$33

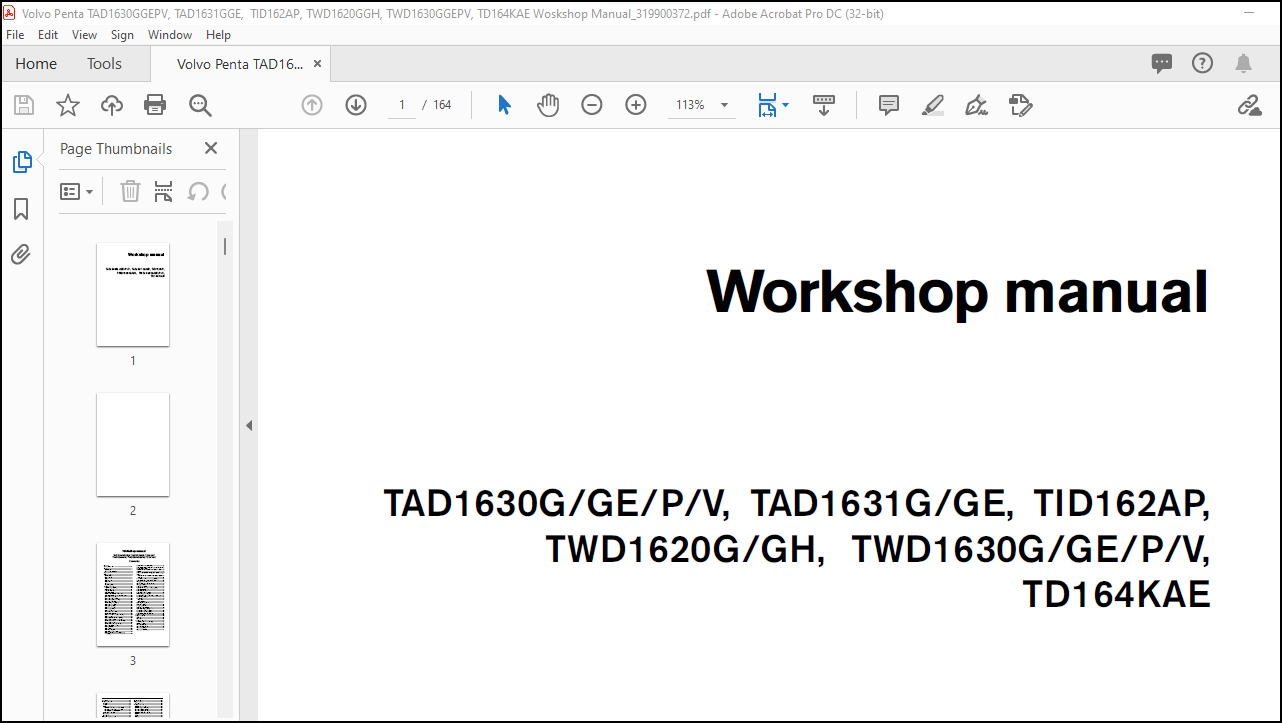

VolvoPenta TAD1630G-GE-P-V TAD1631G-GE TID162AP TWD1620G-GH TWD1630G-GE-P-V TD164KAE Workshop Manual

Volvo Penta TAD1630G-GE-P-V, TAD1631G-GE, TID162AP, TWD1620G-GH, TWD1630G-GE-P-V, TD164KAE Workshop Manual_319900372 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta TAD1630G-GE-P-V, TAD1631G-GE, TID162AP, TWD1620G-GH, TWD1630G-GE-P-V, TD164KAE Workshop Manual_319900372 – PDF DOWNLOAD

Language : English

Pages : 164

Downloadable : Yes

File Type : PDF

Size: 1.86 MB

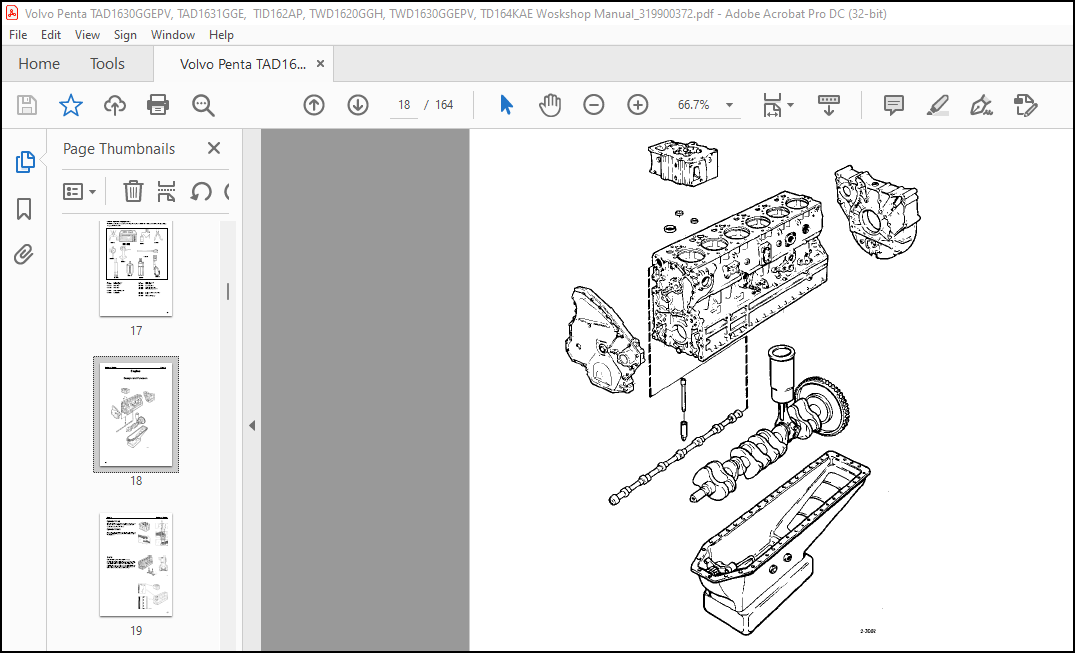

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta TAD1630G-GE-P-V, TAD1631G-GE, TID162AP, TWD1620G-GH, TWD1630G-GE-P-V, TD164KAE Workshop Manual_319900372 – PDF DOWNLOAD

TAD1630G/GE/P/V, TAD1631G/GE, TID162AP,

TWD1620G/GH, TWD1630G/GE/P/V,

TD164KAE

General information:This Service Manual contains technical data, descriptions and maintenance and repair instructions for standard model Volvo Penta products. A list of these products may be found in the section Specifications. The product designation and the serial number and specification is indicated on the engine decal or type plate.

- This information must be included in all correspondence regarding the product. The service manual is produced primarily for the use of Volvo Penta workshops and their qualified personnel. It is assumed that any person using the Service Manual has a fundamental knowledge of the product and is able to carry out mechanical and electrical work to trade standard.

- Volvo Penta continually develops its products; we therefore reserve the right to make changes. All information in this manual is based on product data which was available up to the date on which the manual was printed. New working methods and significant changes introduced to the product after this date are communicated in the form of Service bulletins.

Spare Parts:

Spare parts for the electrical and fuel systems are subject to various national safety standards. Volvo Penta Original Spare Parts meet these standards. No damage of any kind caused by the use of spare parts not approved by Volvo Penta will be compensated by any warranty undertaking.

About this Workshop manual:

Certification means that an engine type has been inspected and approved by the relevant authority. The engine manufacturer guarantees that all engines of the same type are manufactured to correspond to the certified engine.

This places special demands on service and repair work, namely:

• Maintenance and service intervals recommended by Volvo Penta must be complied with.• Only spare parts approved by Volvo Penta may be used.• Service on injection pumps, pump settings and injectors must always be carried out by an authorized Volvo Penta workshop.• The engine must not be converted or modified, except with accessories and service kits which Volvo Penta has approved for the engine.• No changes to the exhaust pipe and engine air inlet duct installations may be made.• No warranty seals (where present on the product) may be broken by unauthorized persons.The general instructions in the Operator’s Manual concerning operation, service and maintenance apply.

TABLE OF CONTENTS:

Volvo Penta TAD1630G-GE-P-V, TAD1631G-GE, TID162AP, TWD1620G-GH, TWD1630G-GE-P-V, TD164KAE Workshop Manual_319900372 – PDF DOWNLOAD

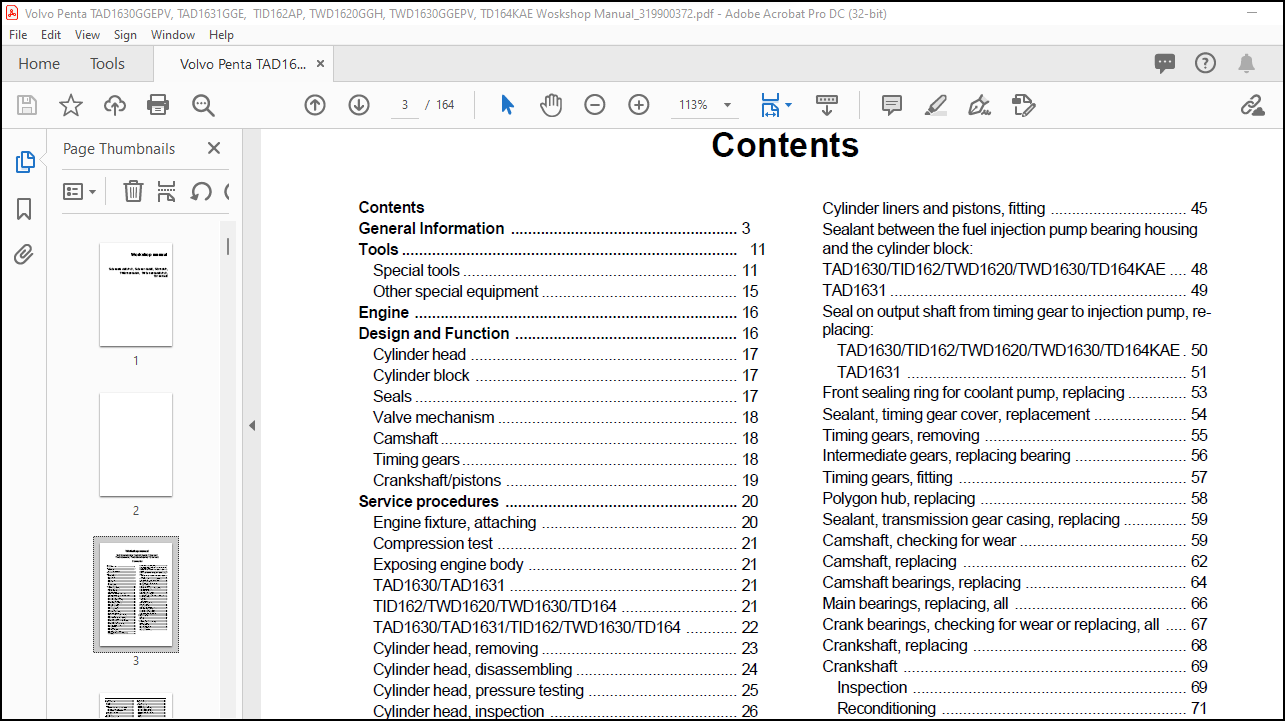

Contents

General Information 3

Tools 11

Special tools 11

Other special equipment 15

Engine 16

Design and Function 16

Cylinder head 17

Cylinder block 17

Seals 17

Valve mechanism 18

Camshaft 18

Timing gears 18

Crankshaft/pistons 19

Service procedures 20

Engine fixture, attaching 20

Compression test 21

Exposing engine body 21

TAD1630/TAD1631 21

TID162/TWD1620/TWD1630/TD164 21

TAD1630/TAD1631/TID162/TWD1630/TD164 22

Cylinder head, removing 23

Cylinder head, disassembling 24

Cylinder head, pressure testing 25

Cylinder head, inspection 26

Cylinder head, face-grinding 26

Valve guides, inspection 27

Valve guides, replacing 28

Valve seats, replacing 28

Valve seats, grinding 29

Valves, grinding 29

Cylinder head, assembling 30

Cylinder head, installation 30

Rocker arm mechanism, reconditioning 33

Valves, adjusting 34

Copper sleeve for injectors, replacing 36

Cylinder liners and pistons, removing 37

Cylinder liners, measurement and inspection 40

Cylinder liners, honing 40

Cylinder liner seats, reconditioning 41

Cylinder block, face-grinding 42

Pistons, checking 43

Pistons, fitting 43

Piston rings, inspection 43

Connecting rods, inspection 43

Pistons, piston rings and connecting rods,

assembling 44

Cylinder liners and pistons, fitting 45

Sealant between the fuel injection pump bearing housing

and the cylinder block:

TAD1630/TID162/TWD1620/TWD1630/TD164KAE 48

TAD1631 49

Seal on output shaft from timing gear to injection pump, replacing:

TAD1630/TID162/TWD1620/TWD1630/TD164KAE 50

TAD1631 51

Front sealing ring for coolant pump, replacing 53

Sealant, timing gear cover, replacement 54

Timing gears, removing 55

Intermediate gears, replacing bearing 56

Timing gears, fitting 57

Polygon hub, replacing 58

Sealant, transmission gear casing, replacing 59

Camshaft, checking for wear 59

Camshaft, replacing 62

Camshaft bearings, replacing 64

Main bearings, replacing, all 66

Crank bearings, checking for wear or replacing, all 67

Crankshaft, replacing 68

Crankshaft 69

Inspection 69

Reconditioning 71

Flywheel, checking for warp 71

Flywheel, replacing 72

Ring gear, replacing 73

Flywheel casing, checking for warp 73

Flywheel bearing, replacing 74

Crankshaft seal, rear, replacing 75

Crankshaft seal, front, replacing 76

Sealant, flywheel casing, replacing 77

Lubrication system 79

Design and Function 79

General 79

Oil cooler 81

Service procedures 82

Lubricating oil pressure, checking 82

Oil filters, replacing 82

Oil cooler, replacing 83

Oil cooler, leakage test 84

Oil pump, replacing 85

Oil pump, reconditioning 87

Fuel system 90

Design and Function 90

General 90

Fuel filters 90

Injection pump 91

TID162AP/TWD1620G/GH/TWD1630/GE 91

TAD1630P/V/TWD1630P/V/TD164KAE 91

TAD1630G/GE y TAD1631G/GE 92

Smoke limiter TAD1630P/V 94

Feed pump 94

Manual pump 94

Instrucciones de reparación 95

Service procedures 95

Injection pump, removal 95

Fitting and adjusting the injection pump 95

Injection pump, setting with measuring tool 998 7057 98

Pump coupling shaft, removing 101

Checking and replacing pump coupling laminates 101

Injectors 101

Injectors, replacing 102

Injectors, reconditioning 103

Opening pressure, adjusting 104

Fuel feed pressure, checking 104

Fuel filters, replacing 105

Feed pump, replacing 105

Feed pump, reconditioning 106

Smoke limiter, TAD1630P/V 107

Replacing the diaphragm 107

Fuel system, bleeding 108

Intake and exhaust systems 109

Design and Function 109

Charge air cooler 109

Turbocharger 109

Air filter 110

Starter heater 110

Exhaust manifold 110

Service procedures 111

Boost pressure, checking 111

Rectifying low boost pressure 112

Checking exhaust back pressure 113

Turbocharger, checking bearing clearance 113

Schwitzer S4T and Holset H3B 113

Turbocharger, reconditioning 115

Schwitzer S4T y TAD1630/1631 115

Holset, TID162/TWD1620/TWD1630 120

Measures in case of turbo failure on TAD- engines 123

Turbocharger, replacing/refitting on engine 123

Charge air cooler, checking for leakage,

TAD-engines 124

Cooling system 125

Design and Function 125

General 125

Service procedures 128

Coolant pump, replacing 128

Coolant pump, reconditioning 130

Sleeve thermostats, replacing 140

Sleeve thermostats, checking 141

Coolant manifold seals, replacing 142

Coolant 144

Anti-freeze 144

Volume 144

Anti-corrosion additives 144

Checking coolant level 144

Draining the coolant 144

Coolant, filling 145

Coolant temperature too high 145

Coolant temperature too low 145

Temperature gauge, checking 145

Level switch, checking 145

Coolant leakage 146

Radiator and charge air cooler, checking 146

Drive belts, adjusting 146

Cooling system, cleaning 146

Cooling system, pressure-testing 147

Checking pressure-testing device 999 6662 147

Pressure testing 147

Pressure valve, checking 148

Electrical system 149

Important 149

Arc welding 149

Starting with auxiliary battery 149

Electronic speed governor, wiring 150

Wiring diagrams 151

Troubleshooting 156