$33

Volvo Penta 5.0GL, 5.7Gi, 5.05.7 GXi, 5.05.7 OSi, 5.7 OSXi Engine Workshop Manual_269597098 PDF

Volvo Penta 5.0GL, 5.7Gi, 5.0-5.7 GXi, 5.0 5.7 OSi, 5.7 OSXi Engine Workshop Manual_269597098 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta 5.0GL, 5.7Gi, 5.0-5.7 GXi, 5.0 5.7 OSi, 5.7 OSXi Engine Workshop Manual_269597098 – PDF DOWNLOAD

Language : English

Pages : 176

Downloadable : Yes

File Type : PDF

Size: 6.35 MB

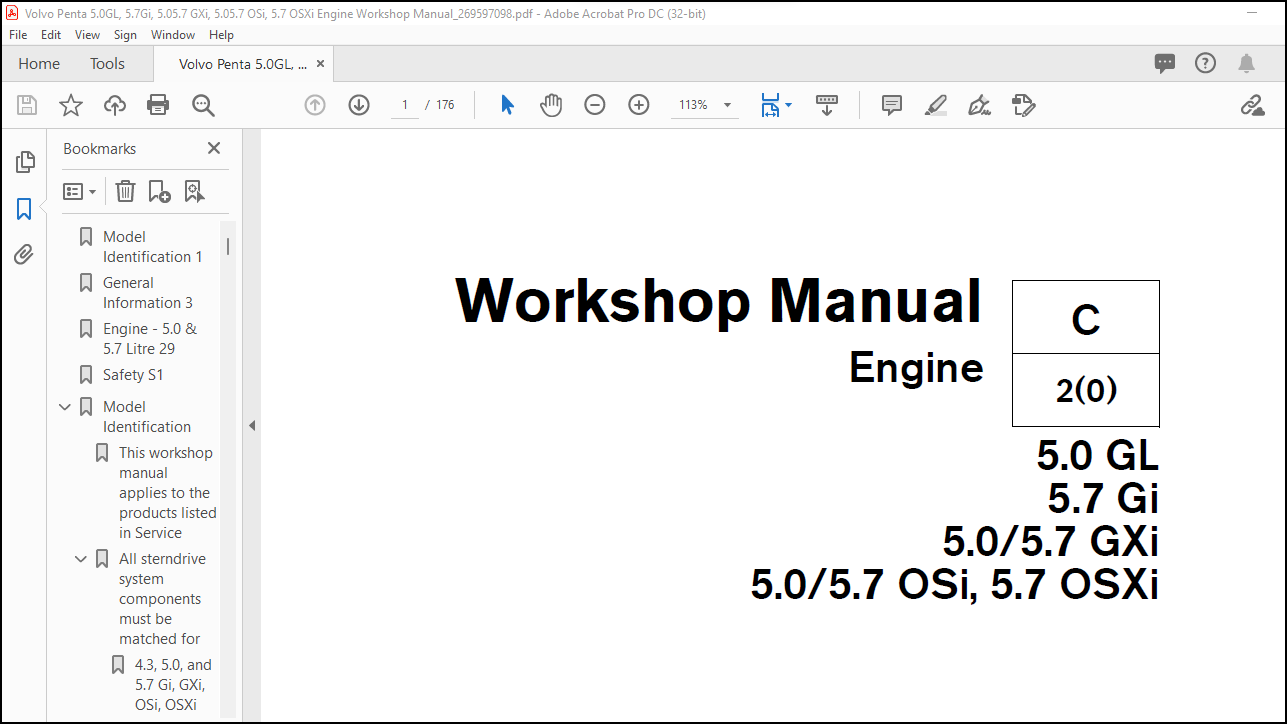

IMAGES PREVIEW OF THE MANUAL:

Volvo Penta 5.0GL, 5.7Gi, 5.05.7 GXi, 5.05.7 OSi, 5.7 OSXi Engine Workshop Manual_269597098

DESCRIPTION:

Volvo Penta 5.0GL, 5.7Gi, 5.0-5.7 GXi, 5.0 5.7 OSi, 5.7 OSXi Engine Workshop Manual_269597098 – PDF DOWNLOAD

Good Service Practice:

Service required for stern drives is generally one of three kinds:

• Normal care and maintenance – which includes putting a

new stern drive into operation, storing engines, lubrication,

and care under special operating conditions such as salt

water and cold weather.

• Operating malfunctions – due to improper engine or drive

mounting, propeller condition or size, boat condition, or the

malfunction of some part of the engine. This includes engine

servicing procedures to keep the engine in prime operating

condition.

• Complete disassembly and overhaul – such as major service

or rebuilding a unit.

It is important to determine before disassembly just what the trouble

is and how to correct it quickly, with minimum expense to the owner.

When repairing an assembly, the most reliable way to ensure a good

job is to do a complete overhaul on that assembly, rather than just to

replace the bad part. Wear not readily apparent on other parts could

cause malfunction soon after the repair job. Repair kits and seal kits

General Information

4 VPA 7748089 English 09-2007

contain all the parts needed to ensure a complete repair, to eliminate

guesswork, and to save time.

Repair time can also be minimized by the use of special tools. Volvo

Penta special tools are designed to perform service procedures

unique to the product that cannot be completed using tools from other

sources. They also speed repair work to help achieve service flat

rate times. In some cases, the use of substitute tools can damage

the part.

TABLE OF CONTENTS:

Volvo Penta 5.0GL, 5.7Gi, 5.0-5.7 GXi, 5.0 5.7 OSi, 5.7 OSXi Engine Workshop Manual_269597098 – PDF DOWNLOAD

Model Identification 1……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 3

General Information 3………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 3

Engine – 5.0 & 5.7 Litre 29…………………………………………………………………………………………………………………………………………………………………………………………………………………………… 3

Safety S1…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 3

Model Identification…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 5

This workshop manual applies to the products listed in Service Bulletin 04-2-67 version 1 dated 08-2007. The unit that you are s……………………………………………………………………………………………………………………………… 5

All sterndrive system components must be matched for either single or dual engine installations. Failure to properly match engin……………………………………………………………………………………………………………………………… 5

4.3, 5.0, and 5.7 Gi, GXi, OSi, OSXi models……………………………………………………………………………………………………………………………………………………………………………………………………… 5

8.1 Gi, GXi, OSi models……………………………………………………………………………………………………………………………………………………………………………………………………………………….. 5

All GL models………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 5

General Information………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 7

Good Service Practice…………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 7

Preparation for Service…………………………………………………………………………………………………………………………………………………………………………………………………………………………… 8

Service Policy…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 8

Replacement Parts………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 8

Parts Catalogs…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 8

Special Service Tools…………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 9

Product References, Illustrations & Specifications…………………………………………………………………………………………………………………………………………………………………………………………………… 9

Tuning the Engine………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 9

Engine Compression Testing…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 9

1. Visually inspect stern drive unit for leaks, missing parts or other obvious defects. Replace deteriorated parts…………………………………………………………………………………………………………………………………… 10

2. Compression check: Proper compression is essential for good engine performance. An engine with low or uneven compression cannot be properly tuned…………………………………………………………………………………………………….. 10

To Prevent Sparking…………………………………………………………………………………………………………………………………………………………………………………………………………………………… 10

Test Conclusion………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 10

1. If compression improves considerably, the piston rings are at fault………………………………………………………………………………………………………………………………………………………………………….. 10

2. If compression does not improve, valves are sticking or seating poorly, or valve guides are worn………………………………………………………………………………………………………………………………………………… 10

3. If two adjacent cylinders indicate low compression pressures and squirting oil on the pistons does not increase the compressi………………………………………………………………………………………………………………………. 10

Compression Pressure Limit in PSI………………………………………………………………………………………………………………………………………………………………………………………………………………. 11

Ignition System Components…………………………………………………………………………………………………………………………………………………………………………………………………………………. 11

Fuel System Components…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 11

Intake Manifold Vacuum Testing…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 12

Test Procedures………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 12

1. Install a vacuum gauge to a good intake manifold source (usually at the PCV valve port), following the gauge manufacturer’s instructions. Start and warm up the engine………………………………………………………………………………….. 12

2. Observe the vacuum gauge while operating the engine over a range of engine speeds……………………………………………………………………………………………………………………………………………………………… 12

Test Results…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 12

1. A steady vacuum reading between 14 and 19in. Hg. (47-64 kPa) at idle indicates an engine in good mechanical condition……………………………………………………………………………………………………………………………… 12

2. A vacuum reading below 14 in. Hg. (47 kPa) at idle, indicates an engine that is not developing enough vacuum. Further testing for base mechanical problems is needed……………………………………………………………………………………. 12

