$38

Terex Demag Crawler Crane CC6800 1250T Operating Manual – PDF DOWNLOAD

Terex Demag Crawler Crane CC6800 1250T Operating Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Demag Crawler Crane CC6800 1250T Operating Manual – PDF DOWNLOAD

Language : English

Pages : 487

Downloadable : Yes

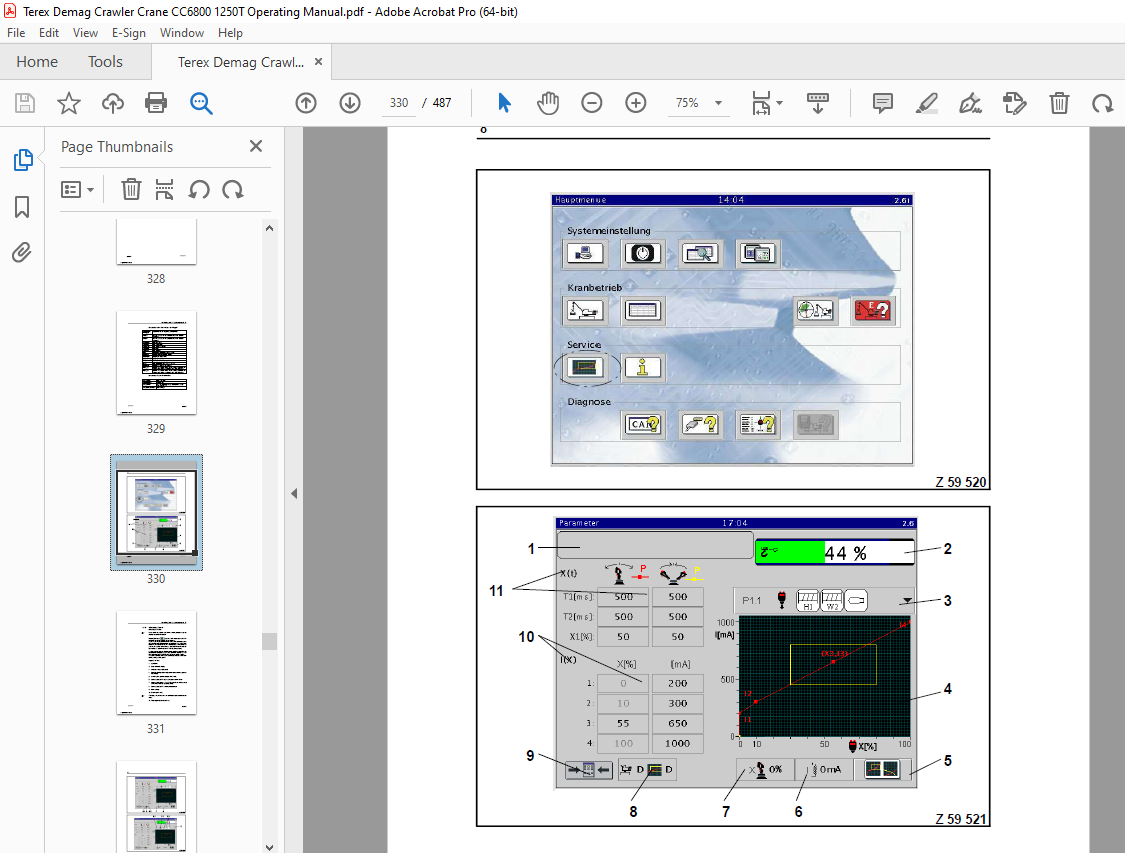

File Type : PDF

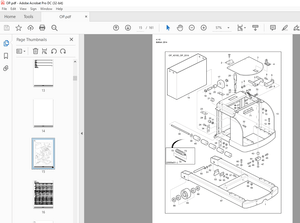

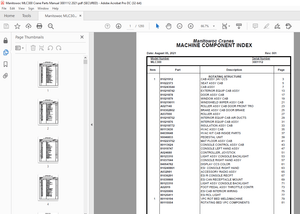

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Demag Crawler Crane CC6800 1250T Operating Manual – PDF DOWNLOAD

