$33

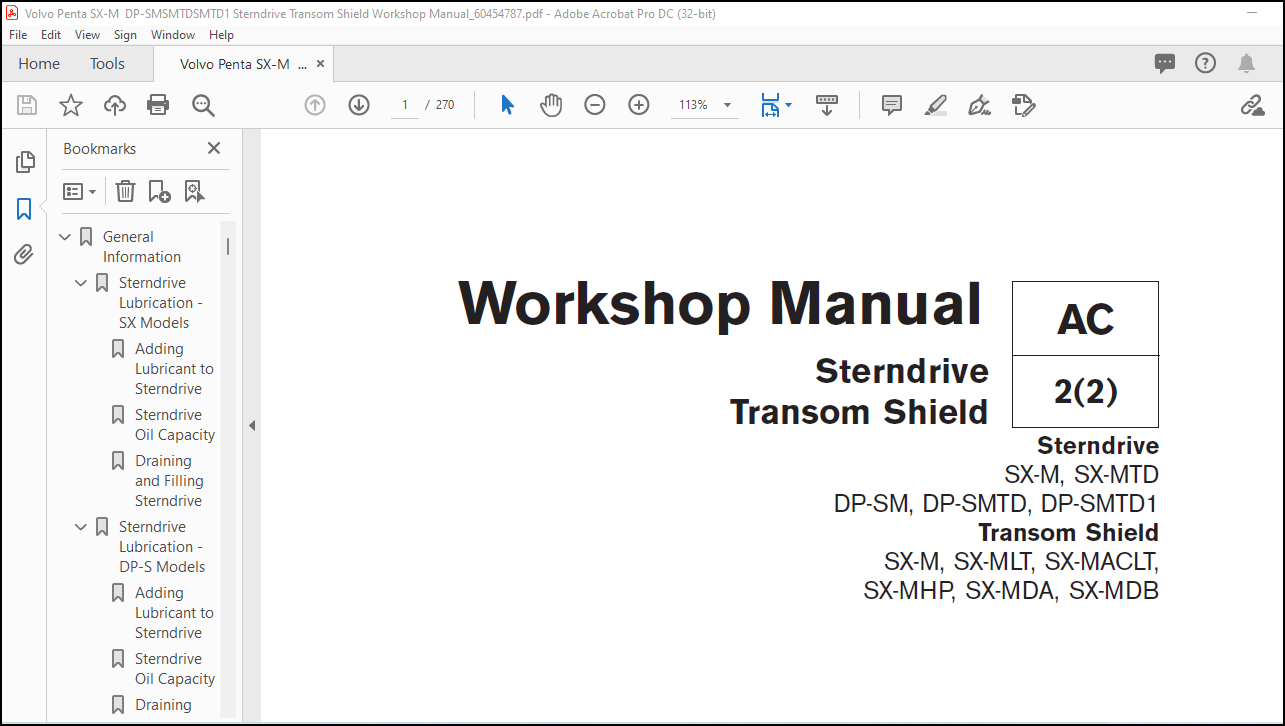

Volvo Penta SX-M DP-SMSMTDSMTD1 Sterndrive Transom Shield Workshop Manual_60454787 – PDF DOWNLOAD

Volvo Penta SX-M DP-SMSMTDSMTD1 Sterndrive Transom Shield Workshop Manual_60454787 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta SX-M DP-SMSMTDSMTD1 Sterndrive Transom Shield Workshop Manual_60454787 – PDF DOWNLOAD

Language : English

Pages : 270

Downloadable : Yes

File Type : PDF

Size: 6.12 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta SX-M DP-SMSMTDSMTD1 Sterndrive Transom Shield Workshop Manual_60454787 – PDF DOWNLOAD

Sterndrive

SX-M, SX-MTD

DP-SM, DP-SMTD, DP-SMTD1

Transom Shield

SX-M, SX-MLT, SX-MACLT,

SX-MHP, SX-MDA, SX-MDB

Good Service Practice:

Service required for this product is generally one of three kinds:

• Normal care and maintenance – which includes putting a new

stern drive into operation, storing engines, lubrication, and care

under special operating conditions such as salt water and cold

weather.

