$39

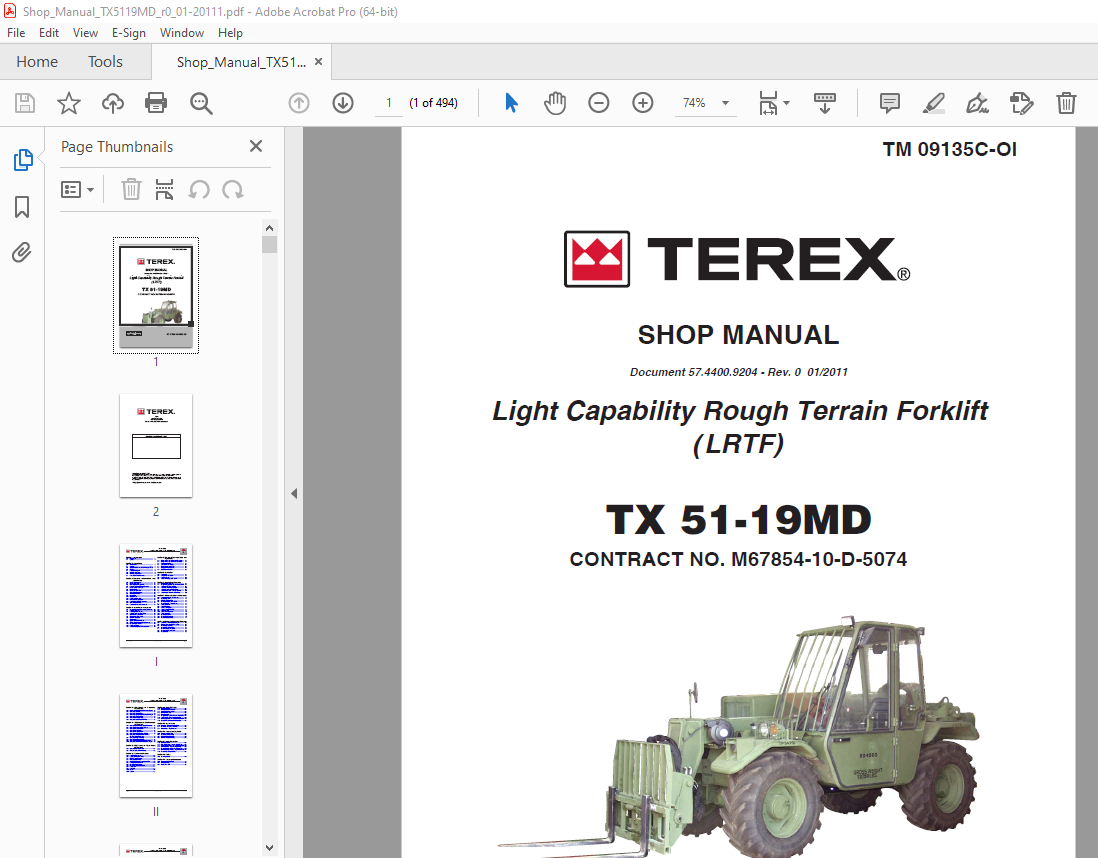

Terex TX 51-19MD Rough Terrain Forklift Shop Manual – PDF DOWNLOAD

Terex TX 51-19MD Rough Terrain Forklift Shop Manual – PDF DOWNLOAD

FILE DETAILS:

Terex TX 51-19MD Rough Terrain Forklift Shop Manual – PDF DOWNLOAD

Language : English

Pages : 494

Downloadable : Yes

File Type : PDF

Light Capability Rough Terrain Forklift

(LRTF)

TX 51-19MD

SHOP MANUAL

Document 57.4400.9204 – Rev. 0 01/2011

PCN 500 091352 00

TM 09135C-OI

CONTRACT NO. M67854-10-D-5074

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex TX 51-19MD Rough Terrain Forklift Shop Manual – PDF DOWNLOAD

