$34

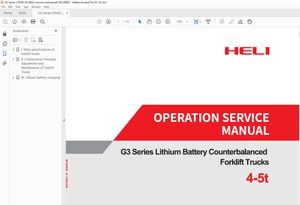

Volvo Penta 4.3GXi-F(F)- 8.1OSi-C(F) EGC Diagnostics Workshop Manual_139179015 – PDF DOWNLOAD

Volvo Penta 4.3GXi-F(F), 4.3OSi-F(F) 5.0GXi-F(F), 5.0OSi-F(F) 5.7Gi-F(F), 5.7GXi-G(F) 5.7OSi-E(F), 5.7OSXi-E(F) 8.1Gi-G(F), 8.1GXi-F(F), 8.1OSi-C(F) Diagnostics Workshop Manual_139179015 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta 4.3GXi-F(F), 4.3OSi-F(F) 5.0GXi-F(F), 5.0OSi-F(F) 5.7Gi-F(F), 5.7GXi-G(F) 5.7OSi-E(F), 5.7OSXi-E(F) 8.1Gi-G(F), 8.1GXi-F(F), 8.1OSi-C(F) Diagnostics Workshop Manual_139179015 – PDF DOWNLOAD

Language : English

Pages : 316

Downloadable : Yes

File Type : PDF

Size: 4.59 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta 4.3GXi-F(F), 4.3OSi-F(F) 5.0GXi-F(F), 5.0OSi-F(F) 5.7Gi-F(F), 5.7GXi-G(F) 5.7OSi-E(F), 5.7OSXi-E(F) 8.1Gi-G(F), 8.1GXi-F(F), 8.1OSi-C(F) Diagnostics Workshop Manual_139179015 – PDF DOWNLOAD

Good Service Practice Service required for the engine and sterndrive is generally one of three

kinds:

• Normal care and maintenance – which includes putting a new

engine and stern drive into operation, storing, lubrication, and

care under special operating conditions such as salt water and

cold weather.

• Operating malfunctions – due to improper engine or drive

mounting, propeller condition or size, boat condition, or the malfunction

of some part of the engine. This includes engine servicing

procedures to keep the engine in prime operating condition.

• Complete disassembly and overhaul – such as major service

or rebuilding a unit.

It is important to determine before disassembly just what the trouble is

and how to correct it quickly, with minimum expense to the owner.

When repairing an assembly, the most reliable way to ensure a good

job is to do a complete overhaul on that assembly, rather than just to

replace the bad part. Wear not readily apparent on other parts could

cause malfunction soon after the repair job. Repair kits and seal kits

contain all the parts needed to ensure a complete repair, to eliminate

guesswork, and to save time.

Repair time can also be minimized by the use of special tools. Volvo

Penta special tools are designed to perform service procedures

unique to the product that cannot be completed using tools from other

sources. They also speed repair work to help achieve service flat rate

times. In some cases, the use of substitute tools can damage the part.

Preparation for Service Proper preparation is extremely helpful for efficient service work. A

clean work area at the start of each job will minimize tools and parts

becoming misplaced. Clean an engine that is excessively dirty before

work starts. Cleaning will occasionally uncover trouble sources. Obtain

tools, instruments and parts needed for the job before work is started.

Interrupting a job to locate special tools or repair kits is a needless

delay.

Caution

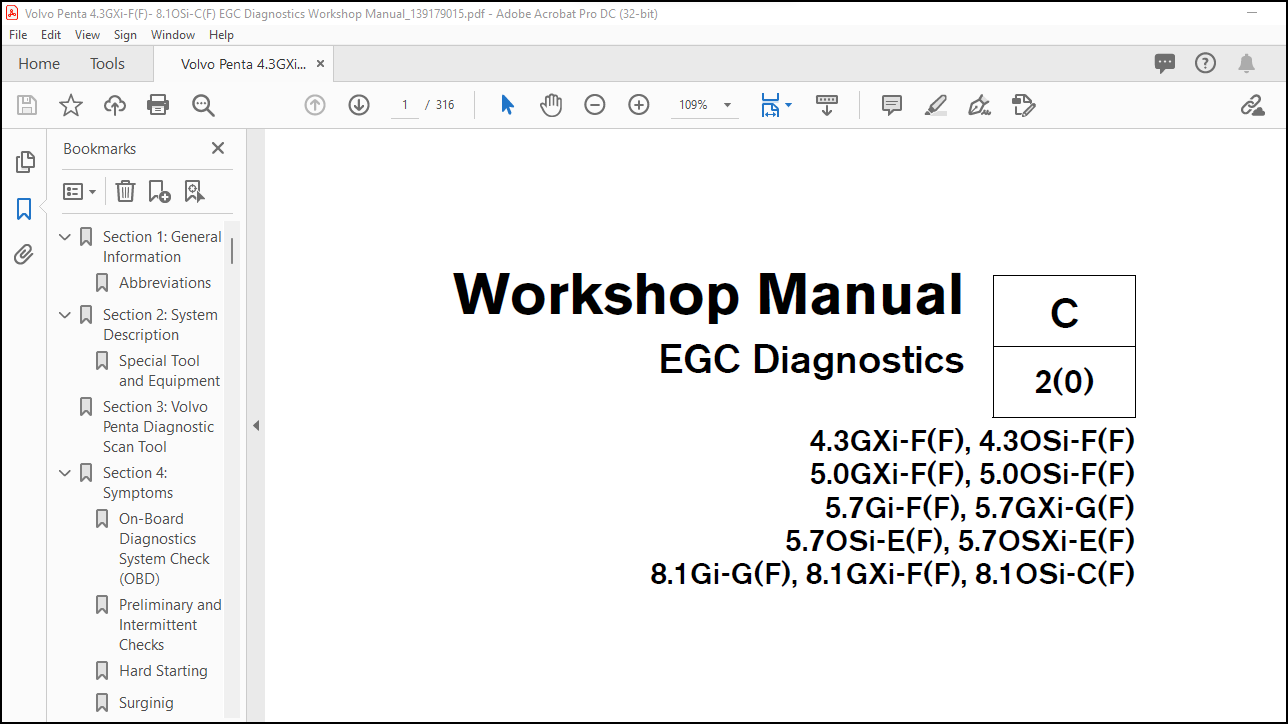

TABLE OF CONTENTS:

Volvo Penta 4.3GXi-F(F), 4.3OSi-F(F) 5.0GXi-F(F), 5.0OSi-F(F) 5.7Gi-F(F), 5.7GXi-G(F) 5.7OSi-E(F), 5.7OSXi-E(F) 8.1Gi-G(F), 8.1GXi-F(F), 8.1OSi-C(F) Diagnostics Workshop Manual_139179015 – PDF DOWNLOAD