• Operating malfunctions – due to improper engine or drive

mounting, propeller condition or size, boat condition, or the malfunction

of some part of the engine. This includes engine servicing

procedures to keep the engine in prime operating condition.

• Complete disassembly and overhaul – such as major service

or rebuilding a unit.

It is important to determine before disassembly just what the trouble is

and how to correct it quickly, with minimum expense to the owner.

When repairing an assembly, the most reliable way to ensure a good

job is to do a complete overhaul on that assembly, rather than just to

replace the bad part. Wear not readily apparent on other parts could

cause a malfunction soon after the repair job. Repair kits and seal kits

contain all the parts needed to ensure a complete repair, to eliminate

guesswork, and to save time.

Repair time can also be minimized by the use of special tools. Volvo

Penta Special Tools are designed to perform service procedures

unique to the product that cannot be completed using tools from other

sources. They also speed repair work to help achieve service flat rate

times. In some cases, the use of substitute tools can damage the part.

Note! Do not operate engine out of water even momentarily. If

operated in test tank, use proper test wheel. Failure to do

so can damage water pump, overheat engine, or allow

excessive engine RPM.

Preparation for Service :

Proper preparation is extremely helpful for efficient service work. A

clean work area at the start of each job will minimize tools and parts

becoming misplaced. Clean an engine that is excessively dirty before

work starts. Cleaning will occasionally uncover trouble sources. Obtain

tools, instruments and parts needed for the job before work is started.

Interrupting a job to locate special tools or repair kits is a needless

delay.

Use proper lifting and handling equipment. Working on stern drives without proper

equipment can cause damage and personal injury.

Always use clean fresh fuel when testing engines. Troubles can often

be traced to the use of old or dirty fuel.

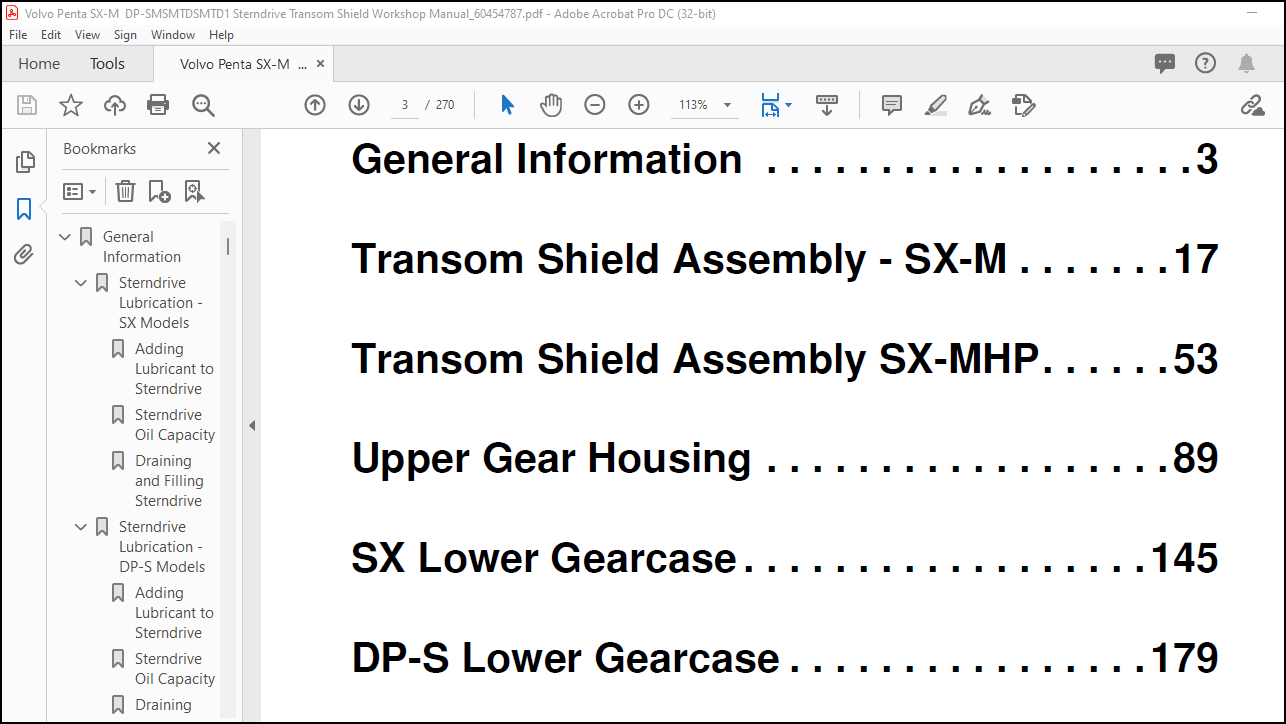

TABLE OF CONTENTS:

Volvo Penta SX-M DP-SMSMTDSMTD1 Sterndrive Transom Shield Workshop Manual_60454787 – PDF DOWNLOAD

General Information…………………………………………. 5

Sterndrive Lubrication – SX Models………………………… 8

Adding Lubricant to Sterndrive………………………… 8

Sterndrive Oil Capacity………………………………. 8

Draining and Filling Sterndrive……………………….. 8

Sterndrive Lubrication – DP-S Models………………………. 10

Adding Lubricant to Sterndrive………………………… 10

Sterndrive Oil Capacity………………………………. 10

Draining and Filling Sterndrive……………………….. 10

Power Trim/Tilt-Fluid Level…………………………… 11

Off -Season Storage Preparations – All Models………………. 11

Painting……………………………………………. 11

Preparation for Boating After Storage………………….. 12

Gimbal Bearing and Inspect Universal Joint bellow……….. 12

Recommendations For Antifouling Paints…………………. 13

Painting The Stern Drive With Antifouling Paint…………. 14

Paints For Stern drives………………………………. 14

Painting The Hull With Antifouling Paint……………….. 14

Metric Conversion Chart………………………………. 15

Periodic Maintenance Chart……………………………. 18

Transom Shield Assembly – SX-M……………………………….. 19

Special Tools…………………………………………… 20

Trim/Tilt Cylinder Removal……………………………….. 20

Trim/Tilt Cylinder Installation…………………………… 22

Pivot Housing Removal……………………………………. 23

Pivot Housing Disassembly………………………………… 25

Pivot Housing Assembly…………………………………… 26

Pivot Housing Installation……………………………….. 26

Gimbal Ring Removal……………………………………… 28

Gimbal Ring Disassembly………………………………….. 30

Gimbal Ring Assembly…………………………………….. 31

Gimbal Ring Installation…………………………………. 32

Trim Sender Adjustment…………………………………… 35

Gimbal Housing Disassembly……………………………….. 36

Water Hose and Bellows Removal………………………… 36

Anode Replacement……………………………………. 36

Trim Sender Removal………………………………….. 37

Water Tube Removal…………………………………… 37

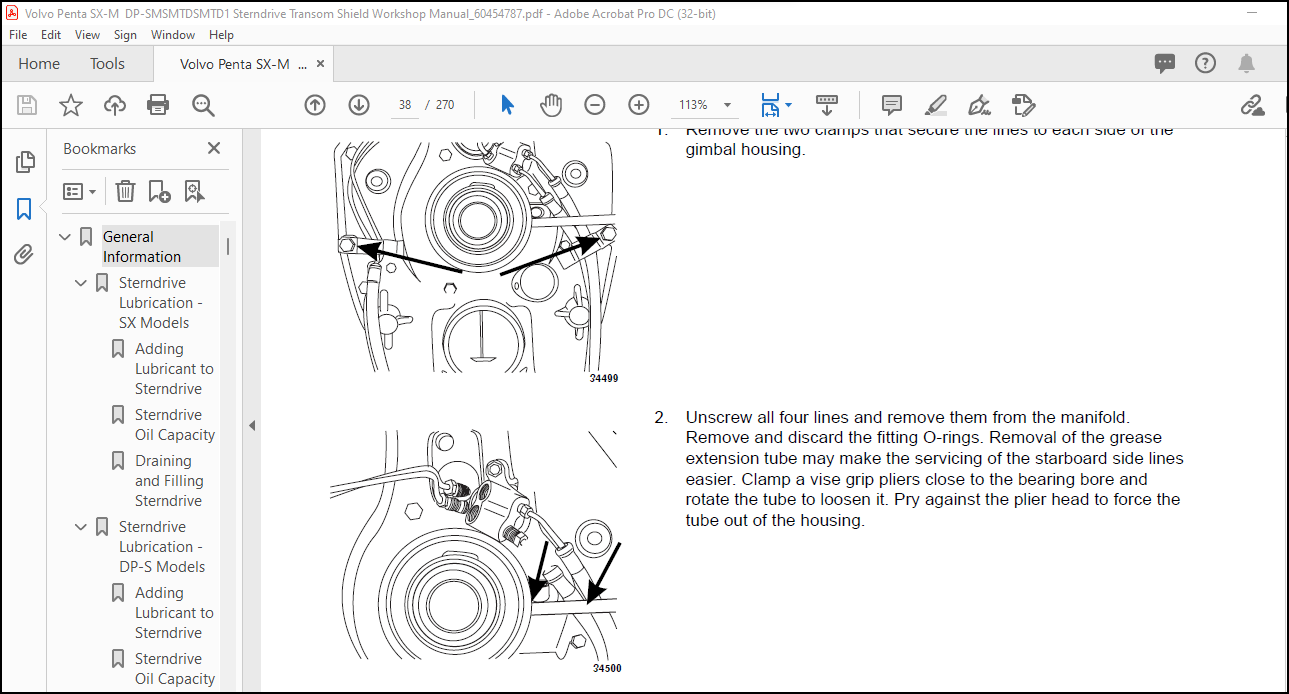

Hydraulic Lines and Manifold Removal…………………… 38

Steering, Gimbal Bearing and Seal Removal………………. 39

Gimbal Housing Cleaning and Inspection…………………. 39

Gimbal Housing Assembly………………………………….. 40

Steering Bearing, Gimbal Bearing and Seal Installation…… 40

Hydraulic Lines and Manifold Installation………………. 41

Trim Sender Installation……………………………… 43

Water Tube Installation………………………………. 44

Water Hose Installation………………………………. 44

U-joint and Exhaust Bellows Installation……………….. 45

Gimbal Housing Removal…………………………………… 46

Shift Cable Sleeve Replacement………………………… 47

Transom and Exhaust Seal Replacement…………………… 48

Gimbal Housing Installation………………………………. 49

Torque Specifications……………………………………. 52

Sealants, Lubricants, and Adhesives……………………….. 53

Service Chart…………………………………………… 54

Transom Shield Assembly SX-MHP……………………………….. 55

Special Tools…………………………………………… 56

Sealants, Lubricants and Adhesives………………………… 56

Trim/Tilt Cylinder Installation…………………………… 58

Pivot Housing Removal……………………………………. 59

Pivot Housing Assembly…………………………………… 62

Pivot Housing Installation……………………………….. 62

Gimbal Ring Removal……………………………………… 64

Gimbal Ring Disassembly………………………………….. 67

Gimbal Ring Assembly…………………………………….. 67

Gimbal Ring Installation…………………………………. 68

Trim Sender Adjustment…………………………………… 71

Gimbal Housing Disassembly……………………………….. 72

Anode Replacement……………………………………….. 72

Trim Sender Removal……………………………………… 73

Water Tube Removal………………………………………. 73

Hydraulic Lines and Manifold Removal………………………. 74

Steering Bearing, Gimbal Bearing and Seal Removal…………… 75

Gimbal Housing Cleaning and Inspection…………………….. 75

Gimbal Housing Assembly………………………………….. 76

Steering Bearing, Gimbal Bearing and Seal Installation…… 76

Hydraulic Lines and Manifold Installation………………. 77

Trim Sender Installation……………………………… 79

Anode and Sensor Housing Installation………………….. 80

Water Tube Installation………………………………. 80

Water Hose Installation………………………………. 80

U-joint and Exhaust Bellows Installation……………….. 81

Gimbal Housing and Transom Plate Removal……………….. 82

Shift Cable Sleeve Replacement………………………… 83

Transom and Exhaust Seal Replacement…………………… 84

Gimbal Housing and Transom Plate Installation…………… 85

Torque Specifications……………………………………. 87

Sealants Lubricants, Adhesives……………………………. 88

Service Chart…………………………………………… 89

Upper Gear Housing………………………………………….. 91

Special Tools…………………………………………… 92

Sealants, Lubricants and Adhesives………………………… 92

Sterndrive Removal………………………………………. 93

Sterndrive Disassembly…………………………………… 93

Upper Gear Housing Disassembly………………………… 94

Shift Actuator Housing Removal………………………… 95

Pinion Bearing Carrier Removal………………………… 95

Output Gear Removal………………………………….. 96

Upper and Lower Output Gear Disassembly………………… 99

Universal Joint Replacement……………………………100

universal joint Installation…………………………..101

Pinion Bearing Carrier Disassembly……………………..102

Upper Housing Stud Replacement…………………………105

Upper Gear Housing Oil Screen………………………….105

Shimming Thrust Plates………………………………..105

Shift Linkage Disassembly……………………………..107

Water Passage Plate Service……………………………108

Shift Linkage Assembly………………………………..108

Pinion Bearing Carrier Assembly………………………..109

Upper and Lower Output Gears Assembly…………………..114

Lower Output Gear Shimming…………………………….115

Upper Output Gear Shimming…………………………….116

Pinion Bearing Carrier Shimming………………………..117

Upper Gear Housing Assembly……………………………….118

Lower Output Gear and Shaft Assembly……………………118

Lower Output Gear Installation…………………………119

Cone Clutch Installation………………………………121

Upper Output Gear Installation…………………………122

Shimming Vertical Movement Of Upper Driveshaft…………..123

Pinion Bearing Carrier Installation…………………….124

Top Cover Shimming……………………………………125

Checking Gear Lash……………………………………125

Lower Gear…………………………………………..126

Upper Gear…………………………………………..126

Correcting Gear Lash………………………………….127

Checking the Gear Teeth Contact Pattern…………………130

Final Assembly of Upper Gear Housing……………………131

Shift Actuator Housing Disassembly……………………..132

Shift Actuator Housing Assembly………………………..134

Shift Actuator Housing Installation…………………….136

Shimming Shift Actuator Housing………………………..136

Assembly of Sterndrive………………………………..138

Pressure and Vacuum Testing Sterndrive………………….139

Pressure Testing……………………………………..140

Vacuum Testing……………………………………….140

Sterndrive Filling……………………………………140

Specifications…………………………………………..144

Sealants, Lubricants and Adhesives…………………………145

Service Chart……………………………………………146

SX Lower Gearcase……………………………………………147

Special Tools……………………………………………148

Lower Gearcase Removal……………………………………149

Lower Gearcase Disassembly………………………………..150

Propshaft Bearing Housing Service………………………150

Seal and Bearing Removal………………………………151

Seal and Bearing Installation………………………….151

Propshaft Bearing Removal……………………………..152

Propshaft Bearing Installation…………………………153

Intermediate Driveshaft and Water Tube Guide Removal……..153

Driveshaft and Gear Removal……………………………154

Pinion Bearing Removal………………………………..157

Driveshaft Bearing Removal and Installation……………..157

Pinion Shimming………………………………………158

Lower Gearcase Assembly…………………………………..160

Propshaft Gear – Bearing Installation…………………..161

Propshaft Gear Shimming……………………………….161

Propshaft Gear – Bearing Cup Installation……………….162

Pinion Bearing Installation……………………………163

Driveshaft and Gear Installation……………………….164

Setting Initial Rolling Torque…………………………165

Initial Propshaft Bearing Housing Shimming………………166

Setting Final Rolling Torque…………………………..167

Gear Lash Checking……………………………………167

Checking Gear Contact – SX Lower Unit…………………..168

Final Propshaft Bearing Housing Shimming………………..170

Propshaft Bearing Housing – Retainer Installation………..171

Lower Gearcase Installation……………………………172

Pressure and Vacuum Testing Sterndrive………………….174

Sterndrive Filling……………………………………175

Specifications…………………………………………..177

Sealants, Lubricants and Adhesives…………………………178

Service Chart……………………………………………179

DP-S Lower Gearcase………………………………………….181

Gearcase Retaining Plate………………………………….182

Special Tools……………………………………………183

Propeller Shaft Runout………………………………..184

Lower Gearcase Removal……………………………………184

Lower Gearease Disassembly………………………………..186

Propeller Shaft Housing Propeller Shaft Removal………….186

Inner Propeller Shaft Removal………………………….187

Water Tube Guide and Anode Removal……………………..188

Driveshaft and Pinion Removal………………………….189

Gearease Bearing and Race Removal………………………190

Lower Driveshaft Bearing………………………………190

Pinion Bearing……………………………………….190

Forward Bearing Race………………………………….191

Propeller Shaft Housing Service……………………………191

Outer Propeller Shaft Service……………………………..193

Forward Gear Service………………………………….196

Driveshaft Service……………………………………197

Magnet Service……………………………………….198

Upper Housing Stud Replacement…………………………199

Pinion Shimming………………………………………199

Forward Gear Shimming…………………………………200

Outer Propeller Shaft Shimming…………………………202

Oil Screen Service – Upper Housing……………………..206

Exhaust Cover Service…………………………………206

Lower Gearcase Assembly…………………………………..207