Manufacturer’s specifications 1

Foreword 1

1 Safety Instructions 3

1 1 General 3

1 2 Intended Use 5

1 3 Operating Conditions and Computed Design of the Crane 9

1 3 1 General 9

1 3 2 Classification of the Crane 9

1 3 3 Classification of the Engines 11

1 3 4 Workplace Ergonomics 13

1 3 5 Load and Utilisation of the Crane 13

1 3 6 Required Ambient Conditions 15

1 3 7 Service Life 17

1 3 8 Standards and Calculation Regulations 19

1 3 9 Dangers to Air Traffic 21

1 4 Safety Regulations 23

1 4 1 Organisational Measures 25

1 4 2 Personnel Selection and Qualifications 27

1 4 3 Particular Hazards 29

1 4 3 1 Electrical Energy 29

1 4 3 2 Gas, Dust, Steam, Smoke 37

1 4 3 3 Crushing / Collision 37

1 4 3 4 Snagging/Dragging 37

1 4 3 5 Crushing / Shearing 39

1 4 3 6 Danger Due to Slipping, Tripping, Falling 39

1 4 4 Combination of Hazards with Combined Operation of Two or

More Cranes 43

1 4 4 1 Operating Areas of Several Cranes Overlap 43

1 4 4 2 Several cranes raising a load together 45

1 4 5 Before Crane Operation 47

1 4 6 During Operation of the Crane 51

1 4 7 Following Crane Operation 61

1 4 8 When Assembling and Dismantling Crane Components 63

1 5 Hand Signals 67

1 5 1 General Hand Signals 69

1 5 2 Hand Signals for Working Movements 71

1 5 3 Hand Signals for Driving Movements 73

1 6 Power Supply Failure 75

Index

053−1000−010 2

2 Description of the crawler−mounted crane 3

2 1 Overview 3

2 2 Superstructure 5

2 3 Undercarriage 7

2 4 Boom Variants 9

2 5 Technical description 13

2 5 1 Chassis 13

2 5 2 Superstructure 13

2 5 3 Additional equipment (options) 15

2 5 4 Hook Blocks 15

2 5 5 Technical Data 17

2 6 Safety−relevant Components 23

2 6 1 Ladders and Cat Walks 23

2 6 2 Headlights 25

2 6 3 Emergency Exit 25

2 7 Decals 27

2 7 1 Signs in the Crane Operator’s Cab 27

2 7 2 Signs and Symbols on the Superstructure 31

2 7 3 Safety Signs 33

4 Crane Operator’s Cab 3

4 1 Controls in the Crane Operator’s Cab 3

4 2 Control lever 5

4 3 Add−on console 13

4 3 1 General arrangement of construction consoles 13

4 3 2 Display and operating elements on the ad−on consoles 15

4 3 3 Display and Control Console LLD System 19

4 3 4 Display and operating console for monitoring of engine 21

4 4 Side panel 33

4 5 Side panel, seat bracket 35

4 6 Radio Remote Control 37

4 7 Mobile Control Panel for Emergency Control 41

4 8 Entering / leaving the cab 45

4 9 Tilting the cab 47

4 10 Adjustment of the crane operator’s seat 49

Index

053−1000−010 3

5 Engine and Drive 3

5 1 Engine control 5

5 2 Starting 7

5 2 1 Before starting 7

5 2 2 Starting Procedure 9

5 2 3 Starting Aid 11

5 2 4 To be Observed Following Starting 13

5 2 5 Warming Up the Hydraulic System 15

5 2 6 Warming−up Procedure 15

5 2 7 Checks with the Diesel Engine Running 17

5 2 8 Instructions for Operation 19

5 2 9 Switching Off 19

5 3 Automatic Driving 19

5 4 Restricted operation using a diesel engine 21

6 Driving the Crawler−mounted Crane 3

6 1 General 3

6 1 1 Main Driving Direction 3

6 1 2 Requirements for Road Surface Conditions 5

6 1 3 Regulations for Driving Operation 5

6 2 Controlling the Undercarriage 9

6 2 1 Control Movements 9

6 2 2 Control Movements for Tailing Operation 9

6 2 3 Options for Controlling the Driving Speed 11

6 3 Driving without Load on the Horizontal and Angled Road

Surface 13

6 3 1 General 13

6 3 2 Driving without Load 15

6 4 Driving with Load on a Horizontal and Graded Road

Surface 17

6 4 1 General 17

6 4 2 Driving with Load on Horizontal, Even Terrain

( 0 35 Slope) 19

6 4 3 Driving with Load on Inclined, Even Territory

( 0 35 incline) 21

7 Slewing and Braking the Superstructure 3

7 1 Speed Control 3

7 2 Slewing 5

7 3 Braking the Superstructure 7

7 4 Mechanical locking of the holding brake in opened

position 9

Index

053−1000−010 4

8 Operating the Safety Equipment 3

8 1 IC−1 crane control 3

8 1 1 Load limit device (LMI) 5

8 1 1 1 Function 5

8 1 1 2 Bridging the Load Limit Device 11

8 1 1 3 LMI fault code table 15

8 1 2 Description of the monitor screens and function keys 31

8 1 2 1 Opening Screen 31

8 1 2 2 Symbols ”Main menu of the Display and operating console of

the LMI system”(LMI screen) 31

8 1 2 3 Symbol ”Main Menu of the Display and Operating Console of

the Engine and Crane Operating System”(MOT screen) 33

8 1 2 4 ”System settings”screen 37