Section 1: General Information……………………………… 5

Abbreviations…………………………………………. 31

Section 2: System Description………………………………. 33

Special Tool and Equipment……………………………… 37

Section 3: Volvo Penta Diagnostic Scan Tool………………….. 39

Section 4: Symptoms……………………………………….. 49

On-Board Diagnostics System Check (OBD)………………….. 50

Preliminary and Intermittent Checks……………………… 52

Hard Starting…………………………………………. 54

Surginig……………………………………………… 56

Hesitation, Sag or Stumble……………………………… 57

Detonation/Spark Knock…………………………………. 58

Lack of Power, Sluggish or Spongy……………………….. 59

Cuts Out, Misses………………………………………. 61

Rough, Unstable, or Incorrect Idle; Stalling……………… 63

Backfire……………………………………………… 65

Dieseling, Run-On……………………………………… 67

Poor Fuel Economy……………………………………… 68

ECM Connector Identification……………………………. 70

Section 5: Diagnostics…………………………………….. 80

DTC 0016 – Never Crank Synced At Start…………………… 83

DTC 0107 – MAP Low Voltage……………………………… 85

DTC 0108 – MAP High Pressure……………………………. 87

DTC 0111 – IAT Higher Than Expected 1……………………. 89

DTC 0112 – IAT Low Voltage……………………………… 91

DTC 0113 – IAT High Voltage…………………………….. 93

DTC 0116 – ECT Higher Than Expected 1……………………. 95

DTC 0117 – ECT Low Voltage……………………………… 97

DTC 0118 – ECT High Voltage…………………………….. 99

DTC 0121 – TPS 1 Lower Than TPS 2………………………..101

DTC 0122 – TPS 1 Signal Voltage Low (ETC)…………………103

DTC 0122 – TPS Signal Voltage Low (IAC)…………………..105

DTC 0123 – TPS 1 Signal Voltage High (ETC)………………..107

DTC 0123 – TPS Signal Voltage High (IAC)………………….109

DTC 0127 – IAT Higher Than Expected 2…………………….111

DTC 0129 – BP Low Pressure………………………………113

DTC 0217 – ECT Higher Than Expected 2…………………….115

DTC 0219 – Maximum Governor Speed Override………………..117

DTC 0221 – TPS 1 Higher Than TPS 2……………………….119

DTC 0222 – TPS 2 Low Voltage…………………………….121

DTC 0223 – TPS 2 High Voltage……………………………123

DTC 0261 – Injector Driver 1 Open………………………..125

DTC 0264 – Injector Driver 2 Open………………………..127

DTC 0265 – Injector Driver 2 Shorted……………………..129

DTC 0267 – Injector Driver 3 Open………………………..131

DTC 0268 – Injector Driver 3 Shorted……………………..133

DTC 0270 – Injector Driver 4 Open………………………..135

DTC 0271 – Injector Driver 4 Shorted……………………..137

DTC 0273 – Injector Driver 5 Open………………………..139

DTC 0274 – Injector Driver 5 Shorted……………………..141

DTC 0276 – Injector Driver 6 Open………………………..143

DTC 0277 – Injector Driver 6 Shorted……………………..145

DTC 0279 – Injector Driver 7 Open………………………..147

DTC 0280 – Injector Driver 7 Shorted……………………..149

DTC 0282 – Injector Driver 8 Open………………………..151

DTC 0283 – Injector Driver 8 Shorted……………………..153

DTC 0326 – Knock 1 Excessive Signal………………………155

DTC 0327 – Knock Sensor 1 Open…………………………..157

DTC 0331 – Knock 2 Excessive Signal………………………159

DTC 0332 – Knock Sensor 2 Open…………………………..161

DTC 0336 – Crank Sync Noise……………………………..163

DTC 0337 – Crankshaft Sensor Loss………………………..165

DTC 0341 – Camshaft Sensor Noise…………………………167

DTC 0342 – Camshaft Sensor Loss………………………….169

DTC 0508 – IAC Ground Short……………………………..171

DTC 0509 – IAC Coil Open/Short…………………………..173

DTC 0522 – Oil Pressure Sender Low Voltage………………..175

DTC 0523 – Oil Pressure Sender High Voltage……………….177

DTC 0524 – Low Oil Pressure……………………………..179

