$35

Volvo Penta 4.3GL GXi OSi-A B C D E Engine Workshop Manual_74550500 – PDF DOWNLOAD

Volvo Penta 4.3GL GXi OSi-A B C D E Engine Workshop Manual_74550500 – PDF DOWNLOAD

DESCRIPTION:

Volvo Penta 4.3GL GXi OSi-A B C D E Engine Workshop Manual_74550500 – PDF DOWNLOAD

4.3GL-A/B/C/D

4.3GXi-A/B(F)/C(F)/D(F)/E(F)

4.30Si-B(F)/C(F)/D(F)/E(F)

General Information

This service manual is divided into sections concerning various systems

and assemblies. Refer to the Contents to locate the section covering

the system or assembly requiring service. Each section title page

has an additional listing that will describe the sections contents in

more detail. Be sure to read the Safety Section at the end of this manual,

and pay special attention to all safety warnings as they appear

throughout the text. Since models are subject to change at any time,

some photos may not depict actual product.

Good Service Practice Service required for stern drives is generally one of three kinds:

• Normal care and maintenance – which includes putting a new

stern drive into operation, storing engines, lubrication, and care

under special operating conditions such as salt water and cold

weather.

• Operating malfunctions – due to improper engine or drive

mounting, propeller condition or size, boat condition, or the malfunction

of some part of the engine. This includes engine servicing

procedures to keep the engine in prime operating condition.

• Complete disassembly and overhaul – such as major service

or rebuilding a unit.

It is important to determine before disassembly just what the trouble is

and how to correct it quickly, with minimum expense to the owner.

When repairing an assembly, the most reliable way to ensure a good

job is to do a complete overhaul on that assembly, rather than just to

replace the bad part. Wear not readily apparent on other parts could

cause malfunction soon after the repair job. Repair kits and seal kits

contain all the parts needed to ensure a complete repair, to eliminate

guesswork, and to save time.

Repair time can also be minimized by the use of special tools. Volvo

Penta special tools are designed to perform service procedures

unique to the product that cannot be completed using tools from other

sources. They also speed repair work to help achieve service flat rate

times. In some cases, the use of substitute tools can damage the part.

Preparation for Service Proper preparation is extremely helpful for efficient service work. A

clean work area at the start of each job will minimize tools and parts

becoming misplaced. Clean an engine that is excessively dirty before

work starts. Cleaning will occasionally uncover trouble sources. Obtain

tools, instruments and parts needed for the job before work is started.

Interrupting a job to locate special tools or repair kits is a needless

delay.

TABLE OF CONTENTS:

Volvo Penta 4.3GL GXi OSi-A B C D E Engine Workshop Manual_74550500 – PDF DOWNLOAD

