$38

Terex Demag Crawler Crane CC1800-1 300T Lubrication Manual – PDF DOWNLOAD

Terex Demag Crawler Crane CC1800-1 300T Lubrication Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crawler Crane CC1800-1 300T Lubrication Manual – PDF DOWNLOAD

Language : English

Pages : 376

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

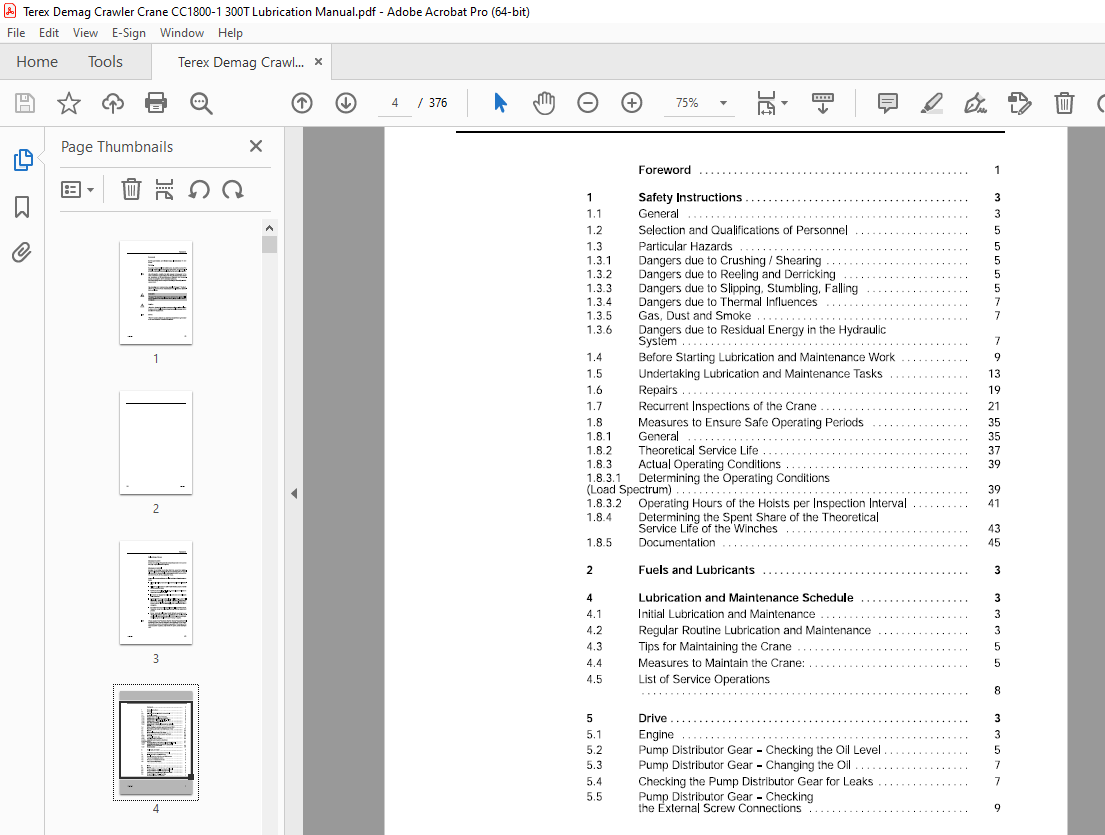

TABLE OF CONTENTS:

Terex Demag Crawler Crane CC1800-1 300T Lubrication Manual – PDF DOWNLOAD

Foreword 1

1 Safety lnstructions З

1 1 General 3

1 2 Selection and Oualifications of Personnel 5

1 3 Particular Hazards 5

1 3 1 Dangers due to Crushing / Shearing 5

1 3 2 Dangers due to Reeling and Derricking 5

1 3 3 Dangers due to Slipping, StumЫing, Falling 5

1 3 4 Dangers due to Thermal lnfluences 7

1 3 5 Gas, Dust and Smoke 7

1 3 6 Dangers due to Residual Energy in the Hydraulic

System 7

1 4 Before Starting Lubrication and Maintenance Work 9

1 5 Undertaking Lubrication and Maintenance Tasks 13

1 6 Repairs 19

1 7 Recurrent I nspections of the Crane

1 8 Measures to Ensure Safe Operating Periods

1 8 1 General

1 8 2 Theoretical Service Life

1 8 3 Actual Operating Conditions

1 8 3 1 Determining the Operating Conditions

(Load Spectrum)

1 8 3 2 Operating Hours of the Hoists рег lnspection lnterval

1 8 4 Determining the Spent Share of the Theoretical

Service Life of the Winches

1 8 5 Documentation

Fuels and Lubricants

Lubrication and Maintenance Schedule

lnitial Lubrication and Maintenance

Regular Routine Lubrication and Maintenance

Tips for Maintaining the Crane

Measures to Maintain the Crane:

List of Service Operations

Drive

Engine

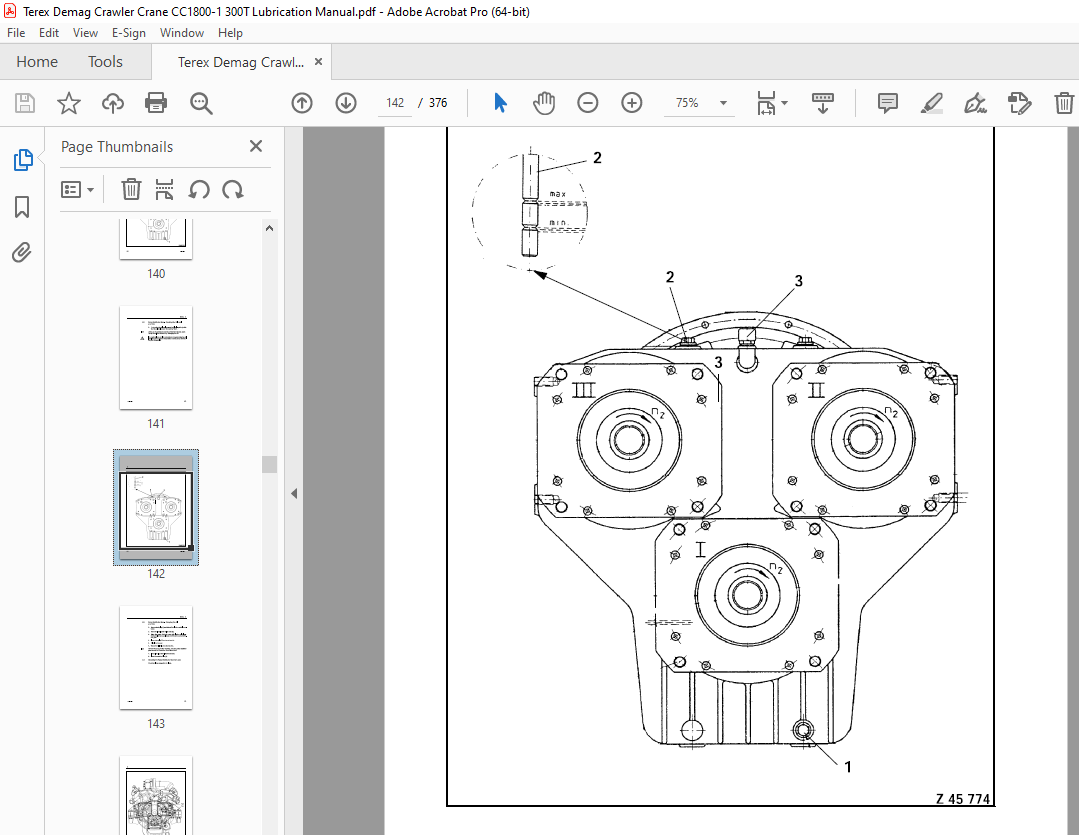

Pump Distributor Gear – Checking the Oil Level

Pump Distributor Gear – Changing the Oil

Checking the Pump Distributor Gear for Leaks

Pump Distributor Gear – Checking

the External Screw Connections

6 Slew Ring Connection З

6 1 Lubricating the Slew Ring Connection 3

6 2 Lubricating the Ring Gear 5

6 3 Checking the Screws of the Slewing Rim;

Operational ReliaЬility of the Fixing Bolts 7

6 3 1 General 7

6 3 2 Checking the Torque of the Screws 7

7 Slew Gear З

7 1 Slew Gear Mechanism, Checking the Oil Level 3

7 2 Slew Gear Mechanism, Changing the Oil 3

7 3 Slew Gear; Checking the Brake 5

7 4 Checking the Slew Gear Mechanism Screw Connections 7

7 5 Slew Gear Mechanism Visual lnspection 7

В Hoists З

8 1 Hoist 1 and 2 – Checking the Oil Level 3

8 2 Hoist 1 and 2 – Changing the Oil 5

8 3 Reeving Winch – Checking the Oil Level 9

8 4 Reeving Winch – Checking the Oil 11

8 5 Hoists and Reeving Winch – Lubricating

the Rope Drum Bearings 13

8 6 Hoists and Reeving Winch; Checking the Brakes 13

8 7 Hoists and Reeving Winch – Checking and Re-tightening

the Screw Connections if Necessary 17

9 Luffing Gears З

9 1 Luffing Gear 1 – Checking the Oil Level 5

9 2 Luffing Gear 1 – Changing the Oil 7

9 3 Luffing Gear 2 – Checking the Oil Level 11

9 4 Luffing Gear 2 – Changing the Oil 13

9 5 Luffing Gear 1 and 2 – Lubricating Rope Drum Bearings 17

9 6 Luffing Gears – Checking the Brakes 17

9 7 Luffing Gears – Checking the Screw Connections and

Re-tightening if Necessary 23

10 Derricking Gear З

10 1 Derricking Gear – Checking the Oil Level 3

10 2 Derricking Gear – Changing the Oil 5

10 3 Derricking Gear – Lubricating the Rope Drum Bearings 5

10 4 Checking the Derricking Gear Brakes 7

10 5 Derricking Gear – Checking the Screw Connections and

Re-tightening if Necessary 13

Equipment З

Maintaining the Hydraulic Cylinders оп the Superstructure

and Equipment 3

Lubricating the Boom Bearings 5

Hook Blocks 7

Lubricating the Hook Blocks 7

Lubricating the Ropes 9

Cleaning the Ropes 11

Ropes 13

Checking and Replacing the Ropes if Necessary 15

General lnformation оп Operation and AssemЫy 27

Transport 27

Storage 29

Mounting 29

Sheaves 41

Checking the Roller Bearings оп the Sheaves 41

Checking the Sheaves 43

Replacing the Roller Bearing оп the Sheaves 43

Checking the Main Boom and Fly Jib, A-frame and

Superlift Mast for Cracks in the Welds 45

Checking the Stay Bars and Bracing Rods 4 7

Checking the Stay Bars and Bracing Rods for Cracks 51

Stay Bars and Bracing Rods – Checking the Length 51

Checking the Wear of the Stay Bars and Bracing Rods 6 7

Checking the Paintwork of the Stay Bars and Bracing Rods 6 7

Checking the Stay Bars and Bracing Rods

for Plastic Deformation 6 7

Hydraulic System З

Hydraulic Oil Reservoir – Checking the Oil Level 3

Hydraulic Oil Reservoir –

Replacing the Return Oil Filter 5

Hydraulic Oil Reservoir –

Replacing the Aeration Filter 5

Leak oil circuit – Return oil filter – cleaning the filter element 7

Hydraulic Pump – Changing the Add-On Filter 9

Replacing the Hydraulic Oil 11

Bleeding the Hydraulic System 13

Checking the Hydraulic System for Leaks 13

Hydraulic System –

Checking the FlexiЫe Pressure TuЬing 15

Hydraulic System –

Replacing the FlexiЫe Pressure Tubing

Hydraulic System –

Checking the Accumulator lnitial Gas Pressure

Lower Luffing Mast Back Stops

Lower Luffing Mast Back Stops –

Checking the Oil Level

Lower Luffing Mast Back Stops – Changing the Oil

Checking the Lower Luffing Mast Back Stops for Leaks

Lower Luffing Gеаг Back Stops –

Checking the Screw Connections

Heating

Checking the System is Functioning Correctly

Checking the Fuses

Fault Diagnosis with the Heating Timer

Checking the Water Level

Replacing the Heat Exchanger

Air Conditioning Equipment (optional)

Switching оп the Air Conditioning Equipment

Servicing the Air Conditioning Equipment

Having the Air Conditioning Equipment Checked

Electrical System

Checking the Lighting System

Checking the Battery Fluid Level

Checking the Limit Switches

Checking the Slip Ring Contacts оп the Rope Winches and

оп the Rotary Joint to the Undercarriage

Precautionary Measures Against СаЫе Fires

Fuel System

Draining Off Water and Residue From the Fuel Tank

Maintaining the Fuel Filter

Fuel System, Checking the Lines

Cooling, Air lntake and Exhaust System

Checking the Coolant Level and Topping Up if Necessary

Cleaning the Cooling System

Changing the Coolant

Cleaning and/or Replacing the Filter Element of the Аiг Filter

Dгу Cleaning

Wet Cleaning

Checking the Element

Exhaust System Visual lnspection

Сгапе Operator’s СаЬ

Checking the Windscreen Washing AssemЫy

Filling Up the Supply Tank of the Windscreen Washing AssemЫy

Undercarriage

Checking the Final Drive Oil Level

Changing the Oil in the Final Drive

Lubricating Bottom and Тор Rollers

Lubricating the Connecting Pins

Maintaining the Hydraulic Cylinders оп the Undercarriage

Tensioning the Crawler Track

Lubricating the Track Pins оп the Track Тур Undercarriage

and Checking the Track Tension in the Case of Running Noises

Checking the Screw Connections and Re-tightening

if Necessary

Central Lubrication System

Component Parts

Operation

Setting the lnterval and Operating Periods

Servicing Central Lubrication System

Filling the Tank of the Central Lubrication System

TrouЫeshooting

Visual lnspections

Visual lnspection of the Superstructure and Crawler

Visual lnspections of the Superlift Counterweight Framework

Visual lnspection of the Equipment