Section 1 – Introduction

1 0 Introduction 3

1 1 Symbols 4

Section 2 – Safety Rules

2 0 Safety Rules 7

2 1 General 7

2 2 Operators Maintenance Staff Responsibilities 7

2 3 Clothing 7

2 4 Personal Equipment 8

2 5 Safety Precautions 8

2 6 Getting Ready to Work 8

2 7 During Work or Maintenance 8

Section 3 – General Information and

Specification

3 0 Machine References 13

3 1 Machine Position 13

3 2 Labels and Warning Decals 14

3 3 Explanation of the Different Symbols 19

3 4 Machine Model and Type 20

3 5 Manufacturer 20

3 6 Machine Identification 20

3 7 Chassis Serial Number 21

3 8 Identification Plates 21

3 9 Allowed Use 21

3 10 Improper Use 21

3 11 Applicable Standards 22

3 12 List of Main Components 22

3 13 Description of Main Components 23

3 14 Optional Accessories 23

3 15 Technical Data and Performance 24

Section 4 – Controls and Instruments

4 0 Preoparation, Inspection and Adjustments 29

4 1 Adjusting the Seat 29

4 2 Fastening the Seat Belts 30

4 3 Adjusting the Rear View Mirrors 30

4 4 Controls and Operations 32

4 5 Controls and Instruments 33

4 6 Control Description 34

4 7 Control Lever 43

4 8 Operating the Control Lever 44

4 9 Tilting the Forks Forward and Rearward 45

4 10 Side Shifting the Forks 46

4 11 Rotating the Forks 47

4 12 Quick-Coupling the Fork Attachment 48

Section 5 – Pre-operation Inspection and

Adjustment

5 0 Pre-operation Inspection and Adjustment 51

5 1 Pre-operation Inspection and Check List 51

5 2 Starting the Engine 51

5 3 Jump-Starting the Engine 52

5 4 Battery Disconnect Switch 52

5 5 Stopping / Parking Machine 53

5 6 Refueling the Machine 53

Section 6 – Lubrication

6 0 Lubrication 57

6 1 Lubricant Specification 57

6 2 Lubricant Chart 58

6 3 Lube and Fluid Capacity Chart 59

Section 7 – Preventive Maintenance

7 0 Preventive Maintenance 63

7 1 Using the Suggested Schedule Check Sheet 63

7 2 50 Hours or Weekly Services 65

7 3 250 Hours or Monthly Services 66

7 4 500 Hours or Quarterly Services 67

7 5 1000 Hours or Semi-Annually Services 68

7 6 3000 Hours or Three Years Services 69

Section 8 – 50 Hours or Weekly Maintenance

8 0 50 Hours Or Weekly Maintenance 73

8 1 Check Engine Oil 73

8 2 Drain Engine Fuel Filter 73

8 3 Check Hydraulic Reservoir Oil 74

8 4 Check Brake Oil Reservoir Level 74

8 5 Lube Boom Pads 74

8 6 Lube Drive Shaft 75

8 7 Lube Axle King Pins 75

8 8 Lube Axle Rear Pivot Pin 75

8 9 Lube Cylinders 75

8 10 Lube Fork Attachments 76

8 11 Lube Boom Pivot 76

8 12 Check Tire Inflation 76

8 13 Check Tire Wheel Nuts 76

8 14 Check Drive Shaft Bolts 77

Section 9 – 250 Hours or Monthly Maintenance

9 0 250 Hours Or Monthly Maintenance 81

9 1 Engine and Hydraulic Oil Sampling 81

9 2 Check Engine Air Filter 81

9 3 Check Engine Drive Belts 82

9 4 Check Axle Wheel Ends Oil 82

9 5 Check Axle Differential Oil 83

9 6 Check Battery 83

Page II TX51-19MD-1-SM 57 4400 9204

TX 51-19MD

Light Capability Rough Terrain Forklift (LRTF)

Section 10 – 500 Hours or Quarterly

Maintenance

10 0 500 Hours or Quarterly Maintenance Checks 87

10 1 Change Engine Oil 87

10 2 Change Engine Oil Filter 88

10 3 Change Engine Air Filter (external cartridge) 89

10 4 Change Engine Fuel Filter 90

10 5 Check Engine Glow Plugs 91

10 6 Change Hydraulic Reservoir Filter 91

Section 11 – 1000 Hours or Semi-Annually

Maintenance

11 0 1000 Hours or Semi-Annually Maintenance 95

11 1 Check Engine Valve Tip Clearance 95

11 2 Check Electrical Alternator 95

11 3 Check Electrical Starter 95

11 4 Check Electrical System 96

11 5 Check Hydraulic Hoses and Fitting 96

11 6 Change Hydraulic Reservoir Oil Filter,

Cleaning Hydraulic Magnet 96

11 7 Change Axle Wheel End Oil 97

11 8 Change Axle Differential Oil 97

11 9 Check Accumulator Pre-charge Pressure 98

11 10 Change Engine Air Filter (internal cartridge) 98

Section 12 – 3000 Hours or Three Years

Maintenance

12 0 3000 Hours or Three Years 101

12 1 Check Atomisers (Fuel Injector) 101

Section 13 – Routine Maintenance

13 0 Routine Maintenance 105

13 1 Replacing the Attachments 105

13 2 Slider Pads Adjustment 106

13 3 Changing Slider Pads 106

13 4 Attachment Plate Removal / Installation 108

13 5 Parking Brake Adjustment 109

13 6 Bleeding Brake System 111

13 7 Proximity Switch Adjustment 111

13 8 Drive Shaft 111

13 9 Fuel Tank 113

13 10 Oil Tank 114

13 11 Radiator 115

Section 14 – Hydraulic Boom

14 0 Boom Introduction 121

14 1 Boom Removal / Installation 121

14 2 Tilt Cylinder Replacement 124

14 3 Boom Disassembly 125

14 4 Boom Assembly 126

14 5 Compensation Cylinder Removal / Installation 127

14 6 Locking Cylinder Removal / Installation 128

14 7 Boom Hoist Cylinder – Removal / Installation 130

14 8 Extend Cylinder Removal / Installation 133

Section 15 – Carraro Axles

15 0 Front Alxe – Removel / Installation 137

15 1 Rear Axle – Removel / Installation 141

15 2 Carraro Axles – Repair manual 143

Section 16 – Troubleshooting Guide

16 0 Troubleshooting Guide 275

16 1 General Troubleshooting 275

16 2 Hydraulic Troubleshooting 276

16 3 Electrical Troubleshooting 281

Section 17 – Hydraulic System

17 0 Hydraulic System 297

17 1 Hyd Drive Pump – Removal / Installation 297

17 2 Cylinder Holding Valve – Removal / Installation 298

17 3 Hydraulic Motor – Removel / Installation 298

17 4 Rexroth Pump (A4vG) – Repair istructions 299

17 5 Rexroth Motor (A6Vm107) – Repair istructions 341

17 6 Rexroth Operating Istructions 381

Section 18 – Engine

18 0 Operating Manual 399

Section 19 – Tables and Enclosures

19 0 Torque Wrench Settings 453

19 1 Pressure Setting 455

19 2 Special Tool List 457

57 4400 9204 TX51-19MD-1-SM Page III

TX 51-19MD

Light Capability Rough Terrain Forklift (LRTF)

Section 20 – 3B6 Technologies LMI System

20 0 3B6 Load Moment Indicator Manual 465

20 1 System lay-out and connections 466

20 2 Components location on the machine 467

20 3 Infolift main unit: Characteristics 468

20 4 Infolift main unit: Dimensions 469

20 5 Load cell amplifier: Dimensions,

characteristics, cable 470

20 6 Control panel description 471

20 7 Display information: Working messages 472

– Power-on sequence

– Safe working condiotion

– Warning condition

– Shut-off condition

– Setting mode

– Shut-off over ride

20 8 Display information: Diagnostics messages 475

– A01 crc error

– A02 cellalarm

– A03 cellallarm

20 9 Standard operating mode 476

– Normal / safe working load

– Pre-warning working load

– Overload working load

– By-pass pushbutton

20 10 Accuracy verification 480

– Pushbuttons functions

– Procedure

20 11 Accuracy verification mode 482

– First time accuracy verification

– Re-accuracy verification

– Load cell reading

– Empty accuracy verification

– Laden accuracy verification

– Cut-off percentage

– Empty moment

– Laden moment

– Filter

20 12 How to set a numeric value 485

20 13 How to set the password 486

20 14 External wiring 487

20 15 Spare parts list 488

20 16 Warnings 488