Gearease Bearing and Race Installation………………….207

Forward Bearing Race………………………………….207

Pinion Bearing……………………………………….207

Lower Driveshaft Bearing………………………………208

Driveshaft and Pinion Installation……………………..209

Setting Initial Rolling Torque…………………………210

Propeller Shaft Housing and Propeller Shaft Installation….211

Setting Final Rolling Torque…………………………..214

Checking Tooth Contact Pattern…………………………216

Adjusting Tooth Contact Pattern and Gear Lash……………217

Final Assembly…………………………………………..218

Lower Gearcase Installation……………………………….219

Pressure and Vacuum Testing……………………………221

Sterndrive Filling……………………………………222

Anode – Testing and Replacement………………………..224

Specifications…………………………………………..225

Sealants, Lubricants and Adhesives…………………………226

Service Chart……………………………………………227

Sterndrive Removal and Installation……………………………229

Sealants, Lubricants and Adhesives…………………………229

Sterndrive Removal……………………………………….229

Sterndrive Installation…………………………………..232

Check and Adjust Trim Sending Unit……………………..237

Shift and Throttle Cable Installation…………………..237

Check Remote Control Shift Cable Stroke…………………237

Shift Cable Installation………………………………238

Throttle Cable Installation……………………………241

Trim/Tilt Hydraulic System……………………………………243

Sealants, Lubricants and Adhesives…………………………243

Special Tools……………………………………………243

System Description……………………………………….244

Reservoir – Checking, Filling and Bleeding………………….244

Troubleshooting – General…………………………………244

Troubleshooting With In-Line Pressure Tester………………..245

How to Install Tester…………………………………….245

System Hydraulic Tests……………………………………245

Test No. 1 – Complete Up Circuit…………………………..245

Test No. 2 – Pump Isolation, Up Circuit…………………….246

Test No. 3 – Complete Down Circuit…………………………246

Test No. 4 – Pump Isolation, Down Circuit…………………..246

Servicing Motor and Pump………………………………….247

Removing Motor and Draining Reservoir…………………..247

Separation of Reservoir and Motor………………………248

Separation of Pump and Manifold………………………..251

Installation of Pump………………………………….251

Installation of Motor and Reservoir…………………….252

Installation of Pump Assembly………………………….253

Servicing Trim/Tilt Cylinders……………………………..254

Filling and Bleeding Dry System………………………..258

Trim Cylinders…………………………………………..258

Trim Motor and Reservoir………………………………258

Hydraulic Pressure Specifications………………………….259

Propellers………………………………………………….261

Sealants, Lubricants and Adhesives…………………………261

Special Tools……………………………………………261

Propeller Selection – SX Models……………………………261

Propeller Removal and Installation – SX Models………………262

Left-Hand Rotation – SX Models…………………………….264

Propeller Selection – DP-S………………………………..264

Propeller Removal and Installation – DP-S Models…………….265

Condition of Boat Bottom………………………………….266

Bottom Painting………………………………………….266

Boat Trailers……………………………………………266

Boat Trim – SX and DP-S…………………………………..267

Propeller Hub Replacement…………………………………267

High Altitude Operation…………………………………..267