ChapterTitleTOC – General Information 1………………………………………. 3

ChapterTitleTOC – General Mechanical 29………………………………………. 3

ChapterTitleTOC – Engine – 4.3 Liter 53………………………………………. 3

ChapterTitleTOC – Steering System 175………………………………………… 3

ChapterTitleTOC – Throttle & Shift Control System 197………………………….. 3

ChapterTitleTOC – Cooling System 205…………………………………………. 3

ChapterTitleTOC – Engine Removal and Installation 225………………………….. 3

Heading1 – Model Identification……………………………………………… 4

Heading1 – Engine Model Number………………………………………………. 4

Heading3 – ……………………………………………………………. 4

Heading3 – ……………………………………………………………. 4

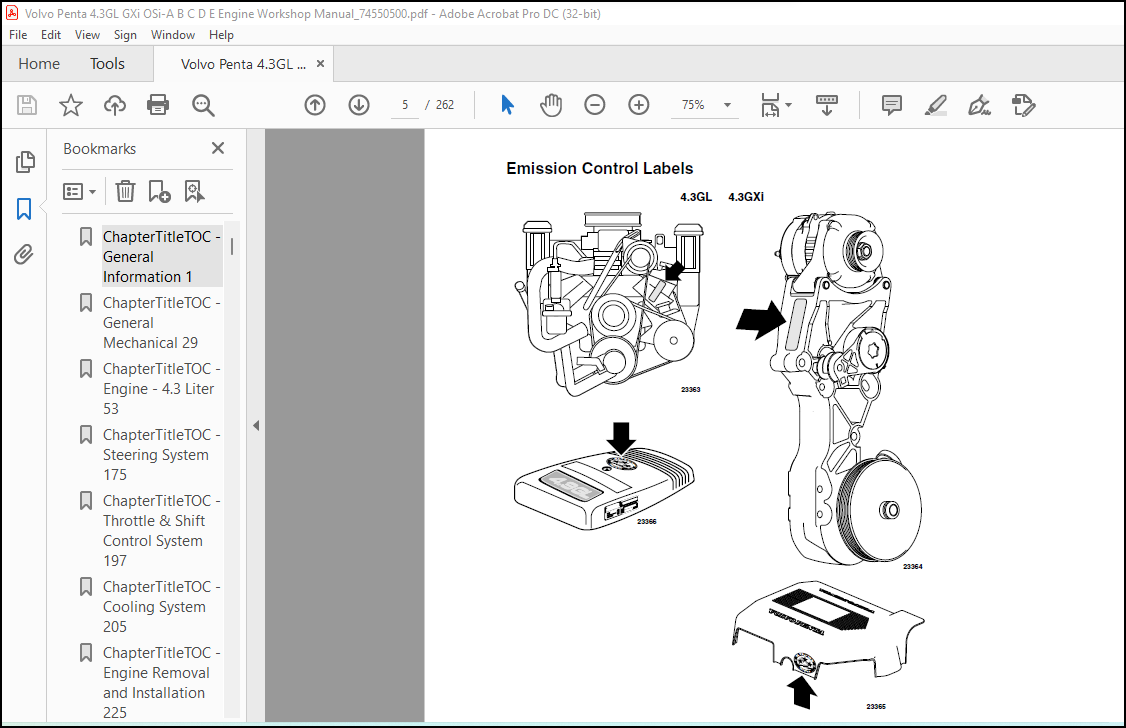

Heading1 – Emission Control Labels…………………………………………… 5

Heading3 – 4.3GL……………………………………………………….. 5

Heading1 – Transom Shield Model Number Location……………………………….. 6

Heading3 – ……………………………………………………………. 6

Heading1 – Sterndrive Model Number Location…………………………………… 6

Heading3 – ……………………………………………………………. 6

Heading3 – ……………………………………………………………. 6

ChapterTitle – Section 1: General Information…………………………………. 7

Heading3 – Good Service Practice…………………………………………. 8

Heading3 – Preparation for Service……………………………………….. 8

Heading3 – Service Policy……………………………………………….. 8

Heading3 – Replacement Parts…………………………………………….. 9

Heading3 – Parts Catalogs……………………………………………….. 9

Heading3 – Special Service Tools…………………………………………. 9

Heading3 – Product References, Illustrations & Specifications……………….. 9

Heading1 – Tuning the Engine…………………………………………….. 10

Heading2 – Engine Compression Testing…………………………………. 10

Heading2 – Test Conclusion…………………………………………… 10

Heading2 – Ignition System Components…………………………………. 11

Heading2 – Fuel System Components…………………………………….. 11

Heading2 – Intake Manifold Vacuum Testing……………………………… 12

Heading3 – Test Procedures…………………………………………… 12

Heading3 – Test Results……………………………………………… 12

Heading2 – Gasoline Requirements……………………………………… 14

Heading2 – Gasoline Containing Alcohol………………………………… 14

Heading1 – Crankcase Oil………………………………………………… 15

Heading3 – Draining and Filling the Engine Crankcase……………………. 15

Heading3 – Oil Filter……………………………………………….. 16

Heading1 – Steering System Lubrication……………………………………. 16

Heading1 – Power Trim/Tilt Fluid Level……………………………………. 16

Heading1 – Off-Season Storage……………………………………………. 17

Heading3 – Limited Use………………………………………………. 17

Heading3 – Storage………………………………………………….. 17

Heading3 – Step 1. Prepare a storage mixture…………………………… 17

Heading3 – Electric Fuel Pumps and Fuel Cells………………………….. 18

Heading3 – Stuck Pumps………………………………………………. 18

Heading3 – Noisy Fuel Pumps………………………………………….. 18

Heading3 – Step 2. Change Motor Oil and Oil Filter:…………………….. 19

Heading3 – Step 3. Change Sterndrive Lubricant:………………………… 19

Heading3 – Step 4. Fog Engine:……………………………………….. 19

Heading3 – Step 5. Drain Cooling System……………………………….. 19

Heading1 – Preparation for Boating After Storage…………………………… 19

Heading1 – Engine Break-in………………………………………………. 20

Heading3 – First Two Hours…………………………………………… 21

Heading3 – Next Eight Hours………………………………………….. 21

Heading3 – Final Ten Hours…………………………………………… 21

Heading3 – Operation After Break-in…………………………………… 22

Heading1 – Submerged Engine……………………………………………… 22

Heading1 – 20-Hour Check………………………………………………… 22

Heading1 – Belt Tension…………………………………………………. 23

Heading3 – ………………………………………………………… 23

Heading2 – Alternator Belt Adjustment…………………………………. 23

Heading3 – ………………………………………………………… 23

Heading2 – Power Steering Pump Belt Adjust ment………………………… 24

Heading3 – ………………………………………………………… 24

Heading1 – Positive Closed-Type Ventilation System (4.3GXi-A only)…………… 24

Heading3 – With Engine Idling………………………………………… 25

Heading3 – With Engine Stopped……………………………………….. 25

Heading3 – Servicing PCV Valve……………………………………….. 25

Heading1 – Troubleshooting – System Isolation……………………………… 25

Heading1 – Engine Troubleshooting Guides………………………………….. 25

Heading2 – Engine Will Not Crank……………………………………… 27

Heading3 – Starter Circuit – Check:…………………………………… 27

Heading2 – Engine Cranks, But Will Not Start…………………………… 27

Heading3 – Ignition Circuit – Check:………………………………….. 27

Heading3 – Fuel System – Check:………………………………………. 27

Heading3 – Cylinder Compression – Check……………………………….. 28

Heading2 – Hard Starting – Cold Engine………………………………… 28

Heading3 – Has Engine Always Done This? Check:…………………………. 28

Heading3 – Was Engine Used For A Long Time? Check:……………………… 28

Heading3 – Is This A New Condition? Check:…………………………….. 28

Heading2 – Hard Starting – Hot Engine…………………………………. 28

Heading3 – Has Engine Always Done This? Check:…………………………. 28

Heading3 – Is This A New Condition? Check:…………………………….. 28

Heading3 – Did Engine Refuse To Start After Being Run? Check:……………. 28

Heading2 – Engine Runs Rough…………………………………………. 29

Heading3 – If At Slow Speed – Check:………………………………….. 29

Heading3 – If At High Speed – Check:………………………………….. 29

Heading2 – Engine Noises and Vibrations……………………………….. 29

Heading3 – Valves – Hydraulic Lifters…………………………………. 29

Heading3 – Ignition System (Ping or Knock)…………………………….. 29

Heading3 – Cooling System……………………………………………. 29

Heading3 – Mountings………………………………………………… 30

Heading3 – Crankshaft Balancer or Flywheel…………………………….. 30

Heading3 – Alternator……………………………………………….. 30

Heading3 – Sterndrive……………………………………………….. 30

Heading2 – Engine Overheats – Check:………………………………….. 30

Heading2 – Engine Dies Out…………………………………………… 30

Heading3 – Loss Of, Or Out Of, Fuel – Check:…………………………… 30

Heading3 – Loss Of Ignition – Check:………………………………….. 30

Heading3 – Engine Stops Or Dies Out Due To Seizure – Check:……………… 31

Heading2 – Engine Won’t Reach Operating RPM – Check:……………………. 31

Heading2 – Defective Engine Lubricating System…………………………. 31

