$39

Terex Crawler Crane HC 185 Operation Manual – PDF DOWNLOAD

Terex Crawler Crane HC 185 Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Crawler Crane HC 185 Operation Manual – PDF DOWNLOAD

Language : English

Pages : 466

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crawler Crane HC 185 Operation Manual – PDF DOWNLOAD

SUBJECT PAGE NO

American Crane Warnings

Preface 1

1 MACHINERY PLAN AND ELEVA TION

Crawler Crane О

Crawler Crane with W0RKH0RSE 0 1

Crawler Crane with W0RKH0RSE 0 2

General Dimensions 1

Machinery Plan View 2

Right Hand Elevation View 3

Left Hand Elevation View 4

Crawler Lower 5

Performance Specifications 6

General Specifications 8

2 OPERATION

Operation Guidelines 101

lmportant Cautions & Warnings 103

Accident Prevention Signs 105-106

Danger Zone Near Electrical Transmission Lines 107

Audio & Visual Warning Systems for Safety 108

Operating lnstructions Warning 109

Control Summary – Layout 11 О

Operator’s Control Console lndex 111

Pre Operation lnspection 112

Starting Operation 113-116

Fueling Operation 116 1

Auto Lube Operation 117-118

Swinging Operation 119-121

Traveling Operation 122-123

Hoist Operation 124-126 2

Operation in Duty Cycle Mode 127

Operation in Crane Mode 128

Operation in Erect Mode 129

Operation in Clam Mode 130

Front and Rear Drum Dog Operation 131

Third Drum Operation 132

Boom Hoist Operation 133-135

Auxiliary Functions 136

Wylie Load Moment lndicator (LMI) Operation 137-145

Anti-Two Block Override 145 1

W0RKH0RSE Attachment Operation 146-150 (НС 185) 146-148 (НС 21 О)

РАТ Load Moment lndicator (LMI) Operation 151 01-151 37

Operator’s Seat 153

Avoiding Rotation of Suspended Loads 155

Working with the W0RKH0RSE Counterweight Fully Extended (НС 185 ONL У) 160-162

Operating Cranes in Extreme Cold 165-165 4

Hand Signals 170-171

Recommended Storage Precautions 187

Printed in U S A Page 1

1/99 (R11-1/02)

