$39

Wacker Neuson Compact Loaders 701s, 701sp Service Manual_1000164190 – PDF DOWNLOAD

Wacker Neuson Compact Loaders 701s, 701sp Service Manual_1000164190 – PDF DOWNLOAD

FILE DETAILS:

Wacker Neuson Compact Loaders 701s, 701sp Service Manual_1000164190 – PDF DOWNLOAD

Language : English

Pages :301

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Wacker Neuson Compact Loaders 701s, 701sp Service Manual_1000164190 – PDF DOWNLOAD

1 Operation 14

11 Important information on this service manual 14

12 Identification of warnings and dangers 15

13 Designated use and exemption from liability 16

14 Type labels and component numbers 17

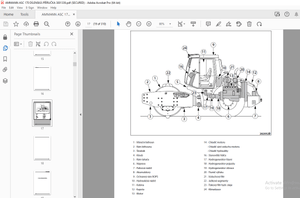

15 Machine overview 19

16 Cab overview 20

17 Cab (legend) 20

18 Round indicating instrument overview 21

19 Round indicating instrument (legend) 21

110 Engine compartment overview 22

701s 22

701sp 23

111 Engine cover (open): overview 24

701s 24

701sp 25

112 Chassis overview 26

113 Tilting the cab 27

2 Specifications 30

21 Chassis 30

22 Engine 30

Fuel injection pump 32

Capacity 32

Tightening torque 32

23 Travelling drive 33

24 Brakes 33

25 Work hydraulics 33

26 Pilot control 34

27 Additional control circuit + 3rd control circuit 34

28 Electric units 35

Fuse box in instrument panel 35

Main fuse box with relays 35

Relays 35

29 Tyres 36

210 Noise levels 36

211 Vibration 36

212 Coolant compound table 36

213 Dimensions 37

214 Model-specific tightening torques 38

215 General tightening torques 38

Tightening torques for hydraulic screw connections (dry assembly) 38

Tightening torques for high-resistance screw connections 40

31 Fluids and lubricants 42

Additional oil change and filter replacement (hydraulics) 43

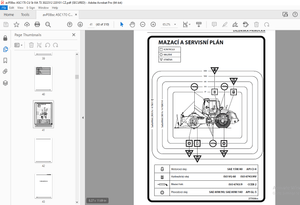

32 Maintenance label 44

Explanation of symbols on the maintenance label 44

33 Maintenance plan (overview) 46

34 Introduction 49

35 Fuel system 50

Specific safety instructions 50

Refuelling 50

Stationary fuel pumps 51

Diesel fuel specification 51

Bleeding the fuel system 51

Emptying the fuel tank 52

Fuel prefilter with water separator 52

Replacing the fuel filter 53

36 Engine lubrication system 54

Checking the oil level 54

Filling up engine oil 55

Changing engine oil 55

Replacing the engine oil filter cartridge 57

37 Cooling system 58

Specific safety instructions 58

Checking/filling up coolant 59

Draining coolant 60

38 Air filter 61

Replacing the filter 62

Functional check once a week of the dust valve 63

39 V-belt 64

Checking V-belt tension 64

Retightening V-belt 65

310 Pressure check 66

General 66

Standard micro ports 66

Variable displacement pump measuring points 67

Preparatory work 69

Main pressure check (P1 & P2) 69

Boost pressure check of pump and pilot control pressure check of work hydraulics 70

