$38

Terex Crawler Crane Superlift CC3800 650 Ton Maintenance Manual – PDF DOWNLOAD

Terex Crawler Crane Superlift CC3800 650 Ton Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Crawler Crane Superlift CC3800 650 Ton Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 572

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

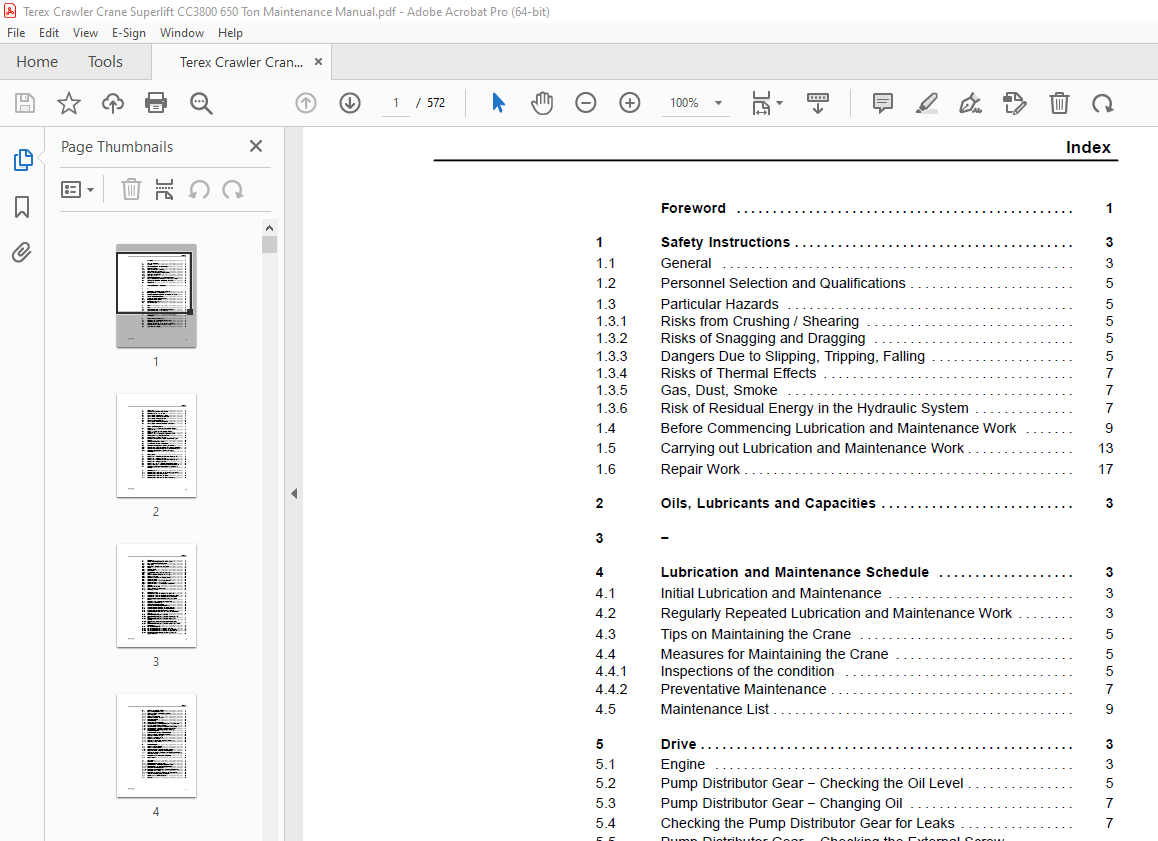

TABLE OF CONTENTS:

Terex Crawler Crane Superlift CC3800 650 Ton Maintenance Manual – PDF DOWNLOAD

Foreword 1

1 Safety Instructions 3

1 1 General 3

1 2 Personnel Selection and Qualifications 5

1 3 Particular Hazards 5

1 3 1 Risks from Crushing / Shearing 5

1 3 2 Risks of Snagging and Dragging 5

1 3 3 Dangers Due to Slipping, Tripping, Falling 5

1 3 4 Risks of Thermal Effects 7

1 3 5 Gas, Dust, Smoke 7

1 3 6 Risk of Residual Energy in the Hydraulic System 7

1 4 Before Commencing Lubrication and Maintenance Work 9

1 5 Carrying out Lubrication and Maintenance Work 13

1 6 Repair Work 17

2 Oils, Lubricants and Capacities 3

3 −

4 Lubrication and Maintenance Schedule 3

4 1 Initial Lubrication and Maintenance 3

4 2 Regularly Repeated Lubrication and Maintenance Work 3

4 3 Tips on Maintaining the Crane 5

4 4 Measures for Maintaining the Crane 5

4 4 1 Inspections of the condition 5

4 4 2 Preventative Maintenance 7

4 5 Maintenance List 9

5 Drive 3

5 1 Engine 3

5 2 Pump Distributor Gear − Checking the Oil Level 5

5 3 Pump Distributor Gear − Changing Oil 7

5 4 Checking the Pump Distributor Gear for Leaks 7

5 5 Pump Distributor Gear − Checking the External Screw

Connections 9

6 Roller−bearing Slewing Ring 3

6 1 Lubricating the Roller−bearing Slewing Ring 3

6 2 Lubricating the Ring Gear 5

6 3 Checking the Bolts on the Slewing Ring for Tightness 7

6 4 Checking the Lip Seals on the Slewing Ring 9

6 5 Quick Release Coupling 11

Index

036−2000−108_en 2

7 Slew Gear 3

7 1 Carrying out Visual and Noise Checks 5

7 2 Lubricating the Slew Gear Pinion 5

7 3 Slew Gearbox − Cleaning the Housing 7

7 4 Slew Gearbox − Checking the Oil Level 7

7 5 Slew Gearbox − Changing the Oil 9

7 6 Cleaning the Bleeder Valves 11

7 7 Slew Gearbox − Checking the Brakes 13

7 8 Slew Gearbox − Checking the Bolted Connections 15

8 Hoists and Reeving Winch 3

8 1 Hoists 1 and 2 − Checking the Transmission Oil Level,

Topping up Oil 5

8 2 Hoist 3 − Checking the Transmission Oil Level,

Topping up Oil 7

8 3 Hoists 1, 2 and 3 − Changing the Transmission Oil 9

8 4 Reeving Winch − Checking the Oil Level 13

8 5 Reeving Winch − Changing the Oil 15

8 6 Hoists and Reeving Winch − Lubricating the Rope Drum

Bearings 19

8 7 Checking the Rope End Fixture 19

8 8 General Overhaul of the Hoist Winches 19

8 9 Hoists and Reeving Winch − Checking the Brakes 21

8 10 Checking the Lower Limit Switches of the Hoists for Function 25

8 11 Checking the Hoist Limit Switches of the Hoists for Function 25

8 12 Hoists and Reeving Winch − Checking the Screw

Connections 27

9 Luffing Gears 3

9 1 Luffing Gear 1 − Checking the Oil Level, Topping up Oil 5

9 2 Luffing Gear 1 − Changing the Oil 7

9 3 Luffing Gear 2 − Checking the Oil Level, Topping up Oil 11

9 4 Luffing Gear 2 − Changing the Oil 13

9 5 Luffing Gear 1 and 2 − Lubricating Rope Drum Bearings 17

9 6 Luffing Gears 1 and 2 − Checking the Luffing Gear Brakes 17

9 7 Checking Exterior Screw Connections and Tightening if

Required 23

10 Derricking Gear 3

10 1 Derricking Gear − Checking the Oil Level, Topping up Oil 5

10 2 Derricking Gear − Changing the Oil 7

10 3 Derricking Gear − Checking the Brakes 11

10 4 Derricking Gear − Checking the Bolted Connections 17

Index

036−2000−108_en 3

11 Equipment 3

11 1 Service the Hydraulic Cylinders and Equipment 3

11 2 Boom − Lubricate the Bearing Points 5

11 3 Hook Blocks 7

11 3 1 Hook Blocks − Lubricate Bearing Points 7

11 4 Ropes 11

11 4 1 Lubricate Ropes 13

11 4 2 Clean Ropes 15

11 4 3 General Notes on Handling and Assembly 15

11 5 Sheaves 35

11 5 1 Check the Roller Bearings on the Sheaves 35

11 5 2 Check the Sheaves 37

11 5 3 Lubricating / Checking the Sheave Bearings 37

11 6 Adjustment Winch 41

11 6 1 Adjustment Winch − Checking the Oil Level 41

11 6 2 Adjustment Winch − Changing Oil 43

11 6 3 Adjustment Winch − Checking Bolted Connections 45

11 7 Carriage 47

11 7 1 Lubricating the Wheels 47

11 7 2 Tyres − Checking the Air Pressure 47

11 7 3 Removing a Wheel 47

12 Hydraulic System 3

12 1 Hydraulic Oil Reservoir − Checking the Oil Level 3

12 2 Hydraulic Oil Reservoir − Replacing the Return Line Filter 5

12 3 Hydraulic Oil Reservoir − Replacing the Aeration Filter 5

12 4 Leak Oil Circuit − Return Oil Filter − Cleaning the Filter

Element 7

12 5 Hydraulic Pump − Changing the Add−on Filter 9

12 6 Replacing the Hydraulic Oil 11

12 7 Bleeding the Hydraulic System 13

12 8 Checking the Hydraulic System for Leaks 13

12 9 Hydraulic System − Checking the Pressure Hoses 15

12 10 Hydraulic System − Changing the Pressure Hoses 15

12 11 Hydraulic System − Handling the Hose Couplings 17

12 12 Hydraulic System − Checking the Accumulator Initial Gas

Pressure 19

12 13 Lower Luffing Mast Support Cylinders 21

12 13 1 Lower Luffing Mast Support Cylinders − Checking the Oil

Level 21

12 13 2 Lower Luffing Mast Support Cylinders − Bleeding the

Cylinders 23

12 13 3 Checking the Lower Luffing Mast Support Cylinders for

Leaks 27

12 13 4 Lower Luffing Mast Support Cylinders − Checking the Bolted

Connections 27

12 14 Fly Jib Support Cylinders 29

12 14 1 Fly Jib Support Cylinders − Checking for Leaks 29

12 14 2 Fly Jib Support Cylinders − Checking the Oil Pressure 29

12 14 3 Fly Jib Support Cylinders − Checking the Gas Pressure 29

12 14 4 Correcting the Oil and/or Gas Pressure and Filling the

Support Cylinder 31

Index

036−2000−108_en 4

13 Heating and Air Conditioning 3

13 1 Engine−Independent Heating 3

13 1 1 Check the System is Functioning Correctly 3

13 1 2 Fault Diagnosis 5

13 1 3 Check the Water Level 9

13 1 4 Replace the Heat Exchanger 9

13 1 5 Replace Fuel Filter 11

13 2 Air Conditioning 13

13 2 1 Switch on the Air Conditioning 13

13 2 2 Air Conditioning − Visual Inspection by the Crane Operator 15

13 2 3 Have the Air Conditioning Checked 19

13 2 4 Air Conditioning − Having the Collector Dryer Replaced 21

13 2 5 Air Conditioning − Error Diagnosis of the Condenser 21

13 2 6 Air Conditioning − Error Diagnosis of the Heating /

Air Conditioning Unit 23

13 3 Liquid Petrol Gas Heating “Trumatic E2400” 31

13 3 1 Check the System is Functioning Correctly 33

13 3 2 Replace the Heat Exchanger 33

13 3 3 Having the System Checked 33

13 3 4 Perform a Visual Check 35

13 3 5 Replacing the Fuse of the Electronic Control Unit 37

13 3 6 Replacing the Gas Cylinder 39

14 Electrical System 3

14 1 Check the Lighting System 3

14 2 Check the Limit Switches 3

14 2 1 Lower Limit Switch − Checking the Functionality 3

14 2 2 Hoist Limit Switch − Checking the Functionality 3

14 3 Checking the Slip Ring Contacts on the Winches and the Rotary

Joint of the Chassis 5

14 4 Preventative Measures Against Cable Fires 5

14 5 Fuse Overview 11

15 Fuel System 3

15 1 Fuel Filter 5

15 1 1 Fuel Separator (Preliminary Filter) 5

15 1 1 1 Fuel Separator − Emptying the Inspection Glass 5

15 1 1 2 Fuel Separator − Changing the Filter Element 7

15 1 2 Fuel Filter in the Diesel Engine 11

15 1 2 1 Fuel Filter in the Diesel Engine − Changing Filter Element 11

15 1 3 Fuel Filter of the Heating 13

15 1 3 1 Fuel Filter of the Heating − Changing the Filter Element 13

15 2 Fuel Tank − Draining Water and Deposits 15

15 3 Fuel System − Checking the Lines 15

15 4 Filling up 17

Index

036−2000−108_en 5

16 Cooling, Intake and Exhaust System 3

16 1 Cooling System 3

16 1 1 Cooling System − Visual Check 3

16 1 2 Cleaning the Cooling System 3

16 1 3 Checking the Coolant Level, Topping up If Required 5

16 1 4 Changing the Coolant 7

16 2 Intake System 11

16 2 1 Intake System − Visual Check 11

16 2 2 Replacing the Filter Element of the Air Filter 11

16 2 3 Cleaning the Filter Element 13

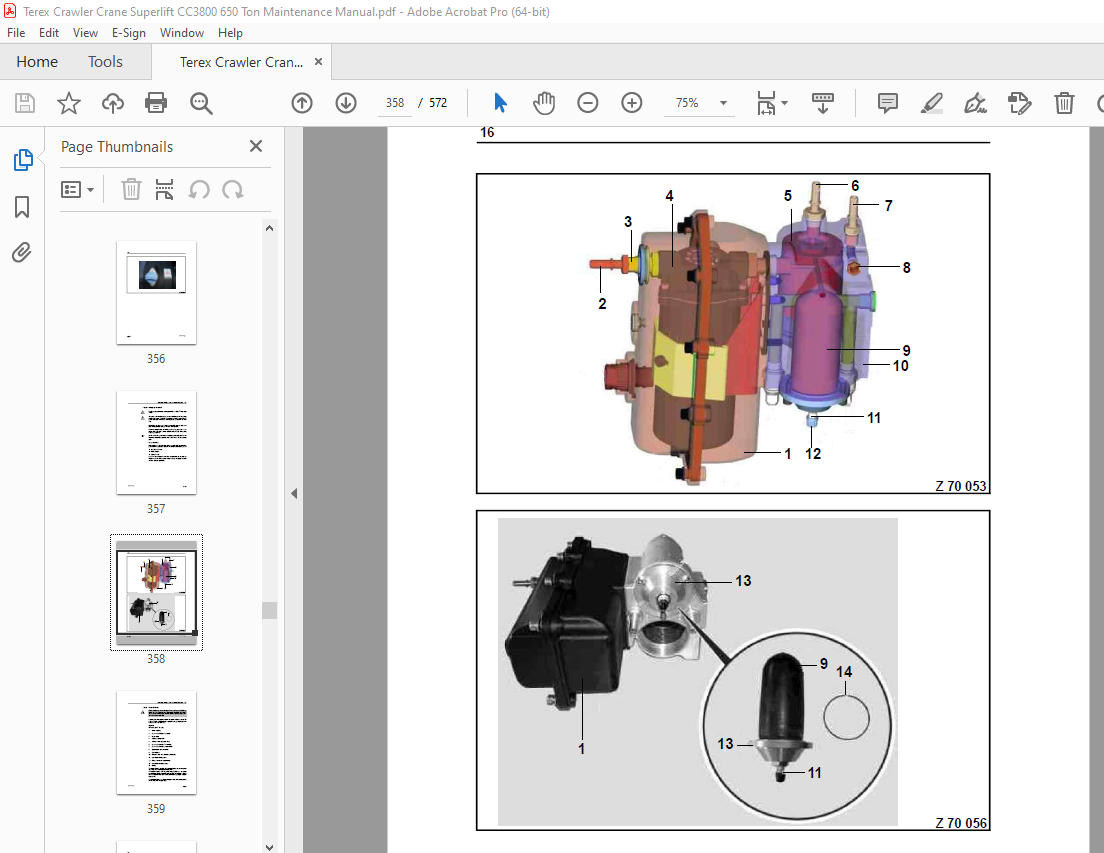

16 3 SCR System 15

16 3 1 Carrying out Visual Inspections of the SCR System 17

16 3 2 Safety Instructions when Handling AdBlue) 19

16 3 3 AdBlue) Tank 21

16 3 4 Pump Module 25

16 3 4 1 Pump Module − Filling the Compressed Air Reservoir 27

16 3 4 2 Pump Module − Replacing the AdBlue) Filter 29

16 3 4 3 Pump Module − Checking the AdBlue) Filter for Debris

Residue 31

16 3 5 SCR Catalytic Converter 33

16 3 6 SCR System − Draining the Compressed Air Tanks 35

16 3 7 SCR System − Air Drier: Replace Granulate Cartridge 35

17 Piston Rods 1

17 1 Exposed Chrome Surfaces − Applying Protective Grease 1

18 Crane Operator’s Cab 3

18 1 Check the Windscreen Washer System for Proper

Functioning 3

18 2 Fill up the Supply Tank of the Windscreen Washer System 3

18 3 Lubricating the Cab Tilt Cylinder 5

19 Crawler Chassis 3

19 1 Drive Gearbox 3

19 1 1 Transmission − Checking the Oil Level 3

19 1 2 Drive − Checking the Oil Level 5

19 1 3 Motor Flange − Checking the Oil Level 5

19 1 4 Transmission − Changing Oil 7

19 1 5 Drive − Changing Oil 9

19 1 6 Motor Flange − Changing the Oil 11

19 1 7 Cleaning the Bleeder Valves / Filters 13

19 1 8 Cleaning the Drive Gearbox 13

19 2 Lubricating the Idlers, Support and Track Rollers 15

19 3 Lubricating the Connecting Pins 15

19 4 Servicing the Hydraulic Cylinders on the Chassis 15

19 5 Tensioning the Track Group 17

19 6 Lubricating the Track Pins on the Track Group of the

Crawler−mounted Crane and Checking the Track Tension in

the Case of Running Noises 19

19 7 Checking the Screw Connections of the Drive Gearbox 21

19 8 Central Lubricating System 23

19 8 1 Component Parts 23

19 8 2 Function 23

19 8 3 Servicing the Central Lubricating System 25

19 8 4 Filling the Tank of the Central Lubrication System 27

19 8 5 Troubleshooting 29

Index

036−2000−108_en 6

20 Counterweight Dolly 3

20 1 Lubricate the Ball Bearing Slewing Ring 3

20 2 Lubricating the Ring Gear 3

20 3 Check the Screws of the Slewing Ring 5

20 4 Slewing Gear 7

20 4 1 Slew Gear Mechanism − Checking the Oil Level 7

20 4 2 Slew Gear Mechanism − Changing Oil 7

20 4 3 Slew Gear Mechanism − Checking the Disc Brake 9

20 4 4 Slew Gear Mechanism − Checking the Bolted Connections 11

20 4 5 Slew Gear Mechanism − Visual Inspection 11

20 5 Final Drive − Check the Oil Level 13

20 6 Final Drive − Replacing Oil 15

20 7 Tyres − Check the Air Pressure, Tread and Rims 19

20 8 Tyres − Checking the Wheel Nuts, Tightening if Required 21

20 9 Check Weld Seams for Cracks 23

21 Visual Checks 3

21 1 Visual Check − Superstructure and Crawler Chassis 3

21 2 Visual Checks on the Superlift Counterweight Supporting

Frame 3

21 3 Visual Check − Equipment 5

22 Inspections of the Crane 3

22 1 Recurrent Inspections of the Crane 3

22 1 1 Inspection of Load−bearing Steel Constructions 15

22 1 2 Inspection of the Disc Wheels (Rims) 57

22 1 3 Inspection of the Winches 59

22 1 3 1 Theoretical Service Life 61

22 1 3 2 Actual Operating Conditions 63

22 1 3 3 Determining the Operating Conditions (Load Spectrum) 63

22 1 3 4 Operating Hours of the Hoists per Inspection Interval 65

22 1 3 5 Determining the Spent Share of the Theoretical Service Life

of the Winches 67

22 1 3 6 Documentation 69

22 1 4 Load Hook 73

22 1 4 1 Inspection and Surveillance Measures 73

22 1 5 Inspection of the Sheaves 75

22 1 6 Inspection of the Ropes 77

22 1 7 Documentation 91

23 Central Lubricating System 3

23 1 Function 5

23 1 1 Setting the Interval and Operating Times 7

23 2 Service the Central Lubricating System 11

23 2 1 Filling the Tank of the Central Lubrication System 13

23 3 Troubleshooting 15