TABLE OF CONTENTS

НС 185/НС 21 О

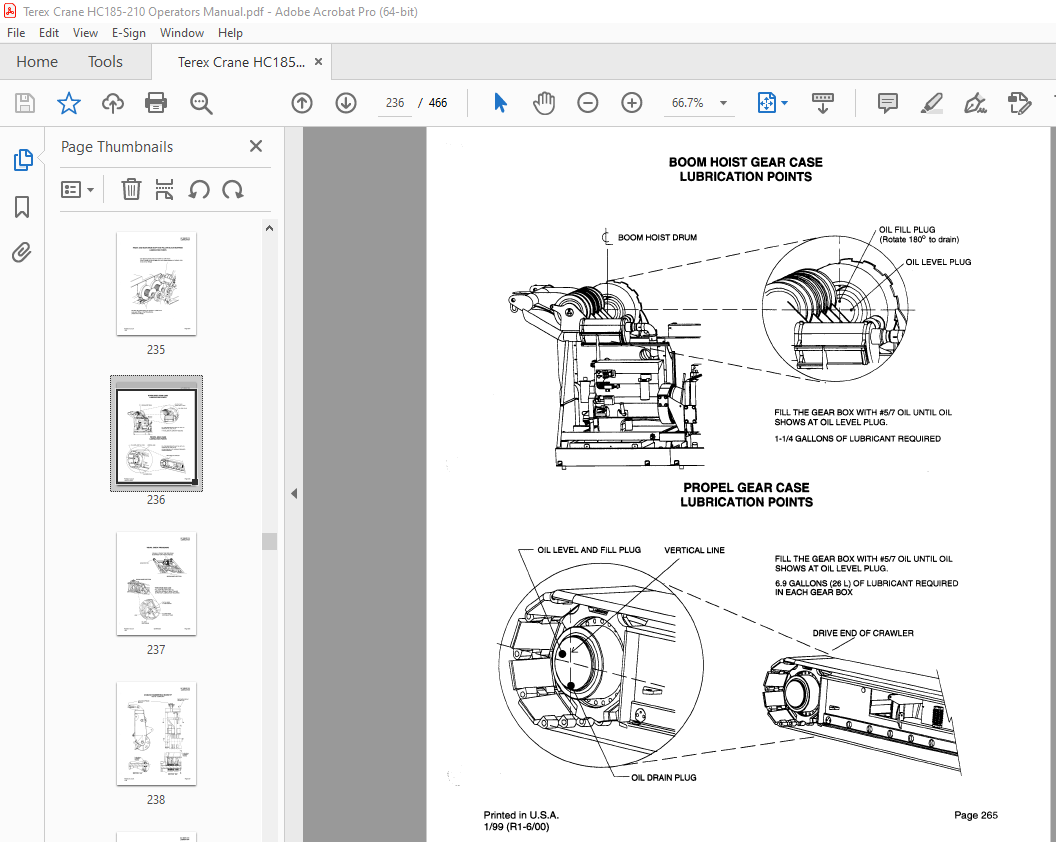

3 LUBRICA TION

General Lubrication lnformation 201

Crane Upper and Lower Lubrication 221

Lubrication lnterval Chart 251

Lubrication, Fuel and Coolant Specifications 252

Location of Auto Lube Components 255

Auto Lube System Diagram 256

Auto Lube Stem Function Description 257

Auto Lube System Check – Visual Check Procedure 258-261 1

Lubrication Points

Swing System Lubrication 262

Swing Planetary Lubrication 263

Front & Rear Drum Shaft & Pillow Block Bearings 264

Boom Hoist Gear Case 265

Visual Check Procedure – Third Drum 266

Hammerhead Boom Tip 267

Offset Tip 268

Recommended Lubricants 271-27 4

4 HVDRAULIC SVSTEMS

Hydraulic Component Locations 400-401

Hydraulic Component List 402-404

Hydraulic Specifications 41 О

Hydraulic System Summary 411

Hydraulic System Description 412-414

lnspection, Maintenance and TrouЫeshooting 415-420

Contaminant Test Procedure for Hydraulic Fluid 421 00-421 11

Hydraulic Schematics 425-432

5 ELECTRICAL SVSTEMS

Schematic Sheets (НС 185 ONL У) 530-539

Schematic Sheets (Without WORKHORSE) (НС 185 ONL У) 540-547

Schematic Sheets (НС 210 ONL~ 550-558

6 ВООМ RIGGING AND JIB

Boom Composition 600

lmportant Notes Concerning Rigging 601

General Boom lnstallation lnformation 601 01 -603 01

Boom Stops Shipping Position 603 8

Boom lnner lnstallation Procedure 604 00-604 01

Boom lnner Removal Procedure 605 00-605 01

Load Out Procedure 605 02

Boom AssemЫy with Assist Crane 606 00-607 01

Boom AssemЫy without Assist Crane 608 00-612 01

Wind Speed Limitations 615

Raising and Lowering Long Booms 616-617

Typical Blocking of Track Side Frames for Long Boom Erection or Lowering 618

Wire Rope Specifications & Drum Capacity 619

Printed in U S A

1/99 (R11-1/02)

Page2

Т ABLE OF CONTENTS

НС 185/НС 210

6 ВООМ RIGGING AND JIB (Continued)

lnstalling Wire Rope Onto а Drum 620

Pulling the Load Line from the Boom Tip to the Drum 621-622

Attaching the Ropes to the Drums 623

Pulling the Load Line from the Drum to Boom Tip 624-625

Wire Rope Clip lnstallation Procedure 626-627

Securing the Dead End of а Rope When Using а Wedge Socket 628

Wedge Socket Warning & Application lnstructions 630

Reeving Diagrams

77″ SH Boom with Luffing Tip – 1, 2, 3, 4, 5, 6, 7 & 8 Parts of Line 635-635 3

77″ SA Boom with Hammerhead Tip – 2, 3 & 4 Parts of Line 636

77″ SA Boom with Hammerhead Tip – 5, 6, 7 & 8 Parts of Line 637

77″ SA Boom with Hammerhead Tip – 9, 1 О, 11 & 12 Parts of Line 637 1

77″ SA Boom with 3 Sheave Offset Tip, 2 Part Line 638

77″ SA Boom with 3 Sheave Offset Tip, 3 Part Line 639

77″ SA Boom with 3 Sheave Offset Tip, 3 Part Main Line & Single Auxiliary Line 639 1

