$38

Terex Demag Crawler Crane CC2500-1 500 Ton Lubrication Manual – PDF DOWNLOAD

Terex Demag Crawler Crane CC2500-1 500 Ton Lubrication Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crawler Crane CC2500-1 500 Ton Lubrication Manual – PDF DOWNLOAD

Language : English

Pages : 248

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

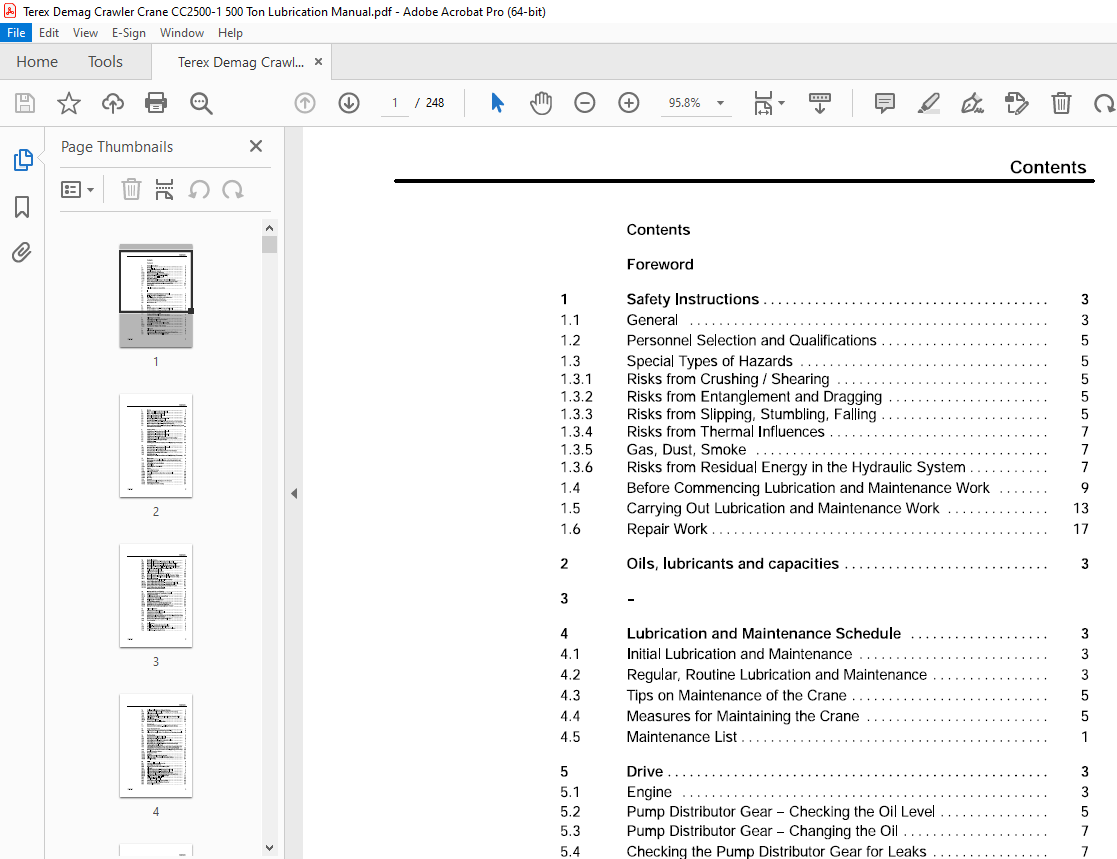

TABLE OF CONTENTS:

Terex Demag Crawler Crane CC2500-1 500 Ton Lubrication Manual – PDF DOWNLOAD

Contents

Foreword

Contents

1 Safety lnstructions 3

1 1 General з

1 2 Personnel Selection and Oualifications 5

1 3 Special Types of Hazards 5

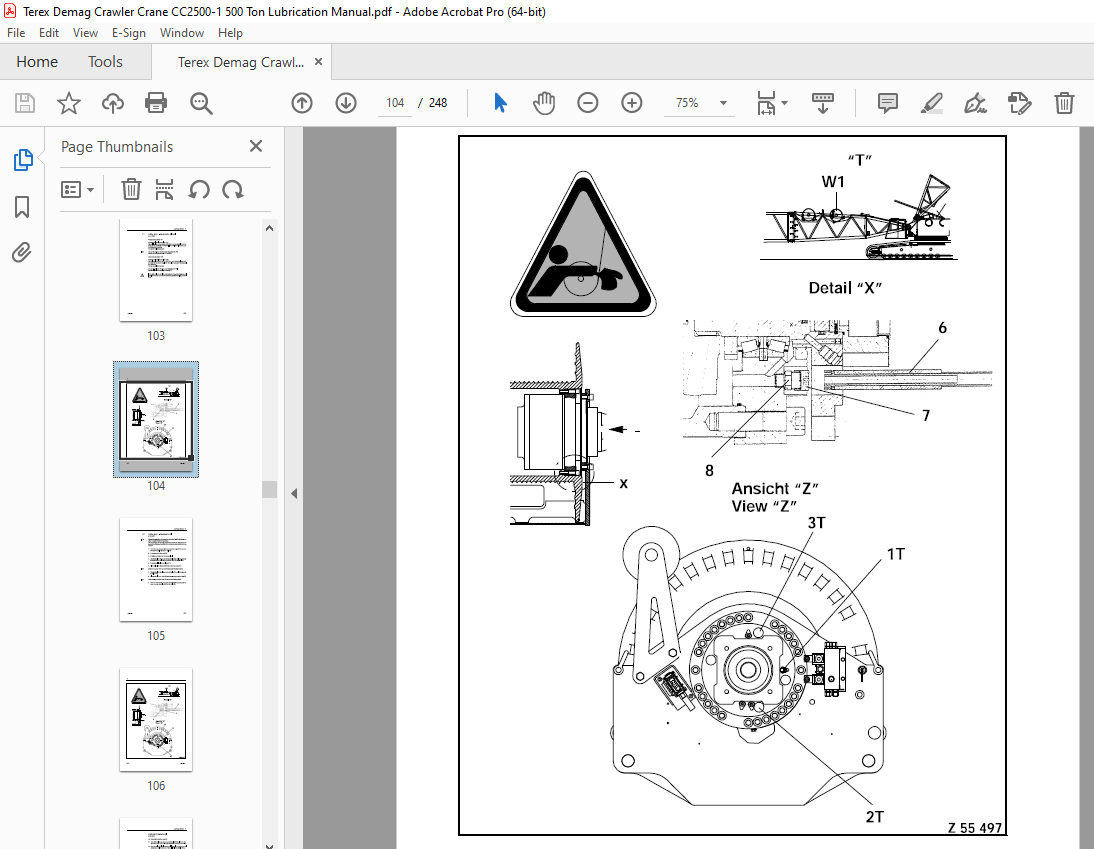

1 3 1 Risks from Crushing / Shearing 5

1 3 2 Risks from Entanglement and Dragging 5

1 3 3 Risks from Slipping, StumЫing, Falling 5

1 3 4 Risks from Thermal lnfluences 7

1 3 5 Gas, Dust, Smoke 7

1 3 6 Risks from Residual Energy in the Hydraulic System 7

1 4 Before Commencing Lubrication and Maintenance Work 9

1 5 Carrying Out Lubrication and Maintenance Work 1 З

1 6 Repair Work 17

2 Oils, lubricants and capacities 3

Lubrication and Maintenance Schedule

lnitial Lubrication and Maintenance

Regular, Routine Lubrication and Maintenance

Tips оп Maintenance of the Crane

Measures for Maintaining the Crane

Maintenance List

Drive

Engine

Pump Distributor Gear – Checking the Oil Level

Pump Distributor Gear – Changing the Oil

Checking the Pump Distributor Gear for Leaks

Pump Distributor Gear –

Checking the External Screw Connections

Slew Ring Connection

Lubricating the Slew Ring Connection

Lubricating the Ring Gear

Checking the Screws of the Slewing Rim

General

Checking the Torque of the Screws

Slew gear

Slew Gear – Checking the Brake

Checking the Slew Gear Mechanism Screw Connections

Slew Gear Mechanism Visual lnspection

8 Hoists 3

8 1 Hoist 1 and 2 – Checking the Oil Level 3

8 2 Hoist 1 and 2 – Changing the Oil 5

8 3 Hoist 3 – Checking the Oil Level 9

8 4 Hoist 3 – Changing the Oil 11

8 5 Reeving Winch – Checking the Oil Level 15

8 6 Reeving Winch – Checking the Oil 17

8 7 Hoists and Reeving Winch – Lubricating the Rope Drum Bearings 19

8 8 Hoists and Reeving Winch – Checking the Brakes 19

8 9 Hoists and Reeving Winch – Checking and Re-tightening the Screw

Connections if Necessary 23

Luffing Gears 3

Luffing Gear 1 – Checking the Oil Level 5

Luffing Gear 1 – Changing the Oil 7

Luffing Gear 2 – Checking the Oil Level 11

Luffing Gear 2 – Changing the Oil 13

Luffing Gear 1 and 2 – Lubricating Rope Drum Bearings 17

Luffing Gears – Checking the Brakes 17

Luffing Gears –

Checking the Screw Connections and Re-tightening if Necessary 23

derricking gear 3

Derricking Gear – Checking the Oil Level 3

Derricking Gear – Changing the Oil 5

Derricking Gear – Lubricating the Rope Drum Bearings 7

Checking the Derricking Gear Brakes 9

Derricking Gear –

Checking the Screw Connections and Re-tightening if Necessary 15

Equipment 3

Maintaining the Hydraulic Cylinders оп the Superstructure and

Equipment 3

Lubricating the Boom Bearings 5

Hook Blocks 7

Lubricating the Hook Blocks 7

Ropes 9

Lubricating the Ropes 11

Cleaning the Ropes 1 3

General lnformation оп Operation and AssemЫy 13

Transport 13

Bearing 15

Mounting 15

Sheaves 27

Checking the Roller Bearings оп the Sheaves 27

Checking the Sheaves 29

Lubricating the sheave bearing 29

Hydraulic System

Hydraulic Oil Reservoir – Checking the Oil Level

Hydraulic Oil Reservoir – Replacing the Return Oil Filter

Hydraulic Oil Reservoir – Replacing the Aeration Filter

Leak oil circuit – Return oil filter – cleaning the filter element

Hydraulic Pump – Changing the Add-On Filter

Replacing the Hydraulic Oil

Bleeding the Hydraulic System

Checking the Hydraulic System for Leaks

Hydraulic System – Checking the FlexiЫe Pressure Tublng

Hydraulic System – Replacing the FlexiЫe Pressure Tublng

Hydraulic System –

Checking the Accumulator lnitial Gas Pressure

Lower Luffing Mast Back Stops

Lower Luffing Mast Back Stops – Checking the Oil Level

Lower Luffing Mast Back Stops – Changing the Oil

Checking the Lower Luffing Mast Back Stops for Leaks

Lower Luffing Gеаг Back Stops –

Checking the Screw Connections

Heating and Air conditioning

Checking the System is Functioning Correctly

Checking the Fuses

Fault Diagnosis with the Heating Timer

Checking the Water Level

Replacing the Heat Exchanger

Air conditioning (option)

Switching оп the Air Conditioning Equipment

Servicing the Air Conditioning Equipment

Having the Air Conditioning Equipment Checked

Electrical System

Checking the Lighting System

Checking the Battery Fluid Level

Checking the Limit Switches

Checking the Slip Ring Contacts оп the Rope Winches and оп the

Rotary Joint to the Undercarriage

Precautionary Measures Against СаЫе Fires

Fuse Overview

Fuel System

Fuel filter – emptying the inspection glass

Fuel Filter – Changing the Filter Element

Draining Off Water and Residue From the Fuel Tank

Fuel System, Checking the Lines

Cooling, Air lntake and Exhaust System 3

Checking the Coolant Level and Topping Up if Necessary 3

Cleaning the Cooling System 5

Changing the Coolant 7

Cleaning and/or Replacing the Filter Element of the Air Filter 11

Dry Cleaning 1 3

Checking the Element 15

Exhaust System Visual lnspection 15

Piston Rods 1

Exposed Chrome Surfaces – Applying Protective Grease 1

Сгапе Operator’s СаЬ 3

Checking the Windscreen Washing AssemЫy 3

Filling Up the Supply Tank of the Windscreen Washing AssemЫy 3

Undercarriage 3

Checking the Final Drive Oil Level 3

Changing the Oil in the Final Drive 5

Lubricating front idlers, track and carrier rollers 7

Lubricating the Connecting Pins 7

Maintaining the Hydraulic Cylinders оп the Undercarriage 7

Tensioning the Crawler Track 9

Lubricating the Track Pins оп the Track Туре Undercarriage and

Checking the Track Tension in the Case of Running Noises 13

Checking the Screw Connections and Re-tightening if Necessary 15

Central Lubrication System 17

Component Parts 17

function 17

Servicing Central Lubrication System 19

Filling the Tank of the Central Lubrication System 21

TrouЫeshooting 23

Dolly 3

Lubricate ball bearing slewing rim 3

Lubricating the Ring Gear 3

Checking the Screws of the Slewing Rim 5

Slew gear 7

Slew Gear Mechanism – Checking the Oil Level 7

Slew Gear Mechanism – Changing the Oil 7

Slew gear mechanism – checking the disc brake 9

Checking the Slew Gear Mechanism Screw Connections 11

Slew Gear Mechanism Visual lnspection 11

Final drive – check oil level 13

Travel drive – replace oil 15

Check tyre air pressure, tread and rims 20

Check tyre wheel nuts, tighten if required 22

Check welds for cracks 24

Visual checks

Visual check – superstructure and crawler chassis

Visual checks оп the Superlift counterweight supporting frame

Visual check – equipment

Examinations of the Crane

Recurring Сгапе lnspections

lnspection of Load-Bearing Steel Constructions

lnspection of the Disc Wheels (Rims)

lnspection of the Winches

Hook

lnspection of the Sheaves

lnspection of the Ropes

Documentation

Check гореs, герlасе if required