DTC 0562 – System Voltage Low……………………………181

DTC 0563 – System Voltage High…………………………..183

DTC 0601 – Flash Checksum Invalid………………………..185

DTC 0604 – RAM Failure………………………………….187

DTC 0606 – COP Failure………………………………….189

DTC 0627 – Fuel Pump Relay Coil Open……………………..191

DTC 0628 – Fuel Pump Relay Control Ground Short……………193

DTC 0629 – Fuel Pump Relay Coil Short to Power…………….195

DTC 0642 – V REF #1 Voltage Low (ETC)…………………….197

DTC 0642 – V REF Voltage Low (IAC)……………………….199

DTC 0642 – V REF Voltage Low (IAC)……………………….201

DTC 0643 – V REF #1 Voltage High (ETC)……………………203

DTC 0643 – V REF Voltage High (IAC)………………………205

DTC 0652 – V REF #2 Voltage Low………………………….207

DTC 0653 – V REF #2 Voltage High…………………………209

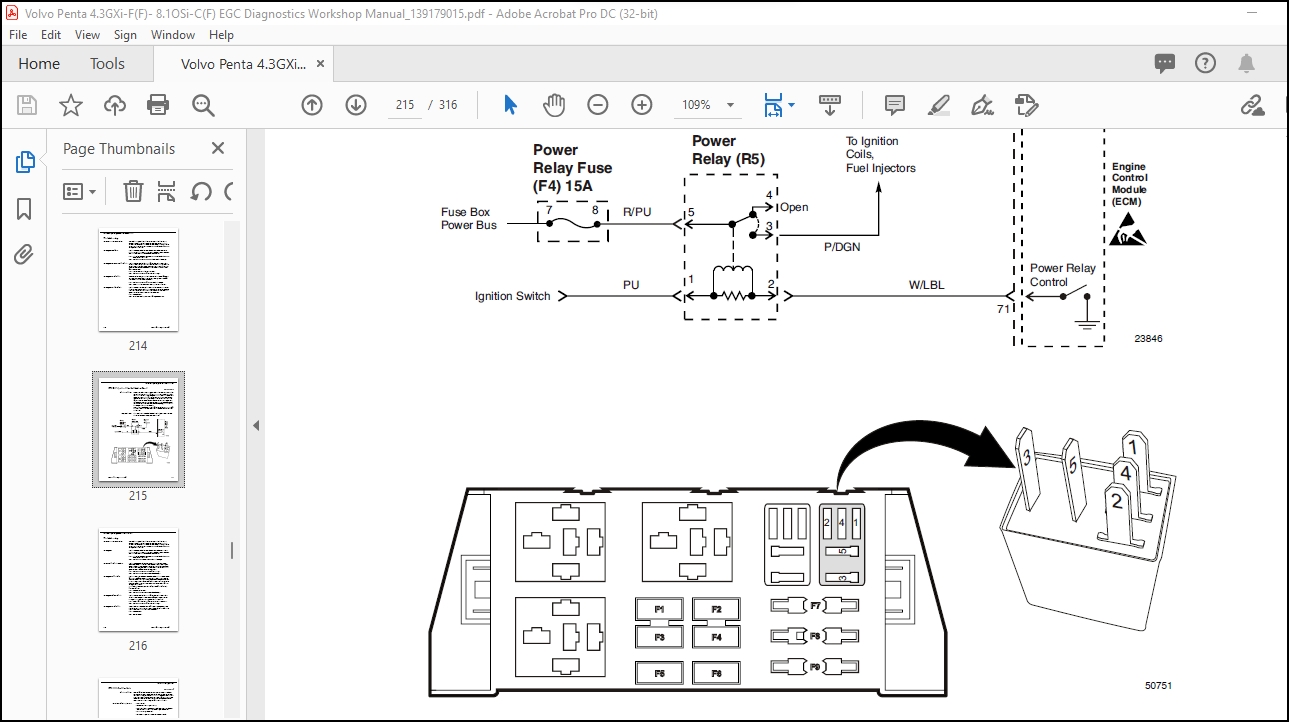

DTC 0685 – Ignition Relay Coil Open………………………211

DTC 0686 – Ignition Relay Control Ground Short…………….213

DTC 0687 – Ignition Relay Coil Short to Power……………..215

DTC 1111 – Fuel Rev Limit……………………………….217

DTC 1112 – Spark Rev Limit………………………………219

DTC 1121 – TCP 1/2 Simultaneous Voltages Out-of-Range………221

DTC 1122 – TCP 1 and TCP 2 Do Not Match or IVS…………….223

DTC 1511 – Trim Sender Voltage High (2-Wire)………………225

DTC 1511 – Trim Sender Voltage High (3-Wire)………………227

DTC 1611 – 5V 1/2 Simultaneous Out-of-Range……………….229

DTC 1612 – RTI 1 Loss…………………………………..231

DTC 1613 – RTI 2 Loss…………………………………..233

DTC 1614 – RTI 3 Loss…………………………………..235

DTC 1615 – A/D Loss…………………………………….237

DTC 1616 – Invalid Interrupt…………………………….239

DTC 1628 – CAN Address Conflict Failure…………………..241

DTC 1631 – Water Temperature Gauge Open/Short to Ground…….243

DTC 1631 – Water Temperature Gauge Open/Short to Ground…….245

DTC 1632 – Water Temperature Gauge Short to Power………….247

DTC 1633 – Oil Pressure Gauge Open / Short to Ground……….249

DTC 1634 – Oil Pressure Gauge Short to Power………………251

DTC 1635 – Trim Position Gauge Open / Short to Ground………253

DTC 1636 – Trim Position Gauge Short to Power……………..255

DTC 1641 – Buzzer Control Ground Short……………………257

DTC 1642 – Buzzer Open………………………………….259

DTC 1643 – Buzzer Control Short to Power………………….261

DTC 2111 – Throttle Unable To Close………………………263

DTC 2112 – Throttle Unable To Open……………………….265

DTC 2115 – TCP 1 Higher Than IVS limit……………………267

DTC 2116 – TCP 2 Higher Than IVS Limit……………………269

DTC 2120 – TCP 1 Invalid Voltage, TCP 2 Disagrees with IVS….271

DTC 2121 – TCP 1 Lower Than TCP 2………………………..273

DTC 2122 – TCP 1 High Voltage……………………………275

DTC 2123 – TCP 1 Low Voltage…………………………….277

DTC 2125 – TCP 2 Invalid Voltage, TCP 1 Disagrees with IVS….280

DTC 2126 – TCP 1 Higher Than TCP 2……………………….282

DTC 2127 – TCP 2 Low Voltage…………………………….284

DTC 2128 – TCP 2 High Voltage……………………………287

DTC 2130 – IVS Stuck At-Idle TCP 1/2 Match………………..289

DTC 2131 – IVS Stuck Off-Idle……………………………291

DTC 2135 – TPS 1/2 Simultaneous Voltages Out-of-Range………293

DTC 2139 – TCP 1 Lower Than IVS limit…………………….295

DTC 2140 – TCP 2 Lower Than IVS Limit…………………….297

DTC 2229 – BP High Pressure……………………………..299

DTC 2428 – EGT Temperature High………………………….301

DTC 2618 – Tachometer Output Ground Short…………………303

DTC 2619 – Tachometer Output Short to Power……………….305

Section 6: ECM Limits………………………………………309

Vodia Index by Number………………………………………314