3. Possible causes of low intake manifold vacuum are late ignition timing, low compression, poor engine sealing, leaks at vacuum lines and connections or bad MAP sensor…………………………………………………………………………………… 12

4. If the gauge fluctuates at idle, possible causes are sticking or leaking valves, or an ignition miss…………………………………………………………………………………………………………………………………………….. 12

5. If the gauge fluctuates at idle but smooths out as engine RPM increases, check for bad valves or camshaft………………………………………………………………………………………………………………………………………… 12

6. If the gauge fluctuates more with increases engine RPM, check for weak or broken valve springs, bad valves, ignition miss, or a leaking head gasket…………………………………………………………………………………………………… 12

7. If the vacuum gauge fluctuates regularly with each engine cycle, check for a bad valve…………………………………………………………………………………………………………………………………………………………. 12

8. If the vacuum reading drops steadily as engine RPM increases, check the exhaust system between the engine and vertical drive for restrictions………………………………………………………………………………………………………… 12

9. See table and chart below and on the following page for more information……………………………………………………………………………………………………………………………………………………………………… 13

Vacuum Gauge Readings…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 13

Gasoline Requirements…………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 14

Gasoline Containing Alcohol……………………………………………………………………………………………………………………………………………………………………………………………………………………….. 14

Crankcase Oil……………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 15

Draining and Filling the Engine Crankcase……………………………………………………………………………………………………………………………………………………………………………………………………….. 15

Temperature Viscosity Recommendations…………………………………………………………………………………………………………………………………………………………………………………………………………… 16

Crankcase Capacities………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 16

Oil Filter………………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 16

Canister type………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 16

Replaceable Element Type………………………………………………………………………………………………………………………………………………………………………………………………………………………. 17

Power Steering…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 17

Steering System Lubrication……………………………………………………………………………………………………………………………………………………………………………………………………………………. 17

Power Trim/Tilt Fluid Level……………………………………………………………………………………………………………………………………………………………………………………………………………………….. 17

Off-Season Storage……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 17

Limited Use………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 18

Storage……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 18

Step 1. Prepare a storage mixture………………………………………………………………………………………………………………………………………………………………………………………………………………. 18

Step 2. Change Motor Oil and Oil Filter:………………………………………………………………………………………………………………………………………………………………………………………………………… 19

Step 3. Change Drive Lubricant:………………………………………………………………………………………………………………………………………………………………………………………………………………… 19

Step 4. Fog Engine:…………………………………………………………………………………………………………………………………………………………………………………………………………………………… 19

Step 5. Drain Cooling System…………………………………………………………………………………………………………………………………………………………………………………………………………………… 19

Front……………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 19

1. Disable ignition system See Engine Compression Testing on page 5…………………………………………………………………………………………………………………………………………………………………………….. 19

2. Remove inlet and outlet hoses from raw water pump and crank the engine with starter 1-2 revolutions……………………………………………………………………………………………………………………………………………… 19

3. Reconnect ignition system……………………………………………………………………………………………………………………………………………………………………………………………………………….. 20

Starboard……………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 20

4. Disconnect and drain large hose at circulation pump………………………………………………………………………………………………………………………………………………………………………………………… 20

Port………………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 20

5. Remove exhaust manifold drain plug. Clear hole with a small wire to ensure complete drainage……………………………………………………………………………………………………………………………………………………. 20

6. Remove cap from engine flush hose and lower hose into bilge…………………………………………………………………………………………………………………………………………………………………………………. 20

Preparation for Boating After Storage………………………………………………………………………………………………………………………………………………………………………………………………………………. 20

1. Install all drain plugs. Install cooling hoses and clamps. Check condition of hoses, manifold end caps and clamps. Connect hoses to engine and tighten clamps securely. Install boat drain plug, if removed…………………………………………………….. 20

2. Remove the distributor cap and rotor. Wipe the inside of the distributor cap dry with a clean cloth and spray with Corrosion Spray. Replace the rotor and cap……………………………………………………………………………………………… 20

3. Clean the battery terminals. With the ignition switch in the “OFF” position, install the battery and attach the battery cables. Spray terminals with Corrosion Spray……………………………………………………………………………………….. 20

4. Open the fuel shut-off valve (if so equipped) and check all fuel line connections for leaks………………………………………………………………………………………………………………………………………………………… 20

5. Check the flame arrestor and clean if necessary. Reinstall, make sure all parts are in place and tighten nut securely…………………………………………………………………………………………………………………………………. 20

6. Make a thorough check of the boat and engine for loose or missing nuts and screws. Pump the bilge dry and air out the engine compartment………………………………………………………………………………………………………………… 20

7. Test run engine: Launch boat or use a flushing adaptor installed on Sterndrive……………………………………………………………………………………………………………………………………………………………………. 20

8. With engine compartment open, start the engine. Monitor the voltmeter, oil pressure and water temperature gauges frequently to be sure all systems are operating properly. Check for fuel, oil, and water leaks…………………………………………………. 20

Engine Break-in………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 21

First Two Hours………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 21

Next Eight Hours……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 21

Final Ten Hours………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 21

1. Check crankcase oil level frequently. Maintain oil level in safe range, between “add” and “full” marks on dipstick………………………………………………………………………………………………………………………………… 21

2. Watch oil pressure gauge. If gauge indication drops below the normal operating oil pressure range (See Engine Specifications ………………………………………………………………………………………………………………………. 22

3. Watch engine temperature indicator to be sure there is proper water circulation……………………………………………………………………………………………………………………………………………………………….. 22

Operation After Break-in………………………………………………………………………………………………………………………………………………………………………………………………………………………. 22

Submerged Engine or Water Ingestion in Cylinders…………………………………………………………………………………………………………………………………………………………………………………………………….. 22

1. Remove spark plugs immediately and crank engine to remove water from cylinders. Do not attempt to crank engine with water present in cylinders, internal engine damage will result…………………………………………………………………………… 22

2. Drain, flush and refill crankcase with new oil, See Draining and Filling the Engine Crankcase on page 11…………………………………………………………………………………………………………………………………………….. 22

3. Change oil filter, See Oil Filter on page 12………………………………………………………………………………………………………………………………………………………………………………………………….. 22

20-Hour Check……………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 23

1. Change engine oil and oil filter…………………………………………………………………………………………………………………………………………………………………………………………………………….. 23

2. Check power trim/tilt reservoir for proper fluid level…………………………………………………………………………………………………………………………………………………………………………………………. 23

3. Clean and inspect the ceramic filter located under the fuel pump………………………………………………………………………………………………………………………………………………………………………………… 23

4. Check flame arrestor for proper mounting……………………………………………………………………………………………………………………………………………………………………………………………………… 23

5. Start engine and check complete fuel system for leaks………………………………………………………………………………………………………………………………………………………………………………………….. 23

6. Lubricate steering cable ram with Volvo Penta grease P/N 828250. Check power steering pump reservoir for correct fluid level ………………………………………………………………………………………………………………………….. 23

7. Check shift system for proper adjustment and operation. Verify cable attachment clamp on pivot housing is fully seated and secure. Inspect cable anchor and cotter pin at shift linkage on stern drive for proper installation and free movement……………………. 23

8. Inspect exhaust system. Tighten all hose clamps, and check for leaks. Verify all clamps on exhaust and u-joint bellows are properly located and tightened…………………………………………………………………………………………………. 23

9. Check tension on drive belt…………………………………………………………………………………………………………………………………………………………………………………………………………………. 23

10. Check all engine mount screws, stern drive mounting nuts and transom shield mounting nuts for tightness…………………………………………………………………………………………………………………………………………….. 23

11. Check for any deficiencies, malfunctions, signs of abuse, etc. Correction of any problems at this time will prevent the worsening of a minor problem and help ensure a trouble-free boating season……………………………………………………………. 23

12. Check oil level in Sterndrive and add as necessary with GL-5 Synthetic Gear Lubricant or Mobilube 1 SHC Fully Synthetic SAE 75W-90 (meeting or exceeding MIL-L-2105C or D, API GL-4 or 5) gear lubricant………………………………………………………. 23

13. Make sure engine can achieve maximum rated RPM with normal load………………………………………………………………………………………………………………………………………………………………………………… 23

Positive Closed Ventilation System…………………………………………………………………………………………………………………………………………………………………………………………………………………. 23

With Engine Idling……………………………………………………………………………………………………………………………………………………………………………………………………………………………. 24

1. Remove PCV valve from its mounting, but leave vacuum inlet side connected to hose. If the valve is functioning properly and n………………………………………………………………………………………………………………………. 24

