$38

Terex Demag Crane CC2800-1 600T Operator Manual – PDF DOWNLOAD

Terex Demag Crane CC2800-1 600T Operator Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crane CC2800-1 600T Operator Manual – PDF DOWNLOAD

Language : English

Pages : 410

Downloadable : Yes

File Type : PDF

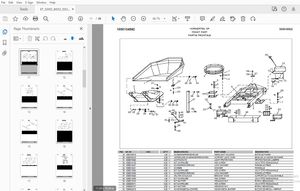

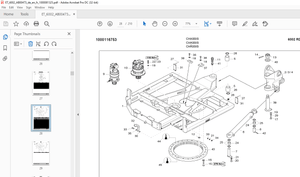

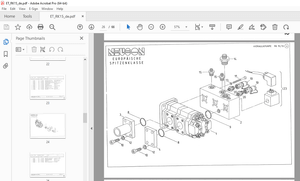

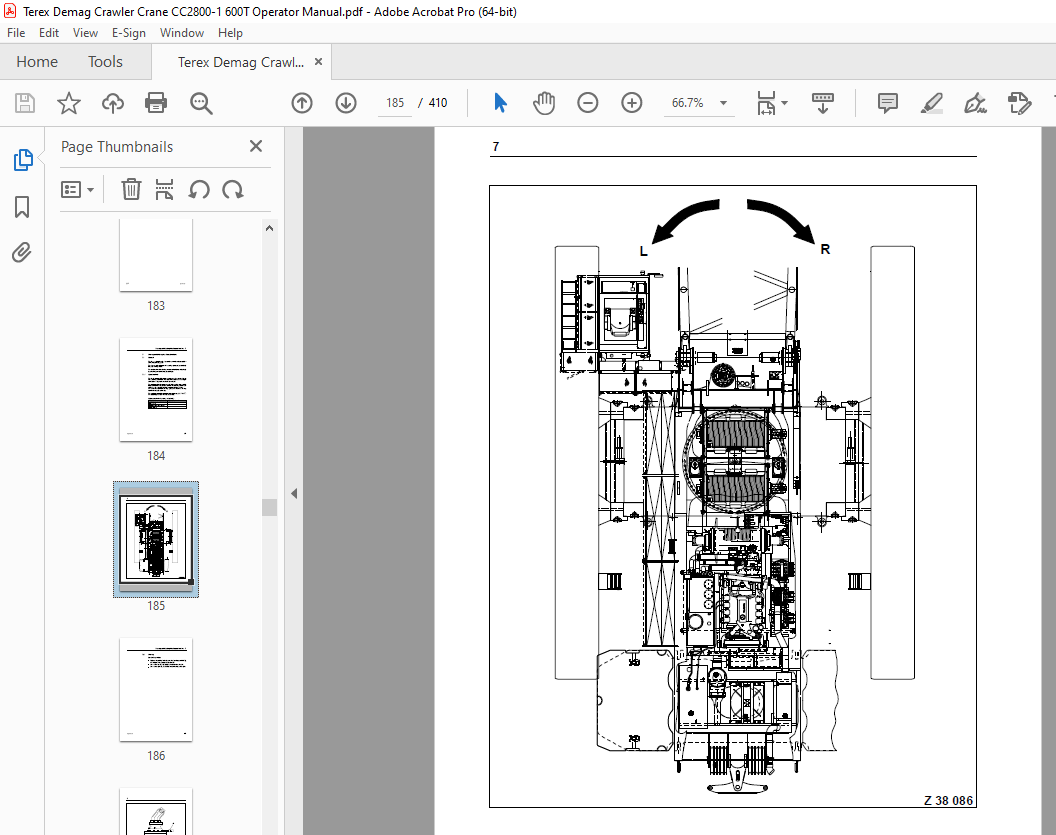

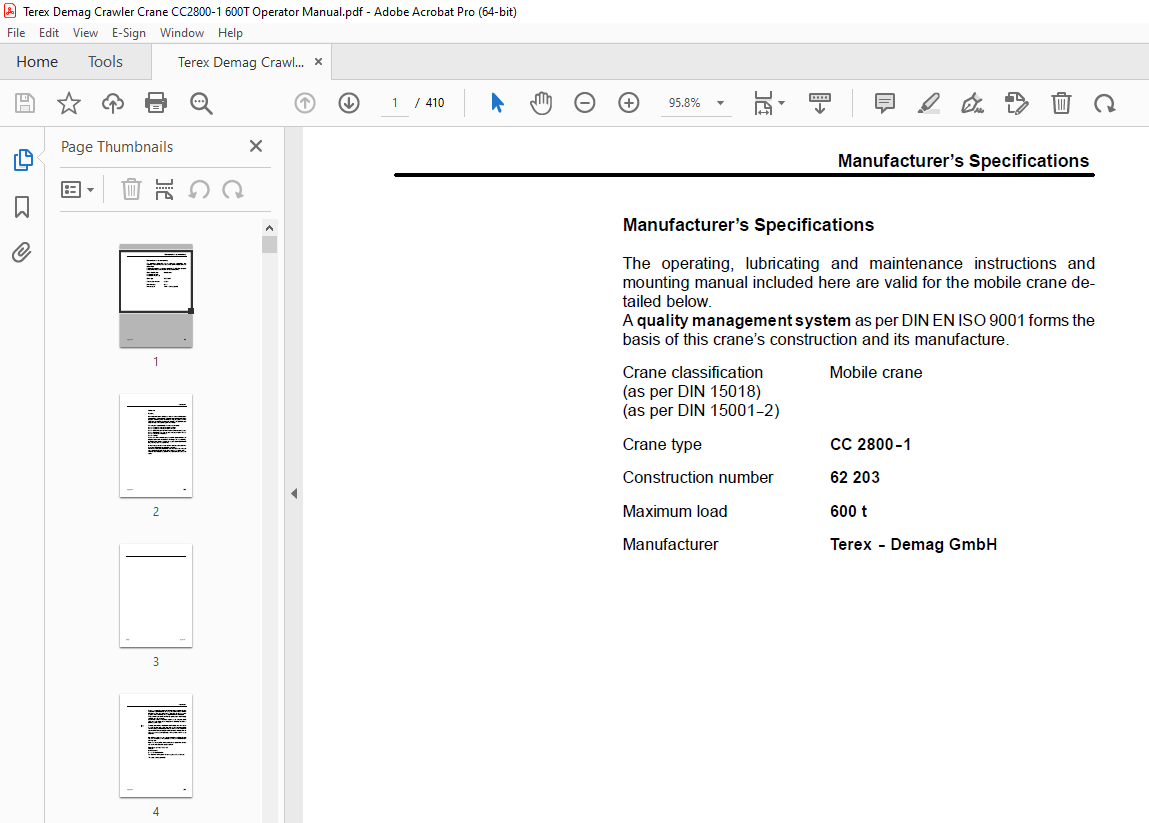

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Demag Crane CC2800-1 600T Operator Manual – PDF DOWNLOAD

Manufacturer’s Specifications 1

Foreword 1

1 Safety Instructions 3

1 1 General 3

1 2 Intended Use 3

1 3 Operating Conditions and Computed Design of the Crane 5

1 3 1 General 5

1 3 2 Workplace Ergonomics 7

1 3 3 Load and Utilisation of the Crane 7

1 3 4 Required Ambient Conditions 9

1 3 5 Service Life 11

1 3 6 Standards and Calculation Regulations 11

1 3 7 Dangers to Air Traffic 13

1 4 Safety Regulations 15

1 4 1 Organisational Measures 15

1 4 2 Selection and Qualifications of Personnel 17

1 4 3 Particular Hazards 19

1 4 3 1 Electrical Energy 19

1 4 3 2 Gas, Dust, Steam, Smoke 21

1 4 3 3 Crushing / Collision 23

1 4 3 4 Snagging / Dragging 23

1 4 3 5 Crushing / Shearing 23

1 4 3 6 Hazards due to Slipping, Stumbling, Falling 23

1 4 4 Combination of Hazards with Combined Operation of Two

or More Cranes 27

1 4 4 1 Operating Areas of Several Cranes Overlap 27

1 4 4 2 Raising a Load Using More than One Crane 29

1 4 5 Before Operating the Crane 31

1 4 6 During Operation of the Crane 33

1 4 7 After Crane Operation 41

1 4 8 When Mounting and Dismantling Crane Components 43

1 5 Hand Signals 47

1 5 1 General Hand Signals 49

1 5 2 Hand Signals for Working Movements 51

1 5 3 Hand Signals for Driving Movements 53

1 6 Power Failure 55

Index

062–1003–201 2

2 Structure of the Crawler–mounted Crane 3

2 1 Overview 3

2 2 Superstructure 5

2 3 Undercarriage 7

2 4 Boom Variants 9

2 5 Technical Data 17

2 5 1 Drive Motor 17

2 5 2 Pump Distributor Gear 17

2 5 3 Hydraulic Pumps 17

2 5 4 Slew Gear 19

2 5 5 Winches 19

2 5 6 Safety Equipment 21

2 5 7 Heater 21

2 5 8 Cab 21

2 5 9 Drive Gearbox (Undercarriage) 21

4 Crane operator’s cab 3

4 1 Cab 3

4 2 Assembled console 9

4 2 1 Overview assembled console 9

4 2 2 Display– and Operating Elements on the Consoles 11

4 2 3 Display and Control Console LLD System 13

4 2 4 Display– and Operating Console for Engine Control and

Crane Operation 15

4 3 Side desk 27

4 4 Side desk seat console 29

4 5 Radio remote control 31

4 6 Mobile Control Panel for Emergency Control 33

5 Engine and Drive 3

5 1 General 3

5 1 1 Cooling System 7

5 1 2 Hydraulic Pumps 7

5 2 Starting Up, Operating and Shutting Down the Power Units 9

5 3 Starting the Diesel Engine 11

5 3 1 Starting Procedure 13

5 3 2 To be observed following starting 15

5 3 3 Warming Up the Hydraulic System 17

5 3 4 Warming–up Procedure 17

5 3 5 Checks with the Diesel Engine Running 19

5 3 6 Notes on Operation 21

5 3 7 Switching Off 21

Index

062–1003–201 3

6 Driving the Crawler–mounted Crane 3

6 1 General 3

6 1 1 Main Direction of Travel 3

6 1 2 Requirements for the Road Surface 5

6 1 3 Regulations for Driving Operation 5

6 2 Steering the Undercarriage 9

6 2 1 Steering Movements 9

6 2 2 Option for Regulating the Driving Speed and the Drive Force 11

6 3 Driving without Load on Horizontal and Sloping Ground 15

6 3 1 General 15

6 4 Driving the Crane without Load —

Application SH, SH/LH, SSL, SSL/LSL 17

6 5 Driving the Crane without Load — Application SW 19

6 6 Driving the Crane without Load — Application SWSL 23

6 7 — 27

6 8 — 27

6 9 — 27

6 10 — 27

6 11 Driving with Load 29

6 11 1 Driving with Load, Boom Along the Longitudinal Axis of

the Crawlers 31

6 11 2 Driving with Load, Boom Not Along the Longitudinal Axis of

the Crawlers (Positioning Loads) 31

7 Slewing and Braking the Superstructure 3

7 1 General 3

7 1 1 Speed control 3

7 2 Slewing 5

7 3 Braking the Superstructure 7

7 4 Mechanical Locking of the Parking Brake in the Open Position 7

8 Operating the Safety Equipment 3

8 1 System Start 9

8 2 Description of the IC–1 9

8 2 1 Symbols “Main Menu” 11

8 2 2 “System Mask” 15

8 2 3 Symbols in the Status Display “B” 19

8 2 4 Symbols in the Operating Mode Line “C” 21

8 3 Entering the Operating Mode 25

8 4 Setting the Configuration Programs for Assembling the Crane 31

8 4 1 Configuration Program “RG0” 31

8 4 2 Erection Operation 33

8 5 Entering the Reeving Number 35

8 5 1 Load Monitoring Assembly 37

8 5 2 Tilt indicator 39

8 5 3 Troubleshooting 41

8 6 Bridging the Load Limit Device 51

8 7 Bridging Shut–Down of Load Moment Reducing Movements 51

8 8 Bridging the Shut Down of all Movements 53

Index

062–1003–201 4

9 Working with the Crane Equipment 3

9 1 Simultaneous crane movements 3

9 2 Operating Hoist 1 (H1) 5

9 2 1 General 5

9 2 2 Preparing for Operation 5

9 2 3 Operation at Normal Speed 7

9 2 4 Operation at High Speed 9

9 3 Operating Hoist 2 (H2) 11

9 3 1 General 11

9 3 2 Preparing for Operation 11

9 3 3 Operation at Normal Speed 13

9 3 4 Operation at High Speed 15

9 4 Operating Hoist 3 (H3) 17

9 4 1 General 17

9 4 2 Preparing for Operation 17

9 4 3 Operation at Normal Speed 19

9 4 4 Operation at High Speed 21

9 5 Crane Operation with Double Hook Block, Hoist 1 and

Hoist 2 in Combined Operation 23

9 5 1 Preparing for Operation 23

9 5 2 Operation at Normal Speed 25

9 5 3 Operation at High Speed 27

9 6 Operating the Derricking Gear (E) 29

9 6 1 General 29

9 6 2 Operating Derricking Gear (E) during configuration operation

(Erecting and Lowering a Boom Combination) 31

9 6 2 1 Operation at Normal Speed 31

9 6 2 2 Operation at High Speed 33

9 6 2 3 Simultaneous Operation of Derricking Gear (E) and

Luffing Gear 1 (W1) 35

9 6 2 4 Simultaneous Operation of Derricking Gear (E) and

Luffing Gear 2 (W2) 39

9 6 3 Operating the Derricking Gear (E) during Crane Operation 43

9 6 3 1 Operation at Normal Speed 43

9 6 3 2 Operation at High Speed 45

9 6 3 3 Simultaneous Operation of Derricking Gear (E) and Hoist 1 (H1) 47

9 6 3 4 Simultaneous Operation of Derricking Gear (E) and Hoist 3 (H3) 51

9 6 4 Operating Range of the Main Boom 55

9 7 Operating Luffing Gear 1 (W1 = OE) 57

9 7 1 General 57

9 7 2 Operating Luffing Gear 1 (W1) when configuration operation

(Erecting and Lowering a Boom Combination) 59

9 7 2 1 Operation at Normal Speed 59

9 7 2 2 Operation at High Speed 61

9 7 2 3 Simultaneous Operation of Luffing Gear 1 (W1) and

Luffing Gear 2 (W2) 63

9 7 2 4 Simultaneous Operation of Derricking Gear ”W1” and

Luffing Gear ”E” 65

9 7 3 Operating Luffing Gear 1 (W1) during Crane Operation 67

9 7 3 1 Simultaneous Operation of Luffing Gear 1 (W1) and Hoist 2 (H2) 67

9 7 3 2 Simultaneous Operation of Luffing Gear 1 (W1) and Hoist 3 (H3) 71

Index

062–1003–201 5

9 7 4 Operating Range of the Fly Jib 73

9 8 Operating Luffing Gear 2 (W2 = OE) 75

9 8 1 General 75

9 8 2 Operating Luffing Gear 2 (W2) when configuration operation

(Erecting and Lowering a Boom Combination) 77

9 8 2 1 Operation at Normal Speed 77

9 8 2 2 Operation at High Speed 79

9 8 2 3 Simultaneous Operation of Luffing Gear 1 (W1) and

Luffing Gear 2 (W2) 81

9 8 2 4 Simultaneous Operation of Luffing Gear ”W2” and

Derricking Gear ”E” 81

9 8 3 Operating Luffing Gear 2 (W2) during Crane Operation 83

9 8 3 1 Operation at Normal Speed 83

9 8 3 2 Operation at High Speed 85

9 8 3 3 Simultaneous Operation of Luffing Gear 2 (W2) and Hoist 1 (H1) 87

9 8 3 4 Simultaneous Operation of Luffing Gear 2 (W2) and Hoist 3 (H3) 91

9 8 4 Operating Range of the Main Boom 93

9 9 Operating the Reeving Winch 95

9 9 1 General 95

9 9 2 Operation 95

9 10 Working Instructions 97

9 10 1 General 97

9 10 2 Positioning the Crane 99

9 11 Wind Speeds — Dynamic Pressure 101

9 11 1 General 101

9 11 2 Crane under Load (Crane Operation) 103

9 11 3 Parking the Crane 107

9 11 4 Lowering the Boom System 111

10 Working with the Superlift 3

10 1 Description of the Superlift Equipment 3

10 2 Operating Principle 5

10 3 Safety Instructions for Working with the Superlift 7

10 4 Operating the Crane without a Superlift Counterweight 11

10 5 Operating the Crane with the Superlift Counterweight 13

10 5 1 Preparations for Raising a Load 13

10 5 2 Raising the Load 17

10 5 3 Setting Down the Load 21

11 Operation of the Heating and Ventilation 3

11 1 General 3

11 2 Heater Operation 7

11 2 1 Setting the Timer 7

11 2 2 Heater Operation without Preselection with Ignition ”OFF” 9

11 2 3 Heater Operation without Preselection with Ignition ”ON” 11

11 2 4 Heater Operation with Preselection 13

11 2 5 Safety Equipment 17

Index

062–1003–201 6

14 Radio Remote Control 3

14 1 General 3

14 2 Preparations for Assembly using the Radio Remote Control 3

14 3 Table Outline of the Assembly Procedures 11

14 3 1 Assembly Procedures on the Superstructure 11

14 3 2 Assembly Procedures on the Chassis 11

14 3 3 Assembly Procedures on the Counterweight Dolly 13

14 3 4 Assembly Procedures on the Jack–Up System 13

14 4 Assembly Procedures in Case of Failure on the Radio of

Remote Control 15

14 5 Table Outline of the Assembly Procedures in Case of

Remote Control Failure 17

14 5 1 Assembly Procedures on the Superstructure 17

14 5 2 Assembly Procedures on the Chassis (UW) 17

14 5 3 Assembly Procedures on the Counterweight Dolly (GW) 19

14 5 4 Assembly Procedures on the Jack–Up System 19