$46

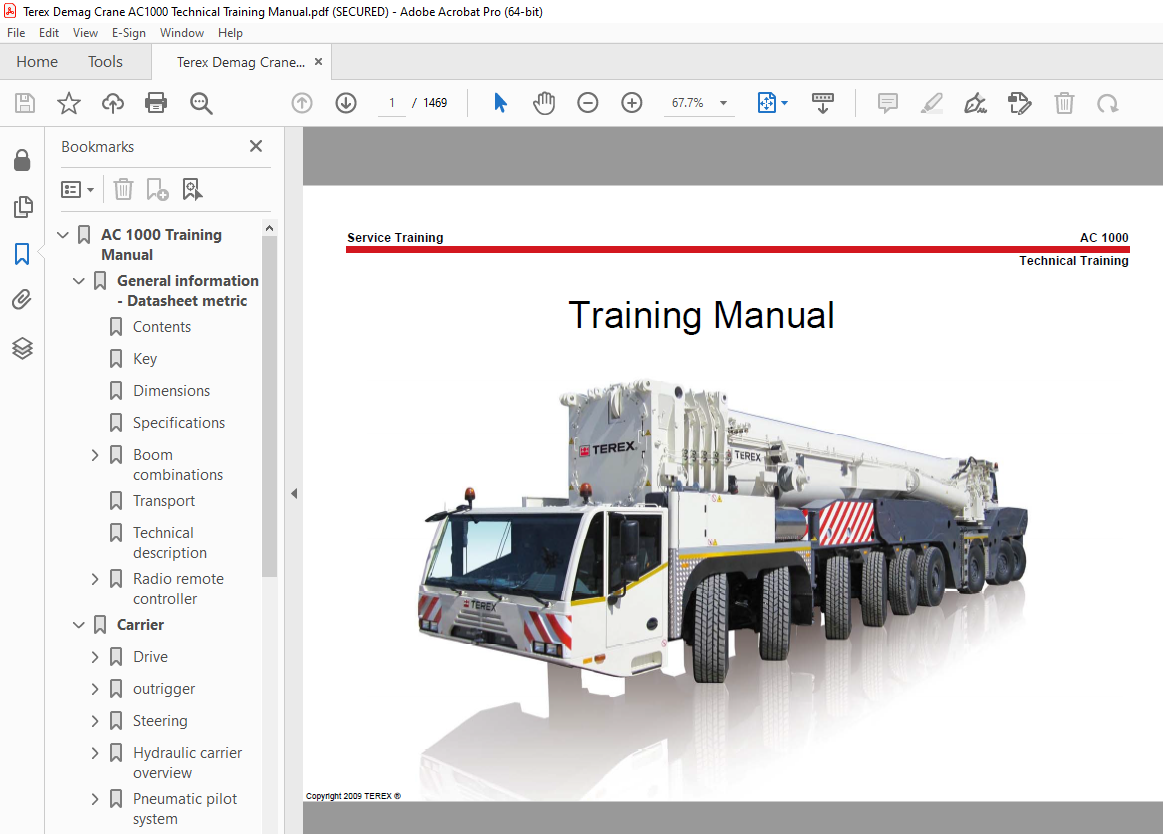

Terex Demag Crane AC 1000 Service Training Manual – PDF DOWNLOAD

Terex Demag Crane AC 1000 Service Training Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crane AC 1000 Service Training Manual – PDF DOWNLOAD

Language : English

Pages : 1469

Downloadable : Yes

File Type : PDF

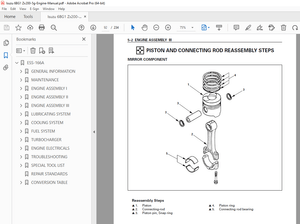

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Demag Crane AC 1000 Service Training Manual – PDF DOWNLOAD

AC 1000 Training Manual 1

General information – Datasheet metric 2

Contents 3

Key 4

Dimensions 5

Specifications 7

Boom combinations 13

HA / HA-SSL (HA50) 17

F / F-A 0°(HA50) 23

SF-SSL (30°), SF-A-SSL (30°) (HA50) 27

WIHI / WIHI-SSL (HA50) 30

WIHI-VA-SSL (60°) (HA50) 55

HA / HA-SSL (HA100) 60

F-SSL / F-A-SSL (15°/30°) 70

LF / LF-A (0°) 75

LWIHI / LWIHI-SSL (HA100) 79

Transport 16

Technical description 99

Radio remote controller 116

Components 117

Screen 118

Switsch description 119

Carrier 120

Drive 121

View engin, gear box and pump comb 122

Assemly engin and gearbox 123

Engin technical data OM 502 LA EN 3b 124

Gear box 129

Installation dimensions 130

Technical Manual ZF TC Tronic heavy duty, for transmission definition and installation inspections 132

Torque converter lock-up clutch with CAN application 132

Order n° 4245 765 101b 132

Copyright by ZF, Edition: 2009-04 133

Preface 134

List of chapters 136

Table of Contents 137

List of Changes: 4245 765 101 139

Important safety instructions 140

Technical Data and Installation Dimensions 141

1 Structure and Function 142

1 1 Structure of the TC HD 143

1 2 Structure and Function of the Torque Converter 144

1 3 Structure and Function of the Torque Converter Lock-Up Clutch 144

1 4 Structure and Function of the Shift Clutch 145

1 5 Warning Buzzer • Oil Temperature Monitoring 145

2 Mounting of Engine and Transmission 146

2 1 Mounting of Engine and Transmission 147

2 2 Mounting Points for Transport 147

3 Engine Connection 148

3 1 General information 149

3 2 Assembly Sequence 149

4 Torque Converter 150

4 1 Converter 151

4 2 Torque converter diagram 152

4 3 Oil Flow Rate With Ecofluid M in Torque Converter Operation at 90 °C 153

5 Cooling System 154

5 1 Oil/Water Heat Exchanger 155

5 2 Oil/Air Cooler 158

5 3 Installation instructions 159

5 4 Oil Fill Variants 160

6 Operation 162

6 1 Setting Off, Driving Forwards 163

6 2 Maneuvering 164

6 3 Driving in Torque Converter Mode 164

7 Maintenance 166

7 1 Oil Grades 167

7 2 Oil Fill Volume 167

7 3 Oil Change Intervals 167

7 4 Operation at Low Temperatures 167

7 5 Draining Used Oil 168

7 6 Oil Filling and Oil Level Checks 169

7 7 Filter Change 171

7 8 Oil Pressures in Torque Converter, Lock-Up Clutch 172

7 9 Tightening Torques 173

8 Peripherals 174

9 ECU 410 S 176

9 1 TC Tronic HD With ECU 41 Control Unit 177

9 2 Control unit 178

10 Electrical Power and Connection Diagrams 180

10 1 Electrical Power and Connection Diagrams 181

10 2 Electrical circuit diagram 182

10 3 Connection diagram, electrical 183

10 4 TC HD Wiring 185

10 5 Connection Diagram, Hydraulics 186

11 Diagnosis 188

11 Diagnosis, Description of Inputs and Outputs 189

12 Type Plates 190

12 1 Position of type plates 191

12 2 View of type plates (examples) 192

13 Installation Drawings 194

From drawing no 4245 600 001/1 196

From drawing no 4245 600 001/2 197

From drawing no 4245 600,002/1 198

From drawing no 4245 600,002/2 199

Distribution box 201

Gear box outputs 203

Pneumatic pilot system 204

Axle mounting 205

Axle 1 to 9 206

Cooling system EN3a and EM3b 215

Fuel system 217

Air filter system 218

EM SCR- Anlage 220

Over view 220

Suply unit 221

Pneumatic location in frame 222

Diagram SCR- system 223

SCR system EM 3b connection 224

Adblue supply unit 225

outrigger 228

Outrigger beam 229

Slewing cylinder 233

Mounting outrigger plate 234

Self- configuration of the outrigger 235

1 General 235

1 AC1000 with 12t axle load, 16″ tyres 235

1 1 Configuration of the front supports with rear auxiliary supports 0

Dismantling the auxiliary supports 0

1 3 Configuring the rear supports 0

1 4 Deconfiguring the supports 0

2 AC1000 with 100m boom with 16 5 t axle load (United Kingdom), 16″ tyres 247

2 1 Configuration of the front supports with rear supports 0

2 2 Deconfiguring the front supports with rear supports 0

3 AC1000 with 50m boom with 13 5 t axle load, 16″ tyres 251

4 Configuring the supports with the radio remote control 252

4 1 Switching on and selecting the “Supports” operating screen 0

4 2 Description of the “Supports” operating screen 0

4 3 Emergency operation 0

Steering 0

Steering overview 258

View Steering electric and hydraulic 259

Function description steering system 260

Overview steering hydraulik and electric 268

Steering electric 0

Technical datas steering computer 269

Steering hydraulic 274

Hydr – block Failop assistance steering circuit A8+9 275

Hydr – block Failsafe A7 277

Hydr – block Failop main steering circuit A8+9 279

Angle transducer steering 281

safety angle transducer 533 211 A1+A9(old) und A1,A6, A7, A9 (new) 281

angle transducer 533 250 A1+A7 old version 284

angle transducer 533 257 A6+A9 old version 285

safety angle transducer 533 450 with lever at the top pdf 286

System documentation steering 287

General system description 287

Functional description 318

Diagnostics and alarm memory 363

Alarm codes 403

Diagnostic trouble codes 444

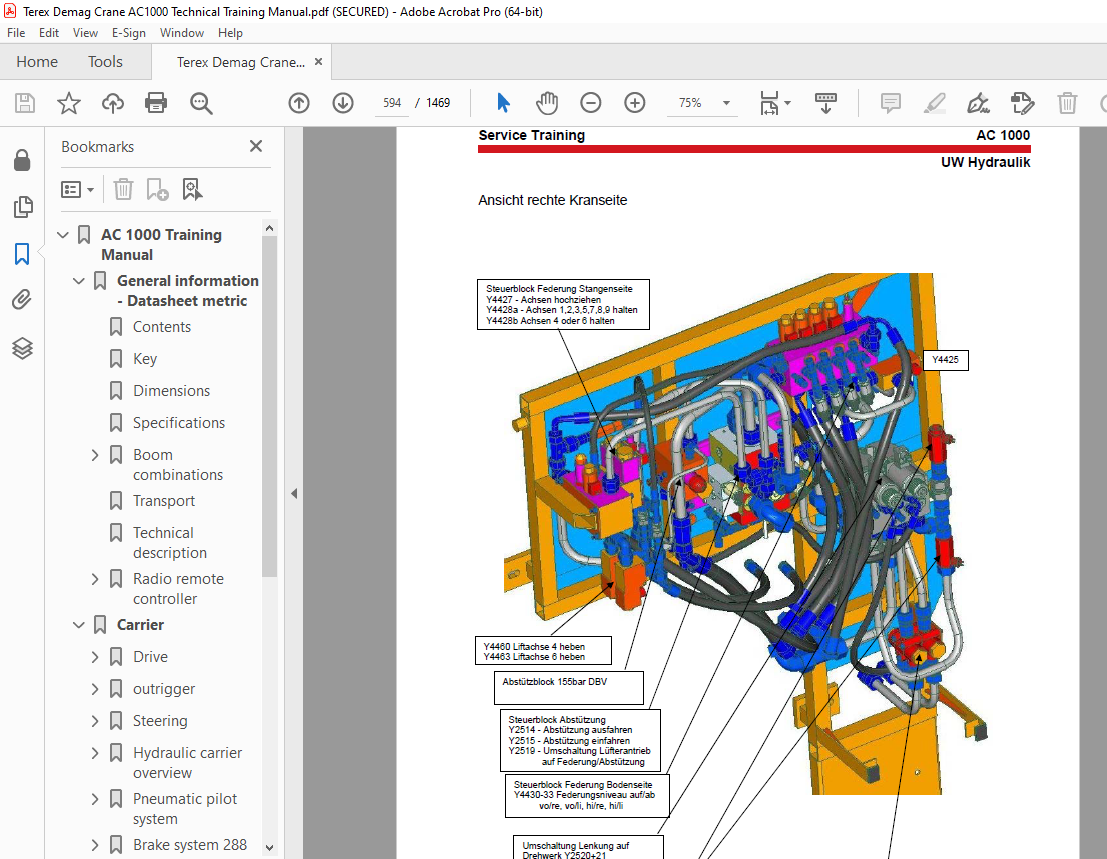

Hydraulic carrier overview 593

Hydraulic drawing carrier 291 701 12f 595

Hydraulic tank 199 901 12d 598

Hydraulic tank 197 373 12d 599

Ass pump 197 255 12c 602

States diagram of solenoid valves 603

Pneumatic pilot system 606

Brake system 289 161 12c 608

ass pneumatic frame right 289 162 12b 611

ass pneumatik frame right side 520 270 12a 612

Brake system 288 045 12b 613

Assembly and maintenance instruction 615

Control system carrier 645

Indicator Lights in the Driver Information System 646

Electric carrier 0

Electric schematics carrier 395 104 12 V2 9 690

Elektric cabin 874

interface for programming und steering computer 896

Superstructure 0

Power unit superstructure hydraulic pumps 897

System description 898

Hoist 900

Reassignment of control lever functions 901

Hoist 0 909

Hoist 1 910

Hoist 2 911

Hoist 3 912

Reeving winch 913

Reeving winch without hoist 3 913

Reeving winch with hoist 3 917

Whirl 921

Counterweight 923

View rigging counterweight 924

Configuring the counterweight 926

Counterweight configurations page 1-9 948

Mounting counterweight frame with cyl 957

Main boom 959

Drawings 0

Tele 50m 960

Tele 50m boom assembly 393 000 12F1 960

Tele 50m boom assembly 393 000 12F2 961

Tele 50m roop reeving 4 IC 393 000 12F3 962

Tele 50m roop reeving 4 IC 393 000 12F4 963

Tele 100m 964

Tele 100m boom assembly 393 001 12F1 964

Tele 100m boom assembly 393 001 12F2 965

Tele 100m roop reeving 8 IC 393 001 12F3 966

Tele 100m roop reeving 8 IC 393 001 12F4 967

Telescopic cylinder with SVE 968

Tele sections 970

Basic case 39200012F1 970

1 IC 39210012E1 971

1 IC 39210012E2 972

2 IC 39220012E1 973

2 IC 39220012E2 974

3 IC 39230012E1 975

3 IC 39230012E2 976

4 IC 39240012E1 977

4 IC 39240012E2 978

5 IC 39250012E1 979

5 IC 39250012E2 980

6 IC 39260012E1 981

6 IC 39260012E2 982

7 IC 39270012E1 983

7 IC 39270012E2 984

8 IC 39280012E1 985

8 IC 39280012E2 986

Positioning cut off device 987

Tele cut off 5 – 6 IC 988

Position Tele 1 – 4 IC 989

Position Tele 5 – 8 IC 990

Telecylinder 393 050 12h 991

Telecylinder 393 051 12 993

SVE 393 052 12g 994

Mounting parts 4 IC 995

Emergency release pinning T1- T8 996

1 IC 56631312A 996

2 IC 56631412A1 997

3 IC 56631512A1 998

4 IC 56631612A1 999

5 IC 56631712A1 1000

6 IC 56631812A1 1001

7 IC 56631912A1 1002

8 IC 56632012A1 1003

Heavy attachment 8 IC 1004

Heavy attachment 4 IK 1005

Main boom view 1006

SVE- function prox switches 1008

Telescope example 1009

Telescope example Tele 5 from 0% zu 100% 1011

Telecope example Tele 1 from 0% to 100% 1012

Pinning positions 1013

Telemanual 1014

Configuration program for the 100m boom 1015

Replacement main boom 50m to 100m 1027

Hydraulic superstructure 1030

Hydr – drawing superstructure 291 700 12e 1031

Hydraulic function superstructure 1034

Description of the pump actuation 1037

View rotary joint 1048

Hydraulic connection rotary joint 1049

Slew gear 1050

Hydraulic drawing slew gear 1051

Control modes slew gear 1052

Pressure-less circuit, closed circuit right 1053

Open circuit left and right 1054

Electric superstructure 1194

E-drawing 565 026 12 V2 1 0 1057

X2 1194

Fail safe inductive sensor 1208

Control system superstructure 1226

Menus operating display 1227

Menus IC-1 Service 1248

Error codes 1317

Equipment 0

SSL 1371

View SSL- Cylinder 1372

SSL configuration progamm 1373

Main boom bracing 396 549 12c 1387

SSL cpl 396 572 12d 1394

SSL arm cpl left 396 573 12d 1396

Conditions SSL functions 1398

Retension matrix 100m and 50m m b 1400

View sensors and prox switches 1402

Pressure adjustment SSL 1403

Luffing fly jib 1404

Overview lenght combinations WIHI 1405

WIHI 50m HA 24m- 126m 1405

LWIHI an 100m HA 24m- 84m 1406

SF 50m HA 8m- 74m and F 14m- 74m 1407

LF – 100m HA and F – 100m HA 1408

Two hook block mode 24m-84m 1409

Offsetable luffing fly jib on 50m boom 1410

Combination luffing fly jib 1412

Dimensions and weights jib parts 1411

Assembling WIHI 50m HA 1412

Rigging =< 72m 1413

WIHI low and high position 1414

Erecting WIHI => 78m 1415

Removel or change WIHI lenght =< 72m 1416

Lowering WIHI => 78m 1417

Rigging WIHI with offset 40° 1418

Assembling LWIHI 100m HA 1419

Rigging LWIHI 1420

LWIHI low and high position 1421

LWIHI removal or change jib lenght 1422

2-Hook block mode 1423

Offset on Pos 6 to Pos 4 1424

Offset F44m with 0°, 8°, 20° and 40° 1425

Option VA- Adapter assembling 1426

Option VA- Adapter rigging until 72m 1427

Option VA- Adapter to telescope 1428

Option VA- Adapter rigging WIHI => 78m 1429

Reeving mode on pos 9 HiA- head piece 6m > 78m 1430

Reeving mode on pos 7 HiA- head piece 3m =< 72m 1431

Intermediate bracing 1432

Fix bridle with rocker arm 1433

Configuring and operating the fixed bridle 1434

Configuring and operating the luffing fly jib 1449

Assembling proximity switches 1467