2. Reinstall PCV valve, then remove crankcase air inlet hose at flame arrestor connection. Loosely hold a small piece of stiff p………………………………………………………………………………………………………………………. 24

With Engine Stopped…………………………………………………………………………………………………………………………………………………………………………………………………………………………… 24

Servicing PCV Valve…………………………………………………………………………………………………………………………………………………………………………………………………………………………… 24

Troubleshooting – System Isolation…………………………………………………………………………………………………………………………………………………………………………………………………………………. 24

System Isolation……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

1. Discharged or dead Battery………………………………………………………………………………………………………………………………………………………………………………………………………………. 25

2. Loose or corroded connections……………………………………………………………………………………………………………………………………………………………………………………………………………. 25

3. Cranking System Troubleshooting Chart in the Electrical Ignition/ Fuel Service Manual………………………………………………………………………………………………………………………………………………………….. 25

1. Distributor Cap………………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

2. Coil and spark plug leads……………………………………………………………………………………………………………………………………………………………………………………………………………….. 25

3. Ignition timing………………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

4. Automatic spark advance…………………………………………………………………………………………………………………………………………………………………………………………………………………. 25

5. Appropriate Ignition Troubleshooting Chart in the Electrical/Ignition/Fuel Service Manual………………………………………………………………………………………………………………………………………………………. 25

6. EFI Models: Refer to EFI Diagnostic Manual………………………………………………………………………………………………………………………………………………………………………………………………… 25

1. Fuel Tank, valves, and lines…………………………………………………………………………………………………………………………………………………………………………………………………………….. 25

2. Fuel pump and filter……………………………………………………………………………………………………………………………………………………………………………………………………………………. 25

3. Carburetor and Filter…………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

4. Boat Fuel System Troubleshooting Chart……………………………………………………………………………………………………………………………………………………………………………………………………. 25

5. Carburetor Troubleshooting Chart…………………………………………………………………………………………………………………………………………………………………………………………………………. 25

6. Engine Fuel System Troubleshooting Chart………………………………………………………………………………………………………………………………………………………………………………………………….. 25

1. Compression……………………………………………………………………………………………………………………………………………………………………………………………………………………………. 25

2. Ignition system………………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

3. Fuel system and carburetor………………………………………………………………………………………………………………………………………………………………………………………………………………. 25

4. Lubrication system……………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

5. Cooling System…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 25

6. Sterndrive and propeller………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

7. PCV Valve……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

8. Engine Troubleshooting Guides……………………………………………………………………………………………………………………………………………………………………………………………………………. 25

Engine Troubleshooting Guides……………………………………………………………………………………………………………………………………………………………………………………………………………………… 25

Engine Will Not Crank…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 26

Starter Circuit – Check:…………………………………………………………………………………………………………………………………………………………………………………………………………………… 26

Engine Cranks, But Will Not Start………………………………………………………………………………………………………………………………………………………………………………………………………………. 26

Ignition Circuit………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 26

Fuel System………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 27

Cylinder Compression………………………………………………………………………………………………………………………………………………………………………………………………………………………. 27

Hard Starting – Cold Engine……………………………………………………………………………………………………………………………………………………………………………………………………………………. 27

Has Engine Always Done This?……………………………………………………………………………………………………………………………………………………………………………………………………………….. 27

1. Carburetor choke operation and adjustment……………………………………………………………………………………………………………………………………………………………………………………………… 27

2. Fuel lines for obstructions………………………………………………………………………………………………………………………………………………………………………………………………………….. 27

3. For debris inside fuel tank………………………………………………………………………………………………………………………………………………………………………………………………………….. 27

4. See Electrical/Ignition/Fuel System Service Manual……………………………………………………………………………………………………………………………………………………………………………………… 27

Was Engine Not Used For A Long Time? (more than two months)……………………………………………………………………………………………………………………………………………………………………………………. 27

1. For clean external canister and carburetor fuel filters…………………………………………………………………………………………………………………………………………………………………………………. 27

2. Empty carburetor float bowl due to evaporation…………………………………………………………………………………………………………………………………………………………………………………………. 27

3. Water in fuel due to condensation…………………………………………………………………………………………………………………………………………………………………………………………………….. 27

4. Fuel quality deterioration…………………………………………………………………………………………………………………………………………………………………………………………………………… 27

5. See Electrical/Ignition/Fuel System Service Manual……………………………………………………………………………………………………………………………………………………………………………………… 28

Is This A New Condition?…………………………………………………………………………………………………………………………………………………………………………………………………………………… 28

1. Carburetor choke operation and adjustment……………………………………………………………………………………………………………………………………………………………………………………………… 28

2. Carburetor accelerator pump………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

3. Fuel system for leaks, dirt, or obstructions…………………………………………………………………………………………………………………………………………………………………………………………… 28

4. Engine timing and ignition system…………………………………………………………………………………………………………………………………………………………………………………………………….. 28

5. See Electrical/Ignition/Fuel System Service Manual……………………………………………………………………………………………………………………………………………………………………………………… 28

Hard Starting – Hot Engine…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

Has Engine Always Done This?……………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

1. Carburetor choke operation and adjustment……………………………………………………………………………………………………………………………………………………………………………………………… 28

2. See Electrical/Ignition/Fuel System Service Manual……………………………………………………………………………………………………………………………………………………………………………………… 28

Is This A New Condition?…………………………………………………………………………………………………………………………………………………………………………………………………………………… 28

1. Brand, type or octane of fuel………………………………………………………………………………………………………………………………………………………………………………………………………… 28

2. Spark plugs………………………………………………………………………………………………………………………………………………………………………………………………………………………… 28

3. Water in fuel………………………………………………………………………………………………………………………………………………………………………………………………………………………. 28

4. Condition of battery and cables………………………………………………………………………………………………………………………………………………………………………………………………………. 28

5. Starter motor for overheat damage…………………………………………………………………………………………………………………………………………………………………………………………………….. 28

Did Engine Refuse To Start After Being Run?………………………………………………………………………………………………………………………………………………………………………………………………….. 28

1. Ignition system primary circuit………………………………………………………………………………………………………………………………………………………………………………………………………. 28

2. Ignition coil(s)/ignition module……………………………………………………………………………………………………………………………………………………………………………………………………… 28

3. Engine timing………………………………………………………………………………………………………………………………………………………………………………………………………………………. 28

4. Carburetor choke operation and adjustment……………………………………………………………………………………………………………………………………………………………………………………………… 28

5. See Electrical/Ignition/Fuel System Service Manual……………………………………………………………………………………………………………………………………………………………………………………… 28

Engine Runs Rough…………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

If At Slow Speed………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

1. Idle speed and idle mixture………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

2. Engine timing and spark plugs………………………………………………………………………………………………………………………………………………………………………………………………………… 28

3. Fuel pump pressure………………………………………………………………………………………………………………………………………………………………………………………………………………….. 28

4. Water or contaminants in fuel………………………………………………………………………………………………………………………………………………………………………………………………………… 28

5. Carburetor or manifold vacuum leak……………………………………………………………………………………………………………………………………………………………………………………………………. 28

6. Internal carburetor fuel leak………………………………………………………………………………………………………………………………………………………………………………………………………… 29

7. See Electrical/Ignition/Fuel System Service Manual……………………………………………………………………………………………………………………………………………………………………………………… 29

If At High Speed………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 29

1. Air leak on suction side of fuel system……………………………………………………………………………………………………………………………………………………………………………………………….. 29

2. Too low octane fuel…………………………………………………………………………………………………………………………………………………………………………………………………………………. 29

3. Ignition system secondary circuit…………………………………………………………………………………………………………………………………………………………………………………………………….. 29

4. Engine timing………………………………………………………………………………………………………………………………………………………………………………………………………………………. 29

5. Wrong model or size carburetor, improper main jets or power valve, defective secondary fuel circuit, secondary vacuum diaphragm failure………………………………………………………………………………………………………….. 29

6. External canister and carburetor fuel filters………………………………………………………………………………………………………………………………………………………………………………………….. 29

7. Fuel pump pressure………………………………………………………………………………………………………………………………………………………………………………………………………………….. 29

8. Engine compression………………………………………………………………………………………………………………………………………………………………………………………………………………….. 29

9. Water or contaminants in fuel, water in cylinders………………………………………………………………………………………………………………………………………………………………………………………. 29

10. See General Information section and Electrical/Ignition/ Fuel System Service Manual……………………………………………………………………………………………………………………………………………………….. 29

Engine Noises and Vibrations…………………………………………………………………………………………………………………………………………………………………………………………………………………… 29