Heading3 – Engine Components – Check:…………………………………. 31

Heading3 – Oil Pressure Warning System – Check:………………………… 31

Heading2 – Low Battery Voltage After Short Stor age…………………….. 32

Heading3 – Engine/Boat Components – Check:…………………………….. 32

Heading1 – General Engine Specifications………………………………….. 33

Heading2 – 4.3GL-A/B/C/D…………………………………………….. 33

Heading3 – Battery size……………………………………………… 33

Heading3 – Bore and stroke…………………………………………… 33

Heading3 – Carburetor (GL)…………………………………………… 33

Heading3 – Charging system…………………………………………… 33

Heading3 – Cooling system……………………………………………. 33

Heading3 – Cylinders (number)………………………………………… 33

Heading3 – Displacement……………………………………………… 33

Heading3 – Firing order……………………………………………… 33

Heading3 – Fuel filter………………………………………………. 33

Heading3 – Fuel type………………………………………………… 33

Heading3 – Full throttle operating range………………………………. 33

Heading3 – Idle RPM…………………………………………………. 33

Heading3 – Ignition timing…………………………………………… 33

Heading3 – Oil capacity……………………………………………… 33

Heading3 – Engine Oil filter…………………………………………. 33

Heading3 – Oil type…………………………………………………. 33

Heading3 – Power steering fluid………………………………………. 33

Heading3 – Spark plugs………………………………………………. 33

Heading3 – Spark plug gap……………………………………………. 33

Heading3 – Spark plug installation torque……………………………… 33

Heading2 – 4.3GXi-A/B/C/D/E………………………………………….. 34

Heading3 – Battery size……………………………………………… 34

Heading3 – Bore and stroke…………………………………………… 34

Heading3 – Charging system…………………………………………… 34

Heading3 – Cooling system……………………………………………. 34

Heading3 – Cooling System Capacity (F) Series………………………….. 34

Heading3 – Cylinders (number)………………………………………… 34

Heading3 – Displacement……………………………………………… 34

Heading3 – Firing order……………………………………………… 34

Heading3 – Fuel filter………………………………………………. 34

Heading3 – Fuel type………………………………………………… 34

Heading3 – Full throttle operating range………………………………. 34

Heading3 – Idle RPM…………………………………………………. 34

Heading3 – Ignition timing…………………………………………… 34

Heading3 – Oil capacity……………………………………………… 34

Heading3 – Engine Oil filter…………………………………………. 34

Heading3 – Oil type…………………………………………………. 34

Heading3 – Power steering fluid………………………………………. 34

Heading3 – Spark plugs………………………………………………. 34

Heading3 – Spark plug gap……………………………………………. 34

Heading3 – Spark plug installation torque……………………………… 34

ChapterTitle – Section 2: General Mechanical………………………………….. 35

Heading1 – General Description…………………………………………… 35

Heading1 – Cleanliness and Care………………………………………….. 36

Heading1 – Use of RTV Sealer and Anaerobic Gasket Eliminator………………… 36

Heading3 – Using RTV Sealer………………………………………….. 36

Heading3 – Using Anaerobic Gasket Eliminator…………………………… 37

Heading1 – Replacing Engine Gaskets………………………………………. 37

Heading1 – Cylinder Bores……………………………………………….. 38

Heading3 – Measuring Cylinder Bore Taper and Out-of-Round……………….. 38

Heading3 – ………………………………………………………… 38

Heading3 – ………………………………………………………… 38

Heading3 – Cylinder Bore Reconditioning……………………………….. 38

Heading3 – ………………………………………………………… 38

Heading3 – Removing Cylinder Bore Ridge……………………………….. 39

Heading3 – ………………………………………………………… 39

Heading3 – ………………………………………………………… 39

Heading3 – Boring…………………………………………………… 39

Heading3 – Honing…………………………………………………… 40

Heading3 – ………………………………………………………… 40

Heading1 – Piston and Connecting Rod……………………………………… 41

Heading3 – Disassemble:……………………………………………… 41

Heading3 – Piston Pin……………………………………………….. 41

Heading3 – Clean:…………………………………………………… 41

Heading3 – Inspect:…………………………………………………. 42

Heading1 – Measuring Piston Pin to Piston Clearance………………………… 42

Heading3 – Measure:…………………………………………………. 42

Heading3 – Piston pin diameter……………………………………….. 42

Heading3 – Piston pin to piston clearance……………………………… 42

Heading1 – Piston Selection……………………………………………… 43

Heading3 – Check the used piston to cylinder bore clearance……………… 43

Heading3 – Measure:…………………………………………………. 43

Heading1 – Assembling the Piston and Connecting Rod………………………… 43

Heading3 – Assemble:………………………………………………… 44

Heading1 – Installing the Piston Rings……………………………………. 44

Heading3 – Measure:…………………………………………………. 44

Heading3 – Inspect:…………………………………………………. 45

Heading3 – Assemble:………………………………………………… 45

Heading3 – Measure:…………………………………………………. 45

Heading1 – Camshaft Bearings…………………………………………….. 46

Heading2 – Camshaft Bearing Removal…………………………………… 46

Heading3 – Disassemble:……………………………………………… 46

Heading3 – Cleaning and Inspection……………………………………. 46

Heading3 – Clean:…………………………………………………… 46

Heading3 – Inspect:…………………………………………………. 46

Heading2 – Camshaft Measurements……………………………………… 46

Heading3 – Measure:…………………………………………………. 47

Heading3 – Assemble:………………………………………………… 47

Heading1 – Cylinder Head………………………………………………… 48

Heading3 – Disassemble………………………………………………. 48

Heading3 – Cleaning and Inspection……………………………………. 48

Heading3 – Clean……………………………………………………. 48

Heading3 – Inspect………………………………………………….. 49

Heading3 – Measure:…………………………………………………. 49

Heading3 – ………………………………………………………… 49

Heading3 – ………………………………………………………… 50

Heading3 – Repair…………………………………………………… 50

Heading2 – Valve Grinding……………………………………………. 50

Heading3 – Valve Seat Grinding……………………………………….. 50

Heading3 – Reaming Valve Guides………………………………………. 51

Heading3 – Assembly…………………………………………………. 51

Heading2 – Valves and components……………………………………… 51

Heading3 – Measure:…………………………………………………. 51

Heading1 – Crankshaft and Connecting Rod Bearings………………………….. 51

Heading3 – Cleaning and Inspection……………………………………. 51

Heading3 – Clean:…………………………………………………… 51

Heading3 – Inspect:…………………………………………………. 52

Heading3 – Measuring Bearing Clearance………………………………… 52

Heading3 – Micrometer Method…………………………………………. 52

Heading3 – Plastic Gauge Method………………………………………. 53

Heading3 – Crankshaft Runout…………………………………………. 53

Heading3 – Measure:…………………………………………………. 53

Heading3 – Connecting Rod Side Clearance………………………………. 54

Heading3 – Measure:…………………………………………………. 54

Heading3 – Crankshaft End Play……………………………………….. 54

Heading3 – Measure:…………………………………………………. 54

Heading3 – Inspect:…………………………………………………. 54

Heading1 – Thread Repair………………………………………………… 54

Heading1 – Special Tools………………………………………………… 56

ChapterTitle – Section 3: Engine – 4.3 Liter………………………………….. 59

Heading1 – General Description…………………………………………… 60

Heading3 – Engine Construction……………………………………….. 60

Heading3 – Cylinder Block……………………………………………. 60

Heading3 – Cylinder Heads……………………………………………. 61

Heading3 – Crankshaft……………………………………………….. 61

Heading3 – Camshaft…………………………………………………. 61

Heading3 – Pistons and Connecting Rods………………………………… 61

Heading3 – Balance Shaft…………………………………………….. 61

Heading3 – Valve Train………………………………………………. 61

Heading3 – Intake Manifold…………………………………………… 61

Heading1 – Tools and Shop Equipment………………………………………. 61

Heading1 – Accessories………………………………………………….. 62

Heading1 – Cleaning…………………………………………………….. 62

Heading1 – Draining The Engine…………………………………………… 62

Heading1 – Engine Lubrication……………………………………………. 63

Heading1 – Exhaust Manifold……………………………………………… 63

Heading3 – Removal………………………………………………….. 63

Heading3 – Inspection……………………………………………….. 64

Heading3 – Installation……………………………………………… 64

Heading3 – ………………………………………………………… 64

Heading3 – ………………………………………………………… 65

Heading3 – ………………………………………………………… 65

Heading3 – ………………………………………………………… 65

Heading1 – Starter……………………………………………………… 66

Heading3 – Remove…………………………………………………… 66

Heading3 – ………………………………………………………… 66

Heading3 – Installation……………………………………………… 66

Heading3 – ………………………………………………………… 67

Heading1 – Intake Manifold………………………………………………. 67

Heading3 – Removal………………………………………………….. 67

Heading3 – ………………………………………………………… 67

Heading3 – ………………………………………………………… 68

Heading3 – ………………………………………………………… 68

Heading3 – Disconnect:………………………………………………. 68

Heading3 – ………………………………………………………… 68

Heading3 – ………………………………………………………… 69

Heading3 – Remove:………………………………………………….. 69

Heading2 – Remove Distributor………………………………………… 69

Heading3 – ………………………………………………………… 69

Heading3 – ………………………………………………………… 70

Heading3 – ………………………………………………………… 70

Heading3 – ………………………………………………………… 70

Heading3 – ………………………………………………………… 70

Heading3 – ………………………………………………………… 71

Heading3 – ………………………………………………………… 71

Heading3 – Clean:…………………………………………………… 71

Heading2 – Disassemble Intake Manifold (GXi only)………………………. 72

Heading3 – ………………………………………………………… 72

Heading3 – ………………………………………………………… 72

Heading3 – ………………………………………………………… 72

Heading3 – ………………………………………………………… 73

Heading3 – ………………………………………………………… 73

Heading3 – ………………………………………………………… 73

Heading3 – ………………………………………………………… 73

Heading3 – ………………………………………………………… 74

Heading3 – ………………………………………………………… 74

Heading3 – Clean and Inspect…………………………………………. 74

Heading3 – ………………………………………………………… 74

Heading2 – Assemble Intake Manifold…………………………………… 74

Heading3 – ………………………………………………………… 75

Heading3 – ………………………………………………………… 75

Heading3 – ………………………………………………………… 75

Heading2 – Intake Manifold Installation……………………………….. 75

Heading3 – Install or Connect:……………………………………….. 75

Heading3 – ………………………………………………………… 76

Heading3 – ………………………………………………………… 76

Heading3 – ………………………………………………………… 76

Heading3 – ………………………………………………………… 77

Heading3 – Tighten:…………………………………………………. 77

Heading2 – Distributor Installation…………………………………… 77

Heading3 – ………………………………………………………… 78

Heading3 – ………………………………………………………… 78

Heading3 – ………………………………………………………… 78

Heading3 – ………………………………………………………… 79

Heading3 – ………………………………………………………… 79

Heading3 – ………………………………………………………… 80

Heading3 – ………………………………………………………… 80

Heading3 – ………………………………………………………… 81

Heading3 – ………………………………………………………… 81

Heading3 – ………………………………………………………… 82

Heading3 – Alternator with mounting bracket……………………………. 82

Heading3 – Connect:…………………………………………………. 82

Heading1 – Rocker Arm Cover……………………………………………… 83

Heading3 – Remove:………………………………………………….. 83

Heading3 – ………………………………………………………… 83

Heading3 – ………………………………………………………… 83

Heading3 – Clean:…………………………………………………… 83

Heading3 – Inspect:…………………………………………………. 83

Heading3 – Installation……………………………………………… 83

Heading3 – Tighten:…………………………………………………. 84

Heading1 – Valve Train………………………………………………….. 84

Heading3 – Removal………………………………………………….. 84

Heading3 – ………………………………………………………… 84

Heading3 – ………………………………………………………… 84

Heading3 – ………………………………………………………… 84

Heading3 – ………………………………………………………… 85

Heading3 – ………………………………………………………… 85

Heading3 – Clean:…………………………………………………… 85

Heading3 – Inspect:…………………………………………………. 86

Heading3 – ………………………………………………………… 86

Heading3 – ………………………………………………………… 86

Heading2 – Valve Lifters and Guides Clean and Inspect…………………… 87

Heading3 – ………………………………………………………… 87

Heading2 – Valve Lifters…………………………………………….. 87

Heading3 – Installation……………………………………………… 87

Heading2 – Valve Lifter Installation………………………………….. 88

Heading2 – Valve Lifter Pushrod Guides………………………………… 88

Heading2 – Valve Push Rod……………………………………………. 88

Heading2 – Valve Rocker Arm Support…………………………………… 88

Heading2 – Rocker Arm……………………………………………….. 89

Heading2 – Install Rocker Arm Assemblies………………………………. 89

Heading2 – Tighten Rocker Arm Assemblies………………………………. 89

Heading2 – Valve Rocker Arm Cover Installation…………………………. 90

Heading3 – Tighten………………………………………………….. 90

Heading1 – Cylinder Head………………………………………………… 90

Heading3 – Removal………………………………………………….. 90

Heading3 – ………………………………………………………… 91

Heading3 – ………………………………………………………… 91

Heading3 – ………………………………………………………… 91

Heading3 – ………………………………………………………… 91

Heading2 – Cylinder Head Disassemble and Recondition……………………. 92

Heading3 – Disassemble:……………………………………………… 92

Heading3 – ………………………………………………………… 92

Heading2 – Cylinder Head Clean and Inspect…………………………….. 93

Heading3 – Clean:…………………………………………………… 93

Heading3 – Inspect:…………………………………………………. 93

Heading3 – Valve Spring Tension………………………………………. 94

Heading2 – Valve Spring Straightness………………………………….. 94

Heading2 – Valve Stems………………………………………………. 94

Heading3 – ………………………………………………………… 95

Heading2 – Valve Guide Reaming and Seat Grind ing………………………. 95

Heading3 – Measuring:……………………………………………….. 95

Heading3 – ………………………………………………………… 95

Heading3 – Reaming:…………………………………………………. 96

Heading3 – Inspect………………………………………………….. 96

Heading3 – ………………………………………………………… 96

Heading2 – Cylinder Head Assemble…………………………………….. 97

Heading2 – Install Oil Seal………………………………………….. 98

Heading3 – Install Valve Spring………………………………………. 99

Heading3 – ………………………………………………………… 99

Heading3 – Installation……………………………………………… 99

Heading3 – …………………………………………………………100

Heading3 – …………………………………………………………100

Heading3 – …………………………………………………………100

Heading3 – …………………………………………………………100

Heading3 – Tighten:………………………………………………….101

Heading3 – …………………………………………………………101

Heading1 – Oil Pan and OIl Pump…………………………………………..101

Heading3 – Removal…………………………………………………..101

Heading3 – …………………………………………………………102

Heading3 – …………………………………………………………102

Heading3 – …………………………………………………………102

Heading2 – Oil Pan Clean and Inspect…………………………………..103

Heading3 – …………………………………………………………103

Heading3 – …………………………………………………………103

Heading3 – Oil Pump Removal…………………………………………..103

Heading3 – …………………………………………………………104

Heading3 – …………………………………………………………104

Heading2 – Oil Pump Disassemble……………………………………….104

Heading3 – …………………………………………………………105

Heading3 – …………………………………………………………105

Heading3 – …………………………………………………………106

Heading3 – …………………………………………………………106

Heading3 – …………………………………………………………106

Heading2 – Oil Pump Clean and Inspect………………………………….106

Heading3 – Oil Pump Assemble………………………………………….107

Heading3 – …………………………………………………………107

Heading3 – …………………………………………………………108

Heading3 – …………………………………………………………108

Heading3 – …………………………………………………………108

Heading3 – Oil Pump Installation………………………………………108

Heading3 – …………………………………………………………109

Heading3 – …………………………………………………………109

Heading3 – Oil Pan Installation……………………………………….109

Heading3 – …………………………………………………………109

Heading3 – …………………………………………………………110

Heading3 – …………………………………………………………110

Heading3 – …………………………………………………………110

Heading3 – …………………………………………………………111

Heading3 – …………………………………………………………111

Heading1 – Water Pump……………………………………………………111

Heading3 – GXi………………………………………………………111

Heading3 – Removal…………………………………………………..111

Heading3 – …………………………………………………………112

Heading3 – …………………………………………………………112

Heading3 – Inspection………………………………………………..112

Heading3 – Installation………………………………………………112

Heading3 – …………………………………………………………112

Heading3 – …………………………………………………………113

Heading3 – GL……………………………………………………….113

Heading3 – Remove……………………………………………………113

Heading3 – …………………………………………………………113

Heading3 – …………………………………………………………113

Heading3 – …………………………………………………………114

Heading3 – …………………………………………………………114

Heading3 – …………………………………………………………114

Heading3 – …………………………………………………………114

Heading2 – Water Pump Installation…………………………………….115

Heading3 – …………………………………………………………115

Heading3 – …………………………………………………………115

Heading3 – …………………………………………………………115

Heading3 – …………………………………………………………116

Heading1 – Crankshaft Balancer……………………………………………116

Heading3 – Removal…………………………………………………..116

Heading3 – …………………………………………………………116

Heading3 – …………………………………………………………116

Heading3 – …………………………………………………………117

Heading3 – …………………………………………………………117

Heading2 – Crankshaft Balancer Inspect…………………………………117

Heading2 – Crankshaft Balancer Installation…………………………….117

Heading3 – …………………………………………………………118

Heading3 – …………………………………………………………118

Heading3 – …………………………………………………………118

Heading3 – …………………………………………………………119

Heading3 – …………………………………………………………119

Heading3 – …………………………………………………………119

Heading1 – Engine Front Cover…………………………………………….119

Heading3 – Removal…………………………………………………..120

Heading3 – …………………………………………………………120

Heading3 – …………………………………………………………120

Heading2 – Engine Front Cover Installa tion…………………………….121

Heading3 – …………………………………………………………121

Heading3 – …………………………………………………………121

Heading1 – Timing Chain and Sprocket………………………………………121

Heading3 – Removal…………………………………………………..121

Heading3 – …………………………………………………………122

Heading3 – …………………………………………………………122

Heading3 – …………………………………………………………122

Heading3 – …………………………………………………………123

Heading3 – …………………………………………………………123

Heading3 – …………………………………………………………123

Heading3 – Inspection………………………………………………..124

Heading3 – …………………………………………………………124

Heading3 – …………………………………………………………124

Heading3 – Installation………………………………………………125

Heading3 – …………………………………………………………125

Heading3 – …………………………………………………………125

Heading3 – …………………………………………………………126

Heading3 – …………………………………………………………126

Heading3 – …………………………………………………………126

Heading1 – Balance Shaft…………………………………………………127

Heading3 – Removal…………………………………………………..127

Heading3 – …………………………………………………………127

Heading3 – …………………………………………………………127

Heading3 – …………………………………………………………128

Heading3 – Clean and Inspect………………………………………….128

Heading3 – …………………………………………………………129

Heading2 – Balance Shaft Bearing or Bushing…………………………….129

Heading3 – Removal…………………………………………………..129

Heading3 – Balance Shaft Bearing or Bushing Installation…………………130

Heading3 – Balance Shaft Installation………………………………….130

