$43

Terex Crawler Crane Superlift CC3800 650 Ton Operating Manual – PDF DOWNLOAD

Terex Crawler Crane Superlift CC3800 650 Ton Operating Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Crawler Crane Superlift CC3800 650 Ton Operating Manual – PDF DOWNLOAD

Language : English

Pages : 861

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crawler Crane Superlift CC3800 650 Ton Operating Manual – PDF DOWNLOAD

Foreword 1

Safety lnstructions

General

lntended Use

Operating Conditions and Computed Design of the Crane

General

Classification of the Crane

Classification of the Engines

Workplace Ergonomics

Load and Utilisation of the Crane

Required Amblent Conditions

Service Life

Scrapping / Disposal

Standards and Calculation Regulations

Dangers to Air Traffic

Safety Regulations

Organisational Measures

Personnel Selection and Qualifications

Particular Hazards

Electric Energy

Gas, Dust, Steam, Smoke

Crushing / Collision

Becoming Entangled / Dragged in

Crushing/Shearing

Dangers Due to Slipping, Tripping, Falling

Comblnation of Hazards with Comblned Operation of Two or

Маге Cranes

Operating Areas of Several Cranes Overlap

Several Cranes Raising а Load Together

Crane Operation

Before Crane Operation

During Operation of the Crane

Following Crane Operation

Power Supply Failure

When AssemЫing and Dismantling Crane Components

Hand Signals

General Hand Signals

Hand Signals for Working Movements

Hand Signals for Driving Movements

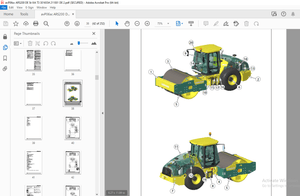

Structure of the Crawler-mounted Crane

Overview

Superstructure

Crawler Chassis

Counterweight Dolly 325 t (716 5 kip)

Boom Variants

Allocation and Description of the Hook Operations with the

Relevant Boom Variants

Technical Description

Chassis

Superstructure

Additional Equipment (Options)

Hook Ыocks

Technical Data

Safety-relevant Components

General

Ladders and Catwalks

Fall Protection

Headlights

Emergency Exit

Signs

General Signs

Description and Fitting Location of the Signs

Meaning of the Signs

СЕ Safety Signs

Description and Fitting Location of the Signs

Meaning of the Signs

Safety Signs (Only for the USA)

Description and Fitting Location of the Signs

Meaning of the Signs

Crane Operator’s СаЬ

Operating Elements and Displays in the Crane Operator’s

СаЬ

Control Levers

Front Console

Overview of the Front Console

Display and Operating Elements оп the Front Console

Display and Operating Console for Monitoring the Engine and

Crane Operation

Area А – lndicator Light Area

Area В – Functional Displays

Area С – Crane Operation

Area D – Assignment with Different Screens PossiЫe

(Неге: Quick Menu)

Area Е – Engine Scaling Display

Display and Control Console LM I System

lndex

Overhead Console

lgnition Switch

Right Arm Console

Entering / Exiting the СаЬ

Tilting the СаЬ

Tilting the Crane Operator’s СаЬ

Workplace Ergonomics

Adjusting the Crane Operator’s Seat

Sunshade

Lighting Equipment

Opening / Closing Windows

Side Window, Rear Window

Front Window

Warning Lamp

Radio Remote Control

Moblle Control Panel for Emergency Control

Engine and Drive

Engine Control

Before Starting the Engine

Starting Procedure

Safety Regulations during the Starting Procedure

Starting the Engine

Jump Starting

External Start with Jump Leads

External Start with the lntegrated Socket

То Ве Observed after Starting the Engine

Standard Hydraulic System

Warming up the Hydraulic System

Warming-up Procedure

Hydraulic System for Low Temperatures

Warming up the Hydraulic System

Warming-up Procedure

Checks with the Diesel Engine Running

Faults in the SCR System (only for Engines in Accordance with

Exhaust Emission Standard ЕМ3Ь / ЕРА Тler 4i)

Operating Restrictions for Exhaust Emission Standard

ЕРА Tier4i

lnstructions for Operation

Switching Off the Engine

Automotive Driving

Load Limit Control

Driving the Crawler-mounted Crane

General

Main Driving Direction

Requirements for Road Surface Conditions

Regulations for Driving Operation

Control of the Crawler Chassis

Control Movements

Control Movements for Tailing Operation

Options for Controlling the Driving Speed

Normal Range

High Speed

Brakes

Driving without Load оп the Horizontal and Angled Road

Surface

General

Driving without Load

Driving with Load оп а Horizontal and lnclined Road

Surface

General

Driving with Load оп Horizontal, Level Terrain

(< 0 3° Gradient)

Driving with Load оп lnclined, Level Terrain

( > 0 3° Gradient)

Slewing and Braking the Superstructure

Speed Control

Slewing

Normal Operation

High Speed Operation

Switching оп the Slewing Movement with “Slewing Aid”

Braking the Superstructure

Mechanical Locking of the Holding Brake in Ореп Position

Operating the Safety Equipment

IC-1 Crane Control

Overload Cut-off Using the Load Limit Device (LLD)

Function

Bridging the Load Limit Device

Control Elements: “EN 13000” Design Compared to the

“Non-EN 13000” Design

8 1 1 2 2 Bridging the Load Limit Device in the Non-EN 13000

Version

8 1 1 2 2 1 Bridging the Shut-down of the Load-moment-reducing

Movements 13

8 1 1 2 2 2 Bridging the Shut-down of Load-moment-increasing

Movements 15

8 1 1 2 2 3 Bridging the Shut-down of AII Movements 17

8 1 1 2 2 4 Configuration Operation 19

8 1 1 2 2 5 Crane Operation 21

8 1 1 2 2 6 Operation with Bridged Crane Control 23

4

036-1000-108 _ еп

lndex

8 1 1 2 3 Bridging the Load Limit Device in the EN 13000 Version 25

8 1 1 2 3 1 Bridging the Shut-down of the Load-moment-reducing

Movements with the Setup Function 25

8 1 1 2 3 2 Bridging the Shut-down of Load-moment-increasing

Movements with the Setup Function 27

8 1 1 2 3 3 Bridging the Shut-down of all Movements with the Setup

Function 29

8 1 1 2 3 4 Bridging the Shut-down of the Load-moment-reducing

Movements with the Key-operated Pushbutton 31

8 1 1 2 3 5 Bridging the Shut-down of the Load-moment-increasing

Movements with the Key-operated Pushbutton 33

8 1 1 2 3 6 Bridging the Shut-down of all Movements with the

Key-operated Pushbutton 35

8 1 1 2 3 7 Configuration Operation 37

8 1 1 2 3 8 Crane Operation 39

8 1 1 2 3 9 Operation with Activated Setup Buttons 41

8 1 1 2 3 1 О Operation with Bridged Crane Control 43

8 1 2 Error Code ТаЫеs 45

8 1 2 1 Load Limit Device Errors 45

8 1 2 2 System Errors in the Control System 53

8 1 2 3 Error Messages from Monitoring the Operative States 63

8 1 2 4 Signal Errors оп the Sensor System and Actor Technology 69

8 1 2 5 lnformation Messages with No Effect оп Crane Control 83

8 1 3 System Start / Switching the System off 89

8 1 4 Operating the LLD System 91

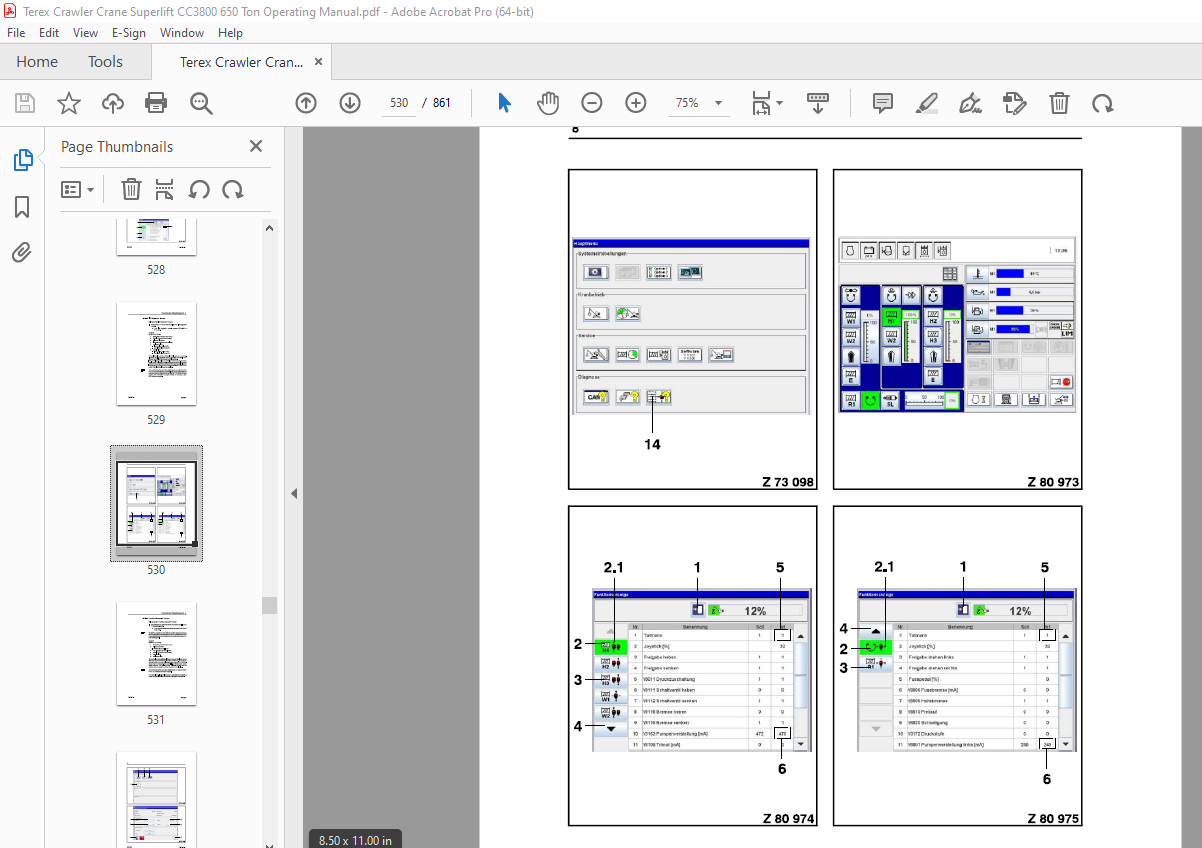

8 1 5 Description of the Monitor Screens and Function Keys 93

8 1 5 1 Opening Screen 93

8 1 5 2 Main Menu of the Display and Operating Console of the LLD System

(LLD Screen) 93

8 1 5 3 “System Settings” Screen 97

8 1 5 4 “Set up Crane Туре” Screen 99

8 1 5 5 “Options Menu” Screen 101

8 1 5 5 1 Calling up the “Options Menu” Screen 101

8 1 5 5 1 1 “Options” Selection 101

8 1 5 5 1 2 “Factory Options” Selection 103

8 1 5 6 “Set up Display” Screen 105

8 1 5 7 “LLD” Screen 107

8 1 5 7 1 Section А- Configuration Display 109

8 1 5 7 2 Section В – Message Strip 111

8 1 5 7 2 1 Error display “LLD” 113

8 1 5 7 2 2 Error Display “PLC” 115

8 1 5 7 3 Section С – Crane Display 117

8 1 5 7 3 1 Display of Derricking Gear Force 119

8 1 5 7 4 Section D – Load Utilisation Display 121

8 1 5 7 4 1 Load Monitoring Equipment 121

8 1 5 7 5 Section К – Assignment with Different Screens PossiЬle (here:

“Operating Mode Selection” Screen

“Slewing and Gradient Level lndicator” Display

“Operating Range Limit” Screen

“Hook Height” Display

“Ground Pressure” Display

“Lateral Auxiliary Support” Display

8 1 5 8 “Operating Range Limit” Screen 155

8 1 5 8 1 Setting up the Various Limits 159

8 1 5 9 “Service Functions” Screen 167

8 1 5 1 О “Operating Hour Meter” Screen 169

8 1 5 10 1 Calling up the “Operating Hour Meter” Screen 169

8 1 5 10 2 Explanation of Symbols in the “Operating Hour Meter”

Screen 171

8 1 5 10 3 lmportant Code of Practise 171

8 1 5 10 4 Evaluation of the Recorded Operating Hours 175

8 1 5 11 “Winch Oil Level” Screen 177

8 1 5 12 “Software Update” Screen 179

8 1 5 12 1 Updates – General 181

8 1 5 12 2 System Software Update 183

8 1 5 12 3 Control Application Update 187

8 1 5 12 4 Crane Data Update (Crane Data) 189

8 1 5 12 5 LLD Application Update (LMI) 191

8 1 5 12 6 LLD Data Update (LMI Data) 193

8 1 5 12 7 Monitoring and Messages 193

8 1 5 13 “Data Logger” Screen 197

8 1 5 13 1 “Data Logger” Screen (Data Recorder) 197

8 1 5 13 2 “Hoist Logger” Screen 199

8 1 5 13 3 ‘Wind Logger” Screen 201

8 1 5 14 “CAN Display” Screen 203

8 1 5 15 “1/0 Diagnosis” Screen 205

8 1 5 16 “Function Diagnosis” Screen 207

8 1 5 17 Main Menu of the Display and Operating Console of the Engine

and Crane Operating System (МОТ Screen) 209

8 1 5 17 1 “System Settings” Screen 209

8 1 5 17 2 “Set up Crane Туре” Screen 211

8 1 5 17 3 “Set up Display” Screen 213

8 1 5 17 4 “МОТ” Screen 213

8 1 5 17 4 1 “Rope Limit Switch Bridging” Display 215

8 1 5 17 4 2 “Operating Hour Meter” Screen 217

8 1 5 17 4 3 “Counterweight Dolly” Display 217

8 1 5 17 4 4 “Support Frame Lift Cylinder” Display 217

8 1 5 17 4 5 “Adjustment Winch” Display 217

8 1 6 Procedure in the Event of Errors 219

8 1 6 1 Error-Free Operation/Malfunction 219

8 1 6 2 Failure of Crane Control (CAN Stop) 219

8 1 6 3 Failure of а Monitor 219

8 2 Limit Switches 221

Hoist Limit Switches 221

Bridging the Hoist Limit Switches 223

Rope End Limit Switches 225

Function 225

Release Switch System for Crane Movements 227

General 227

Assignment of the Release Buttons 227

Activating the Release Buttons 227

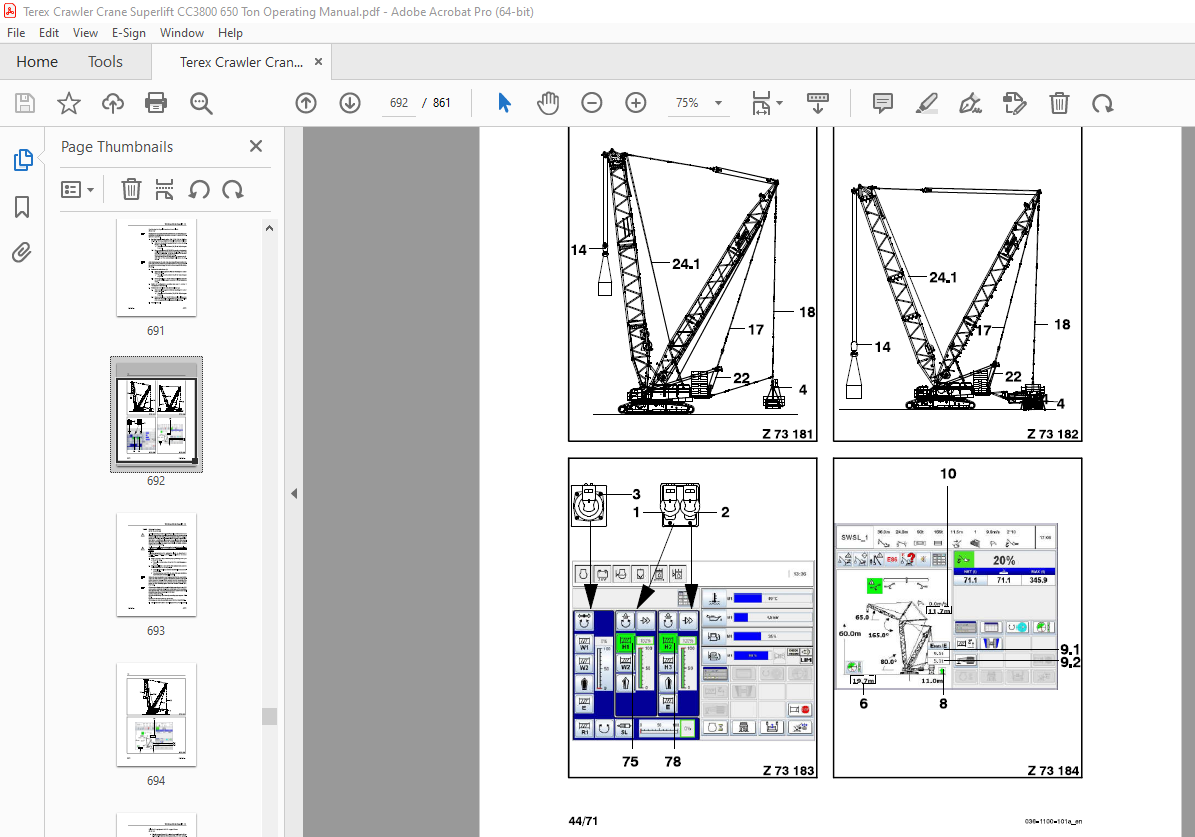

Working with the Superlift

Modus Operandi

Safety lnstructions for Working with the Superlift

General Safety lnstructions

Safety lnstructions for Working with SL Equipment with SL

Support Frame

Safety lnstructions for Working with SL Equipment with

Counterweight Dolly

Requirements for the Ground Conditions at the Operating

Site

Description and Design of the Superlift

Description and Design of the Standard Superlift

Description and Design of the VariaЫe Superlift (Vario Superlift)

Description and Design of the SL Equipment with Counterweight

Dolly

Working with the Crane without Superlift Counterweight

(SL Counterweight)

Working with the Crane with Superlift Counterweight

(SL Counterweight)

Preparations for Raising the Load

Preparations for Raising the Load with the Standard Superlift

Preparations for Raising the Load with VariaЫe Superlift

(Vario Superlift)

Preparations for Raising the Load with SL Equipment and

Counterweight Dolly

Raising the Load

Changing the Load Radius (Change to the Working

Radius)

Adjusting the Superlift Counterweight Radius (SCR)

Setting the Superlift Counterweight Radius (SCR) Using the

Radio Remote Control for the Superlift with Counterweight

Dolly

Setting the Superlift Counterweight Radius (SCR) Using the

Control Levers in the Crane Operator’s СаЬ for the Superlift

with Counterweight Dolly

Changing the Superlift Mast Radius

Selecting the Adjustment Winch (Vario Winch)

Automatic Adjustment of the SLC

Manual Adjustment of the SLC

Support Frame Lift Cylinder (Optional)

Selecting the Support Frame Lift Cylinders

Operating the Support Frame Lift Cylinders

Setting the Load Down

Heating and Ventilation

General

Engine-dependent Heating

Engine-independent СаЬ Heater Arrangement

Operating / Safety lnstructions

Operating Control of the Heater Timer

Air Conditioning

Liquid Gas Heating System (Optional)

lmportant Notes

Heating

Ventilation

Shutting off

Notes оп Heating Operation

Shut-Down With the Window Switch

Parking the Crane

Wind Speeds

Lowering the Boom System

Emergency Operation

Safety lnstructions

Emergency Control System with the Moblle Control Panel

Emergency Operation with the Emergency Unit

General

Emergency Unit

Description of the Emergency Unit

Hydraulic Electronic Components

Drive

Operating and Monitoring Controls

Fuel Tank

Connecting the Emergency Unit to the Crane

Starting the Emergency Unit

Driving the Crane Movements during Emergency Operation

Removing the Emergency Unit

Radio Remote Control

General

Preparing the Radio Remote Control

Connection Fault

Activating the Radio Remote Control

Radio Remote Control for AssemЫy of the Basic Unit

Radio Remote Control for Configuring

Radio Remote Control for the Adjustment Winch and Vario-

Cylinder in the Superlift Rods

Radio Remote Control for the Counterweight Dolly

Radio Remote Control for Rope Change

Driving with the Counterweight Dolly

Safety lnstructions

General

Requirements for the Ground Conditions at the Operating Site

Description of Mechanics

Basic Position and Angle Functions

Reversing (Definition)

Description of the Software

Setting the Operating Modes

Selecting the Display “Counterweight Dolly”

Selecting the Operating Mode “Tailing”

Selecting the Operating Mode “Parallel Driving”

Selecting the Operating Mode “Circular Travel”

Selecting the Radio Remote Control

Swivelling bolster Positions

Procedure when Changing Operating Mode

Shutdown Criteria

Parking the Counterweight Dolly