8 1 2 5 ”Set crane type”screen 37

8 1 2 6 ”Set display”screen 39

8 1 2 7 ”LMI”screen 41

8 1 2 8 ”MOT”screen 51

8 1 3 Operating the LMI System 53

8 1 3 1 Switching On 53

8 1 3 2 Entering the Operating Mode 55

8 1 3 3 Setting the Configuration Programs for Assembling the

Crane 63

8 1 3 4 Configuration operation 69

8 1 4 ”View table” screen 71

8 1 5 ”Operating range limit”screen 77

8 1 5 1 Switching On 77

8 1 5 2 Setting up the Various Limits 79

8 1 6 Display of the ground pressure 85

8 1 7 ”Data logger” screen (data recorder) 87

8 1 8 ”Parameters” screen 93

8 1 9 Load Monitoring Assembly 107

8 1 10 Gradient and slewing angle display 109

8 1 11 Troubleshooting 111

8 1 11 1 ”Error messages” screen 113

8 1 12 ”CAN”screen 117

8 1 13 ”I/O” screen 119

8 1 14 ”Function diagnostics”screen 121

8 1 15 Malfunction procedure 123

8 1 15 1 Fault−free operation/ malfunction 123

8 1 15 2 Failure of the crane control (CAN stop) 123

8 1 15 3 Failure of a monitor 123

8 2 Limit switches 125

8 2 1 Hoist limit switch 125

8 2 2 Lower limit switch 129

8 3 Dead man’s handle 131

Index

053−1000−010 5

9 Working with the Crane Equipment 3

9 1 Preparations 3

9 1 1 Positioning the Crane 3

9 1 2 Working Instructions 5

9 1 3 Wind Speeds − Dynamic Pressure 5

9 1 3 1 Permitted wind speeds with crane operation 7

9 2 Selection of the functions for crane operation 13

9 2 1 Allocation of the control levers 13

9 2 2 Selection of functions 15

9 3 Configuring the crane equipment 17

9 3 1 Simultaneous Operation of Derricking Gear (E) and Luffing

Gear 1 (W1) 17

9 3 2 Simultaneous Operation of Derricking Gear ”E” and Luffing

Gear ”W2” 17

9 3 3 Simultaneous Operation of Luffing Gear 1 (W1) and Luffing

Gear 2 (W2) 19

9 4 Operating the Reeving Winch 21

9 4 1 General 21

9 4 2 Operation 21

9 5 Crane Operation 23

9 5 1 Winch selection for crane operation 23

9 5 1 1 Operating the Derricking Gear (E) 23

9 5 1 2 Simultaneous Operation of Derricking Gear (E) and Hoist 1

(H1) 23

9 5 1 3 Operating Range of the Main Boom 23

9 5 2 Luffing gear 1 (W1) operation 25

9 5 2 1 Simultaneous Operation of Luffing Gear 1 (W1) and Hoist 2

(H2) 25

9 5 2 2 Operating Range of the Fly Jib 25

9 5 2 3 Luffing gear 1 as Hoist 3 (optional) 25

9 5 3 Operation of the luffing gear 2 (W2) 27

9 5 3 1 Simultaneous Operation of Luffing Gear 2 (W2) and Hoist

Gear 1 (H1) 27

9 5 3 2 Operating Range of the Main Boom 27

9 5 4 Crane Operation with Double Hook Block, Hoist 1 and Hoist 2

in Combined Operation 29

9 5 4 1 Preparing for Operation 29

9 5 4 2 Operation at Normal Speed 33

9 5 4 3 Operation at High Speed 33

9 5 5 Operation with 2 reeved hook blocks 37

10 Working with the Superlift 3

10 1 Description of the Superlift Equipment 3

10 2 Modus operandi 5

10 3 Safety instructions for working with the Superlift 7

10 4 Operating the crane without the Superlift counterweight 11

10 5 Operating the Crane with the Superlift Counterweight 13

10 5 1 With standard Superlift equipment 13

053−1000−010 6

11 Operating the Heating and Ventilation 3

11 1 Operating the Heating 3

11 1 1 Controls 5

11 2 Heating operation 7

11 2 1 Setting the timer 7

11 2 2 Heating operation without preselection with ignition ”OFF” 9

11 2 3 Heating operation without preselection with ignition ”ON” 11

11 2 4 Heating operation with preselection 13

11 2 5 Safety Equipment 17

11 3 Operating the air conditioning system 19

11 3 1 Controls 19

12 Parking the Crane 3

12 1 Wind Speeds 3

12 2 Lowering the Boom System 7

13 Emergency operation 3

13 1 Emergency control system with the mobile control panel 3

14 Radio Remote Control 3

14 1 General 3

14 2 Preparations for Assembly using the Radio Remote Control 3

14 3 Tabular Collation of the Assembly Procedures 7

14 3 1 Assembly Procedures on the Superstructure 7

14 3 2 Assembly Procedures on the Chassis 9

14 3 3 SS−CR Roller bearing slewing rim 13

14 3 4 Assembly procedures on the SL counterweight 15

14 3 5 Adjust the SL Vario winch 15

14 3 6 Adjust the SL telescopic tube 15

14 3 7 Assembly procedures on the SL counterweight vehicle 17

14 4 Assembly Procedures in Case of Radio Remote Control

Failure 19

14 5 Virtual radio remote control 19

14 6 Manual control of assembly procedures 21

14 6 1 Assembly Procedures on the Counterweight Dolly 21

14 7 Error diagnosis 23