Heading3 – …………………………………………………………131

Heading3 – …………………………………………………………131

Heading3 – …………………………………………………………131

Heading3 – …………………………………………………………132

Heading3 – …………………………………………………………132

Heading3 – …………………………………………………………132

Heading3 – …………………………………………………………133

Heading1 – Camshaft……………………………………………………..133

Heading3 – Remove……………………………………………………133

Heading3 – …………………………………………………………133

Heading3 – …………………………………………………………133

Heading3 – Inspect…………………………………………………..133

Heading3 – …………………………………………………………134

Heading3 – …………………………………………………………134

Heading3 – …………………………………………………………135

Heading3 – Installation………………………………………………135

Heading1 – Camshaft Bearings……………………………………………..136

Heading3 – Remove……………………………………………………136

Heading3 – …………………………………………………………136

Heading3 – …………………………………………………………137

Heading3 – Installation………………………………………………137

Heading3 – …………………………………………………………138

Heading3 – …………………………………………………………138

Heading3 – …………………………………………………………139

Heading1 – Piston, Connecting Rod, and Bearings…………………………….139

Heading3 – …………………………………………………………140

Heading3 – …………………………………………………………140

Heading3 – …………………………………………………………140

Heading3 – …………………………………………………………141

Heading2 – Piston and Connecting Rod Disas semble……………………….141

Heading3 – …………………………………………………………141

Heading3 – …………………………………………………………142

Heading2 – Clean and Inspect………………………………………….142

Heading3 – …………………………………………………………142

Heading3 – …………………………………………………………143

Heading3 – …………………………………………………………143

Heading3 – …………………………………………………………143

Heading3 – …………………………………………………………144

Heading3 – …………………………………………………………144

Heading3 – …………………………………………………………144

Heading3 – …………………………………………………………145

Heading3 – …………………………………………………………145

Heading2 – Piston Selection…………………………………………..145

Heading3 – …………………………………………………………146

Heading3 – …………………………………………………………146

Heading3 – Piston and Connecting Rod Assemble…………………………..146

Heading3 – …………………………………………………………147

Heading3 – …………………………………………………………147

Heading3 – Installation………………………………………………148

Heading3 – …………………………………………………………148

Heading3 – …………………………………………………………148

Heading3 – …………………………………………………………149

Heading3 – …………………………………………………………149

Heading3 – …………………………………………………………149

Heading3 – …………………………………………………………150

Heading1 – Engine Coupler………………………………………………..150

Heading3 – Removal…………………………………………………..150

Heading3 – …………………………………………………………150

Heading3 – …………………………………………………………150

Heading3 – …………………………………………………………151

Heading3 – …………………………………………………………151

Heading3 – …………………………………………………………151

Heading3 – Inspection………………………………………………..151

Heading3 – Installation………………………………………………152

Heading3 – …………………………………………………………152

Heading3 – …………………………………………………………152

Heading3 – …………………………………………………………152

Heading3 – …………………………………………………………153

Heading1 – Flywheel……………………………………………………..153

Heading3 – Removal…………………………………………………..153

Heading3 – …………………………………………………………153

Heading3 – …………………………………………………………153

Heading3 – Inspection………………………………………………..154

Heading3 – Installation………………………………………………154

Heading1 – Crankshaft Rear Oil Seal and Housing…………………………….154

Heading3 – Remove……………………………………………………154

Heading3 – …………………………………………………………154

Heading3 – …………………………………………………………155

Heading3 – …………………………………………………………155

Heading3 – …………………………………………………………155

Heading3 – Installation………………………………………………156

Heading3 – …………………………………………………………156

Heading3 – …………………………………………………………156

Heading3 – …………………………………………………………157

Heading1 – Crankshaft……………………………………………………158

Heading3 – Remove……………………………………………………158

Heading3 – …………………………………………………………158

Heading3 – …………………………………………………………158

Heading3 – …………………………………………………………159

Heading3 – …………………………………………………………159

Heading2 – Crankshaft and Bearings Clean and Inspect…………………….159

Heading3 – …………………………………………………………160

Heading3 – …………………………………………………………160

Heading3 – …………………………………………………………160

Heading3 – …………………………………………………………161

Heading3 – …………………………………………………………161

Heading3 – …………………………………………………………161

Heading3 – …………………………………………………………162

Heading3 – …………………………………………………………162

Heading3 – …………………………………………………………162

Heading3 – …………………………………………………………163

Heading2 – Measuring Crankshaft Bearing Clear ances……………………..163

Heading2 – Micrometer Method for Crankshaft Bearings…………………….163

Heading3 – …………………………………………………………164

Heading3 – …………………………………………………………164

Heading3 – Measuring Crankshaft Bearing Clearances (Plastic Gauge Method)….164

Heading3 – …………………………………………………………164

Heading3 – …………………………………………………………165

Heading3 – …………………………………………………………165

Heading3 – …………………………………………………………165

Heading3 – …………………………………………………………166

Heading3 – Crankshaft and Bearings Installation…………………………166

Heading3 – …………………………………………………………166

Heading3 – …………………………………………………………167

Heading3 – …………………………………………………………167

Heading3 – …………………………………………………………167

Heading1 – Recondition Engine Block……………………………………….168

Heading2 – Engine Block Plug………………………………………….168

Heading3 – Removal…………………………………………………..168

Heading3 – …………………………………………………………168

Heading3 – …………………………………………………………169

Heading3 – …………………………………………………………169

Heading3 – …………………………………………………………169

Heading3 – …………………………………………………………170

Heading3 – …………………………………………………………170

Heading3 – …………………………………………………………170

Heading3 – …………………………………………………………171

Heading2 – Engine Block Clean and inspect………………………………171

Heading3 – …………………………………………………………172

Heading2 – Cylinder Boring and Honing………………………………….172

Heading3 – Honing Procedure…………………………………………..172

Heading2 – Boring Procedure…………………………………………..173

Heading1 – Remove and Install Engine………………………………………174

Heading1 – Engine Specifications………………………………………….174

ChapterTitle – Section 4: Steering System……………………………………..181