Work hydraulics pressure check 71

Checking the pilot control pressure of the drive hydraulics 72

Checking the parking brake release pressure 72

Checking the speed-sensitive control pressure 73

Checking the pressure of the 3rd control circuit (Power Flow option 701sp) 73

311 Test report 701s 74

312 Test report 701sp 76

313 Hydraulic system 78

Specific safety instructions 78

Checking the hydraulic oil level 79

Bleeding the hydraulic pump 80

Filling up hydraulic oil 80

After changing the hydraulic oil 81

Changing hydraulic oil 81

Monitoring the hydraulic oil reflux filter 82

Replacing the reflux filter 82

Checking hydraulic pressure lines 83

314 Travelling drive 84

Checking the oil level and filling up oil 84

Draining oil 84

315 Tyre maintenance 85

Tyre check 85

Wheel change 85

Raising and jacking up the machine 86

Removing the wheels 86

Mounting the wheels 86

316 Lubrication work 87

Loader unit 87

Lubrication points on the bucket 87

Maintenance of attachments 87

317 Electrical system 88

Specific safety instructions 88

Service and maintenance work at regular intervals 88

Instructions concerning specific components 89

Alternator 89

Battery 90

Jump-starting the engine 90

318 General maintenance work 91

Cleaning 91

General instructions for all areas of the machine 91

Inside the cab 92

Exterior of the machine 92

Engine compartment 92

Screw connections and attachments 92

Pivots and hinges 92

41 Engine 95

Turbocharged engine 4TNV84T-XNSS Power Flow (up to serial no DB00708) 95

Engine 4TNV88-XNSS (up to serial no DB00708) 97

42 Fuel system 99

43 Checking and adjusting valve clearance100

Valve clearance 4TNV88-XNSS (8 valves)100

Valve clearance 4TNV84T-XNSS (16 valves)101

44 Tightening order for cylinder head bolts102

45 Checking the injection nozzles103

Pressure check103

Injection nozzle 4TNV88-XNSS (8 valves)103

Injection nozzle 4TNV84T-XNSS (16 valves)103

46 Checking the nozzle jet104

47 Injection time104

Checking injection time104

Setting injection time105

Replacement of fuel injection pump106

48 Manual/pedal throttle107

49 Adjusting engine speed107

410 Compression108

411 Checking the coolant thermostat108

412 Checking the thermal switch109

413 Oil pressure switch109

414 Checking the coolant circuit109

415 Turbocharger RHB 31110

Tolerance values111

41 Engine (tier 3)112

4TNV88-BKNSS (from serial no DC00713)112

Turbocharged engine 4TNV84T-ZKNSS (from serial no DC00713)114

42 Fuel system116

43 Removing the valve cover117

44 Checking and adjusting valve clearance117

Valve clearance 4TNV88-BKNSS (8 valves)117

Valve clearance 4TNV84T-ZKNSS (16 valves)118

45 Tightening order for cylinder head bolts119

46 Checking the injection nozzles120

Pressure check120

Injection nozzle 4TNV88-BKNSS (8 valves)120

Injection nozzle 4TNV84T-ZKNSS (16 valves)120

47 Checking the nozzle jet121

48 Injection time121

Checking injection time121

Setting injection time123

Replacement of fuel injection pump124

49 Manual/pedal throttle125

410 Adjusting engine speed125

411 Compression126

412 Checking the coolant thermostat126

413 Checking the thermal switch127

414 Oil pressure switch127

415 Checking the coolant circuit127

416 Turbocharger RHB 31128

Tolerance values129

417 Engine trouble130

418 Electronic engine control unit (E-ECU) 4TNV84T-ZKNSS132

Turbocharged engine 4TNV84T-ZKNSS (from serial no DC00713)132

Features132

419 Engine error codes133

420 Error diagnosis137

E-ECU connector assignment137

Important information on the ECU maintenance wiring harness138

Flash code 7 – proportional injection pump solenoid (control rack)139

Related DTC (Diagnostic Trouble Codes)139

Diagnosis description141

Flash code 5 – manual throttle143

Related DTC143

Work description145

Flash code 4-1 ECU internal146

Related DTC146

Work description147

Flash code 4-1 ECU temperature sensor and 2-5 ECU temperature rise alarm148

Related DTC148

Work description149

Flash code 4 coolant temperature sensor and 3-6 coolant temperature rise alarm150

Related DTC150

Work description152

Flash code 2-4 – sensor 5 V154

Related DTC154

Work description155

Flash code 2-3 – power supply voltage157

(1) P0562/1: power supply voltage error (voltage too low)157

DTC detection conditions157

Troubleshooting157

Diagnosis description157

(2) P0563/0: power supply voltage error (voltage too high)158

DTC detection conditions158

Troubleshooting158

Diagnosis description158

Flash code 6 – engine speed sensor159

Work description161

Flash code 1-1 – backup engine speed sensor162

Related DTC162

Work description164

Flash code 9 – overspeed error165

(1) P0219/0: overspeed error165

DTC detection conditions165

Troubleshooting165

Diagnosis description165

Flash code 1-7 – proportional solenoid relay of the injection pump (control rack)166

Related DTC166

Work description168

Flash code 1-5 – preheating relay170

Related DTC170

Work description171

Flash code 1-4 – CSD (cold start device) solenoid coil174

Related DTC174

Work description175

Flash code 1-3 – EGR (exhaust gas recirculation) valve177

Related DTC177

Work description179

Flash code 2-1 – oil pressure switch and 3-1 – oil pressure drop error181

Related DTC181

Work description183

Flash code 8 – proportional injection pump solenoid (control rack)185

Related DTC185

Work description187

Flash code 1-6 – main relay189

Related DTC189

Work description191

Flash code 1-2 – CAN (Controller Area Network) communication193

Related DTC193

Work description194

5 Hydraulic system197

51 Rexroth A20 – VG45 hydraulic pump197

Pump unit: exploded view199

Pump distribution200

52 Main valve block201

Ports201

Legend201

Main valve block diagram202

53 Hydraulic control203

Control lever203

Joystick (left)204

Joystick (right)207

Auxiliary hydraulics control210

Function210

Adjustment210

54 Travelling drive211

Function211

Drive (exploded view)211

Front drive gear213

Rear drive gear (braked)214

Travelling drive layout215

55 Valves216

3/3 directional valve (flush valve)216

56 Parallel bucket lift217

Function217

Layout218

57 Breather filter219

58 Troubleshooting in the hydraulic system220

59 Hydraulics diagram A4 (701s)221

510 Hydraulics diagram (legend) (701s)222

511 Hydraulics diagram A4 (701sp)223

512 Hydraulics diagram (legend) (701sp)224

513 Hydraulics diagram H-controls A4 (701sp)225

514 Hydraulics diagram H controls (701sp) (legend)226

515 Hydraulics diagram H-controls with lock A4 (701sp)227

516 Hydraulics diagram H controls with lock (701sp) (legend)228

513 Hydraulics diagram 701s A3 up to serial no DB00708229

514 Hydraulics diagram 701sp A3 up to serial no DB00708230

515 Hydraulics diagram 701s A3 from serial no DC00713231

516 Hydraulics diagram 701sp A3 from serial no DC00713232

517 Hydraulics diagram H-controls 701 sp A3233

518 Hydraulics diagram H-controls with lock 701 sp A3234

6 Electrical system236

61 Ohm’s Law (current, voltage, resistance); power236

62 Measuring equipment, measuring methods236

63 Cable colour coding238

64 Relays238

Use, mode of function238

65 Electric units239

Fuse box in instrument panel239

Main fuse box with relays239

Relays239

66 Socket240

67 Turn indicators (option)240

68 Round indicating instrument overview241

69 Switches: overview242

610 Alternator242

611 Starter243

612 Wiring diagram up to serial no DB00708 (legend)245

613 Wiring diagram up to serial no DB00708246

614 Wiring diagram from serial no DC00713 (legend)247

615 Wiring diagram from serial no DC00713248

616 701s engine – chassis wiring harness 1000147293 up to serial no DB00708 (legend)250

617 701s engine – chassis wiring harness 1000147293 up to serial no DB00708251

618 701s engine – chassis wiring harness 1000183063 from serial no DC00713 (legend)252

619 701s engine – chassis wiring harness 1000183063 from serial no DC00713253

620 701sp engine – chassis wiring harness 1000185442 from serial no DC00713 (legend)254

621 701sp engine – chassis wiring harness 1000185442 from serial no DC00713255

622 Switches wiring harness 1000139289 up to serial no DB00708 (legend)256

623 Switches wiring harness 1000139289 up to serial no DB00708257

624 701s switches wiring harness 1000183064 from serial no DC00713 (legend)258

625 701s switches wiring harness 1000183064 from serial no DC00713260

626 701sp switches wiring harness 1000185268 from serial no DC00713 (legend)261

627 701sp switches wiring harness 1000185268 from serial no DC00713263

628 Wiring harness 1000147262: rear lights (option)264

629 Wiring diagram up to serial no DB00708 (legend)266

630 Wiring diagram up to serial no DB00708267

631 Wiring diagram from serial no DC00713 (legend)268

632 Wiring diagram from serial no DC00713269

633 701s engine – chassis wiring harness 1000147293 up to serial no DB00708 (legend)271

634 701s engine – chassis wiring harness 1000147293 up to serial no DB00708272

635 701s engine – chassis wiring harness 1000183063 from serial no DC00713 (legend)273

636 701s engine – chassis wiring harness 1000183063 from serial no DC00713274

637 701sp engine – chassis wiring harness 1000185442 from serial no DC00713 (legend)275

638 701sp engine – chassis wiring harness 1000185442 from serial no DC00713276

639 Switches wiring harness 1000139289 up to serial no DB00708 (legend)277

640 Switches wiring harness 1000139289 up to serial no DB00708278

641 701s switches wiring harness 1000183064 from serial no DC00713 (legend)279

642 701s switches wiring harness 1000183064 from serial no DC00713280

643 701sp switches wiring harness 1000185268 from serial no DC00713 (legend)281

644 701sp switches wiring harness 1000185268 from serial no DC00713282

645 Wiring harness 1000147262: rear lights (option) A3283

7 Options286

71 Rear working light286

Wiring harness286

Connections286

72 BP – Biohyd SE 46287

Properties287

73 Biodegradable oil Panolin287

Properties287

74 Rearview mirror package287

75 Drive interlock (antitheft protection)288

Machine288

Disabling the drive interlock288

Enabling the drive interlock288

Programming288

76 Rotating beacon289

Wiring harness290

Connections290

77 Crane-handling bracket291

78 FOPS roof level 2292

79 Backup warning system293

Function293

Position293

710 Side window294

Attachment294

711 Full cab glazing (option)295

712 Stabilisers296

713 Road travel certification297

714 Airboss tyres298

Attachment298

715 Power Flow ports298

Couplings299

IMAGES PREVIEW OF THE MANUAL: