$33

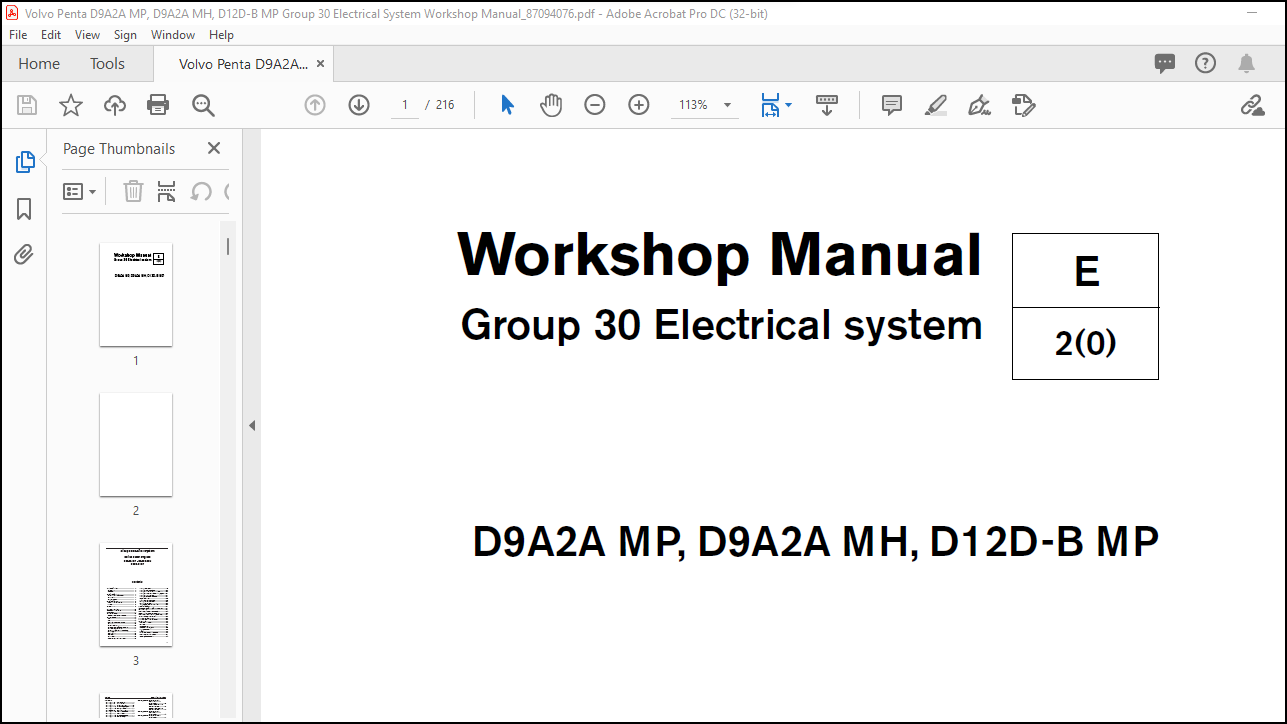

Volvo Penta D9A2A MP, D9A2A MH, D12D-B MP Group 30 Electrical System Workshop Manual_87094076 – PDF

Volvo Penta D9A2A MP, D9A2A MH, D12D-B MP Group 30 Electrical System Workshop Manual_87094076 – PDF

FILE DETAILS:

Volvo Penta D9A2A MP, D9A2A MH, D12D-B MP Group 30 Electrical System Workshop Manual_87094076 – PDF

Language : English

Pages : 216

Downloadable : Yes

File Type : PDF

Size: 1.2 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta D9A2A MP, D9A2A MH, D12D-B MP Group 30 Electrical System Workshop Manual_87094076 – PDF

General information:

About this Workshop Manual:

This Workshop Manual contains descriptions and instructions for the repair of marine diesel engines D9A2A MP, D9A2A MH and D12D-B MP. The engine designation and number are noted on the number plate and engine decal. The engine designation and number must always be given in all correspondence about any product.

- The Workshop Manual is produced primarily for the use of Volvo Penta workshops and service technicians. This assumes that people who use the Manual have basic knowledge of marine drive systems and can do the tasks of a mechanical or electrical nature associated with the trade.

- Volvo Penta constantly improves its products, so we reserve the right to make modifications without prior notification. All information in this manual is based on product data which was available up to the date on which the manual was printed. Any material changes introduced into the product or service methods after this date are notified by means of Service Bulletins.

Spare parts:

Spare parts for electrical- and fuel systems are subject to various national safety requirements, such as U.S. Coast Guard Safety Regulations. Volvo Penta Original Spare Parts meet these specifications. Any damage, occasioned by use of non–original Volvo Penta spares for the product, will be not be compensated by the warranty offered by Volvo Penta.

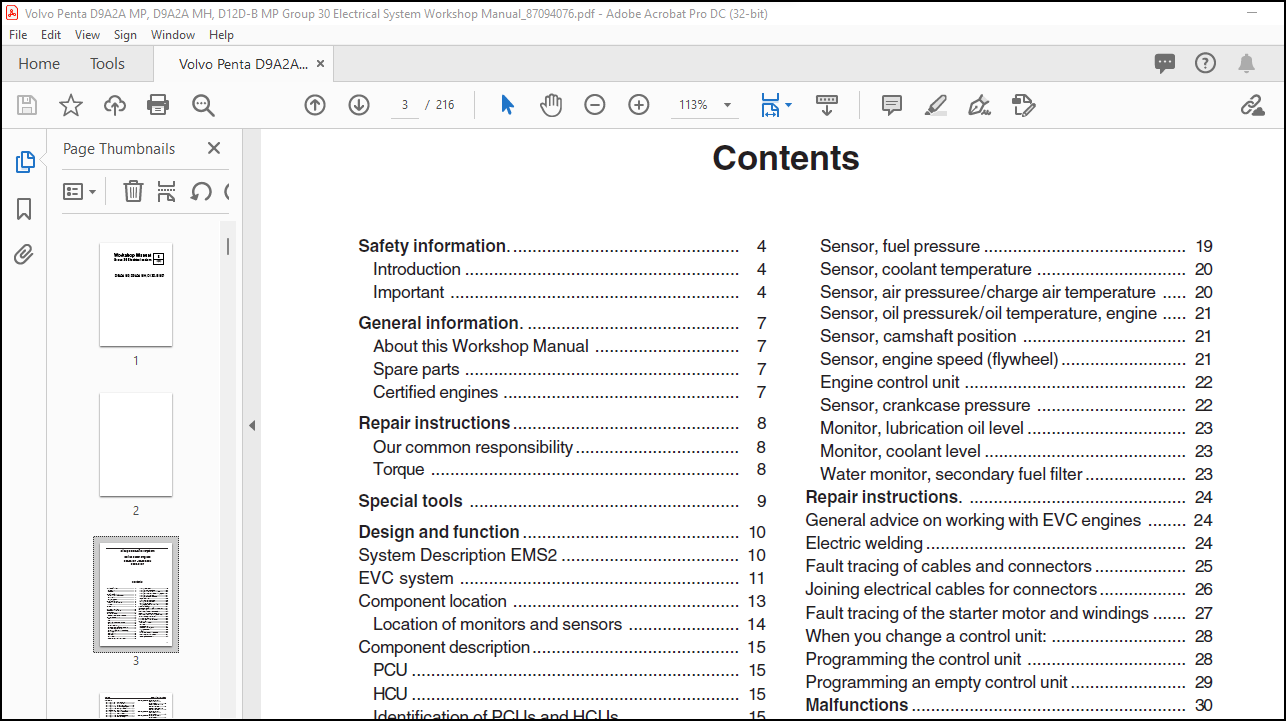

TABLE OF CONTENTS:

Volvo Penta D9A2A MP, D9A2A MH, D12D-B MP Group 30 Electrical System Workshop Manual_87094076 – PDF