Heading2 – Special Tools…………………………………………………181

Heading3 – Kent-Moore Special Tools……………………………………….181

Heading3 – Sealants, Lubricants and Adhesives………………………………182

Heading1 – Power Steering System………………………………………….182

Heading2 – Description……………………………………………….182

Heading3 – …………………………………………………………183

Heading1 – Pump Operation………………………………………………..183

Heading3 – …………………………………………………………183

Heading1 – System Operation………………………………………………184

Heading3 – No Steering Input – Steering Wheel Not Turning………………..184

Heading3 – Steering To Port – Steering Wheel Turning To Left……………..184

Heading3 – Steering To Starboard – Steering Wheel Turning To Right………..185

Heading3 – Steering Without Power Assist……………………………….185

Heading1 – Pump Removal………………………………………………….185

Heading3 – …………………………………………………………185

Heading3 – Serpentine Belt Models Only…………………………………186

Heading3 – …………………………………………………………186

Heading3 – …………………………………………………………186

Heading3 – …………………………………………………………186

Heading3 – V-Belt Models Only…………………………………………187

Heading3 – …………………………………………………………187

Heading3 – …………………………………………………………187

Heading1 – Pump Installation……………………………………………..187

Heading3 – …………………………………………………………187

Heading3 – …………………………………………………………188

Heading3 – Serpentine Belt Models Only…………………………………188

Heading3 – …………………………………………………………188

Heading3 – V-Belt Models Only…………………………………………188

Heading1 – Hydraulic Fluid……………………………………………….188

Heading2 – Checking Fluid Level……………………………………….188

Heading1 – Purging Air From Steering System………………………………..189

Heading1 – Power Steering Pump Belt Adjustment……………………………..189

Heading3 – Serpentine Belt Models……………………………………..189

Heading3 – V- Belt Models…………………………………………….190

Heading3 – …………………………………………………………190

Heading3 – …………………………………………………………190

Heading1 – Steering Cylinder……………………………………………..190

Heading3 – …………………………………………………………190

Heading1 – Cylinder Removal………………………………………………191

Heading3 – …………………………………………………………191

Heading3 – …………………………………………………………191

Heading3 – …………………………………………………………191

Heading3 – …………………………………………………………191

Heading3 – …………………………………………………………191

Heading3 – …………………………………………………………192

Heading1 – Cylinder Servicing…………………………………………….192

Heading3 – …………………………………………………………192

Heading3 – …………………………………………………………192

Heading1 – Cylinder Installation………………………………………….193

Heading3 – …………………………………………………………193

Heading3 – …………………………………………………………193

Heading3 – …………………………………………………………193

Heading3 – …………………………………………………………193

Heading3 – …………………………………………………………194

Heading1 – Cable Installation…………………………………………….194

Heading3 – …………………………………………………………194

Heading3 – …………………………………………………………194

Heading3 – …………………………………………………………194

Heading3 – …………………………………………………………195

Heading3 – …………………………………………………………195

Heading3 – …………………………………………………………195

Heading1 – Lubrication…………………………………………………..195

Heading3 – …………………………………………………………195

Heading1 – Hoses………………………………………………………..196

Heading1 – System Diagnosis………………………………………………196

Heading2 – System Checks……………………………………………..196

Heading1 – Tie Bar Adjustment – Twin Engine Installation…………………….196

Heading3 – …………………………………………………………196

Heading3 – …………………………………………………………197

Heading2 – Power Steering System Diagnosis Chart………………………..197

Heading1 – External Leakage………………………………………………198

Heading2 – General Procedure………………………………………….198

Heading2 – Leakage Checks…………………………………………….198

Heading2 – Easily Fixed Leaks…………………………………………198

Heading1 – Pump Leakage………………………………………………….199

Heading3 – …………………………………………………………199

Heading2 – Pump Pressure Test…………………………………………199

Heading3 – …………………………………………………………199

Heading1 – Cable Installation Problems…………………………………….200

Heading3 – …………………………………………………………200

Heading3 – …………………………………………………………200

Heading3 – …………………………………………………………200

Heading3 – …………………………………………………………201

Heading1 – Feedback To The Helm…………………………………………..201

ChapterTitle – Section 5: Throttle & Shift Control System……………………….203

Heading1 – Installation of Shift and Throttle Cables………………………..203

Heading3 – …………………………………………………………203

Heading2 – Check Remote Control Shift Cable Stroke………………………204

Heading3 – …………………………………………………………204

Heading3 – …………………………………………………………204

Heading3 – …………………………………………………………204

Heading3 – …………………………………………………………204

Heading2 – Installation of SAE Cables to Engine/ Drive…………………..204

Heading3 – Shift Cable to Sterndrive…………………………………..205

Heading3 – …………………………………………………………205

Heading3 – …………………………………………………………205

Heading3 – …………………………………………………………205

Heading3 – …………………………………………………………205

Heading3 – …………………………………………………………206

Heading3 – …………………………………………………………206

Heading3 – …………………………………………………………206

Heading3 – …………………………………………………………206

Heading3 – …………………………………………………………207

Heading3 – …………………………………………………………207

Heading2 – Throttle Cable to Engine……………………………………207

Heading3 – …………………………………………………………207

Heading3 – …………………………………………………………208

Heading3 – …………………………………………………………208

Heading3 – …………………………………………………………208

Heading3 – …………………………………………………………208

Heading3 – …………………………………………………………208

Heading1 – Neutral Start Switch Tests……………………………………..209

Heading2 – Electrical………………………………………………..209

Heading2 – Mechanical………………………………………………..209

Heading1 – Removal of SAE Remote Control Cables…………………………….209

Heading2 – Throttle Cable From Engine………………………………….210

Heading3 – …………………………………………………………210

Heading2 – Shift Cable From Sterndrive…………………………………210

Heading3 – …………………………………………………………210

Heading3 – …………………………………………………………210

Heading3 – …………………………………………………………210

Heading3 – …………………………………………………………210

ChapterTitle – Section 6: Cooling System………………………………………211

Heading1 – Description…………………………………………………..211

Heading2 – Raw Water Cooled Engines……………………………………211

Heading3 – …………………………………………………………212

Heading2 – Closed Cooling Engines……………………………………..213

Heading1 – Cooling System Troubleshooting………………………………….214

Heading3 – Quiz Customer for the Following Information:………………….214

Heading3 – Possibilities To Consider:………………………………….214

Heading2 – Isolating Cooling Problem:………………………………….215

Heading3 – Air or exhaust gas entering cooling water:……………………215

Heading3 – Insufficient water supply:………………………………….215

Heading3 – Thermostat malfunction……………………………………..215

Heading3 – Engine head gasket leakage………………………………….215

Heading1 – Cooling System Components………………………………………216

Heading2 – Hoses, Clamps, and Drain Plugs………………………………216

Heading2 – Thermostat………………………………………………..216

Heading3 – …………………………………………………………216

Heading2 – Manifolds and Elbows……………………………………….216

Heading2 – Circulating Pump – Engine…………………………………..216

Heading2 – Supply Pump……………………………………………….217

Heading3 – …………………………………………………………217

Heading3 – …………………………………………………………217

Heading2 – Impeller Removal…………………………………………..217

Heading3 – …………………………………………………………218

Heading3 – …………………………………………………………218

Heading3 – …………………………………………………………218

Heading3 – Cleaning and Inspection…………………………………….218

Heading2 – Impeller Installation………………………………………219

Heading3 – …………………………………………………………219

Heading3 – …………………………………………………………219

Heading3 – …………………………………………………………219

Heading1 – Draining Engine Block or Exhaust Manifold………………………..220

Heading2 – 4.3GXi-A/B………………………………………………..220

Heading3 – …………………………………………………………220

Heading2 – 4.3GXi, 4.3OSi F-series (closed cooling)……………………..221

Heading2 – 4.3GXi-C/D………………………………………………..221

Heading2 – 4.3GXi-A, and 4.3GL Draining Only……………………………222

Heading3 – …………………………………………………………222

Heading2 – Draining Supply Pump……………………………………….222

Heading3 – …………………………………………………………222

Heading2 – Thermostat Replacement……………………………………..223

Heading3 – …………………………………………………………223

Heading3 – …………………………………………………………223

Heading3 – …………………………………………………………223

Heading3 – Numbers refer to Cooling System Flow Diagrams…………………224

Heading1 – Sterndrive and Transom Bracket Cooling Schematic………………….225

Heading1 – 4.3GL-A/B/C/D Engine Cooling Diagram…………………………….226

Heading1 – 4.3GXi-A Engine Cooling Diagram…………………………………227

Heading1 – 4.3GXi-B/C/D/E Cooling Diagram………………………………….228

Heading1 – 4.3GXi-BF/CF/DF/EF Engine Cooling Diagram………………………..229

ChapterTitle – Section 7: Engine Removal and Installation……………………….231

Heading2 – Special Tools…………………………………………………231

Heading2 – Sealants, Lubricants and Adhesives………………………………231

Heading1 – Engine Removal………………………………………………..231

Heading3 – Disconnect Battery…………………………………………232

Heading3 – Disconnect Power Steering Lines……………………………..232

Heading3 – …………………………………………………………232

Heading3 – Disconnect Fuel Supply……………………………………..232

Heading3 – …………………………………………………………232

Heading3 – Disconnect Electrical Cables………………………………..233

Heading3 – …………………………………………………………233

Heading3 – …………………………………………………………233

Heading3 – …………………………………………………………233

Heading3 – Disconnect Throttle Cable…………………………………..234

Heading3 – …………………………………………………………234

Heading3 – Disconnect Exhaust Hose…………………………………….234

Heading3 – …………………………………………………………234

Heading3 – Disconnect Water Hose………………………………………234

Heading3 – …………………………………………………………234

Heading3 – Separate Engine Mounts……………………………………..235

Heading3 – …………………………………………………………235

Heading3 – …………………………………………………………235

Heading3 – …………………………………………………………235

Heading2 – Exhaust Pipe Replacement……………………………………235

Heading3 – Removal…………………………………………………..235

Heading3 – …………………………………………………………236

Heading3 – Installation………………………………………………236

Heading3 – …………………………………………………………236

Heading3 – …………………………………………………………236

Heading2 – Engine Installation………………………………………..236

Heading3 – Attach Engine Mount………………………………………..236

Heading3 – …………………………………………………………237

Heading3 – …………………………………………………………237

Heading2 – Engine Alignment…………………………………………..237

Heading3 – …………………………………………………………237

Heading3 – …………………………………………………………238

Heading2 – Connect Exhaust Hose……………………………………….238

Heading3 – …………………………………………………………238

Heading3 – …………………………………………………………238

Heading2 – Connect Throttle Cable……………………………………..238

Heading3 – …………………………………………………………238

Heading3 – Carbureted Models Only……………………………………..239

Heading3 – …………………………………………………………239

Heading3 – …………………………………………………………239

Heading3 – …………………………………………………………239

Heading3 – …………………………………………………………239

Heading3 – Connect Water Hose…………………………………………240

Heading3 – …………………………………………………………240

Heading3 – …………………………………………………………240

Heading3 – Connect Power Steering Lines………………………………..240

Heading3 – …………………………………………………………240

Heading3 – …………………………………………………………241

Heading3 – …………………………………………………………241

Heading3 – …………………………………………………………241

Heading3 – …………………………………………………………241

Heading3 – Connect Electrical Cables…………………………………..242

Heading3 – …………………………………………………………242

Heading3 – …………………………………………………………242

Heading3 – …………………………………………………………243

Heading2 – Connect Fuel Supply………………………………………..243

Heading3 – …………………………………………………………243

Heading1 – Rear Engine Mounts…………………………………………….243

Heading3 – Removal…………………………………………………..243

Heading3 – …………………………………………………………244

Heading3 – Disassembly……………………………………………….244

Heading3 – …………………………………………………………244

Heading3 – Assembly………………………………………………….244

Heading3 – …………………………………………………………244

Heading3 – Installation………………………………………………245

Heading3 – …………………………………………………………245

Heading3 – …………………………………………………………245

Heading1 – Determining Minimum Engine Height……………………………….246

Heading3 – …………………………………………………………246

IMAGES PREVIEW OF THE MANUAL: