$34

Volvo Penta TAD1250VE, TAD1251VE, TAD1252VE Group 21-26 Workshop Manual_441403095 – PDF DOWNLOAD

Volvo Penta TAD1250VE, TAD1251VE, TAD1252VE Group 21-26 Workshop Manual_441403095 – PDF DOWNLOAD

DESCRIPTION:

Volvo Penta TAD1250VE, TAD1251VE, TAD1252VE Group 21-26 Workshop Manual_441403095 – PDF DOWNLOAD

TAD1250VE, TAD1251VE, TAD1252VE

Safety information

Introduction

The workshop manual contains descriptions and repair

instructions for products or product versions noted in

the table of contents, supplied by Volvo Penta. This

manual should be used together with the workshop

manual Technical data for each engine. Check that

you have the correct workshop manual for your engine.

Read this safety information and the workshop manual

General information and Repair instructions carefully

before service work is started.

Important

In this book and on the product you will find the following

special warning symbols.

WARNING! Warns for the risk of personal injury,

major damage to product or property, or serious

malfunctions if the instruction is ignored.

IMPORTANT! Is used to call attention to things

which could cause damage or malfunctions to

product or property.

NOTE! Is used to call attention to important information,

to facilitate work processes or operation.

To give you a perspective on the risks which always

need to be observed and precautions which always

have to be taken, we have noted them below.

Make it impossible to start the engine by cutting

system current with the main switch(es)and lock

it (them) in the off position before starting service

work. Set up a warning notice by the helm

station.

All service work should normally be done on a

stationary engine. Some work, such as adjustments,

need the engine to be running, however.

Approaching an engine which is operating is a

safety hazard. Remember that loose clothing or

long hair can fasten in rotating parts and cause

serious personal injury.

If work is done adjacent to a running engine, a

careless movement or a dropped tool can lead

to personal injury in the worst case. Take care

to avoid contact with hot surfaces (exhaust

pipes, Turbocharger, air intake pipe, starter

heater etc.) and fluids in pipes and hoses in an

engine which is running or has just been

stopped. Reinstall all protective parts removed

during servicework before starting the engine.

Check that the warning or information labels on

the product are always clearly visible. Replace

labels which have been damaged or painted

over.

Never start the engine without installing the air

cleaner filter. The rotating compressor turbine in

the turbocharger can cause severe injury. Foreign

objects entering the intake ducts can also

cause mechanical damage.

Never use start spray or similar products as a

starting aid. They may cause an explosion in

the inlet manifold. Danger of personal injury.

Only start the engine in a well- ventilated area.

When operated in a confined space, exhaust

fumes and crankcase gases must be ventilated

from the engine bay or workshop area.

Avoid opening the coolant filling cap when the

engine is hot. Steam or hot coolant can spray

out and the system pressure will be lost. When

needed, open the filler cap slowly and release

the pressure in the system. Be extremely careful

if a tap, plug or coolant hose has to be removed

from a hot engine. Steam or hot coolant

might spray out in an unexpected direction.

Hot oil can cause burns. Avoid skin contact with

hot oil. Ensure that the lubrication system is not

under pressure before carrying out any work.

Never start or operate the engine with the oil filler

cap removed, otherwise oil could be ejected.

Stop the engine before carrying out operations

on the engine cooling system.

