$38

Terex Demag Crawler Crane CC2800-1 600T Maintenance Manual PDF

Terex Demag Crawler Crane CC2800-1 600T Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crawler Crane CC2800-1 600T Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 328

Downloadable : Yes

File Type : PDF

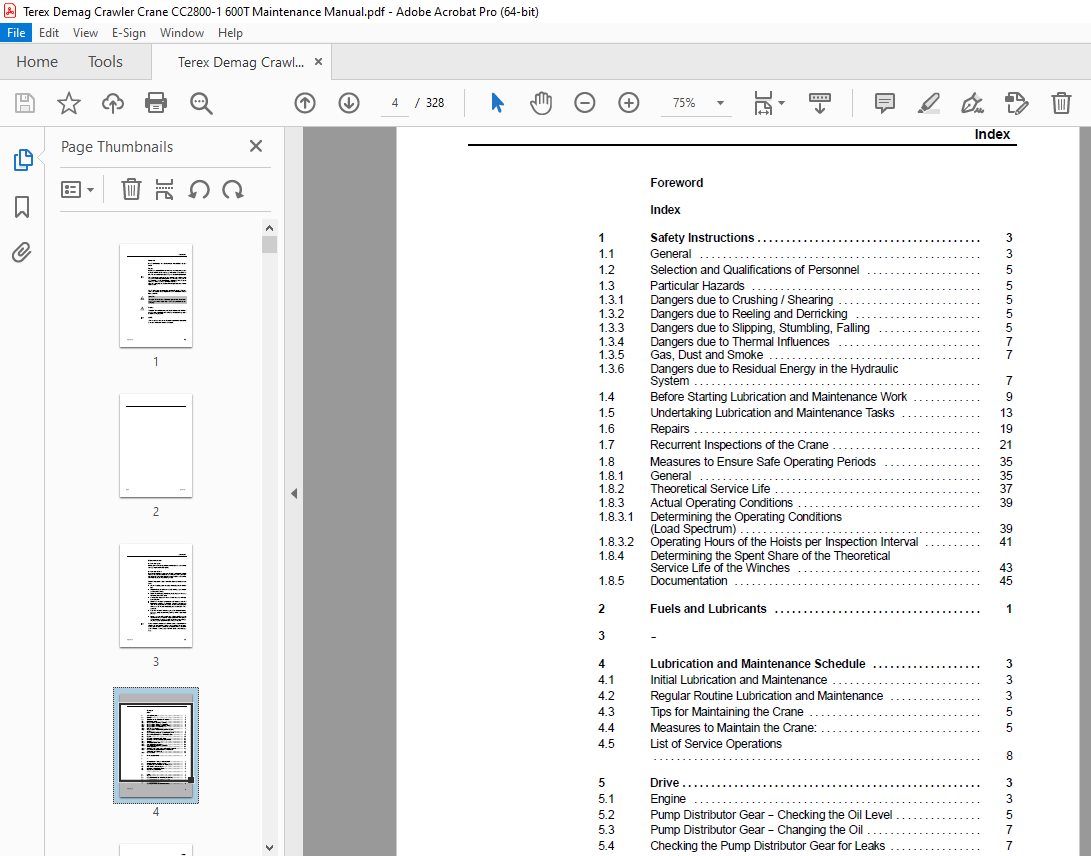

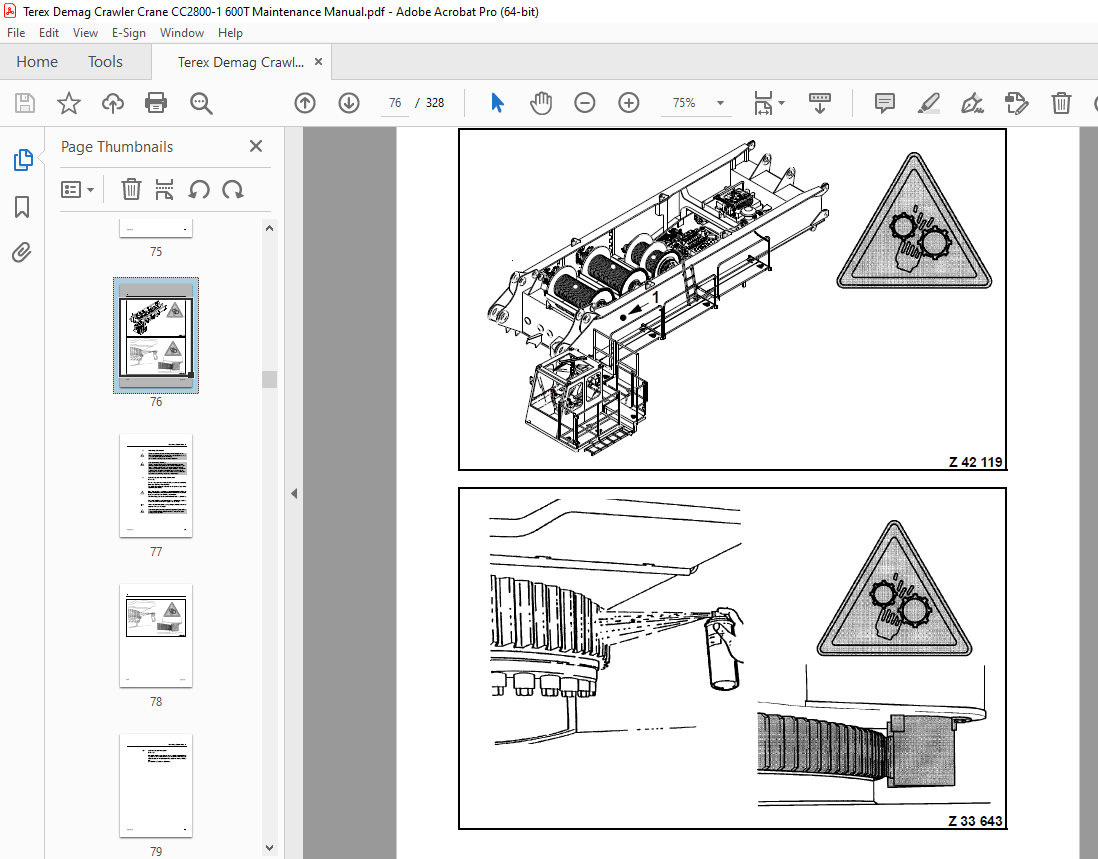

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Demag Crawler Crane CC2800-1 600T Maintenance Manual – PDF DOWNLOAD

Foreword

Index

1 Safety Instructions 3

1 1 General 3

1 2 Selection and Qualifications of Personnel 5

1 3 Particular Hazards 5

1 3 1 Dangers due to Crushing / Shearing 5

1 3 2 Dangers due to Reeling and Derricking 5

1 3 3 Dangers due to Slipping, Stumbling, Falling 5

1 3 4 Dangers due to Thermal Influences 7

1 3 5 Gas, Dust and Smoke 7

1 3 6 Dangers due to Residual Energy in the Hydraulic

System 7

1 4 Before Starting Lubrication and Maintenance Work 9

1 5 Undertaking Lubrication and Maintenance Tasks 13

1 6 Repairs 19

1 7 Recurrent Inspections of the Crane 21

1 8 Measures to Ensure Safe Operating Periods 35

1 8 1 General 35

1 8 2 Theoretical Service Life 37

1 8 3 Actual Operating Conditions 39

1 8 3 1 Determining the Operating Conditions

(Load Spectrum) 39

1 8 3 2 Operating Hours of the Hoists per Inspection Interval 41

1 8 4 Determining the Spent Share of the Theoretical

Service Life of the Winches 43

1 8 5 Documentation 45

2 Fuels and Lubricants 1

3 —

4 Lubrication and Maintenance Schedule 3

4 1 Initial Lubrication and Maintenance 3

4 2 Regular Routine Lubrication and Maintenance 3

4 3 Tips for Maintaining the Crane 5

4 4 Measures to Maintain the Crane: 5

4 5 List of Service Operations

8

5 Drive 3

5 1 Engine 3

5 2 Pump Distributor Gear — Checking the Oil Level 5

5 3 Pump Distributor Gear — Changing the Oil 7

5 4 Checking the Pump Distributor Gear for Leaks 7

5 5 Pump Distributor Gear —

Checking the External Screw Connections 9

Index

062–2003–151 2

6 Slew Ring Connection 3

6 1 Lubricating the Slew Ring Connection 3

6 2 Lubricating the Ring Gear 5

6 3 Checking the Screws of the Slewing Rim;

Operational Reliability of the Fixing Bolts 7

6 3 1 General 7

6 3 2 Checking the Torque of the Screws 7

7 Slew Gear 3

7 1 Slew Gear Mechanism, Checking the Oil Level 3

7 2 Slew Gear Mechanism, Changing the Oil 3

7 3 Slew Gear; Checking the Brake 5

7 4 Checking the Slew Gear Mechanism Screw Connections 7

7 5 Slew Gear Mechanism Visual Inspection 7

8 Hoists 3

8 1 Hoist 1 and 2 — Checking the Oil Level 3

8 2 Hoist 1 and 2 — Changing the Oil 5

8 3 Hoist 3 — Checking the Oil Level 9

8 4 Hoist Gear 3 — Changing the Oil 11

8 5 Reeving Winch — Checking the Oil Level 15

8 6 Reeving Winch — Checking the Oil 17

8 7 Hoists and Reeving Winch — Lubricating

the Rope Drum Bearings 19

8 8 Hoists and Reeving Winch; Checking the Brakes 19

8 9 Hoists and Reeving Winch — Checking and Re–tightening

the Screw Connections if Necessary 23

9 Luffing Gears 3

9 1 Luffing Gear 1 — Checking the Oil Level 5

9 2 Luffing Gear 1 — Changing the Oil 7

9 3 Luffing Gear 2 — Checking the Oil Level 11

9 4 Luffing Gear 2 — Changing the Oil 13

9 5 Luffing Gear 1 and 2 — Lubricating Rope Drum Bearings 17

9 6 Luffing Gears — Checking the Brakes 17

9 7 Luffing Gears — Checking the Screw Connections

and Re–tightening if Necessary 23

10 Derricking Gear 3

10 1 Derricking Gear — Checking the Oil Level 3

10 2 Derricking Gear — Changing the Oil 5

10 3 Checking the Derricking Gear Brakes 9

10 4 Derricking Gear — Checking the Screw Connections

and Re–tightening if Necessary 15

Index

062–2003–151 3

11 Equipment 3

11 1 Maintaining the Hydraulic Cylinders on the Superstructure

and Equipment 3

11 2 Lubricating the Boom Bearings 5

11 3 Hook Blocks 7

11 3 1 Lubricating the Hook Blocks 7

11 4 Lubricating the Ropes 9

11 4 1 Cleaning the Ropes 11

11 5 Ropes 13

11 5 1 Checking and Replacing the Ropes if Necessary 15

11 5 2 General Information on Operation and Assembly 27

11 5 3 Transport 27

11 5 4 Storage 29

11 5 5 Mounting 29

11 6 Sheaves 41

11 6 1 Checking the Roller Bearings on the Sheaves 41

11 6 2 Checking the Sheaves 43

11 6 3 Replacing the Roller Bearing on the Sheaves 43

11 7 Checking the Main Boom and Fly Jib, A–frame and

Superlift Mast for Cracks in the Welds 45

11 8 Checking the Stay Bars, Bracing Rods and Mounting Rods 47

11 8 1 Checking the Stay Bars, Bracing Rods and Mounting Rods

for Cracks 51

11 8 2 Stay Bars, Bracing Rods and Mounting Rods — Checking

the Length 51

12 Hydraulic System 3

12 1 Hydraulic Oil Reservoir — Checking the Oil Level 3

12 2 Hydraulic Oil Reservoir —

Replacing the Return Oil Filter 5

12 3 Hydraulic Oil Reservoir —

Replacing the Aeration Filter 5

12 4 Leak oil circuit — Return oil filter — cleaning the filter element 7

12 5 Hydraulic Pump — Changing the Add–On Filter 9

12 6 Replacing the Hydraulic Oil 11

12 7 Bleeding the Hydraulic System 13

12 8 Checking the Hydraulic System for Leaks 13

12 9 Hydraulic System —

Checking the Accumulator Initial Gas Pressure 15

12 10 Hydraulic System —

Checking the Accumulator Initial Gas Pressure 17

12 11 Lower Luffing Mast Back Stops 21

12 11 1 Lower Luffing Mast Back Stops —

Checking the Oil Level 21