77″ SA Boom with 3 Sheave Offset Tip, 4 Part Line 640

77″ SA Boom with 3 Sheave Offset Tip, 5 Part Line 641

77″ SA Boom with 3 Sheave Offset Tip, 6 Part Line 642

77″ SA Boom with 3 Sheave Offset Tip, 7 Part Line 643

77″ SA Boom with 3 Sheave Offset Tip, 8 Part Line 644

Load Line Chart (in feet) for 77″ SA (1 14m) Boom 646

Load Line Chart (in meters) for 77″ SA (1 14m) Boom 647

Reeving of 3rd Drum for Counterweight Handling, 3 Part Reeving 648

Mast Suspension Reeving 649

Basic Pendant Arrangement 649 1

Boom Composition Charts 650-653 1

Jib ComЬinations Using 50 Ft “S” Center Sections 658

Jib ComЬinations Using 50 Ft “L” Center Sections 659

#9HL, #15 and #16HL Jibs 660-660 5

Jib AssemЫy and lnstallation 661-662

Jib DisassemЫy 663

Backstay Pendant lnstallation, Hammerhead & Jib 663 1

Backstay Pendant lnstallation, Offset Tip & Jib 663 2

Backstay Pendant lnstallation, Luffing Head 663 3

Jib Length Composition Charts – #9HL, #15 and #16HL Jibs 664

Whipline, Backstay & Frontstay Rope Specs for #9HL Jibs 665

Jib Frontstay Composition Chart for #9HL, #15 and #16HL Jibs 666

Jib Backstay Line Lengths for #9HL, #14 and #16HL Jibs 667

Jib Load Line Length Chart 668

Boom lnspection 669

7 MAINTENANCE AND ADJUSTMENT

Asbestos Notice 701

Tool Kit List 702

General Maintenance lnstructions 703

Clutch and Brake Maintenance 704-705

Engine Throttle Adjustment 706

Printed in U S A Page3

1/99 (R11-1/02)

Т ABLE OF CONTENTS

НС 185/НС 210

7 MAINTENANCE AND ADJUSTMENT (Continued)

Clutch Adjustment for Р214 Hydraulic Pump Drive 707

Clutch Adjustment for “Twin Disc” SP214 Hydraulic Pump Drive 707 01

General Bearing Maintenance 708

Welding lnstructions 712

General Boom Guidelines 712 1

AII Boom and Jib Lacing – Guidelines for Field Evaluation 712 2-712 5

Tubular Chord Boom – Guidelines for Field Evaluation 713-713 5

Lacing Repairs (Sleeve Method) 714-715

Welding Procedures for Lacing Replacement in High Strength Tubular Booms 715 1-715 3

lnspection Procedures 7 40

Wire Rope Maintenance 740 2-740 3

Tackle Block Maintenance 740 6

Sheave lnspection 7 40 8

Main Hoist AssemЫy – Front 7 42

Front and Rear Drum Brake Adjustment 743-743 1

Front and Rear Hoist Drum Clutch Adjustment 744

Counterweight Sliding Beam lnspection and Maintenance 7 45

Lagging Removal and lnstallation 747

TurntaЫe Bearing lnspection Procedure for Cranes 748-749

TurntaЫe Bearing lnspection Data Sheet 750

Oil Cooler Maintenance 751

Filter Maintenance for Cummins М11, М14 & Hydraulic Systems 751 5 – 751 7

lnspection Procedure for lnternal Leaking of Vertical Cylinders – Jacks 752

Swivel Seal Replacement 754-756

Welding Procedures for Surface Build-up of Crawler Track Shoes & Rollers 762 12-762 14

Track Sag 765-766

Structural Bolting Specifications 799 11-799 15

8 INSTALLATION

Fiberglide lnsert lnstallation 800

Counterweight lnstallation & Removal with WORKHORSE Attachment (НС 185 ONL У) 801-803

Counterweight lnstallation & Removal with WORKHORSE Attachment (НС 21 О ONL У) 801-802

Crane DisassemЫy with Transport Package 805-807

Crane AssemЫy with Transport Package 808-81 О

Sideframe Counterweight lnstallation & Removal 810 1 – 810 4

Blocking for Transportation 813

Blocking for Transportation оп I-Beam Trailer Only 814

Blocking for Transportation 815-816

Lifting Arrangement for an НС185/НС 21 О without Boom lnner 818-819

9 RATINGS

lmportant Load Lifting Restrictions and Regulations 3499-3499 3

Calculating Total Load Weight Appendix “А”

Weights of Materials 902

Fraction/Decimal Conversion 903