Valves – Hydraulic Lifters…………………………………………………………………………………………………………………………………………………………………………………………………………………. 29

1. Rapping only when starting (oil too heavy for prevailing weather, varnish on lifter, oil needs to be changed)…………………………………………………………………………………………………………………………………. 29

2. Intermittent rapping (leakage at lifter check ball)…………………………………………………………………………………………………………………………………………………………………………………….. 29

3. Idle noise (excessive leak down rate, faulty check ball seat)……………………………………………………………………………………………………………………………………………………………………………. 29

4. Generally noisy (excessive oil in crankcase, stuck lifter plunger)……………………………………………………………………………………………………………………………………………………………………….. 29

5. Loud noise at operating temperature (scored lifter plunger, fast leak down rate, oil viscosity too light for prevailing weather or operating temperatures)…………………………………………………………………………………………. 29

6. See appropriate Engine section……………………………………………………………………………………………………………………………………………………………………………………………………….. 29

Ignition System (Ping or Knock)…………………………………………………………………………………………………………………………………………………………………………………………………………….. 29

1. Improper tuning…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 29

2. Incorrect spark plug wire routing…………………………………………………………………………………………………………………………………………………………………………………………………….. 29

3. Use higher octane fuel………………………………………………………………………………………………………………………………………………………………………………………………………………. 29

4. See Electrical/Ignition/Fuel Service Manual……………………………………………………………………………………………………………………………………………………………………………………………. 29

Cooling System……………………………………………………………………………………………………………………………………………………………………………………………………………………………. 29

1. Supply pump………………………………………………………………………………………………………………………………………………………………………………………………………………………… 29

2. Loose belts, pulleys………………………………………………………………………………………………………………………………………………………………………………………………………………… 29

3. See Cooling System Manual……………………………………………………………………………………………………………………………………………………………………………………………………………. 29

Mountings………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 29

1. Loose, broken or worn engine mounts…………………………………………………………………………………………………………………………………………………………………………………………………… 29

2. Loose lag screws holding mounts to stringer……………………………………………………………………………………………………………………………………………………………………………………………. 29

Crankshaft Balancer or Flywheel…………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

1. Loose bolt(s)………………………………………………………………………………………………………………………………………………………………………………………………………………………. 30

Alternator……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

1. Loose pulley, worn bearings………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

2. Loose mounting bolts………………………………………………………………………………………………………………………………………………………………………………………………………………… 30

Sterndrive……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

1. Failed U-joints or gimbal bearing…………………………………………………………………………………………………………………………………………………………………………………………………….. 30

2. Damaged internal drive components…………………………………………………………………………………………………………………………………………………………………………………………………….. 30

3. Worn, bent or broken propeller hub or blades…………………………………………………………………………………………………………………………………………………………………………………………… 30

4. Loose, worn or damaged engine coupler…………………………………………………………………………………………………………………………………………………………………………………………………. 30

Engine Overheats……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 30

1. Actual engine temperature by verifying with an accurate thermometer at the thermostat housing…………………………………………………………………………………………………………………………………………………… 30

2. Gauge operation and wiring circuit……………………………………………………………………………………………………………………………………………………………………………………………………….. 30

3. Sending unit operation and wiring circuit…………………………………………………………………………………………………………………………………………………………………………………………………. 30

4. Supply pump, circulating pump and belt(s)…………………………………………………………………………………………………………………………………………………………………………………………………. 30

5. Water intake screens for blockage………………………………………………………………………………………………………………………………………………………………………………………………………… 30

6. Thermostat…………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

7. Water supply hoses……………………………………………………………………………………………………………………………………………………………………………………………………………………… 30

8. Engine timing………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

9. Water leaks on pressure side of supply pump……………………………………………………………………………………………………………………………………………………………………………………………….. 30

10. Air leaks on suction side of supply pump including the transom shield and sterndrive………………………………………………………………………………………………………………………………………………………….. 30

11. Engine compression…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

Engine Dies Out………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 30

Loss Of, Or Out Of, Fuel…………………………………………………………………………………………………………………………………………………………………………………………………………………… 30

1. Fuel gauge operation and wiring………………………………………………………………………………………………………………………………………………………………………………………………………. 30

2. Fuel level in tank………………………………………………………………………………………………………………………………………………………………………………………………………………….. 30

3. Water or debris in fuel……………………………………………………………………………………………………………………………………………………………………………………………………………… 30

4. Fuel pickup tube and screen blockage………………………………………………………………………………………………………………………………………………………………………………………………….. 30

5. Fuel tank vent blockage……………………………………………………………………………………………………………………………………………………………………………………………………………… 30

6. Plugged external canister or carburetor fuel filters……………………………………………………………………………………………………………………………………………………………………………………. 30

7. Air leak on suction side of fuel system……………………………………………………………………………………………………………………………………………………………………………………………….. 30

8. Fuel leak on pressure side of fuel system……………………………………………………………………………………………………………………………………………………………………………………………… 30

9. Inoperative, restricted or incorrectly sized anti-siphon valve…………………………………………………………………………………………………………………………………………………………………………… 30

10. Boat fuel lines too small in diameter………………………………………………………………………………………………………………………………………………………………………………………………… 30

11. Fuel pump pressure and suction………………………………………………………………………………………………………………………………………………………………………………………………………. 30

12. Carburetor cleanliness and operation…………………………………………………………………………………………………………………………………………………………………………………………………. 31

13. See Electrical/Ignition/Fuel System Service Manual…………………………………………………………………………………………………………………………………………………………………………………….. 31

Loss Of Ignition………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 31

1. Primary and secondary ignition circuits……………………………………………………………………………………………………………………………………………………………………………………………….. 31

2. Ignition switch…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 31

3. Circuit breakers……………………………………………………………………………………………………………………………………………………………………………………………………………………. 31

4. Wiring between engine and dash……………………………………………………………………………………………………………………………………………………………………………………………………….. 31

5. Main engine harness wiring…………………………………………………………………………………………………………………………………………………………………………………………………………… 31

6. See Electrical/Ignition/Fuel Service Manual……………………………………………………………………………………………………………………………………………………………………………………………. 31

Engine Stops Or Dies Out Due To Seizure……………………………………………………………………………………………………………………………………………………………………………………………………… 31

1. Vertical drive for internal damage……………………………………………………………………………………………………………………………………………………………………………………………………. 31

2. Oil pressure gauge and crankcase oil level…………………………………………………………………………………………………………………………………………………………………………………………….. 31

3. Temperature gauge and cooling system operation…………………………………………………………………………………………………………………………………………………………………………………………. 31

4. Internal engine components as required………………………………………………………………………………………………………………………………………………………………………………………………… 31

Engine Won’t Reach Operating RPM……………………………………………………………………………………………………………………………………………………………………………………………………………. 31

1. Propeller pitch or diameter, damaged blades, slipping hub……………………………………………………………………………………………………………………………………………………………………………….. 31

2. Crankcase oil volume………………………………………………………………………………………………………………………………………………………………………………………………………………… 31

3. Marine growth on hull and drive………………………………………………………………………………………………………………………………………………………………………………………………………. 31

4. Fuel type or octane…………………………………………………………………………………………………………………………………………………………………………………………………………………. 31

5. Wrong Sterndrive gear ratio………………………………………………………………………………………………………………………………………………………………………………………………………….. 31

6. Operating at high altitude…………………………………………………………………………………………………………………………………………………………………………………………………………… 31

7. Restricted carburetor air intake……………………………………………………………………………………………………………………………………………………………………………………………………… 31

8. Restricted exhaust outlets in engine, transom bracket or drive…………………………………………………………………………………………………………………………………………………………………………… 31

9. Poor cylinder compression……………………………………………………………………………………………………………………………………………………………………………………………………………. 31

10. Carburetor size and type correct for engine…………………………………………………………………………………………………………………………………………………………………………………………… 31

11. Fuel pump pressure and vacuum……………………………………………………………………………………………………………………………………………………………………………………………………….. 31

12. Boat overloaded, or load improperly placed……………………………………………………………………………………………………………………………………………………………………………………………. 31

13. Engine overheating…………………………………………………………………………………………………………………………………………………………………………………………………………………. 31

14. Engine timing and ignition system operation…………………………………………………………………………………………………………………………………………………………………………………………… 31

15. Remote control cables and linkage for proper attachment and travel………………………………………………………………………………………………………………………………………………………………………. 31

Defective Engine Lubricating System…………………………………………………………………………………………………………………………………………………………………………………………………………….. 31

Engine Components…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 31

1. Clogged or incorrect oil filter………………………………………………………………………………………………………………………………………………………………………………………………………. 31

2. Worn oil pump gears, cover or shaft…………………………………………………………………………………………………………………………………………………………………………………………………… 31

3. Worn or collapsed oil pump relief valve spring, or foreign material caught on valve seat……………………………………………………………………………………………………………………………………………………. 32

4. Oil pump relief valve plunger loose in cover…………………………………………………………………………………………………………………………………………………………………………………………… 32

5. Damaged filter bypass grommet………………………………………………………………………………………………………………………………………………………………………………………………………… 32

6. Clogged oil pickup screen, broken tube or housing………………………………………………………………………………………………………………………………………………………………………………………. 32

7. Plugged crankshaft or blocked oil galleys……………………………………………………………………………………………………………………………………………………………………………………………… 32

8. Dirty or defective hydraulic lifters, clogged push rod passages………………………………………………………………………………………………………………………………………………………………………….. 32

9. Poor quality, incorrect viscosity or quantity of oil……………………………………………………………………………………………………………………………………………………………………………………. 32

10. Oil level too high – too much oil in the crankcase…………………………………………………………………………………………………………………………………………………………………………………….. 32

11. Incorrect hose routing on remote filter systems……………………………………………………………………………………………………………………………………………………………………………………….. 32

12. Water in crankcase oil from condensation, defective head gasket, oil cooler, or cracked manifold/block water passages…………………………………………………………………………………………………………………………. 32

Oil Pressure Warning System………………………………………………………………………………………………………………………………………………………………………………………………………………… 32

1. Oil gauge/warning horn operation and wiring……………………………………………………………………………………………………………………………………………………………………………………………. 32

2. Engine temperature………………………………………………………………………………………………………………………………………………………………………………………………………………….. 32

3. Oil pressure gauge and warning horn sender operation and wiring………………………………………………………………………………………………………………………………………………………………………….. 32

4. Oil level too high or too low, oil level should be within the “Safe” range on the dipstick………………………………………………………………………………………………………………………………………………….. 32

Low Battery Voltage After Short Storage…………………………………………………………………………………………………………………………………………………………………………………………………………. 32

Engine/Boat Components…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 32

1. All electrical accessories including ignition circuit off……………………………………………………………………………………………………………………………………………………………………………….. 32

2. Disconnect main battery negative cable from battery…………………………………………………………………………………………………………………………………………………………………………………….. 32

3. Connect ammeter or voltmeter in series between negative battery cable and negative battery post……………………………………………………………………………………………………………………………………………… 32

4. Disconnect main engine harness 10-Pin Connector………………………………………………………………………………………………………………………………………………………………………………………… 32

5. Repair or replace components as necessary……………………………………………………………………………………………………………………………………………………………………………………………… 32

Engine – 5.0 & 5.7 Litre……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 33

General Description………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 34

Cylinder Block……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 34

Cylinder Head………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 34

Camshaft…………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 35

Crankshaft…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 35

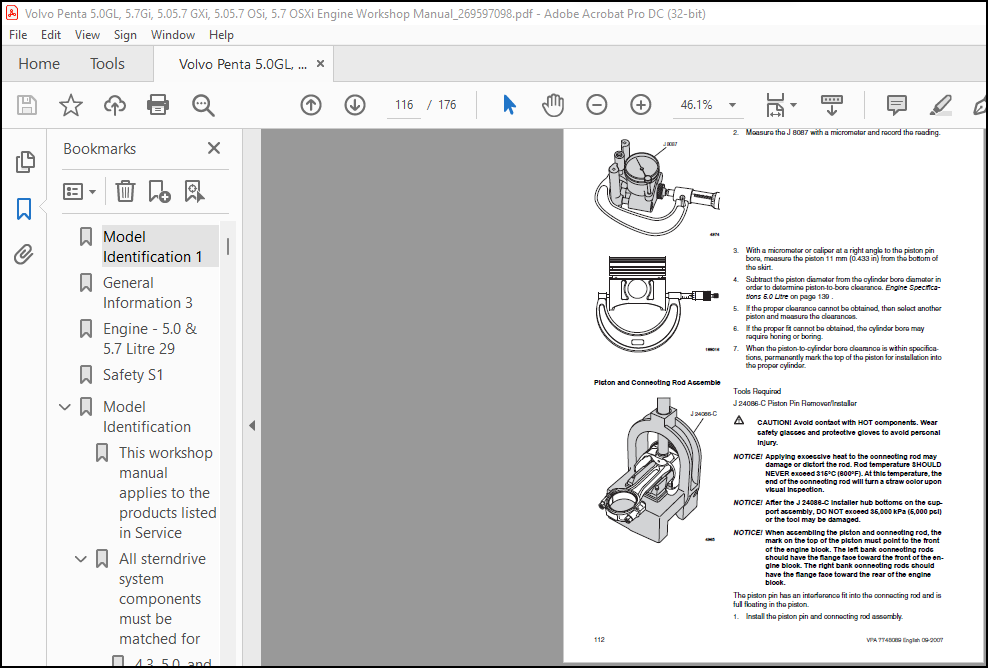

Pistons and Connecting Rods……………………………………………………………………………………………………………………………………………………………………………………………………………………. 35

Lubrication………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 35

Tools and Shop Equipment………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 35

Accessories……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 35

Cleaning………………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 36

Draining The Engine………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 37

Raw Water Cooled Engines………………………………………………………………………………………………………………………………………………………………………………………………………………………. 37

1. With the engine turned off, locate and open the engine drain petcocks located on both sides of the engine block…………………………………………………………………………………………………………………………………… 37

2. Remove drain plugs from exhaust manifolds. After the water has completely drained, reinstall the drain plugs and torque to 29 N.m (22 lb. ft.)……………………………………………………………………………………………………….. 38

3. Note the hose orientation on the raw water pump. Loosen the hose clamps and remove the hoses from the raw water pump………………………………………………………………………………………………………………………………. 38

4. Crank the engine briefly, (1 or 2 crankshaft revolutions) but do not start the engine, to clear the water from the pump……………………………………………………………………………………………………………………………. 38

5. Loosen the hose clamp on the large diameter hose and remove it from the circulation pump……………………………………………………………………………………………………………………………………………………….. 38

6. Loosen the hose clamp on the lower fuel cell cooling line and remove hose from fuel cell. Allow water to drain from hose…………………………………………………………………………………………………………………………… 39

7. Reinstall all hoses and secure all clamps in the same orientation as removed………………………………………………………………………………………………………………………………………………………………….. 39

Draining seawater from the Closed Cooling System…………………………………………………………………………………………………………………………………………………………………………………………………. 39

1. With the engine turned off locate and loosen the lower drain cap from the heat exchanger (1). After water has completely drained, retighten the lower drain cap of the heat exchanger to 18-30ft.lb. (25-41 Nm)……………………………………………… 39

2. Note the hose orientation on the raw water pump. Loosen the hose clamps and remove the hoses from the raw water pump. Crank t………………………………………………………………………………………………………………………. 39

3. Remove drain plugs from exhaust manifolds. Probe the drains with a wire to ensure rust particles have not blocked the drain. After water is completely drained, reinstall drain plugs and tighten securely………………………………………………….. 40

Engine Lubrication……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 40

4. Oil is drawn up through the oil pump screen and passes through the pump to the oil filter. The oil filter is a full-flow pape………………………………………………………………………………………………………………………….. 40

Exhaust Manifold…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 41

Removal……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 41

1. Drain water from exhaust manifolds……………………………………………………………………………………………………………………………………………………………………………………………………….. 41

2. Disconnect water hose from manifold………………………………………………………………………………………………………………………………………………………………………………………………………. 41

3. Loosen upper exhaust hose clamps, then remove high rise elbow……………………………………………………………………………………………………………………………………………………………………………….. 41

4. Remove manifold attaching screws, then remove the manifold………………………………………………………………………………………………………………………………………………………………………………….. 41

Inspection…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 41

1. Inspect for cracks……………………………………………………………………………………………………………………………………………………………………………………………………………………… 41

2. To pressure check manifold, use a plate such as pictured, and a new elbow gasket to seal water passage in manifold. Be sure t………………………………………………………………………………………………………………………. 41

Installation…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 41

1. Clean mating surfaces on manifold and head. Install new exhaust gasket, then install manifold and secure with screws. Tighten screws to 20-26 ft. lb. (27-35 N.m)………………………………………………………………………………………. 41

2. Install a new gasket and high rise elbow to manifold. Tighten bolts to 12-18 ft. lb. (16-24 N.m)………………………………………………………………………………………………………………………………………………… 42

3. Clean the gasket mounting surfaces on both the riser and the manifold………………………………………………………………………………………………………………………………………………………………………… 42

4. Use spray on gasket remover to remove ALL traces of riser gasket. Heavy scrapping with tools on gasket surfaces may gouge surface, preventing proper seal……………………………………………………………………………………………… 42

5. Follow pre-cautions on can of gasket remover to prevent damage to paint on manifold, riser or engine…………………………………………………………………………………………………………………………………………….. 42

6. Use 80 grit sandpaper and a sanding block, or equivalent to smooth the gasket mounting surfaces on the riser and manifold………………………………………………………………………………………………………………………….. 42

7. Place gasket over mounting surface on manifold…………………………………………………………………………………………………………………………………………………………………………………………….. 43

8. Install riser, on to exhaust manifold…………………………………………………………………………………………………………………………………………………………………………………………………….. 43

9. Make sure gasket is properly placed………………………………………………………………………………………………………………………………………………………………………………………………………. 43

10. Install bolts and washers to secure riser………………………………………………………………………………………………………………………………………………………………………………………………… 43

11. Install any parts secured under bolts……………………………………………………………………………………………………………………………………………………………………………………………………. 43

12. Torque riser bolts in a crossing pattern to 40 Nm…………………………………………………………………………………………………………………………………………………………………………………………. 43

13. (30 ft. lb.). Make at least two passes to insure proper torque is reached……………………………………………………………………………………………………………………………………………………………………. 43

14. Install all other parts mounted to risers………………………………………………………………………………………………………………………………………………………………………………………………… 43

15. Install exhaust hose and secure with clamps………………………………………………………………………………………………………………………………………………………………………………………………. 43

16. Connect water hose and secure with clamp…………………………………………………………………………………………………………………………………………………………………………………………………. 43

17. Start engine and check for fuel leaks……………………………………………………………………………………………………………………………………………………………………………………………………. 43

Starter…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 43

Remove………………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 43

1. Disconnect power from the engine…………………………………………………………………………………………………………………………………………………………………………………………………………. 43

2. Remove battery cable (2) from solenoid extension nut……………………………………………………………………………………………………………………………………………………………………………………….. 43

3. Remove solenoid extension nut (4) and cover (3) from solenoid……………………………………………………………………………………………………………………………………………………………………………….. 43

4. Remove accessory wires from solenoid (5)………………………………………………………………………………………………………………………………………………………………………………………………….. 43

5. Remove start wire nut (6)……………………………………………………………………………………………………………………………………………………………………………………………………………….. 43

6. Remove start wire from solenoid start terminal (7)…………………………………………………………………………………………………………………………………………………………………………………………. 43

7. Remove starter mounting bolts……………………………………………………………………………………………………………………………………………………………………………………………………………. 44

8. Remove starter…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 44

Installation…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 44

1. Hold stater against engine mounting pad with mounting holes aligned………………………………………………………………………………………………………………………………………………………………………….. 44

2. Install starter bolts and tighten to 41-49 Nm (30-36 ft.lb)…………………………………………………………………………………………………………………………………………………………………………………. 44

3. Connect accessory wires (5) to solenoid…………………………………………………………………………………………………………………………………………………………………………………………………… 44

4. Install solenoid extension nut (4) and washer on solenoid terminal. Tighten to 19 – 28 N.m (14 – 20 ft. lb.)……………………………………………………………………………………………………………………………………… 44

5. Install solenoid extension nut cover (3)………………………………………………………………………………………………………………………………………………………………………………………………….. 44

6. Connect battery cable (2) to solenoid extension nut………………………………………………………………………………………………………………………………………………………………………………………… 44

7. Install battery cable bolt (1) and washer. Tighten to 19 – 28 N.m (14 – 20 ft. lb.)……………………………………………………………………………………………………………………………………………………………. 44

8. Install start wire (7) on solenoid stud “S”……………………………………………………………………………………………………………………………………………………………………………………………….. 44

9. Install start wire nut (6) and washer. Tighten to 3 – 5 N.m (26 – 44 in. lb.)…………………………………………………………………………………………………………………………………………………………………. 44

10. Connect start wire to solenoid start terminal (1)…………………………………………………………………………………………………………………………………………………………………………………………. 44

11. On GL models, connect the purple wire to the solenoid “R” terminal in the same manner…………………………………………………………………………………………………………………………………………………………. 45

Intake Manifold………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 45

Removal……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 45

1. Disconnect power from engine…………………………………………………………………………………………………………………………………………………………………………………………………………….. 45

2. Drain water from engine block. See Draining The Engine on page 33……………………………………………………………………………………………………………………………………………………………………………. 45

3. If the engine has closed cooling installed, remove drain plugs from engine block. Catch the coolant from the engine and dispose of properly………………………………………………………………………………………………………….. 45

Disconnect:………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 45

4. Disconnect hoses from thermostat housing………………………………………………………………………………………………………………………………………………………………………………………………….. 45

5. Disconnect Throttle cable……………………………………………………………………………………………………………………………………………………………………………………………………………….. 45

a. Remove cotter pin (1) and washer (2) and remove throttle cable from throttle lever…………………………………………………………………………………………………………………………………………………………. 45

b. Loosen and remove anchor block bolt (3) and nut (4)…………………………………………………………………………………………………………………………………………………………………………………….. 45

c. Release cable block (5) and trunnion (6)………………………………………………………………………………………………………………………………………………………………………………………………. 45

6. Crankcase ventilation hose from rocker arm covers (both sides if applicable)………………………………………………………………………………………………………………………………………………………………….. 45

Remove:……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 45

1. Disconnect wire at temperature gauge sender unit and engine wiring harness from alternator……………………………………………………………………………………………………………………………………………………… 45

Remove Distributor, Gi and GXi Models…………………………………………………………………………………………………………………………………………………………………………………………………………… 46

1. Disconnect distributor high tension leads and ignition primary lead from distributor cap……………………………………………………………………………………………………………………………………………………….. 46

2. Remove the distributor cap bolts and discard………………………………………………………………………………………………………………………………………………………………………………………………. 46

3. Remove the distributor cap………………………………………………………………………………………………………………………………………………………………………………………………………………. 46

4. Mark the position of the rotor on the housing……………………………………………………………………………………………………………………………………………………………………………………………… 46

5. Scribe a line on distributor housing and intake manifold for reassembly in the same position……………………………………………………………………………………………………………………………………………………. 47

6. Loosen hold down clamp and remove the distributor………………………………………………………………………………………………………………………………………………………………………………………….. 47

7. Remove Distributor and discard Gasket…………………………………………………………………………………………………………………………………………………………………………………………………….. 47

8. Disconnect and remove alternator…………………………………………………………………………………………………………………………………………………………………………………………………………. 47

9. Remove Fuse box………………………………………………………………………………………………………………………………………………………………………………………………………………………… 47

10. Carburetor fuel line from carburetor and fuel pump or fuel lines from fuel rails. To disconnect fuel lines from fuel rail, see Quick Connect Fitting Service in EFI Diagnostic Workshop Manual……………………………………………………………. 47

11. Remove intake manifold attaching bolts. Lift manifold from engine. Discard front and rear seals and gaskets……………………………………………………………………………………………………………………………………… 48

Clean:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 48

Disassemble Intake Manifold (Gi, GXi, OSi, & OSXi)……………………………………………………………………………………………………………………………………………………………………………………………….. 48

12. Remove Flame arrestor and bracket……………………………………………………………………………………………………………………………………………………………………………………………………….. 48

13. Remove throttle body attaching studs…………………………………………………………………………………………………………………………………………………………………………………………………….. 48

14. Remove throttle body and gasket. Discard the gasket……………………………………………………………………………………………………………………………………………………………………………………….. 48

15. Remove Thermostat housing bolts…………………………………………………………………………………………………………………………………………………………………………………………………………. 49

16. Remove Thermostat housing and discard gasket……………………………………………………………………………………………………………………………………………………………………………………………… 49

17. Remove MAT/MAP sensor stud and remove sensor from manifold…………………………………………………………………………………………………………………………………………………………………………………. 49

18. Remove four retaining studs and remove fuel rail assembly………………………………………………………………………………………………………………………………………………………………………………….. 49

19. Remove upper intake manifold attaching bolts……………………………………………………………………………………………………………………………………………………………………………………………… 50

20. Remove upper intake manifold……………………………………………………………………………………………………………………………………………………………………………………………………………. 50

21. Remove and discard upper intake manifold to lower intake manifold gasket…………………………………………………………………………………………………………………………………………………………………….. 50

22. Remove impulse limiter…………………………………………………………………………………………………………………………………………………………………………………………………………………. 50

Clean and Inspect…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 50

1. Clean the upper intake manifold in cleaning solvent…………………………………………………………………………………………………………………………………………………………………………………….. 50

2. Dry with compressed air……………………………………………………………………………………………………………………………………………………………………………………………………………… 50

3. Clean the lower intake manifold in cleaning solvent…………………………………………………………………………………………………………………………………………………………………………………….. 50

4. Dry with compressed air……………………………………………………………………………………………………………………………………………………………………………………………………………… 50

Assemble Intake Manifold………………………………………………………………………………………………………………………………………………………………………………………………………………………. 51

1. If removed. coat the threads of the impulse limiter with sealing compound P/N 1141570………………………………………………………………………………………………………………………………………………………….. 51

2. Install impulse limiter into lower intake manifold and tighten to 14-19 N.m (10-14 ft. lb.)…………………………………………………………………………………………………………………………………………………….. 51

3. Place a NEW upper intake manifold gasket into the upper intake manifold gasket groove………………………………………………………………………………………………………………………………………………………….. 51

4. Place the upper intake onto the lower intake manifold………………………………………………………………………………………………………………………………………………………………………………………. 51

5. Install upper intake manifold bolts………………………………………………………………………………………………………………………………………………………………………………………………………. 51

6. Tighten the upper intake manifold bolts in two stages………………………………………………………………………………………………………………………………………………………………………………………. 51

7. Inspect O-rings on fuel injectors. Replace any damaged, cut, or missing O-rings……………………………………………………………………………………………………………………………………………………………….. 51

8. Install the fuel injectors into the lower intake manifold…………………………………………………………………………………………………………………………………………………………………………………… 51

9. Install the fuel rail retaining studs and tighten to……………………………………………………………………………………………………………………………………………………………………………………….. 51

Intake Manifold Installation…………………………………………………………………………………………………………………………………………………………………………………………………………………… 51

Install or Connect:……………………………………………………………………………………………………………………………………………………………………………………………………………………….. 52

1. Apply a 4.0 mm (0.157 in) patch of adhesive Volvo Penta P/N 1161277 or equivalent to the cylinder head side of the lower intake manifold gasket at each end………………………………………………………………………………………… 52

2. Install the lower intake manifold gasket onto the cylinder head. Use the gasket locator pins in order to properly seat the lower intake manifold gasket on the cylinder head…………………………………………………………………………. 52

3. Apply a 5.0 mm (0.197 in) bead of adhesive Volvo Penta P/N 1161277 or equivalent to the front top of the engine block………………………………………………………………………………………………………………………….. 52

4. Apply a 5.0 mm (0.197 in) bead of adhesive Volvo Penta P/N 1161277 or equivalent to the rear top of the engine block.Extend the adhesive bead 13 mm (0.50 in) onto each lower intake manifold gasket……………………………………………………. 52

5. Install the intake manifold assembly onto the engine block………………………………………………………………………………………………………………………………………………………………………………. 53

6. If reusing the fasteners, apply threadlock Volvo Penta P/N 1161053 or equivalent to the threads of the manifold bolts………………………………………………………………………………………………………………………….. 53

7. Install the manifold bolts…………………………………………………………………………………………………………………………………………………………………………………………………………… 53

Tighten:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 53

8. Tighten the intake manifold bolts…………………………………………………………………………………………………………………………………………………………………………………………………….. 53

a. Tighten the bolts in sequence (1-8) on the first pass to 3 N.m (27 lb. in)…………………………………………………………………………………………………………………………………………………………….. 53

b. Tighten the bolts in sequence (1-8) on the first pass to 12 N.m (106 lb. in)…………………………………………………………………………………………………………………………………………………………… 53

c. Tighten the bolts in sequence (1-8) on the first pass to 15 N.m (11 lb. ft.)…………………………………………………………………………………………………………………………………………………………… 53

9. Connect fuel lines to fuel rail. See Quick Connect Fitting Service on page 346 of EFI Diagnostic Workshop Manual 7742218……………………………………………………………………………………………………………………….. 53

Distributor Installation………………………………………………………………………………………………………………………………………………………………………………………………………………………. 53

Gi and GXi models…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 54

1. Rotate the crankshaft balancer clockwise until the alignment marks on the crankshaft balancer (1) are aligned with the tabs on the engine front cover (2) and the number 1 piston is at top dead center of the compression stroke………………………….. 54

2. If not already removed, remove and discard the distributor cap screws…………………………………………………………………………………………………………………………………………………………………….. 54

3. Remove the distributor cap…………………………………………………………………………………………………………………………………………………………………………………………………………… 54

4. Install NEW distributor gasket onto the distributor…………………………………………………………………………………………………………………………………………………………………………………….. 54

5. Align the indent hole on the distributor gear with the paint mark on the distributor housing………………………………………………………………………………………………………………………………………………… 55

6. Align the slotted tang in the oil pump driveshaft with the distributor driveshaft. Rotate the oil pump driveshaft with a screwdriver if necessary…………………………………………………………………………………………………. 55

7. Align the flat (1) in the distributor housing toward the front of the engine………………………………………………………………………………………………………………………………………………………………. 55

8. Install the distributor and distributor clamp. The flat in the distributor housing must be pointing toward the front of the engine………………………………………………………………………………………………………………. 56

9. Once the distributor is fully seated, align the distributor rotor segment with the number 8 pointer (1) that is cast into the distributor base……………………………………………………………………………………………………. 56

10. Install the distributor clamp bolt. and Tighten the bolt to 25 N.m (18 lb. ft.)…………………………………………………………………………………………………………………………………………………………… 56

11. Install the distributor cap and NEW distributor cap bolts.Tighten the screws to 2.4 N.m (21 lb. in)…………………………………………………………………………………………………………………………………………. 57

12. Set timing, GL Models see Electrical Fuel and Ignition Workshop Manual. Gi and GXi Models see EFI Diagnostic Workshop Manual, On Board Repair……………………………………………………………………………………………………. 57

Alternator with mounting bracket……………………………………………………………………………………………………………………………………………………………………………………………………………. 57

13. Install distributor cap and high tension leads. See the General Information section in Electrical/Ignition/Fuel Service Manual for correct firing order and spark plug wire routing………………………………………………………………….. 57

14. Install oil pressure sending unit……………………………………………………………………………………………………………………………………………………………………………………………………. 57

Connect:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 57

15. All electrical connections. Apply black neoprene dip, or equivalent, on all exposed connections…………………………………………………………………………………………………………………………………………….. 57

16. Fuel lines to carburetor and fuel pump or throttle body and fuel pump/vapor separator……………………………………………………………………………………………………………………………………………………… 57

17. Throttle cable…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 57

18. All water hoses, and close all drain petcocks…………………………………………………………………………………………………………………………………………………………………………………………. 57

19. Both crankcase ventilation hoses…………………………………………………………………………………………………………………………………………………………………………………………………….. 57

20. Battery cables…………………………………………………………………………………………………………………………………………………………………………………………………………………….. 57

21. Start engine. Check ignition timing, carburetor idle speed and mixture. Check for leaks……………………………………………………………………………………………………………………………………………………. 57

Rocker Arm Cover…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 58

Remove:……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 58

1. Valve rocker arm cover bolts…………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

2. Valve rocker arm cover………………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

3. Gasket………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 58

Clean:………………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 58

a. Parts in solvent. Remove all sludge and varnish……………………………………………………………………………………………………………………………………………………………………………………………. 58

b. Old gaskets from the gasket surfaces……………………………………………………………………………………………………………………………………………………………………………………………………… 58

Inspect:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

a. Gasket flanges for bending or damage……………………………………………………………………………………………………………………………………………………………………………………………………… 58

b. Rubber grommets and parts for deterioration……………………………………………………………………………………………………………………………………………………………………………………………….. 58

Installation…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 58

1. New gasket…………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

2. Valve rocker arm cover………………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

3. Valve rocker arm cover bolts…………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

Tighten:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 58

1. Valve rocker arm cover bolts to 106 in. lb. (12 N.m)……………………………………………………………………………………………………………………………………………………………………………………….. 58

Valve Train……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 58

Removal……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 58

1. Remove rocker arms……………………………………………………………………………………………………………………………………………………………………………………………………………………… 58

2. Remove pushrods and keep in order with the valve lifters and rocker arms……………………………………………………………………………………………………………………………………………………………………… 59

3. Remove valve lifter retainer bolts and valve guide retainer…………………………………………………………………………………………………………………………………………………………………………………. 59

4. Remove the valve guides and valve lifters…………………………………………………………………………………………………………………………………………………………………………………………………. 59

5. Remove the lifters one at a time using J 9290-01/J 3049 or equivalent and place them in an organizer rack………………………………………………………………………………………………………………………………………… 60

6. Store all reusable components in an exact order, so they may be reassembled in the same wear pattern location from which they were removed…………………………………………………………………………………………………………… 60

Clean:………………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 60

1. Mark, sort and organize the components for assembly………………………………………………………………………………………………………………………………………………………………………………………… 60

2. Clean the components with cleaning solvent………………………………………………………………………………………………………………………………………………………………………………………………… 60

3. Dry the components with compressed air……………………………………………………………………………………………………………………………………………………………………………………………………. 60

Inspect:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 60

4. Inspect the valve rocker arm components for the following:………………………………………………………………………………………………………………………………………………………………………………….. 60

5. Inspect the valve push rods for the following:…………………………………………………………………………………………………………………………………………………………………………………………….. 61

Valve Lifters and Guides Clean and Inspect………………………………………………………………………………………………………………………………………………………………………………………………………. 61

1. Mark, sort and organize the components for assembly………………………………………………………………………………………………………………………………………………………………………………………… 61

2. Clean the components with cleaning solvent………………………………………………………………………………………………………………………………………………………………………………………………… 61

3. Dry the components with compressed air……………………………………………………………………………………………………………………………………………………………………………………………………. 61

4. Inspect the valve lifter pushrod guides (1) for excessive wear, cracks or damage………………………………………………………………………………………………………………………………………………………………. 61

5. Inspect the valve lifter guide retainer for wear, damage or stress cracking in the leg areas (2) and wear or damage in the bolt holes (3)……………………………………………………………………………………………………………. 61

6. Inspect the valve lifter for the following:……………………………………………………………………………………………………………………………………………………………………………………………….. 61

Installation……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 61

Valve Lifter Installation……………………………………………………………………………………………………………………………………………………………………………………………………………………… 62

1. Apply lubricant GM P/N 12345501 or equivalent to the valve lifter rollers…………………………………………………………………………………………………………………………………………………………………….. 62

2. Install the valve lifters……………………………………………………………………………………………………………………………………………………………………………………………………………….. 62

Valve Lifter Pushrod Guides……………………………………………………………………………………………………………………………………………………………………………………………………………………. 62

3. Install the valve lifter pushrod guides…………………………………………………………………………………………………………………………………………………………………………………………………… 62

4. Tighten the valve lifter pushrod guide bolts to 25 N.m (18 lb. ft.)………………………………………………………………………………………………………………………………………………………………………….. 62

Valve Push Rod……………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 62

1. Install the valve pushrods………………………………………………………………………………………………………………………………………………………………………………………………………………. 62

Install Rocker Arm Assemblies………………………………………………………………………………………………………………………………………………………………………………………………………………….. 63

2. Install the following components:………………………………………………………………………………………………………………………………………………………………………………………………………… 63

Valve Lash Adjustment…………………………………………………………………………………………………………………………………………………………………………………………………………………………. 63

1. Turn the valve rocker arm nuts clockwise until all of the valve lash is removed……………………………………………………………………………………………………………………………………………………………….. 63

2. Turn the crankshaft clockwise until the alignment mark on the crankshaft balancer is aligned with the notch in the engine front cover tab……………………………………………………………………………………………………………. 63

3. Look at the number 1 cylinder valves as the crankshaft balancer alignment mark approaches the notch in the engine front cover………………………………………………………………………………………………………………………. 63

4. With the engine in the number 1 cylinder firing position, adjust the exhaust valves for cylinder numbers 1, 3, 4, and 8 and the intake valves for cylinder numbers 1, 2, 5, and 7 using the following process:………………………………………………. 63

5. Turn the crankshaft clockwise 1 revolution until the alignment mark on the crankshaft balancer is aligned with the notch in the engine front cover tab………………………………………………………………………………………………… 64

6. With the engine in the number 6 cylinder firing position, adjust the exhaust valves for cylinder numbers 2, 5, 6 and 7 and the intake valve for cylinder numbers 3, 4, 6 and 8 using the following process:…………………………………………………. 64

Valve Rocker Arm Cover Installation…………………………………………………………………………………………………………………………………………………………………………………………………………….. 64

1. Install the NEW valve rocker arm cover gasket into the groove of the valve rocker arm cover…………………………………………………………………………………………………………………………………………………….. 64

2. Install the NEW valve rocker arm cover bolt grommets into the valve rocker arm cover…………………………………………………………………………………………………………………………………………………………… 64

3. Install the valve rocker arm cover onto the cylinder head…………………………………………………………………………………………………………………………………………………………………………………… 64

4. Install the valve rocker arm cover bolts………………………………………………………………………………………………………………………………………………………………………………………………….. 64

5. Tighten the valve rocker arm cover bolts to 12 N.m (106 lb. in)……………………………………………………………………………………………………………………………………………………………………………… 64

Cylinder Head……………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 64

Removal……………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 64

1. Remove spark plugs……………………………………………………………………………………………………………………………………………………………………………………………………………………… 65

2. Remove cylinder head bolts………………………………………………………………………………………………………………………………………………………………………………………………………………. 65

3. Remove cylinder heads…………………………………………………………………………………………………………………………………………………………………………………………………………………… 65

4. Remove and discard head gaskets………………………………………………………………………………………………………………………………………………………………………………………………………….. 65

5. If required, remove the dowel pin (cylinder head locator)…………………………………………………………………………………………………………………………………………………………………………………… 66

Cylinder Head Disassemble and Recondition……………………………………………………………………………………………………………………………………………………………………………………………………….. 66

Disassemble:……………………………………………………………………………………………………………………………………………………………………………………………………………………………… 66

1. Compress the springs with J 8062……………………………………………………………………………………………………………………………………………………………………………………………………… 66

2. Remove the valve stem keys (1)……………………………………………………………………………………………………………………………………………………………………………………………………….. 67

3. Remove the J 8062 from the cylinder head………………………………………………………………………………………………………………………………………………………………………………………………. 67

4. Remove the valve spring cap (2)………………………………………………………………………………………………………………………………………………………………………………………………………. 67

5. Remove the valve spring (3)………………………………………………………………………………………………………………………………………………………………………………………………………….. 67

6. Remove the valve stem oil seal (4)……………………………………………………………………………………………………………………………………………………………………………………………………. 67

7. Discard the valve stem oil seal………………………………………………………………………………………………………………………………………………………………………………………………………. 67

8. Remove the valve……………………………………………………………………………………………………………………………………………………………………………………………………………………. 67

Cylinder Head Clean and Inspect………………………………………………………………………………………………………………………………………………………………………………………………………………… 67

Clean:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………… 67

1. Clean the valve stems and cylinder heads on a buffing wheel……………………………………………………………………………………………………………………………………………………………………………… 67

2. Clean the following components in cleaning solvent:…………………………………………………………………………………………………………………………………………………………………………………….. 67

3. Dry the components with compressed air………………………………………………………………………………………………………………………………………………………………………………………………… 67

4. Use the J 8089 to clean the carbon from the cylinder head combustion chambers……………………………………………………………………………………………………………………………………………………………… 67

5. Inspect the cylinder head for the following:…………………………………………………………………………………………………………………………………………………………………………………………… 67

Inspect:…………………………………………………………………………………………………………………………………………………………………………………………………………………………………. 68

6. Measure the cylinder head for warping with a straight edge and feeler gauge……………………………………………………………………………………………………………………………………………………………….. 68

Valve Spring Tension………………………………………………………………………………………………………………………………………………………………………………………………………………………. 68

1. Use the J 9666 in order to measure the valve spring…………………………………………………………………………………………………………………………………………………………………………………….. 68

Valve Spring Straightness……………………………………………………………………………………………………………………………………………………………………………………………………………………… 68

2. Inspect the valve springs for Straightness………………………………………………………………………………………………………………………………………………………………………………………………… 68

Valve Stems………………………………………………………………………………………………………………………………………………………………………………………………………………………………….. 69

3. Valve stems (1) with excessive valve guide (2) clearance must be repaired or the cylinder head replaced………………………………………………………………………………………………………………………………………….. 69

4. Measure the valve stem-to-guide clearance…………………………………………………………………………………………………………………………………………………………………………………………………. 69

a. Clamp the J 8001 on the exhaust port side of the cylinder head…………………………………………………………………………………………………………………………………………………………………………… 69

b. Position the dial indicator so that the movement of the valve stem from side to side (crosswise to the cylinder head) will ca…………………………………………………………………………………………………………………… 69