$32

Volvo Penta TD1030ME VE- TAD1232GE Group 20-26 Workshop Manual_236694501 – PDF DOWNLOAD

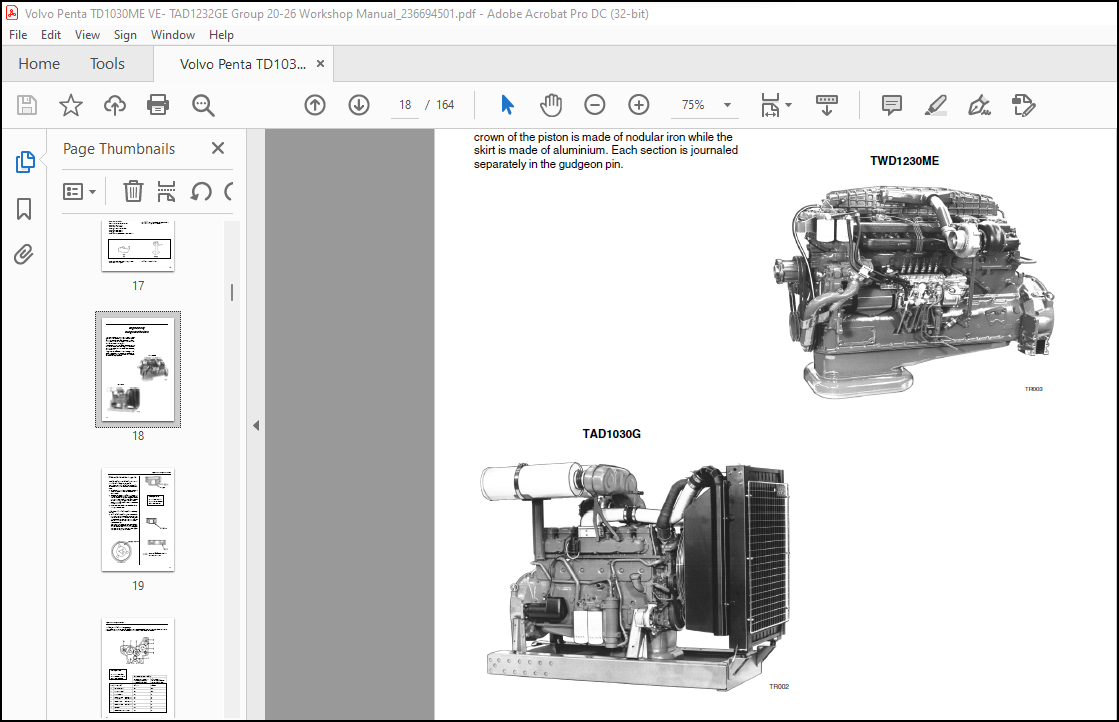

Volvo Penta TD1030ME/VE, TAD1030G/GE/P/V/VE, TWD1030ME/VE,

TWD1031VE, TAD1031GE, TAD1032GE, TWD1210G/P/V,

TWD1211G/P/V, TWD1230ME/VE,TAD1230G/P/V,

TAD1231GE, TWD1231VE, TAD1232GE Group 20-26 Workshop Manual_236694501 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta TD1030ME VE- TAD1232GE Group 20-26 Workshop Manual_236694501 – PDF DOWNLOAD

Language : English

Pages : 164

Downloadable : Yes

File Type : PDF

Size: 8.87 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta TD1030ME VE- TAD1232GE Group 20-26 Workshop Manual_236694501 – PDF DOWNLOAD

TD1030ME/VE, TAD1030G/GE/P/V/VE, TWD1030ME/VE,

TWD1031VE, TAD1031GE, TAD1032GE, TWD1210G/P/V,

TWD1211G/P/V, TWD1230ME/VE,TAD1230G/P/V,

TAD1231GE, TWD1231VE, TAD1232GE

Introduction:

- This Workshop Manual contains descriptions and instructions for the repair of the Volvo Penta products or product types described in the Table of Contents.

- This manual should be used together with the Workshop Manual Technical Data for each engine concerned. Check that you have the correct Workshop Manual for your engine. Before starting work on the engine read the Safety Precautions, General Information and Repair Instructions sections of this Workshop Manual carefully.

About this Workshop Manual:

This Workshop Manual contains descriptions and instructions for the repair of the following engines in standard format: TD1030ME/VE, TAD1030G/GE/P/V/VE, TWD1030ME/VE, TWD1031VE, TAD1031GE, TAD1032GE, TWD1210G/P/V, TWD1211G/P/V, TWD1230ME/VE, TAD1230G/P/V, TAD1231GE, TWD1231VE, TAD1232GE. The Workshop Manual can show operations carried out on any of the engines listed above.

- As a result the illustrations and pictures in the manual that show certain parts on the engines, do not in some cases apply to all the engines listed. However the repair and service operations described are in all essential details the same. Where they are not the same this is stated in the manual and where the difference is considerable the operations are described separately.

- The Engine Designation and Engine Numbers can be found on the product plate (see page 10). Please always include both the engine designation and the engine number in all correspondance. The Workshop Manual is produced primarily for the use of Volvo Penta workshops and service technicians.

- For this reason the manual presupposes a certain basic knowledge and that the user can carry out the mechanical/electrical work described to a general standard of engineering competence. Volvo Penta products are under a continual process of development and we therefore reserve all rights regarding changes and modifications.

- All the information in this manual is based on product specifications available at the time the book was published. Any essential changes or modifications introduced into production or updated or revised service methods introduced after the date of publication will be provided in the form of Service Bulletins.

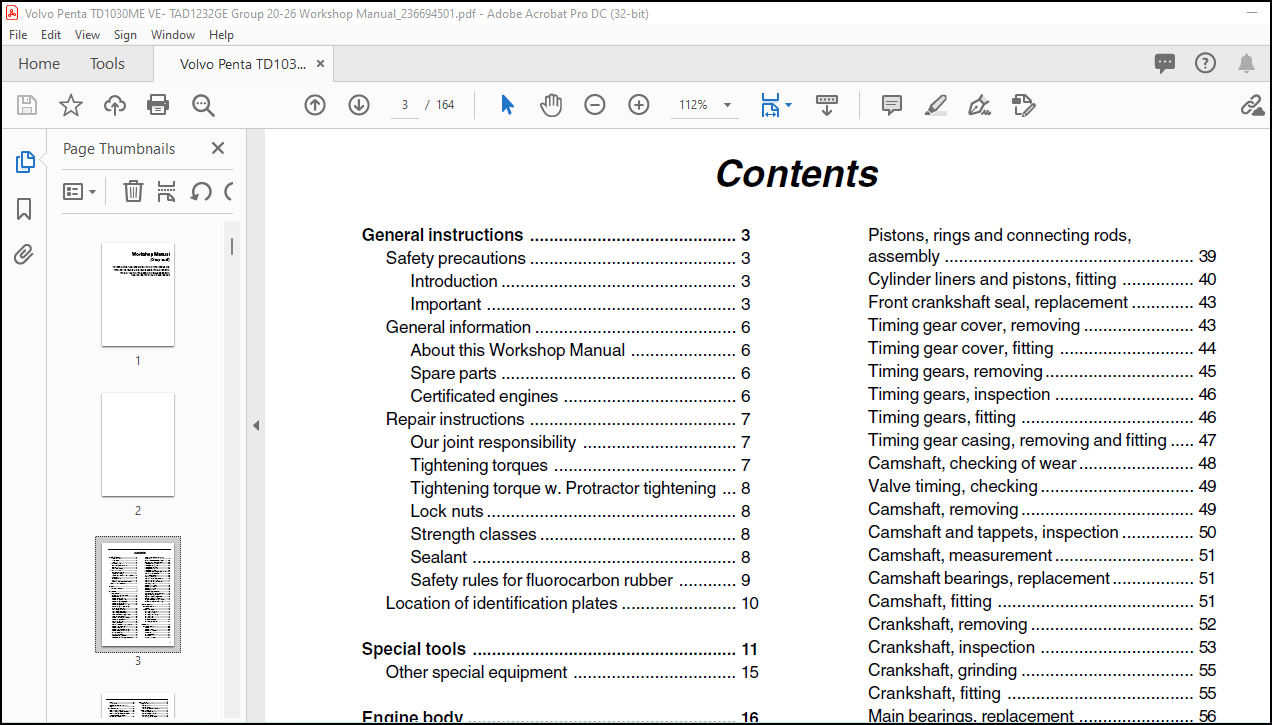

TABLE OF CONTENTS:

Volvo Penta TD1030ME VE- TAD1232GE Group 20-26 Workshop Manual_236694501 – PDF DOWNLOAD

General instructions ……………………………………. 3

Safety precautions ……………………………………. 3

Introduction …………………………………………. 3

Important ……………………………………………. 3

General information …………………………………… 6

About this Workshop Manual …………………. 6

Spare parts …………………………………………. 6

Certificated engines ……………………………… 6

Repair instructions ……………………………………. 7

Our joint responsibility ………………………….. 7

Tightening torques ……………………………….. 7

Tightening torque w. Protractor tightening … 8

Lock nuts ……………………………………………. 8

Strength classes ………………………………….. 8

Sealant ………………………………………………. 8

Safety rules for fluorocarbon rubber ………… 9

Location of identification plates …………………… 10

Special tools ………………………………………………. 11

Other special equipment ……………………………. 15

Engine body ……………………………………………….. 16

Design and function ………………………………….. 16

Nitro-carburated timing gears …………………. 17

Service procedures …………………………………… 20

Cylinder head, removing………………………… 20

Cylinder head, dismantling …………………….. 21

Cylinder head, leakage test ……………………. 21

Cylinder head, inspection ………………………. 23

Cylinder head, surface grinding ………………. 23

Cylinder head, milling of sealing

grooves, 12 ltr engines ………………………….. 24

Valve guides, inspection ……………………….. 26

Valve guides, replacement …………………….. 27

Valve seats, replacement ……………………… 28

Valve seats and valves, grinding ……………. 29

Valve springs, checking ………………………… 30

Rocker mechanism, overhauling …………….. 30

Cylinder head, assembly ……………………….. 31

Cylinder head, fitting …………………………….. 31

Valves, adjustment ………………………………. 33

Cylinder liners and pistons, removing ………. 33

Cylinder liner, inspection ……………………….. 34

Cylinder liners, honing …………………………… 35

Cylinder liner seats, overhauling …………….. 36

Cylinder block, surface grinding ……………… 38

Pistons, checking ………………………………… 38

Piston rings, checking ………………………….. 38

Connecting rods, checking …………………….. 38

Connecting rod bushings, replacement …….. 39

Pistons, rings and connecting rods,

assembly ……………………………………………. 39

Cylinder liners and pistons, fitting …………… 40

Front crankshaft seal, replacement …………. 43

Timing gear cover, removing ………………….. 43

Timing gear cover, fitting ………………………. 44

Timing gears, removing …………………………. 45

Timing gears, inspection ……………………….. 46

Timing gears, fitting ……………………………… 46

Timing gear casing, removing and fitting ….. 47

Camshaft, checking of wear …………………… 48

Valve timing, checking ………………………….. 49

Camshaft, removing ……………………………… 49

Camshaft and tappets, inspection …………… 50

Camshaft, measurement ……………………….. 51

Camshaft bearings, replacement …………….. 51

Camshaft, fitting ………………………………….. 51

Crankshaft, removing ……………………………. 52

Crankshaft, inspection ………………………….. 53

Crankshaft, grinding ……………………………… 55

Crankshaft, fitting ………………………………… 55

Main bearings, replacement …………………… 56

Rear crankshaft seal, replacement ………….. 57

Flywheel bearing, changing ……………………. 58

Flywheel ring gear, replacement ……………… 59

Flywheel, checking for warp …………………… 60

Flywheel casing, checking for warp…………. 60

Flywheel casing, removing/fitting …………… 61

Lubricating system ……………………………………… 62

Design and function ………………………………….. 62

General ………………………………………………. 62

Service procedures …………………………………… 64

Oil pressure, checking ………………………….. 64

Oil pump, removing ………………………………. 64

Oil pump, reconditioning………………………… 65

Oil pump, fitting …………………………………… 67

Oil pump, fitting …………………………………… 69

Oil cooler, changing ……………………………… 70

Oil cooler, leakage test …………………………. 71

Fuel system ………………………………………………… 72

Design and function ………………………………….. 72

General ………………………………………………. 72

Injection pump …………………………………….. 72

Injection timing adjuster ………………………… 73

Governors …………………………………………… 74

Fuel delivery pipes ……………………………….. 74

Feed pump………………………………………….. 75

Hand primer pump ………………………………… 75

Injectors ……………………………………………… 76

Smoke limiter ………………………………………. 76

Fuel shut-off valve for stopping the

engine ………………………………………………… 77

Service procedures …………………………………… 80

Injection pump, removing ………………………. 80

Injection pump, fitting and adjusting ………… 80

Injection pump, setting on the engine ………. 83

Pump coupling, checking and

replacement of laminates ………………………. 86

Injection pump’s drive …………………………… 86

Injection pump’s drive , replacement of

sealing ring …………………………………………. 87

Revs, adjustment …………………………………. 89

Feed pressure, checking ……………………….. 91

Feed pump, replacement ………………………. 92

Feed pump, reconditioning …………………….. 92

Smoke limiter, replacement of diaphragm … 93

Fuel shut-off valve, cleaning ………………….. 94

Fuel shut-off valve, troubleshooting ………… 95

Fuel filter, replacement …………………………. 97

Bleeding ……………………………………………… 97

Injectors, replacement ………………………….. 100

Recommendations for adjusting opening

pressure, setting pressure and changing

injectors ……………………………………………… 100

Injectors, reconditioning ………………………… 102

Opening pressure, adjusting …………………… 102

Copper sleeve for injectors, replacement …. 103

Removal of sealing screw ……………………… 105

Intake and exhaust systems …………………………. 107

Design and function ………………………………….. 107

Starting heater …………………………………….. 107

Turbocharger ……………………………………….. 107

Charge air cooler (Intercooler) ………………… 108

Service procedures …………………………………… 109

Boost pressure, checking ……………………… 109

Exhaust back pressure, checking …………… 111

Bearing clearance, checking ………………….. 111

Turbocharger, removing ………………………… 112

Holset turbocharger ………………………………. 112

KKK Turbocharger ……………………………….. 115

Schwitzer turbocharger …………………………. 119

Turbocharger, cleaning ………………………….. 121

Turbocharger, inspection ……………………….. 121

Turbocharger, fitting ……………………………… 122

Exhaust manifold, changing gaskets ………. 123

Charge air cooler, checking for

leakage (TAD) ……………………………………… 125

Cooling system …………………………………………… 126

Design and function ………………………………….. 126

Cooling system ……………………………………. 127

Coolant pump………………………………………. 127

Thermostat, thermostat housing …………….. 127

Service Procedures …………………………………… 128

Coolant pump, changing………………………… 128

Coolant pump, overhauling …………………….. 129

Changing thermostat …………………………….. 132

Thermostat, function check …………………… 135

Coolant distributor pipe, changing

(Only 12 ltr engines) ……………………………… 136

Thermostatically controlled cooling fan,

function check …………………………………….. 137

Thermostatically controlled cooling fan,

changing …………………………………………….. 138

Coolant ………………………………………………. 139

Checking the coolant level …………………….. 140

Draining the coolant ……………………………… 140

Filling the coolant …………………………………. 140

Checking the temperature gauge …………….. 141

Coolant loss ………………………………………… 141

Charge air cooler insert, changing (TWD) …. 141

Checking the radiator (TAD/TWD) …………… 143

Cleaning the cooling system ………………….. 143

Pressure-testing the cooling system ……….. 144

Checking the pressure valve ………………….. 145

Electrical system …………………………………………. 146

Important ………………………………………………… 146

Arc welding ……………………………………………… 146

Starting with auxiliary battery ……………………… 146

Electronic speed governor ………………………….. 148

Wiring diagrams ……………………………………….. 149

Troubleshooting………………………………………….. 153

References to service bulletines …………………… 160