12 11 2 Lower Luffing Mast Back Stops — Changing the Oil 21

12 11 3 Checking the Lower Luffing Mast Back Stops for Leaks 23

12 11 4 Lower Luffing Gear Back Stops —

Checking the Screw Connections 23

Index

062–2003–151 4

13 Heating 3

13 1 Checking the System is Functioning Correctly 3

13 1 1 Checking the Fuses 5

13 1 2 Fault Diagnosis with the Heating Timer 5

13 2 Checking the Fuel Level 17

13 3 Checking the Water Level 19

13 4 Replacing the Heat Exchanger 19

13 5 Bleeding the heater 21

13 6 Air Conditioning Equipment (optional) 23

13 6 1 Switching on the Air Conditioning Equipment 23

13 6 2 Servicing the Air Conditioning Equipment 23

13 6 3 Having the Air Conditioning Equipment Checked 23

14 Electrical System 3

14 1 Checking the Lighting System 3

14 2 Checking the Battery Fluid Level 3

14 3 Checking the Limit Switches 3

14 4 Checking the Slip Ring Contacts on the Rope Winches and on

the Rotary Joint to the Undercarriage 3

14 5 Precautionary Measures Against Cable Fires 5

15 Fuel System 3

15 1 Draining Off Water and Residue From the Fuel Tank 3

15 2 Maintaining the Fuel Filter 3

15 3 Fuel System, Checking the Lines 5

16 Cooling, Air Intake and Exhaust System 3

16 1 Checking the Coolant Level and Topping Up if Necessary 3

16 2 Cleaning the Cooling System 5

16 3 Changing the Coolant 7

16 4 Cleaning and/or Replacing the Filter Element of the Air Filter 11

16 4 1 Dry Cleaning 13

16 4 2 Wet Cleaning 13

16 4 3 Checking the Element 15

16 5 Replacing the Safety Cartridge (Optional Equipment) 17

16 6 Exhaust System Visual Inspection 17

17 —

18 Crane Operator’s Cab 3

18 1 Checking the Windscreen Washing Assembly 3

18 2 Filling Up the Supply Tank of the Windscreen Washing Assembly 3

19 Undercarriage 3

19 1 Checking the Final Drive Oil Level 3

19 2 Changing the Oil in the Final Drive 5

19 3 Lubricating the Idlers, Bottom and Top Rollers 7

Index

062–2003–151 5

19 4 Lubricating the Connecting Pins 7

19 5 Maintaining the Hydraulic Cylinders on the Undercarriage 7

19 6 Tensioning the Crawler Track 9

19 7 Lubricating the Track Pins on the Track Typ Undercarriage and

Checking the Track Tension in the Case of Running Noises 11

19 8 Checking the Screw Connections and Re–tightening

if Necessary 13

19 9 Central Lubrication System 15

19 9 1 Component Parts 15

19 9 2 Operation 17

19 9 3 Setting the Interval and Operating Periods 19

19 9 4 Servicing Central Lubrication System 23

19 9 5 Filling the Tank of the Central Lubrication System 25

19 9 6 Troubleshooting 27

20 Counterweight carriage 3

20 1 Lubricating the Ball Bearing Slewing Rim 3

20 2 Lubricating the counterweight carriage 3

20 3 Final drive — Checking oil level 5

20 4 Final drive — Changing the oil 7

20 5 Tyres — Checking the air pressure, tread and rims 9

20 6 Tyres — Checking wheel nuts, tightening if required 11

20 7 Checking the Screw Connections 13

20 8 Checking the Welds for Cracks 13

21 Visual Inspections 3

21 1 Visual Inspection of the Superstructure and Crawler 3

21 2 Visual Inspections of the Superlift Counterweight Framework 3

21 3 Visual Inspection of the Equipment 5