$38

Terex Demag Crawler Crane CC6800 1250T Lubrication Manual – PDF DOWNLOAD

Terex Demag Crawler Crane CC6800 1250T Lubrication Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crawler Crane CC6800 1250T Lubrication Manual – PDF DOWNLOAD

Language : English

Pages : 447

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

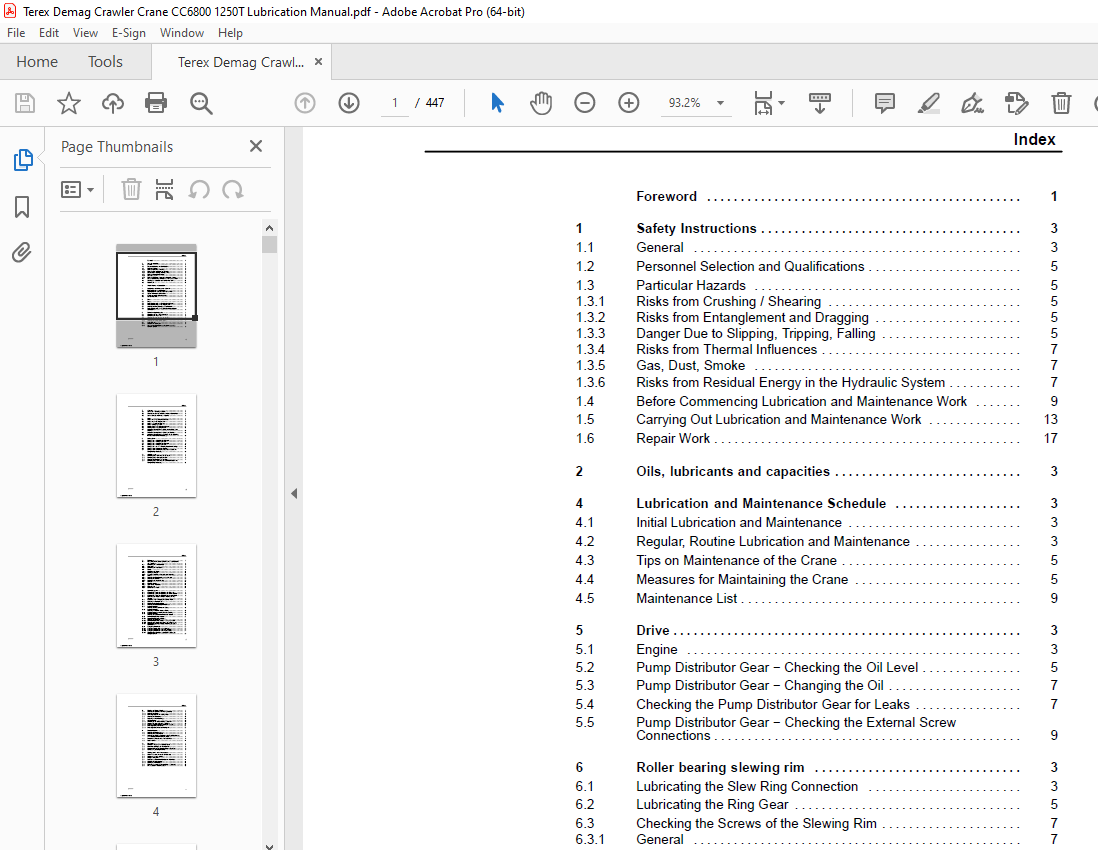

TABLE OF CONTENTS:

Terex Demag Crawler Crane CC6800 1250T Lubrication Manual – PDF DOWNLOAD

Foreword 1

1 Safety Instructions 3

1 1 General 3

1 2 Personnel Selection and Qualifications 5

1 3 Particular Hazards 5

1 3 1 Risks from Crushing / Shearing 5

1 3 2 Risks from Entanglement and Dragging 5

1 3 3 Danger Due to Slipping, Tripping, Falling 5

1 3 4 Risks from Thermal Influences 7

1 3 5 Gas, Dust, Smoke 7

1 3 6 Risks from Residual Energy in the Hydraulic System 7

1 4 Before Commencing Lubrication and Maintenance Work 9

1 5 Carrying Out Lubrication and Maintenance Work 13

1 6 Repair Work 17

2 Oils, lubricants and capacities 3

4 Lubrication and Maintenance Schedule 3

4 1 Initial Lubrication and Maintenance 3

4 2 Regular, Routine Lubrication and Maintenance 3

4 3 Tips on Maintenance of the Crane 5

4 4 Measures for Maintaining the Crane 5

4 5 Maintenance List 9

5 Drive 3

5 1 Engine 3

5 2 Pump Distributor Gear − Checking the Oil Level 5

5 3 Pump Distributor Gear − Changing the Oil 7

5 4 Checking the Pump Distributor Gear for Leaks 7

5 5 Pump Distributor Gear − Checking the External Screw

Connections 9

6 Roller bearing slewing rim 3

6 1 Lubricating the Slew Ring Connection 3

6 2 Lubricating the Ring Gear 5

6 3 Checking the Screws of the Slewing Rim 7

6 3 1 General 7

6 3 2 Checking the Torque of the Screws 7

6 4 Quick Release 9

6 4 1 Lubricate the locking pin 9

6 4 2 Apply conservation grease on the piston rods of the

hydraulic cylinder 9

Index

052−2000−010 2

7 slew gear 3

7 1 Slew Gear − Checking the Brake 3

7 2 Checking the Slew Gear Mechanism Screw Connections 5

7 3 Slew Gear Mechanism Visual Inspection 5

8 Hoists 3

8 1 Hoist 1 and 2 − Checking the Oil Level 3

8 2 Hoist 1 and 2 − Changing the Oil 5

8 3 Hoist 3 − Checking the Oil Level 7

8 4 Hoist 3 − Changing the Oil 9

8 5 Reeving Winch − Checking the Oil Level 11

8 6 Reeving Winch − Checking the Oil 13

8 7 Hoists and Reeving Winch − Lubricating the Rope Drum

Bearings 15

8 8 Hoists and Reeving Winch − Checking the Brakes 15

8 9 Hoists and Reeving Winch − Checking and Re−tightening

the Screw Connections if Necessary 19

9 Luffing Gears 3

9 1 Luffing Gear 1 − Checking the Oil Level 5

9 2 Luffing Gear 1 − Changing the Oil 7

9 3 Luffing Gear 2 − Checking the Oil Level 9

9 4 Luffing Gear 2 − Changing the Oil 11

9 5 Luffing Gear 1 and 2 − Lubricating Rope Drum Bearings 13

9 6 Luffing Gears − Checking the Brakes 13

9 7 Luffing Gears − Checking the Screw Connections and

Re−tightening if Necessary 19

10 derricking gear 3

10 1 Derricking Gear − Checking the Oil Level 3

10 2 Derricking Gear − Changing the Oil 5

10 3 Checking the Derricking Gear Brakes 7

10 4 Derricking Gear − Checking the Screw Connections and

Re−tightening if Necessary 13

Index

052−2000−010 3

11 Equipment 3

11 1 Maintaining the Hydraulic Cylinders on the Superstructure

and Equipment 3

11 2 Lubricating the Boom Bearings 5

11 3 Hook Blocks 7

11 3 1 Lubricating the Hook Blocks 7

11 4 Ropes 9

11 4 1 Lubricating the Ropes 11

11 4 2 Cleaning the Ropes 13

11 4 3 General Information on Operation and Assembly 13

11 5 Sheaves 27

11 5 1 Checking the Roller Bearings on the Sheaves 27

11 5 2 Checking the Sheaves 29

11 5 3 Lubricating the sheave bearing 29

11 6 Carriage 31

11 6 1 Lubricate wheels 31

11 6 2 Tyre − check air pressure 31

11 6 3 Replace tyres 31

11 6 4 Dismantle the wheel 31

12 Hydraulic System 3

12 1 Hydraulic Oil Reservoir − Checking the Oil Level 3

12 2 Hydraulic Oil Reservoir −Replacing the Return Oil Filter 5

12 3 Hydraulic Oil Reservoir − Replacing the Aeration Filter 5

12 4 Leak oil circuit − Return oil filter − cleaning the filter

element 7

12 5 Hydraulic Pump − Changing the Add−On Filter 9

12 6 Replacing the Hydraulic Oil 11

12 7 Bleeding the Hydraulic System 13

12 8 Checking the Hydraulic System for Leaks 13

12 9 Hydraulic System −

Checking the Flexible Pressure Tubing 15

12 10 Hydraulic System −

Replacing the Flexible Pressure Tubing 15

12 11 Hydraulic system − handling the hose couplings 17

12 12 Hydraulic System −

Checking the Accumulator Initial Gas Pressure 19

12 13 Lower Luffing Mast Back Stops 23

12 13 1 Lower Luffing Mast Back Stops −

Checking the Oil Level 23

12 13 2 Lower Luffing Mast Back Stops − Changing the Oil 23

12 13 3 Checking the Lower Luffing Mast Back Stops for Leaks 25

12 13 4 Lower Luffing Gear Back Stops −Checking the Screw

Connections 25

12 14 Outrigger cylinder fly jib 27

12 14 1 Outrigger cylinder fly jib − check for leaks 27

12 14 2 Outrigger cylinder fly jib − check oil pressure 27

12 14 3 Outrigger cylinder fly jib − check gas pressure 27

12 14 4 Correcting the oil and/or gas pressure and filling the

outrigger cylinder 29

Index

052−2000−010 4

13 Heating and Air conditioning 3