Safety information 4

Introduction 4

Important 4

General information 7

About this Workshop Manual 7

Spare parts 7

Certified engines 7

Repair instructions 8

Our common responsibility 8

Torque 8

Special tools 9

Design and function 10

System Description EMS2 10

EVC system 11

Component location 13

Location of monitors and sensors 14

Component description 15

PCU 15

HCU 15

Identification of PCUs and HCUs 15

Controls 16

AUX stop button 16

Solenoid valves, forwardsm– reverse 17

Solenoid valve, low speed 17

Sensor, oil pressuree/oil temperature,

reversing gear 17

Starter motor 18

Alternator 18

Unit injector 19

Piston cooling monitor (D12-800) 19

Sensor, fuel pressure 19

Sensor, coolant temperature 20

Sensor, air pressuree/charge air temperature 20

Sensor, oil pressurek/oil temperature, engine 21

Sensor, camshaft position 21

Sensor, engine speed (flywheel) 21

Engine control unit 22

Sensor, crankcase pressure 22

Monitor, lubrication oil level 23

Monitor, coolant level 23

Water monitor, secondary fuel filter 23

Repair instructions 24

General advice on working with EVC engines 24

Electric welding 24

Fault tracing of cables and connectors 25

Joining electrical cables for connectors 26

Fault tracing of the starter motor and windings 27

When you change a control unit: 28

Programming the control unit 28

Programming an empty control unit 29

Malfunctions 30

Fault code information 30

FMI table 30

General advice 31

System introduction, EVC 32

Starting sequence 32

Network 33

Manual fault tracing in bus cables 33

Fault tracing the EVC system 34

Checking the instruments 35

Fault codes

MID 128, PID 94 Fuel pressure 36

MID 128, PID 97 Water in fuel 41

MID 128, PID 98 Oil level (engine) 44

MID 128, PID 100 Oil pressure, (engine) 47

MID 128, PID 105 Charge air temperature 52

MID 128, PID 106 Charge air pressure 56

MID 128, PID 110 Coolant temperature 61

MID 128, PID 111 Coolant level 65

MID 128, PID 153 Crankcase pressure 68

MID 128, PID 158 Battery voltage 73

MID 128, PID 163 Selected gear 74

MID 128, PID 175 Oil temperature, engine 75

MID 128, PPID 3 Starting relay fault 79

MID 128, PPID 6 External stopping relay 82

MID 128, PPID 8 Piston cooling pressure

(D12-800) 84

MID 128, PPID 98 Engine synchronisation 86

MID 128, PPID 132 Throttle position 87

MID 128, SID 1-6 Unit injectors 1-6 88

MID 128, SID 21 Sensor for camshaft

position (speed sensor,

camshaft) 94

MID 128, SID 22 Speed sensor (flywheel) 97

MID 128, SID 32 Waste gate (D12-800) 100

MID 128, SID 232 5 Volt DC Supply current 102

MID 128, SID 240 Program memory fault 104

MID 128, SID 254 Engine control unit 105

MID 128, PSID 216 Communication fault

J1939 106

MID 128, SID 231 Communication fault

J1939 108

MID 164, PPID 390 Voltagesupplyfault

control 1 in relation to

potentiometer 110

Checking potentiometer in

electronic controls 112

Changing potentiometer in

electronic controls 114

MID 164, PPID 391 Voltagesupplyfault

control 2 in relation to

potentiometer 115

MID 164, PPID 392 Voltagesupply control

potentiometer 117

MID 164, PPID 393 /

MID 187, PPID 393 Power supply

data bus 119

MID 164, PPID 394 Power supply

starter switch 121

Checking the starter

switch 122

MID 164, PPID 397 Main panel lost

communication 123

MID 164, SID 226 Mismatch between

neutral switch and

throttle control 125

MID 164, SID 231 Communication fault,

synchronization bus 127

MID 164, SID 240 /

MID 187, SID 240 Program memory fault 129

MID 164, SID 250 SAE J1708 / J1587

data line 13

MID 164, SID 253 /

MID 187, SID 253 Node configuration fault /

memory fault, calibration 131

MID 164, SID 254 /

MID 187, SID 254 Internal CPU fault 133

MID 164, PSID 95 Control detection 134

MID 164, PSID 96 Too short lever movement

calibrated 136

MID 164, PSID 97 Control calibration

procedure 137

MID 164, PSID 98 Control(s) is/are not

calibrated 138

MID 164, PSID 105 Activation button,

control station 139

MID 164, PSID 106 Start 141

MID 164, PSID 107 Stop 143

MID 164, PSID 218 Communication fault,

data bus, passive /

active control station 145

MID 164, PSID 226 HCU communication fault

to another control station 147

MID 164, PSID 231 Incompatible EVC nodes 149

3

Group 30: Electrical system Contents

MID 187, PID 96 Fuel level 150

MID 187, PID 127 Oil pressure

(reversing gear) 152

MID 187, PID 177 Oil temperature

(reversing gear) 155

MID 187, PID 191 Low speed with feedback 158

MID 187, PPID 400 Power supply, reversing

gear sensor 160

MID 187, SID 231 J1939 Communications

warning / fault 162

MID 187, SID 250 J1587 / J1708 Communication

warning / fault 164

MID 187, PSID 10 Incompatible engine type 166

MIS 187, PSID 16 /

MID 164, PSID 94 Incompatible software,

EVC 167

MID 187, PSID 17 /

MID 164, PSID 99 Configuration fault, data

bus network 168

MID 187, PSID 18 Data bus supply voltage 170

MID 187, PSID 20 Primary solenoid valve 172

MID 187, PSID 22 Secondary solenoid valve 176

MID 187, PSID 32 Data bus, communication

fault with active control

station 178

MID 187, PSID 200 No data on the motor bus 180

MID 187, PSID 226 Data bus, communication

fault with passive /

active helm station 182

MID 187, PSID 231 Incompatible EVC nodes 184

MID 187, PSID 232 /

MID 164, PSID 232 Communication warning

data bus 185

© 2005 AB VOLVO PENTA

We reserve the right to make modifications without prior notice Printed on environmentally compatible paper

Wiring diagram 188

D9-500, D9-575 188

D12-800 190

Twin engine installation 192

Controls 193

Pin configuration, PCU 194

Pin configuration, HCU 195

Automatic configuration and calibration

before starting 196

Calibration procedure, example of workflow 196

Combinations of control levers for EVC

Overview, calibration 197

Preparations 198

Auto configuration 198

Calibration Electronic single lever control 199

Calibration Alternative control station

(without starter switch) 200

Calibration Idling 201

Calibration Mechanical twin lever control,

single / twin Electronically shifted

reversing gear 202

Calibration Mechanical twin lever control,

single / twin Mechanically shifted

reversing gear 203

Checking propeller rotation 204

References to Service Bulletins 205

Technical data 206

Index 208