$32

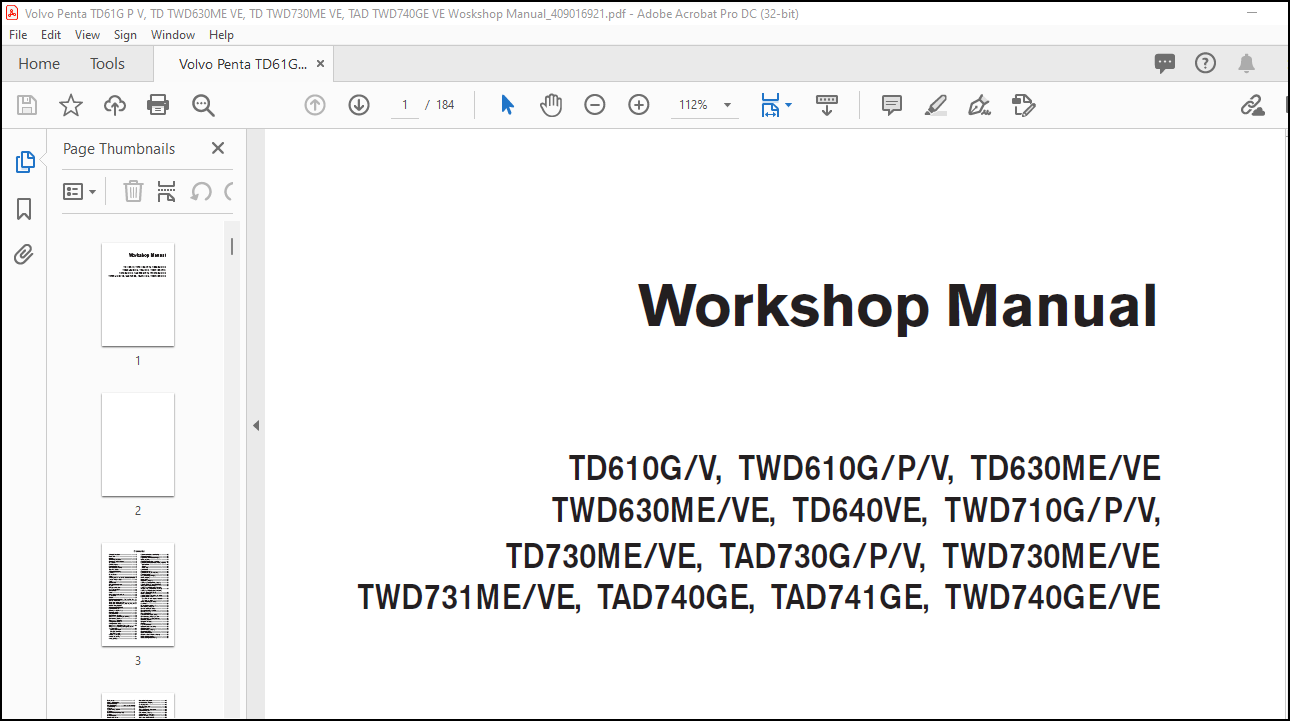

Volvo Penta TD61G P V, TD TWD630ME VE, TD TWD730ME VE, TAD TWD740GE VE Workshop Manual_409016921 PDF

Volvo Penta TD61G P V, TD TWD630ME VE, TD TWD730ME VE, TAD TWD740GE VE Workshop Manual_409016921 – PDF DOWNLOAD

FILE DETAILS:

Volvo Penta TD610G/V, TWD610G/P/V, TD630ME/VE TWD630ME/VE, TD640VE, TWD710G/P/V, TD730ME/VE, TAD730G/P/V, TWD730ME/VE TWD731ME/VE, TAD740GE, TAD741GE, TWD740GE/VE Workshop Manual_409016921 – PDF DOWNLOAD

Language : English

Pages : 184

Downloadable : Yes

File Type : PDF

Size: 9.93 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Volvo Penta TD610G/V, TWD610G/P/V, TD630ME/VE TWD630ME/VE, TD640VE, TWD710G/P/V, TD730ME/VE, TAD730G/P/V, TWD730ME/VE TWD731ME/VE, TAD740GE, TAD741GE, TWD740GE/VE Workshop Manual_409016921 – PDF DOWNLOAD

TD610G/V, TWD610G/P/V, TD630ME/VE

TWD630ME/VE, TD640VE, TWD710G/P/V,

TD730ME/VE, TAD730G/P/V, TWD730ME/VE

TWD731ME/VE, TAD740GE, TAD741GE, TWD740GE/VE

Introduction:

- This Workshop Manual contains technical data, descriptions and repair instructions for the specified products or product variants from Volvo Penta. Ensure to use the correct workshop literature.

- Read this safety information as well as ”General information” and ”Repair instructions” thoroughly before commencing any service work.

About the Workshop Manual:

This Workshop Manual contains descriptions and directions for repair of standard models of engines TD610G/V, TWD610G/P/V, TD630ME/VE, TWD630ME/VE, TD640VE, TWD710G/P/V, TD730ME/VE, TAD730G/P/V, TAD741GE, TWD730ME/VE, TWD731ME/VE, TAD740GE and TWD740GE/VE.

- Engine designation and number are specified on the type plate (see page 12). The engine designation and number must always be provided in all correspondence concerning any of our engines. The Workshop Manual is produced primarily for qualified personnel at Volvo Penta service centres.

- This presupposes that the person using this manual possesses basic knowledge and can carry out the mechanical/electrical work associated with the trade. Volvo Penta employs continuous product development and therefore reserves the right to make technical changes.

- All the information contained in this manual is based on product data available at the time of going to press. Any changes or revisions of consequence that are introduced in the product or service methods after this date will be issued in Service Bulletins.

Spare parts:

- Spare parts for the electric and fuel systems are liable to various national safety requirements. Volvo Penta Original Spare Parts fulfil these requirements.

- Any damage arising from the use of parts that are not Volvo Penta Original Spare Parts will not be covered by any of the warranties provided by Volvo Penta.

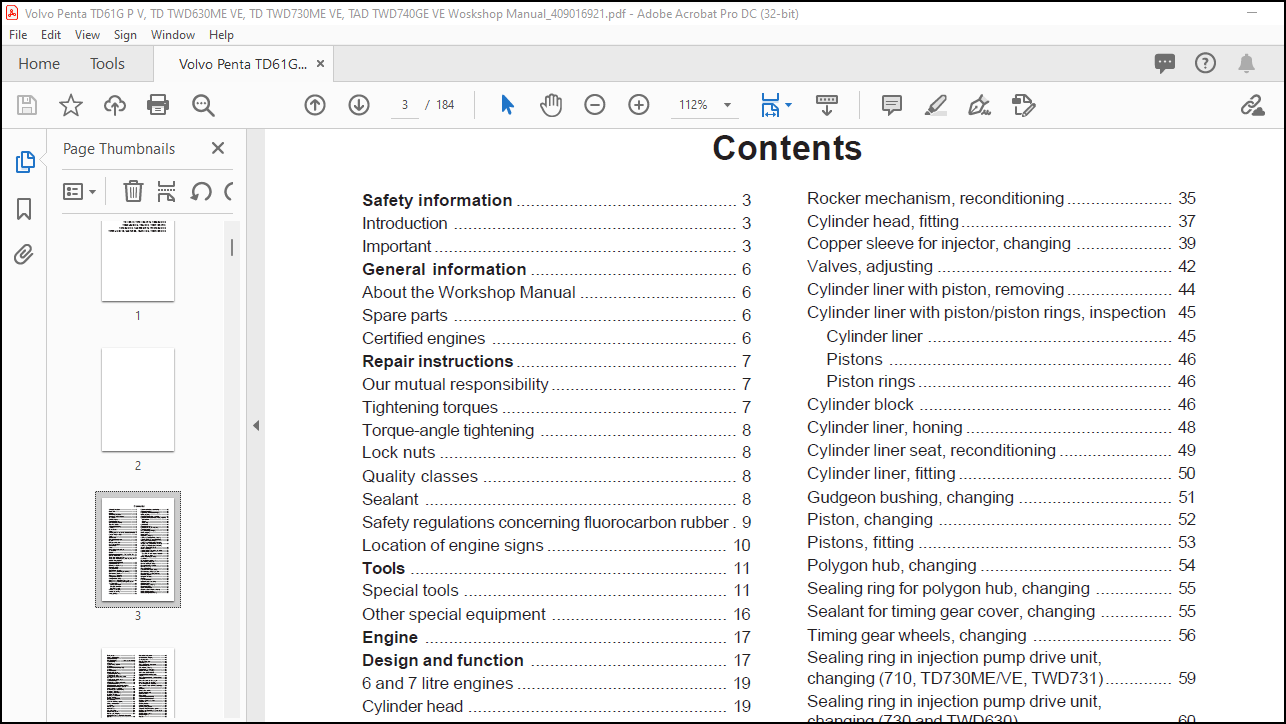

TABLE OF CONTENTS:

Volvo Penta TD610G/V, TWD610G/P/V, TD630ME/VE TWD630ME/VE, TD640VE, TWD710G/P/V, TD730ME/VE, TAD730G/P/V, TWD730ME/VE TWD731ME/VE, TAD740GE, TAD741GE, TWD740GE/VE Woskshop Manual_409016921 – PDF DOWNLOAD

Contents

Safety information ………………………………………. 3

Introduction ………………………………………………….. 3

Important ……………………………………………………… 3

General information ……………………………………. 6

About the Workshop Manual …………………………… 6

Spare parts ………………………………………………….. 6

Certified engines …………………………………………… 6

Repair instructions ………………………………………. 7

Our mutual responsibility ………………………………… 7

Tightening torques …………………………………………. 7

Torque-angle tightening ………………………………….. 8

Lock nuts …………………………………………………….. 8

Quality classes …………………………………………….. 8

Sealant ……………………………………………………….. 8

Safety regulations concerning fluorocarbon rubber . 9

Location of engine signs ……………………………….. 10

Tools ………………………………………………………… 11

Special tools ………………………………………………. 11

Other special equipment ………………………………. 16

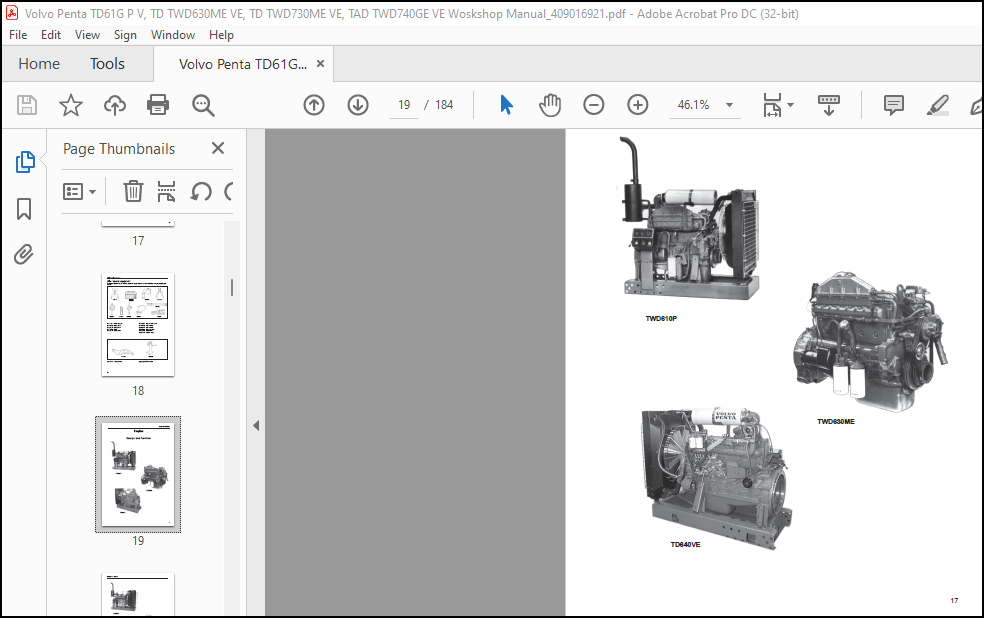

Engine ……………………………………………………… 17

Design and function ………………………………….. 17

6 and 7 litre engines …………………………………….. 19

Cylinder head ……………………………………………… 19

Valves ……………………………………………………….. 19

Cylinder block/cylinder liners …………………………. 20

Sealed joints ………………………………………………. 20

Pistons ……………………………………………………… 20

Fuel delivery pipe 630, 640, 730, 731, 740, 741 .. 21

Crankshaft/camshaft ……………………………………. 21

Timing gear wheels 610, 710 …………………………. 21

Timing gear wheels 630, 640, 730, 731, 740, 741 21

Injection timing adjuster

(TWD630ME, TWD730ME) …………………………… 22

Repair instructions …………………………………….. 23

Mounting the engine fixture …………………………… 23

Fuel delivery pipe ………………………………………… 24

Compression test ………………………………………… 24

Cylinder head, removing ……………………………….. 25

Cylinder head, dismantling/assembling …………… 26

Cylinder head, leak test ……………………………….. 27

Cylinder head, inspection ……………………………… 28

Valve guides, inspection ……………………………….. 29

Valve guides, changing…………………………………. 29

Cylinder head, facing 610, 710 engines …………… 30

Cylinder head, machining sealing grooves, 610

and 710 engines ………………………………………….. 30

Setting cutter depth ………………………………….. 31

Changing cutter set ………………………………….. 32

Machining grooves …………………………………… 33

Valve seats, changing ………………………………….. 34

Valve seats, grinding ……………………………………. 34

Valves, grinding …………………………………………… 35

Rocker mechanism, reconditioning …………………. 35

Cylinder head, fitting…………………………………….. 37

Copper sleeve for injector, changing ……………….. 39

Valves, adjusting …………………………………………. 42

Cylinder liner with piston, removing …………………. 44

Cylinder liner with piston/piston rings, inspection 45

Cylinder liner …………………………………………… 45

Pistons ………………………………………………….. 46

Piston rings …………………………………………….. 46

Cylinder block …………………………………………….. 46

Cylinder liner, honing ……………………………………. 48

Cylinder liner seat, reconditioning …………………… 49

Cylinder liner, fitting ……………………………………… 50

Gudgeon bushing, changing ………………………….. 51

Piston, changing …………………………………………. 52

Pistons, fitting …………………………………………….. 53

Polygon hub, changing …………………………………. 54

Sealing ring for polygon hub, changing ……………. 55

Sealant for timing gear cover, changing …………… 55

Timing gear wheels, changing ……………………….. 56

Sealing ring in injection pump drive unit,

changing (710, TD730ME/VE, TWD731)………….. 59

Sealing ring in injection pump drive unit,

changing (730 and TWD630) …………………………. 60

Camshaft, changing …………………………………….. 62

Sealant for timing gear casing, changing …………. 64

Checking camshaft wear ………………………………. 65

Camshaft and valve tappets, inspection ……….. 66

Camshaft, measuring ……………………………….. 67

Camshaft bearings, changing ………………………… 67

Crankshaft………………………………………………….. 68

Big end bearings, change all …………………………. 71

Main bearings, change all …………………………….. 72

Flywheel bearing, changing …………………………… 74

Flywheel, checking trueness …………………………. 74

Flywheel, changing ……………………………………… 75

Ring gear, changing …………………………………….. 75

Rear crankshaft seal, changing ……………………… 76

Flywheel casing, changing sealant …………………. 77

Flywheel casing, checking trueness ……………….. 78

Lubricating system ……………………………………. 79

Design and function ………………………………….. 79

Oil valves ……………………………………………………. 79

Repair instructions…………………………………….. 80

Lubricant pressure, checking ………………………… 80

Oil filter, changing ……………………………………….. 80

Oil filter housing, changing ……………………………. 81

Oil cooler, changing …………………………………….. 81

Leak test of oil cooler …………………………………… 83

Oil delivery pipe on inclined oil sump ………………. 85

Lubricant pump, changing …………………………….. 85

Lubricant pump, reconditioning ………………………. 88

Fuel system ………………………………………………. 91

Design and function ………………………………….. 91

General information ……………………………………… 91

EDC (TWD740VE) ……………… see separate manual

Injection pump …………………………………………….. 92

Governor ……………………………………………………. 92

Injection timing adjuster ……………………………….. 92

Feed pump …………………………………………………. 93

Smoke limiter (certain engines) ……………………… 93

Injectors …………………………………………………….. 93

Fuel delivery pipe ………………………………………… 94

Repair instructions…………………………………….. 95

Injection pump, removing ………………………………. 95

Injection pump, fitting …………………………………… 99

Injection pump, setting using meter

998 7057 ……………………………………………………108

Injection pump, sealing screw ……………………….110

Injectors, changing ………………………………………111

Copper sleeve for injector, cleaning ………………..112

Injectors, reconditioning ……………………………….113

Recommendations for adjusting opening

set pressure and changing injectors ……………….114

Opening pressure, adjusting ………………………….115

Fuel delivery pressure, checking ……………………116

Feed pump, changing…………………………………..116

Feed pump, reconditioning ……………………………117

Fuel filter, changing ……………………………………..120

Bleeding the fuel system ………………………………120

Fuel cut-off valve ………………………………………….121

Bleeding the fuel system ………………………………123

Troubleshooting …………………………………………..124

Intake and exhaust systems……………………….126

Design and function ………………………………….126

Intercooler ………………………………………………….126

Turbocharger ………………………………………………127

Starting heater ……………………………………………127

Air compressor ……………………………………………128

Repair instructions…………………………………….129

Turbocharger, changing ………………………………..129

Directions in case of turbo fault in intercooler

engines ……………………………………………………..130

Turbocharger, changing/fitting on engine………….130

Low-mounted turbo ………………………………………130

Boost pressure, checking …………………………….131

If the boost pressure is low ……………………………132

Checking exhaust back pressure …………………..133

Turbocharger, checking bearing play ………………134

Measuring axial play ………………………………..134

Measuring radial play ……………………………….134

Turbocharger, reconditioning …………………………135

Schwitzer S2A, S2B ………………………………..135

Holset H1E, H2A……………………………………..139

Exhaust manifold gaskets, changing ………………142

Intake manifold sealant/gasket, changing ………..144

Intercooler, changing ……………………………………145

Intercooler, leakage test ……………………………….145

Air compressor, changing …………………………….146

Cooling system …………………………………………148

Design and function ………………………………….148

Coolant pump ……………………………………………..149

Thermostat housing, thermostat …………………….149

Repair instructions…………………………………….150

Coolant pump, changing ……………………………….150

Coolant pump, reconditioning ………………………..151

Piston thermostat, changing …………………………153

Thermostat, functional check ………………………..155

Coolant manifold mounting seals,

changing ……………………………………………………156

Thermostat-controlled fan, functional check ……..159

Control unit ………………………………………………..159

Fan speed check, fan disengaged ………………….159

Fan speed check, fan engaged ……………………..160

Incorrect engagement temperature …………………160

Thermostat-controlled radiator fan, changing ……160

Coolant ……………………………………………………..161

Anti-freeze………………………………………………….161

Anti-corrosion additives ………………………………..161

Checking coolant level ………………………………….161

Draining coolant ………………………………………….162

Filling coolant ……………………………………………..162

Coolant temperature too high ………………………..162

Coolant temperature too low ………………………….163

Checking temperature sensor ………………………..163

Coolant leaks ……………………………………………..163

Checking radiator ………………………………………..163

Adjusting drive belts …………………………………….163

Cleaning cooling system ………………………………164

Test pressurising the cooling system ……………..165

Checking test pressurising equipment 6662 …….165

Pressure test ……………………………………………..165

Checking pressure valve ……………………………….166

Electrical system ……………………………………….167

Important ……………………………………………………167

Arc welding ………………………………………………..167

Starting with auxiliary battery ………………………..167

EDC system ………………………………………………167

Circuit diagram ……………………………………………168

Electronic engine speed governor …………………..172