13 1 Checking the System is Functioning Correctly 3

13 1 1 Checking the Fuses 5

13 1 2 Fault Diagnosis with the Heating Timer 5

13 2 Checking the Water Level 17

13 3 Replacing the Heat Exchanger 17

13 4 Air Conditioning 19

13 4 1 Switching on the Air Conditioning Equipment 19

13 4 2 Servicing the Air Conditioning Equipment 19

13 4 3 Having the Air Conditioning Equipment Checked 23

13 4 4 Error diagnosis for condenser 23

13 4 5 Error diagnosis for heat conditioning unit 25

14 Electrical System 3

14 1 Checking the Lighting System 3

14 2 Checking the Limit Switches 3

14 3 Checking the Slip Ring Contacts on the Rope Winches and

on the Rotary Joint to the Undercarriage 3

14 4 Precautionary Measures Against Cable Fires 5

14 5 Fuse Overview 11

15 Fuel System 3

15 1 Fuel filter − emptying the inspection glass 5

15 2 Fuel Filter − Changing the Filter Element 5

15 3 Draining Off Water and Residue From the Fuel Tank 9

15 4 Fuel System, Checking the Lines 9

16 Cooling, intake and exhaust system 3

16 1 Check the coolant and top up as necessary 3

16 2 Cleaning the cooling system 5

16 3 Change cooling fluid 7

16 4 Replace and/or clean the filter element of air filters 11

16 4 1 Changing the filter element 11

16 4 2 Cleaning the filter element 13

16 5 Replacing the Safety Cartridge (Optional Equipment) 15

16 6 Exhaust System Visual Inspection 15

Index

052−2000−010 5

17 Piston Rods 1

17 1 Exposed Chrome Surfaces − Applying Protective Grease 1

18 Crane Operator’s Cab 3

18 1 Checking the Windscreen Washing Assembly 3

18 2 Filling Up the Supply Tank of the Windscreen Washing

Assembly 3

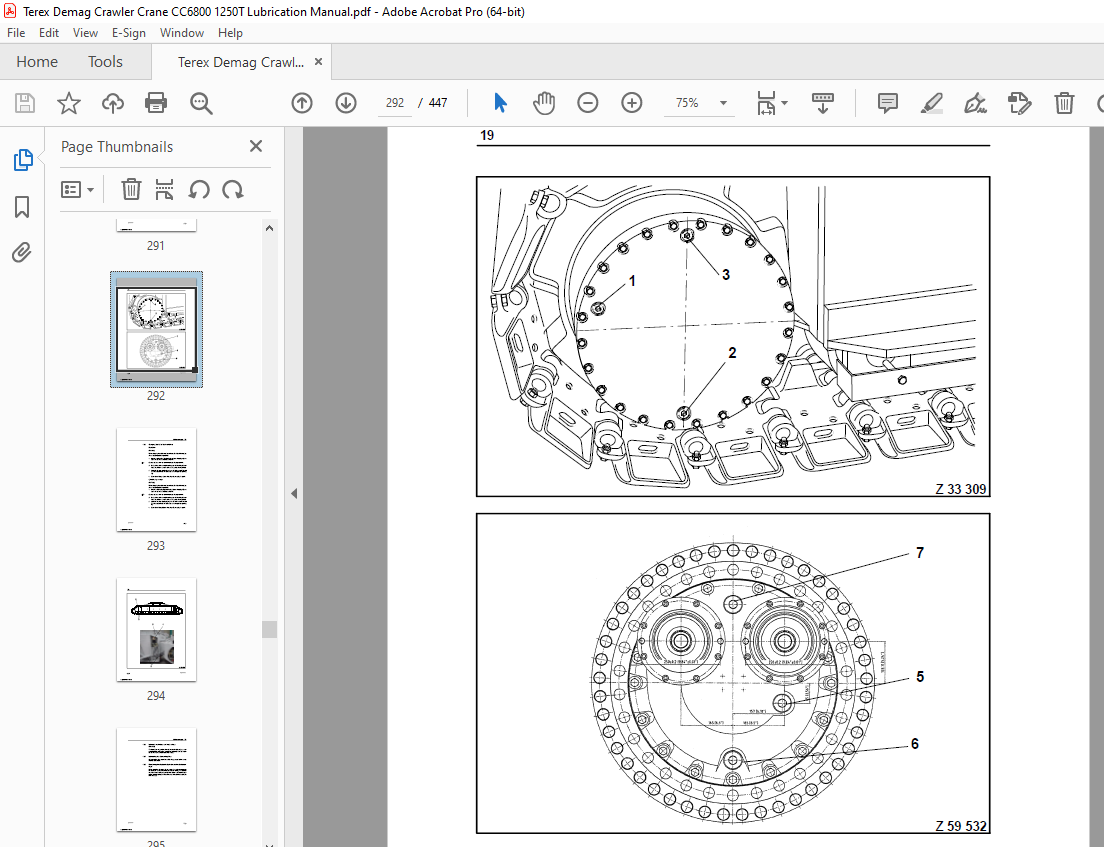

19 Undercarriage 3

19 1 Drive gearbox − Check oil level 3

19 2 Changing the Oil in the Final Drive 5

19 3 Lubricate front idlers and track rollers 7

19 4 Lubricating the Connecting Pins 7

19 5 Maintaining the Hydraulic Cylinders on the Undercarriage 7

19 6 Tensioning the Crawler Track 9

19 7 Lubricating the Track Pins on the Track Type Undercarriage

and Checking the Track Tension in the Case of Running Noises 13

19 8 Checking the Screw Connections and Re−tightening if

Necessary 15

19 9 Central Lubrication System 17

19 9 1 Component Parts 17

19 9 2 Function 17

19 9 3 Servicing Central Lubrication System 19

19 9 4 Filling the Tank of the Central Lubrication System 21

19 9 5 Troubleshooting 23