$34

Volvo Penta 5.0GL-ABCDE- 5.7GXI-A B C D F Engine Workshop Manual_81843740 – PDF DOWNLOAD

Volvo Penta 5.0GL-ABCDE- 5.7GXI-A B C D F Engine Workshop Manual_81843740 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta 5.0GL-ABCDE- 5.7GXI-A B C D F Engine Workshop Manual_81843740 – PDF DOWNLOAD

Language : English

Pages : 250

Downloadable : Yes

File Type : PDF

Size: 10.9 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta 5.0GL-ABCDE- 5.7GXI-A B C D F Engine Workshop Manual_81843740 – PDF DOWNLOAD

5.0GL-A/ Bl Cl 0] E 5.7GXi-A/B/C(F)/D(F)/E(F)/F(F)5.0GXi-A/B(F)lC(F)/D(F)/ E(F) 5.7OSi-A(F)/B(F)lC(F)/D(F)IE(F)5.00OSi-B(F)/C(F)lD(F)/E(F) 5.7OSXi-A(F)/B(F)/C(F)/D(F)/E(F)5.7GL-A/B/C/D/E 5.7GiI-A/B/C/D/ F5.7Gi-A/B(F)/C(F)/D(F)/E(F) 5.7GXi-A/ B/ C/ D/ FGood Service Practice Service required for stern drives is generally one of three kinds:

• Normal care and maintenance – which includes putting a new

stern drive into operation, storing engines, lubrication, and care

under special operating conditions such as salt water and cold

weather.

• Operating malfunctions – due to improper engine or drive

mounting, propeller condition or size, boat condition, or the malfunction

of some part of the engine. This includes engine servicing

procedures to keep the engine in prime operating condition.

• Complete disassembly and overhaul – such as major service

or rebuilding a unit.

It is important to determine before disassembly just what the trouble is

and how to correct it quickly, with minimum expense to the owner.

When repairing an assembly, the most reliable way to ensure a good

job is to do a complete overhaul on that assembly, rather than just to

replace the bad part. Wear not readily apparent on other parts could

cause malfunction soon after the repair job. Repair kits and seal kits

contain all the parts needed to ensure a complete repair, to eliminate

guesswork, and to save time.

Repair time can also be minimized by the use of special tools. Volvo

Penta special tools are designed to perform service procedures

unique to the product that cannot be completed using tools from other

sources. They also speed repair work to help achieve service flat rate

times. In some cases, the use of substitute tools can damage the part.

Preparation for Service Proper preparation is extremely helpful for efficient service work. A

clean work area at the start of each job will minimize tools and parts

becoming misplaced. Clean an engine that is excessively dirty before

work starts. Cleaning will occasionally uncover trouble sources. Obtain

tools, instruments and parts needed for the job before work is started.

Interrupting a job to locate special tools or repair kits is a needless

delay.

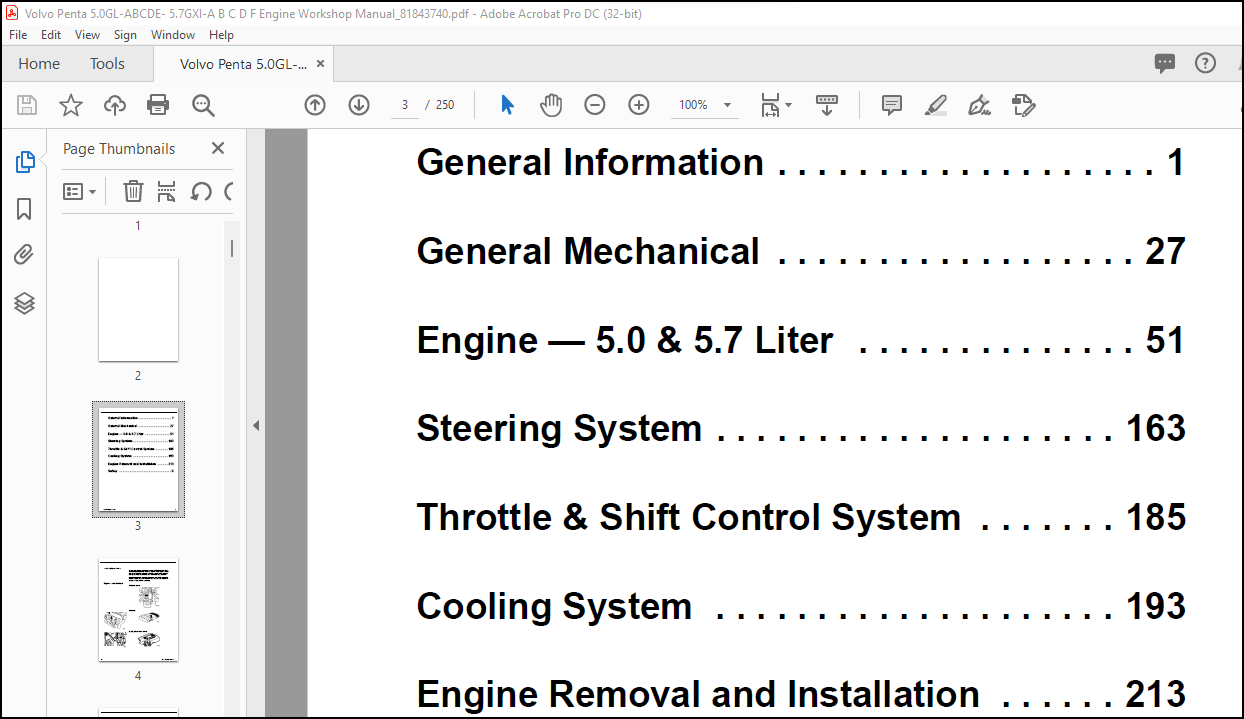

TABLE OF CONTENTS:

Volvo Penta 5.0GL-ABCDE- 5.7GXI-A B C D F Engine Workshop Manual_81843740 – PDF DOWNLOAD

Model Identification………………………………………………………………………………………………………….. 4

Engine Model Number…………………………………………………………………………………………………………… 4

Emission Control Labels……………………………………………………………………………………………………….. 5

Transom Shield Model Number Location……………………………………………………………………………………………. 6

Sterndrive Model Number Location……………………………………………………………………………………………….. 6

Section 1: General Information…………………………………………………………………………………………………. 7

Tuning the Engine…………………………………………………………………………………………………………. 9

Engine Compression Testing……………………………………………………………………………………………… 10

Test Conclusion……………………………………………………………………………………………………….. 10

Ignition System Components……………………………………………………………………………………………… 11

Fuel System Components…………………………………………………………………………………………………. 11

Intake Manifold Vacuum Testing………………………………………………………………………………………….. 12

Gasoline Requirements………………………………………………………………………………………………….. 14

Gasoline Containing Alcohol…………………………………………………………………………………………….. 14

Crankcase Oil…………………………………………………………………………………………………………….. 15

Steering System Lubrication………………………………………………………………………………………………… 16

Power Trim/Tilt Fluid Level………………………………………………………………………………………………… 17

Off-Season Storage………………………………………………………………………………………………………… 17

Preparation for Boating After Storage……………………………………………………………………………………….. 19

Engine Break-in…………………………………………………………………………………………………………… 20

Submerged Engine………………………………………………………………………………………………………….. 22

20-Hour Check…………………………………………………………………………………………………………….. 22

Belt Tension……………………………………………………………………………………………………………… 23

Alternator Belt Adjustment……………………………………………………………………………………………… 23

Power Steering Pump Belt Adjustment……………………………………………………………………………………… 23

Positive Closed-Type Ventilation System……………………………………………………………………………………… 24

Troubleshooting – System Isolation………………………………………………………………………………………….. 25

Engine Troubleshooting Guides………………………………………………………………………………………………. 25

Engine Will Not Crank………………………………………………………………………………………………….. 27

Engine Cranks, But Will Not Start……………………………………………………………………………………….. 27

Hard Starting – Cold Engine…………………………………………………………………………………………….. 28

Hard Starting – Hot Engine……………………………………………………………………………………………… 28

Engine Runs Rough……………………………………………………………………………………………………… 28

Engine Noises and Vibrations……………………………………………………………………………………………. 29

Engine Overheats – Check:………………………………………………………………………………………………. 30

Engine Dies Out……………………………………………………………………………………………………….. 30

Engine Won’t Reach Operating RPM – Check:………………………………………………………………………………… 31

Defective Engine Lubricating System……………………………………………………………………………………… 31

Low Battery Voltage After Short Storage………………………………………………………………………………….. 31

Section 2: General Mechanical………………………………………………………………………………………………….. 33

General Description……………………………………………………………………………………………………….. 33

Cleanliness and Care………………………………………………………………………………………………………. 34

Use of RTV Sealer and Anaerobic Gasket Eliminator…………………………………………………………………………….. 34

Replacing Engine Gaskets…………………………………………………………………………………………………… 35

Cylinder Bores……………………………………………………………………………………………………………. 36

Piston and Connecting Rod………………………………………………………………………………………………….. 39

Measuring Piston Pin to Piston Clearance…………………………………………………………………………………….. 40

Piston Selection………………………………………………………………………………………………………….. 41

Assembling the Piston and Connecting Rod…………………………………………………………………………………….. 41

Installing the Piston Rings………………………………………………………………………………………………… 42

Camshaft Bearings…………………………………………………………………………………………………………. 44

Camshaft Bearing Removal……………………………………………………………………………………………….. 44

Camshaft Measurements………………………………………………………………………………………………….. 44

Cylinder Head…………………………………………………………………………………………………………….. 46

Valve Grinding………………………………………………………………………………………………………… 48

Valves and components………………………………………………………………………………………………….. 49

Crankshaft and Connecting Rod Bearings………………………………………………………………………………………. 49

Thread Repair…………………………………………………………………………………………………………….. 52

Special Tools…………………………………………………………………………………………………………….. 54

Section 3: Engine – 5.0 & 5.7 Liter…………………………………………………………………………………………….. 57

General Description……………………………………………………………………………………………………….. 58

Tools and Shop Equipment…………………………………………………………………………………………………… 59

Accessories………………………………………………………………………………………………………………. 59

Cleaning…………………………………………………………………………………………………………………. 60

Draining The Engine……………………………………………………………………………………………………….. 60

Engine Lubrication………………………………………………………………………………………………………… 60

Exhaust Manifold………………………………………………………………………………………………………….. 61

Starter………………………………………………………………………………………………………………….. 63

Intake Manifold…………………………………………………………………………………………………………… 64

Remove Distributor, Gi and GXi Models……………………………………………………………………………………. 66

Disassemble Intake Manifold (GXi-B and later only)………………………………………………………………………… 68

Assemble Intake Manifold……………………………………………………………………………………………….. 71

Intake Manifold Installation……………………………………………………………………………………………. 72

Distributor Installation……………………………………………………………………………………………….. 73

Rocker Arm Cover………………………………………………………………………………………………………….. 78

Valve Train………………………………………………………………………………………………………………. 78

Valve Lifters and Guides Clean and Inspect……………………………………………………………………………….. 81

Valve Lifter Installation………………………………………………………………………………………………. 82

Valve Lifter Pushrod Guides…………………………………………………………………………………………….. 83

Valve Push Rod………………………………………………………………………………………………………… 83

Install Rocker Arm Assemblies…………………………………………………………………………………………… 83

Valve Lash Adjustment………………………………………………………………………………………………….. 84

Valve Rocker Arm Cover Installation……………………………………………………………………………………… 85

Cylinder Head…………………………………………………………………………………………………………….. 85

Cylinder Head Disassemble and Recondition………………………………………………………………………………… 87

Cylinder Head Clean and Inspect…………………………………………………………………………………………. 88

Valve Spring Straightness………………………………………………………………………………………………. 89

Valve Stems…………………………………………………………………………………………………………… 89

Valve Guide Reaming and Seat Grinding……………………………………………………………………………………. 90

Valve Rocker Arm Stud Removal…………………………………………………………………………………………… 92

Valve Rocker Arm Stud Installation………………………………………………………………………………………. 92

Cylinder Head Assemble…………………………………………………………………………………………………. 93

Install Oil Seal………………………………………………………………………………………………………. 93

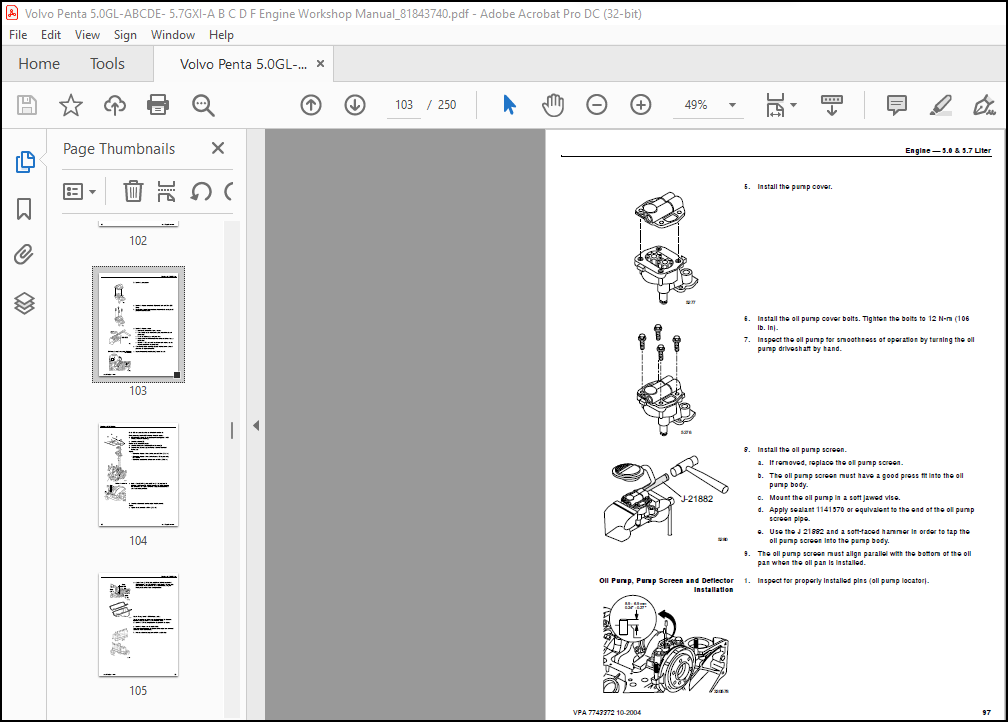

Oil Pan and OIl Pump………………………………………………………………………………………………………. 97

Oil Pan Clean and Inspect………………………………………………………………………………………………. 98

Oil Pump Disassemble……………………………………………………………………………………………………100

Oil Pump Clean and Inspect………………………………………………………………………………………………101

Water Pump………………………………………………………………………………………………………………..106

Water Pump Installation…………………………………………………………………………………………………109

Crankshaft Balancer………………………………………………………………………………………………………..111

Crankshaft Balancer Inspect……………………………………………………………………………………………..112

Crankshaft Balancer Installation…………………………………………………………………………………………112

Engine Front Cover…………………………………………………………………………………………………………114

Engine Front Cover Installation………………………………………………………………………………………….115

Timing Chain and Sprocket……………………………………………………………………………………………….116

Camshaft………………………………………………………………………………………………………………120

Camshaft Bearings………………………………………………………………………………………………………….123

Piston, Connecting Rod, and Bearings…………………………………………………………………………………………127

Piston and Connecting Rod Disassemble…………………………………………………………………………………….129

Clean and Inspect………………………………………………………………………………………………………130

Piston Selection……………………………………………………………………………………………………….133

Engine Coupler…………………………………………………………………………………………………………….138

Flywheel………………………………………………………………………………………………………………….141

Crankshaft Rear Oil Seal and Housing…………………………………………………………………………………………142

Crankshaft………………………………………………………………………………………………………………..145

Crankshaft and Bearings Clean and Inspect…………………………………………………………………………………147

Measuring Crankshaft Bearing Clearances…………………………………………………………………………………..150

Micrometer Method for Crankshaft Bearings…………………………………………………………………………………150

Recondition Engine Block……………………………………………………………………………………………………155

Engine Block Plug………………………………………………………………………………………………………155

Engine Block Clean and inspect…………………………………………………………………………………………..158

Cylinder Boring and Honing………………………………………………………………………………………………159

Boring Procedure……………………………………………………………………………………………………….160

Engine Specifications………………………………………………………………………………………………………161

Tune Up Specifications……………………………………………………………………………………………………..167

Section 4: Steering System……………………………………………………………………………………………………..169

Special Tools……………………………………………………………………………………………………………..169

Volvo Penta Special Tools……………………………………………………………………………………………….169

Kent-Moore Special Tools………………………………………………………………………………………………..169

Power Steering System………………………………………………………………………………………………………170

Description……………………………………………………………………………………………………………170

Pump Operation…………………………………………………………………………………………………………….171

System Operation…………………………………………………………………………………………………………..172

Pump Removal………………………………………………………………………………………………………………173

Pump Installation………………………………………………………………………………………………………….175

Hydraulic Fluid……………………………………………………………………………………………………………176

Checking Fluid Level……………………………………………………………………………………………………176

Purging Air From Steering System…………………………………………………………………………………………….177

Power Steering Pump Belt Adjustment………………………………………………………………………………………….177

Steering Cylinder………………………………………………………………………………………………………….178

Cylinder Removal…………………………………………………………………………………………………………..179

Cylinder Servicing…………………………………………………………………………………………………………180

Cylinder Installation………………………………………………………………………………………………………181

Cable Installation…………………………………………………………………………………………………………182

Lubrication……………………………………………………………………………………………………………….183

Hoses…………………………………………………………………………………………………………………….184

System Diagnosis…………………………………………………………………………………………………………..184

System Checks………………………………………………………………………………………………………….184

Tie Bar Adjustment – Twin Engine Installation…………………………………………………………………………………184

Power Steering System Diagnosis Chart…………………………………………………………………………………….185

External Leakage…………………………………………………………………………………………………………..186

General Procedure………………………………………………………………………………………………………186

Leakage Checks…………………………………………………………………………………………………………186

Easily Fixed Leaks……………………………………………………………………………………………………..186

Pump Leakage………………………………………………………………………………………………………………187

Pump Pressure Test……………………………………………………………………………………………………..187

Cable Installation Problems…………………………………………………………………………………………………188

Feedback To The Helm……………………………………………………………………………………………………….189

Section 5: Throttle & Shift Control System……………………………………………………………………………………….191

Installation of Shift and Throttle Cables…………………………………………………………………………………….191

Check Remote Control Shift Cable Stroke…………………………………………………………………………………..192

Installation of SAE Cables to Engine/ Drive……………………………………………………………………………….192

Throttle Cable to Engine………………………………………………………………………………………………..195

Neutral Start Switch Tests………………………………………………………………………………………………….197

Electrical…………………………………………………………………………………………………………….197

Mechanical…………………………………………………………………………………………………………….197

Removal of SAE Remote Control Cables…………………………………………………………………………………………197

Throttle Cable From Engine………………………………………………………………………………………………198

Shift Cable From Sterndrive……………………………………………………………………………………………..198

Section 6: Cooling System………………………………………………………………………………………………………199

Description……………………………………………………………………………………………………………….199

Raw Water Cooled Engines………………………………………………………………………………………………..199

Closed Cooling Engines………………………………………………………………………………………………….201

Cooling System Troubleshooting………………………………………………………………………………………………202

Isolating Cooling Problem:………………………………………………………………………………………………203

Cooling System Components…………………………………………………………………………………………………..204

Hoses, Clamps, and Drain Plugs…………………………………………………………………………………………..204

Thermostat…………………………………………………………………………………………………………….204

Manifolds and Elbows……………………………………………………………………………………………………204

Circulating Pump – Engine……………………………………………………………………………………………….204

Supply Pump……………………………………………………………………………………………………………205

Impeller Removal……………………………………………………………………………………………………….205

Impeller Installation…………………………………………………………………………………………………..207

Draining Engine Block or Exhaust Manifold…………………………………………………………………………………….208

Draining Supply Pump……………………………………………………………………………………………………210

Thermostat Replacement………………………………………………………………………………………………….210

Sterndrive and Transom Bracket Cooling Schematic………………………………………………………………………………213

5.0/5.7GL Engine Cooling Diagram…………………………………………………………………………………………….214

5.0GXi-A, 5.7Gi-A, 5.7GXi-A/B Cooling Diagram…………………………………………………………………………………215

5.0GXi-B/C/D/E, 5.0OSi-B/C/D/E, 5.7Gi-B/C/D/E, 5.7OSi-A/B/C/D, 5.7GXi-C/D/E/ F, 5.7OSXi-A/B/C/D Cooling Diagram………………………216

5.0GXi-BF/CF/DF/EF, 5.0OSi BF/CF/DF/EF, 5.7Gi-BF/CF/DF/EF, 5.7OSi-AF/BF/ CF/DF, 5.7GXi-CF/DF/EF/FF 5.7OSXi-AF/BF/CF/DF Cooling Diagram….217

Section 7: Engine Removal and Installation……………………………………………………………………………………….219

Special Tools……………………………………………………………………………………………………………..219

Sealants, Lubricants and Adhesives…………………………………………………………………………………………..219

Engine Removal…………………………………………………………………………………………………………….219

Exhaust Pipe Replacement………………………………………………………………………………………………..223

Engine Installation…………………………………………………………………………………………………….224

Engine Alignment……………………………………………………………………………………………………….225

Connect Exhaust Hose……………………………………………………………………………………………………226

Connect Throttle Cable………………………………………………………………………………………………….226

Connect Fuel Supply…………………………………………………………………………………………………….231

Rear Engine Mounts…………………………………………………………………………………………………………231

Determining Minimum Engine Height……………………………………………………………………………………………233