118

15 10 Change Engine Air Filter (internal cartridge) 118

Section 16 – 3000 Hours or Three Years

Maintenance

16 0 3000 Hours or Three Years 121

16 1 Check Atomisers (Fuel Injector) 121

Section 17 – Machine Storage

17 0 Machine Storage 125

17 1 Short Term Storage 125

17 2 Removal of the Machine From Short

Term Storage 126

17 3 Machine Preparation for Long Term Storage 126

17 4 Removal of Machine From Long Term Storage 127

17 5 Engine Storage 127

Section 18 – 3B6 Technologies LMI System

18 0 3B6 Technologies LMI Load Moment 131

18 1 System lay-out and connections 132

18 2 Components location on the machine 133

18 3 Infolift main unit: Characteristics 134

18 4 Infolift main unit: Dimensions 135

18 5 Load cell amplifier: Dimensions, characteristics,

cable 136

18 6 Control panel description 137

18 7 Display information: Working messages 138

– Power-on sequence

– Safe working condiotion

– Warning condition

– Shut-off condition

– Setting mode

– Shut-off over ride

18 8 Display information: Diagnostics messages 140

– A01 crc error

– A02 cellalarm

– A03 cellallarm

18 9 Standard operating mode 142

– Normal / safe working load

– Pre-warning working load

– Overload working load

– By-pass pushbutton

18 10 Accuracy verification 146

– Pushbuttons functions

– Procedure

18 11 Accuracy verification mode 148

– First time accuracy verification

– Re-accuracy verification

– Load cell reading

– Empty accuracy verification

– Laden accuracy verification

– Cut-off percentage

– Empty moment

– Laden moment

– Filter

18 12 How to set a numeric value 151

18 13 How to set the password 152

18 14 External wiring 153

18 15 Spare parts list 154

18 16 Warnings 154

TX 51-19MD

Light Capability Rough Terrain Forklift (LRTF)

57 0009 0573