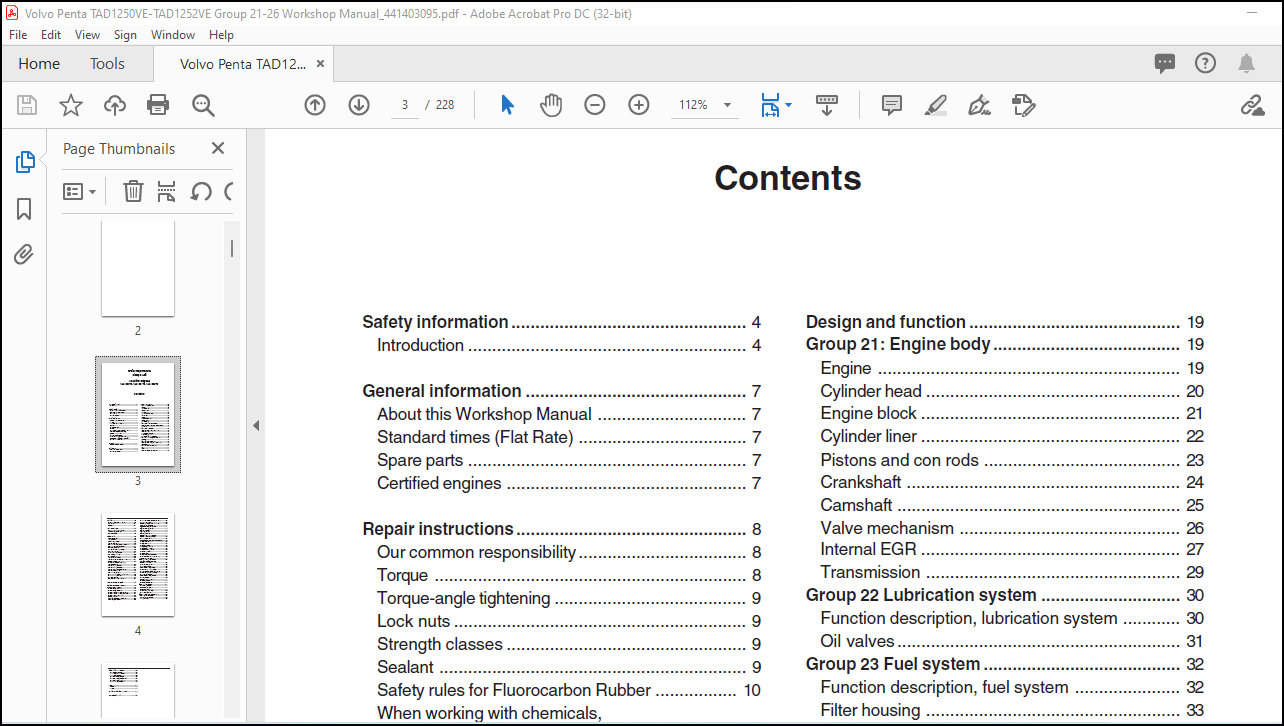

TABLE OF CONTENTS:

Volvo Penta TAD1250VE, TAD1251VE, TAD1252VE Group 21-26 Workshop Manual_441403095 – PDF DOWNLOAD

Safety information …………………………………………. 4

Introduction …………………………………………………. 4

General information ………………………………………. 7

About this Workshop Manual …………………………. 7

Standard times (Flat Rate) …………………………….. 7

Spare parts …………………………………………………. 7

Certified engines ………………………………………….. 7

Repair instructions ………………………………………… 8

Our common responsibility …………………………….. 8

Torque ……………………………………………………….. 8

Torque-angle tightening …………………………………. 9

Lock nuts ……………………………………………………. 9

Strength classes ………………………………………….. 9

Sealant ………………………………………………………. 9

Safety rules for Fluorocarbon Rubber …………….. 10

When working with chemicals,

fuel and lubricating oil …………………………………. 10

Before lifting the engine ………………………………. 11

Actions after lifting the engine ………………………. 11

Instructions for work on engines with

electronic fuel injection ……………………………….. 11

Special tools ………………………………………………. 12

Other special equipment ……………………………… 16

Introduction ………………………………………………… 17

Identification numbers …………………………………. 17

Component location ……………………………………. 18

Design and function …………………………………….. 19

Group 21: Engine body………………………………… 19

Engine ……………………………………………………… 19

Cylinder head …………………………………………….. 20

Engine block ……………………………………………… 21

Cylinder liner ……………………………………………… 22

Pistons and con rods ………………………………….. 23

Crankshaft ………………………………………………… 24

Camshaft ………………………………………………….. 25

Valve mechanism ………………………………………. 26

Internal EGR ……………………………………………… 27

Transmission …………………………………………….. 29

Group 22 Lubrication system ……………………….. 30

Function description, lubrication system ………… 30

Oil valves ………………………………………………….. 31

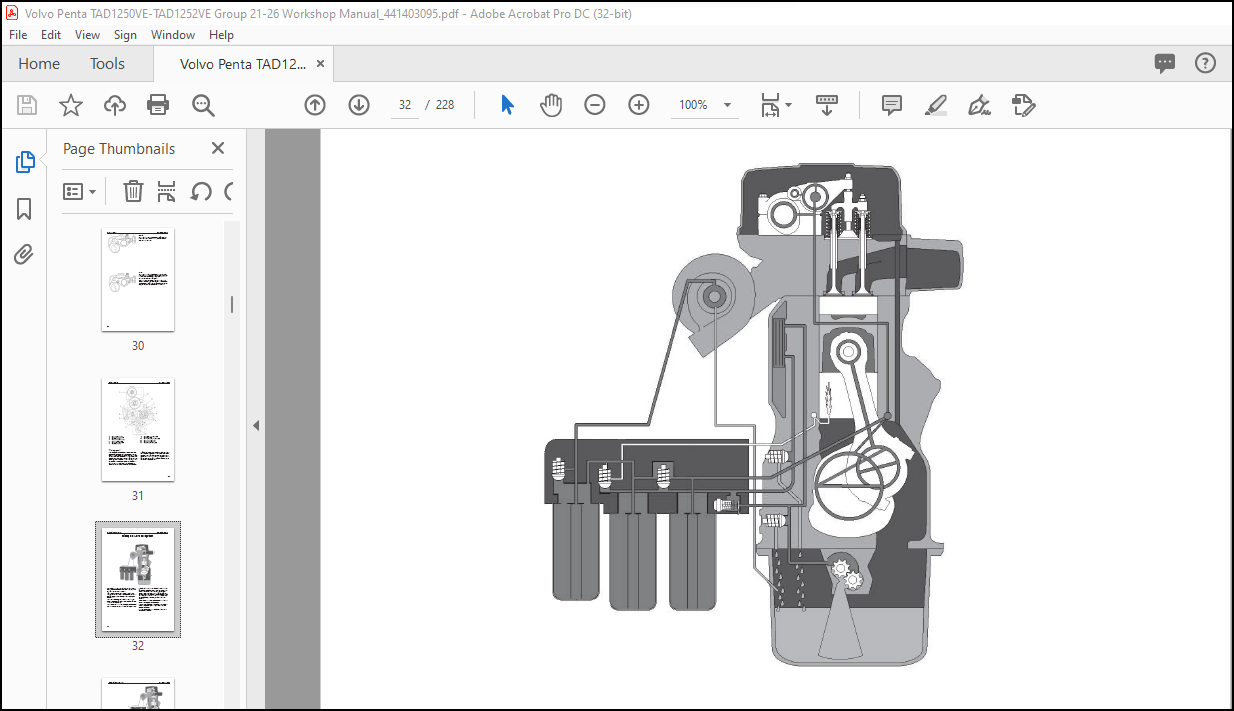

Group 23 Fuel system ………………………………….. 32

Function description, fuel system …………………. 32

Filter housing …………………………………………….. 33

Unit injector, summary ………………………………… 34

Trim code, injector ……………………………………… 34

Unit injector, working phases ……………………….. 35

Group 25 Inlet and exhaust system……………….. 37

Turbocharger ……………………………………………… 38

Group 26: Cooling system ……………………………. 39

Function description, cooling system …………….. 39

Intercooler …………………………………………………. 40

Group 30: Electrical system …………………………. 41

EMS 2 ……………………………………………………… 41

Control unit ……………………………………………….. 41

Electrical component diagram ………………………. 42

Fault tracing ……………………………………………….. 43

Symptoms and possible causes …………………… 43

Malfunctions ……………………………………………… 44

Blockage …………………………………………………… 44

Tests and settings ……………………………………….. 45

Charge pressure, fault tracing ………………………. 45

Turbocharger, inspection ……………………………… 47

Supply pressure …………………………………………. 48

Service work ……………………………………………….. 49

Compression test ……………………………………….. 49

Timing marks …………………………………………….. 52

Adjustment, general ……………………………………. 52

Valves, adjustment …………………………………….. 53

Double rocker arm, inspection (iEGR) ……………. 55

Double rocker arm, adjustment …………………….. 57

Engine oil, changing ……………………………………. 58

Oil filter/By-pass filter, change ……………………… 59

Fuel filter, change ………………………………………. 60

Primary fuel filter, change ……………………………. 61

Fuel system, draining ………………………………….. 62

Draining condensate …………………………………… 62

Venting the fuel system ………………………………. 63

Instructions for operating the starter motor ……… 64

Exhaust system, inspection …………………………. 65

Pressure drop indicator/air filter,

inspection/change ………………………………………. 65

Cooling system, draining ……………………………… 66

Cooling system, cleaning …………………………….. 67

Cooling system, pressure testing ………………….. 68

Cooling system, filling …………………………………. 70

Coolant filter, change ………………………………….. 71

Alternator belt / Drive belt, inspection…………….. 72

Alternator belts, change ………………………………. 72

Drive belt, change ………………………………………. 73

Checking the pressure test unit …………………….. 74

Installing the engine fixture ………………………….. 75

Overhaul / Change components ……………………. 76

Group 21: Engine body………………………………… 76

Cylinder head, removing ………………………………. 76

Cylinder head, installation ……………………………. 89

Cylinder liners and piston, inspection …………….. 93

Cylinder liners and pistons, change (all) …………. 94

Cylinder liners, installation …………………………… 96

Pistons, change …………………………………………. 98

Camshaft, inspection and overhaul ……………….100

Camshaft, wear check ………………………………..102

Bearing housing for camshaft, change …………..103

Camshaft, installation …………………………………104

Crankshaft, inspection and overhaul ……………..108

Main bearings, change (all) ………………………….110

Big end bearings, change (all) ………………………113

Flywheel bearing, change …………………………….114

Flywheel, change ……………………………………….115

Gear ring, change……………………………………….117

Flywheel, indication …………………………………….118

Crankshaft seal, front, change ……………………..119

Crankshaft seal rear, change ……………………….121

Con rod, inspection …………………………………….123

Gudgeon pin bushing, check measurement …….123

Valves, removing ……………………………………….124

Valves, installation ……………………………………..126

Valve seat, change …………………………………….127

Valve guides, inspection ……………………………..129

Valve guides, replacing ……………………………….130

Valve stem seals, change ……………………………131

Valve seats, grinding ………………………………….133

Valves, grinding …………………………………………134

Cylinder head, pressure testing …………………….135

Copper sleeve for injector, changing ……………..139

Timing gear, changing …………………………………143

Group 22: Lubrication system ………………………158

When working with chemicals,

fuel and lubrication oil …………………………………158

Reduction valve, change ……………………………..158

Safety valve, change ………………………………….159

Piston cooling valve, change ……………………….160

Bypass valve, oil filter, change …………………….161

By-pass valve, by-pass filter, change ……………162

Bypass valve, oil cooler, change ………………….163

Sump gasket, change …………………………………164

Piston cooling nozzle, change ……………………..166

Oil filter, change …………………………………………167

Lube oil pressure, check ……………………………..170

Oil cooler, change ………………………………………171

Oil cooler, leakage test ……………………………….175

Group 23: Fuel system …………………………………176

Control unit, change ……………………………………176

Feed pump, changing ………………………………….178

Feed pump, renovation ……………………………….179

Bypass valve, changing ………………………………181

Unit injector, change …………………………………..182

Group 25: Inlet / Exhaust systems ………………..186

Inlet pipe, gasket change …………………………….186

Manifold, gasket change ……………………………..190

Turbo, replacing …………………………………………194

Group 26: Cooling system ……………………………198

Coolant pump, change ………………………………..198

Thermostat, function check………………………….203

Thermostat, change ……………………………………204

Charge air cooler, change ……………………………205

Charge air cooler, leakage test ……………………..206

Charge air cooler, cleaning …………………………..208

Radiator matrix, change ………………………………209

Technical data …………………………………………….214

General …………………………………………………….214

Torque ……………………………………………………..215

References to Service Bulletins ……………………219

Alphabetical register ……………………………………220

IMAGES PREVIEW OF THE MANUAL: