$45

Wacker Neuson Group Telehandlers TH522 Service Manual PDF DOWNLOAD

Wacker Neuson Group Telehandlers TH522 Service Manual

FILE DETAILS:

Wacker Neuson Group Telehandlers TH522 Service Manual

Language : English

Pages : 574

Downloadable : YES

Format : PDF

Size : 81.8 MB

DESCRIPTION:

Wacker Neuson Group Telehandlers TH522 Service Manual

INTRODUCTION:

This Service Manual is designed to help maintain the constant serviceability of your vehicle. Subsequently, this assures the high value of the vehicle thanks to careful care and customer-service monitoring. The experience of our customer service technicians and practical experience are concentrated in this Service Manual. The sequence of images illustrates the repair procedure.

- The text provides the necessary information for making adjustments, using special tools, etc. The main types of maintenance work are listed in such a way that individual tasks and more minor tasks are comprehendible and easily found.

- The book is supplemented to reflect the technical further development of the vehicle and is therefore always up to date as a means of reference. To be on the safe side, please always compare the adjustment values and capacities with the current operating manual of the respective machine. Technical data, dimensions and weights are only given as an indication. Responsibility for errors or omissions not accepted. Some pictures can differ visually from the actual object.

TABLE OF CONTENTS:

Wacker Neuson Group Telehandlers TH522 Service Manual

E Introduction

E1 About this Service Manual E-1

E2 Tightening torques E-7

E3 Safety instructions E-19

B Operation

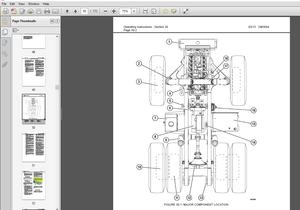

B1 Overview of control elements B-2

B2 Indicator lights and warning lights (overview) B-14

B3 Steering system B-31

B4 Accelerator actuation B-33

B5 Brakes B-35

B6 Travel operation B-36

B7 Differential lock (option) B-43

B8 Lights/signaling system B-45

B9 Wiper/washer system B-49

B10 Heating, ventilation and air conditioning system B-50

B11 Operating hydraulics B-52

B12 Attachments B-65

B13 Work operation B-71

B14 Emergency lowering B-84

B15 Options B-86

1 Maintenance

11 Information on maintenance 1-1

12 Maintenance overview 1-7

13 Fluids and lubricants 1-17

14 Maintenance accesses 1-19

15 Cleaning and maintenance 1-20

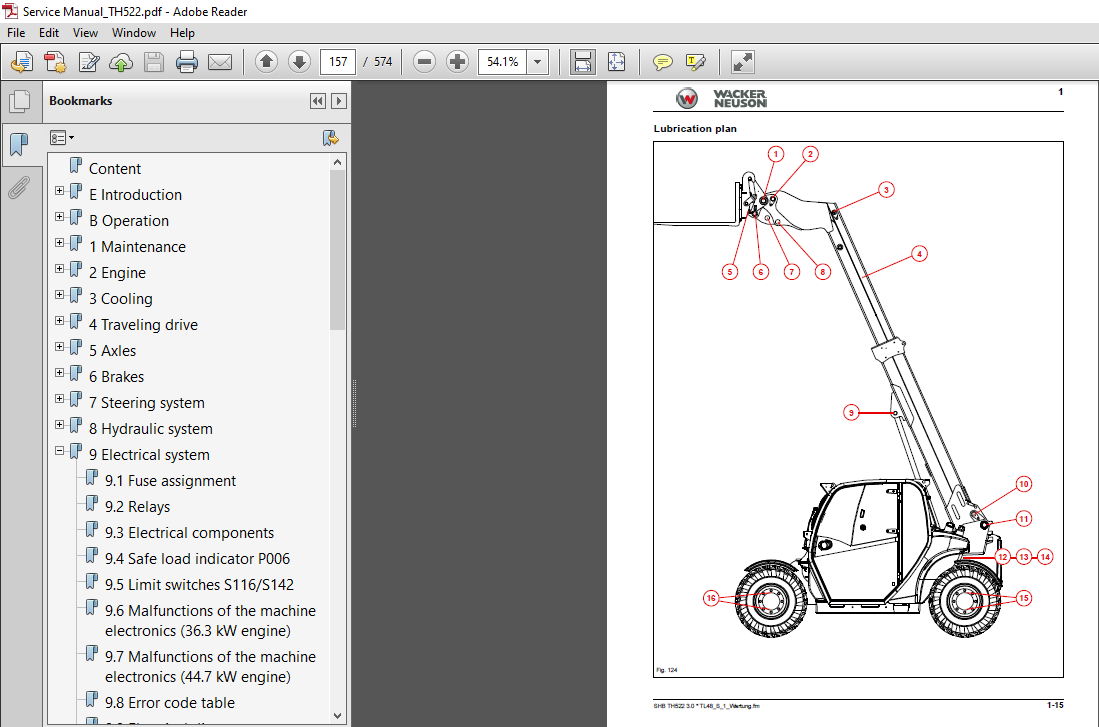

16 Lubrication work 1-22

17 Fuel system 1-22

18 Engine lubrication system 1-29

19 Cooling system 1-31

110 Air filter 1-35

111 V-belt/toothed belt 1-37

112 Hydraulic system 1-39

113 Electrical system 1-43

114 Heating, ventilation and air conditioning system (option) 1-48

115 Washer system 1-51

116 Axles/traveling drive 1-52

117 Braking system 1-53

118 Tires 1-54

119 Maintenance and servicing work on attachments 1-57

120 Maintenance of options 1-58

121 Exhaust gas treatment 1-59

2 Engine

21 Complete component (engine 367 kW) 2-1

22 Alternator (367 kW) 2-27

23 Motor starter M001 (367 kW) 2-31

24 Complete component (engine 443 kW) 2-33

25 Alternator (443 kW) 2-59

26 Motor starter M001 (443 kW) 2-63

27 Diesel particulate filter (engine 443 kW) 2-65

28 Fuel tank 2-67

29 Tank sensor B001 2-77

Content

I-2 SHB TH522 30 * SHB_TH522_V3_enIVZfm

I

3 Cooling

31 Coolant reservoir 3-2

4 Traveling drive

41 Cardan shaft 4-2

42 Servomotor M17/M18 4-5

43 Type label – transfer gearbox 4-11

44 Tightening torques and screw locking 4-13

45 Drain, filler and check plugs 4-15

5 Axles

51 Front axle 5-1

52 Rear axle 5-11

53 Type plate – front/rear axle 5-27

54 Tightening torques and screw locking 5-29

55 Drain, filler and check plugs 5-35

6 Brakes

61 Replacing brake linings 6-2

7 Steering system

71 Steering orbitrol S8 7-1

72 Steering mode valve V64 7-3

8 Hydraulic system

81 Hydraulic oil tank Z41 8-1

82 Variable displacement pump P34/P35 8-3

83 Quickhitch 8-7

84 Telescopic boom 8-15

85 Lift cylinder A57 8-25

86 Push-out cylinder A59 8-31

87 Tilt cylinder A58 8-39

88 Compensation cylinder A60 8-47

89 Designation of hydraulic components 8-53

810 Hydraulics diagram – variant 1 8-55

811 Hydraulics diagram – variant 2 8-57

812 Hydraulic diagram – variant 3 8-59

813 Hydraulics diagram – variant 4 8-61

814 Hydraulics diagram – variant 5 8-63

815 Hydraulics diagram – 4-way control valve 8-65

816 Hydraulics diagram – 5-way control valve 8-67

817 Hydraulics diagram – 6-way control valve 8-69

818 Hydraulics diagram – 7-way control valve 8-71

819 Hydraulics diagram – 8-way control valve 8-73

820 Hydraulics diagram – compensating and lift cylinder 8-75

821 Hydraulics diagram – push-out cylinder 8-77

822 Hydraulics diagram – tilt cylinder 8-79

823 Hydraulics diagram – steering system 8-81

824 Hydraulic circuit diagram – brakes 8-83

825 Hydraulic circuit diagram – differential lock 8-85

826 Hydraulics diagram – 3rd control circuit parallel / 4th control circuit parallel with switchover valve 8-87

827 Hydraulics diagram – 3rd control circuit serial / 4th control circuit parallel 8-89

828 Hydraulics diagram – 3rd and 4th control circuit parallel, rear hydraulic connections serial 8-91

829 Hydraulics diagram – 3rd / 4th control circuit and rear hydraulics parallel, rear hydraulic

connections serial 8-93

830 Hydraulics diagram – 3rd / 4th control circuit and rear hydraulics parallel, rear hydraulic

connections serial, HighFlow and PTO shaft single-acting 8-95

SHB TH522 30 * SHB_TH522_V3_enIVZfm I-3

I

9 Electrical system

91 Fuse assignment 9-2

92 Relays 9-4

93 Electrical components 9-4

94 Safe load indicator P006 9-5

95 Limit switches S116/S142 9-9

96 Malfunctions of the machine electronics (363 kW engine) 9-13

97 Malfunctions of the machine electronics (447 kW engine) 9-15

98 Error code table 9-17

99 Electrical diagram – electronics, power supply 9-19

910 Electrical diagram – Perkins 404D-22 engine 9-20

911 Electrical diagram – Perkins 404D-22 engine 9-21

912 Electrical diagram – Perkins 404F-22 engine 9-22

913 Electrical diagram – Perkins 404F-22 engine 9-23

914 Electrical diagram – Ciam instrument 9-24

915 Electrical diagram – Bauser instrument 9-25

916 Electrical diagram – drive function 9-26

917 Electrical diagram – extension and retraction; VLS; Load control 9-27

918 Electrical diagram – indicator system; Horn 9-28

919 Electrical diagram – StVZO (German traffic regulations) lights 9-29

920 Electrical diagram – StVZO (German traffic regulations) lights 9-30

921 Electrical diagram – working lights; Rotating beacon 9-31

922 Electrical diagram – air conditioning; Seat 9-32

923 Electrical diagram – wiper 9-33

924 Electrical diagram – 12V electrical connection; Hydraulic control circuits 9-34

925 Electrical diagram – Hydraulics 1 9-35

926 Electrical diagram – Hydraulics 2 9-36

927 Electrical diagram – Radio; Cigarette lighter socket; Interior light 9-37

928 Electrical diagram – rear force sensorr 9-38

929 Electrical diagram – steering mode switchover 9-39

930 Designation of electrical components 9-41

931 Connector pin assignment 9-51

932 Pin assignment (only 337 kW engine) 9-71

933 Pin assignment (only 443 kW engine) 9-74

10 Trim

101 Engine cover 10-1

102 Underride protection 10-5

103 Rear covers 10-7

104 Cabin covers 10-9

11 Cabin

111 Seat 11-1

112 Cabin 11-5

113 Air conditioning cooler 11-15

114 Air conditioning system compressor Y031 11-17

12 Automatic coupling

121 Ball coupling 12-12

122 Automatic/rotating trailer coupling 12-16

123 Self-securing coupling 12-18

13 Switch

131 Overview of switch assignment 13-2

Index

INDEX:

A

Abbreviations E-3

Accident prevention regulations

general information E-20

Adding hydraulic oil 1-41

Adjusting the pallet forks B-82

Air conditioning

Disassemble 11-17

Disassemble compressor 11-17

Removing the condenser 1-34

Air conditioning compressor

Disassemble 11-17

Air conditioning cooler

Disassemble 11-15

Install 11-15

Alternator

Disassemble 2-27, 2-59

Install 2-29, 2-61

Attachments

Bucket B-74

Coupling B-68

Fork-and-grab attachment B-80

Maintenance 1-57

Manure forks B-79

Pallet forks B-81, B-83

Universal bucket B-77

Automatic trailer coupling

Disassemble 12-16

Install 12-16

B

Ball coupling

Disassemble 12-13

Install 12-13

Battery

Emergency starting/jump-starting 1-46

Battery master switch B-42, 1-5

Bleed the fuel system 1-28

Brake/inching pedal B-35

Brakes

Replacing brake linings 6-2

C

Cabin

Disassemble 11-5

Install 11-10

Cabin covers

Disassemble 10-9

Install 10-10

Cardan shaft

Disassemble 4-2

Central lubrication system B-93

Checking the antifreeze mixture 1-33

Checking the brake-fluid level 1-53

Checking the hydraulic oil level 1-41

Checking/cleaning/replacing the engine air filter 1-36

Cleaning and maintenance 1-20

Compensating ram

Disassemble 8-47

Compensation cylinder

Install 8-50

Compressor air conditioning system

Disassemble 11-17

Install 11-17

Connector

Pin assignment 9-51

Control elements

Overview B-3

Coolant reservoir

Disassemble 3-2

Install 3-3

Cooling system

Checking the antifreeze mixture 1-33

Checking/adding coolant 1-31

Clean 1-33

D

Designation

Electrical components 8-53, 9-41

Hydraulic components 8-53

Differential housing

Screw lock 5-32

Tightening torques 5-31, 5-32

Differential lock B-44

Index

S-2 SHB TH522 30 * SHB_TH522_V2_enSIXfm

S

E

Electrical components 9-4

Electrical diagram

12 V power outlet 9-37

12V electrical connection 9-34

Air conditioning 9-32

Bauser instrument 9-25

Ciam instrument 9-24

Drive function 9-26

Electronics 9-19

Extension and retraction 9-27

Horn 9-28

Hydraulic control circuits 9-34

Hydraulics1 9-35

Hydraulics2 9-36

Interior light 9-37

Load control 9-27

Perkins 404D-22 engine 9-20, 9-21

Perkins 404F 22-T engine 9-22, 9-23

Power supply 9-19

Radio 9-37

Rear force sensor 9-38

Rotating beacon 9-31

Seat 9-32

Steering mode switchover 9-39

StVZO (German traffic regulations) lights 9-29,

9-30

Turn indicator system 9-28

VLS 9-27

Wiper 9-33

Working lights 9-31

Electrical system

Fuses and relays 1-43

Units 9-4

Emergency lowering B-84

Emergency starting/jump-starting 1-46

Engine

Checking the engine-oil level 1-29

Disassemble 2-6, 2-37

Install 2-16, 2-48

Preheating B-95

Engine cover

Disassemble 10-2

Install 10-3

Engine lubrication system 1-29

Engine oil and hydraulic oil preheating B-95

Error code table 9-17

Excavation work B-76

Exchanging attachments B-65

Explanation of symbols E-3

F

Filling the central lubrication system 1-58

Filling up the washer system 1-51

Fluids and lubricants 1-17

Front axle

Check plug 5-35

Disassemble 5-3

Drain plug 5-35

Filler plug 5-35

Install 5-7

Threaded fittings 4-13, 5-29

Type label 4-11, 5-27

Front cardan shaft

Install 4-3

Front wiper/washer system B-49

Fuel sensor

Disassemble 2-77

Install 2-78

Fuel tank

Disassemble 2-68

Install 2-72

Fuse assignment 9-2

G

General regulations

Accident prevention E-20

Safety E-20

General safety check 1-21

H

handling

Repair book E-2

Hydraulic oil reservoir

Disassemble 8-2

Install 8-2

Hydraulic system

Breather filter 1-40

Hydraulic oil 1-40

Hydraulics diagram

3rd control circuit parallel 8-87, 8-91, 8-93, 8-95

3rd control circuit, serial 8-89

4th control circuit parallel with switchover valve

SHB TH522 30 * SHB_TH522_V2_enSIXfm S-3

S

8-87

4th control circuit, parallel 8-89, 8-91, 8-93, 8-95

4-way control valve 8-65

5-way control valve 8-67

6-way control valve 8-69

7-way control valve 8-71

8-way control valve 8-73

Brakes 8-83

Compensating ram 8-75

Differential lock 8-85

HighFlow and PTO shaft single-acting 8-95

Lift cylinder 8-75

Push-out cylinder 8-77

Rear connections serial 8-91, 8-93, 8-95

Rear hydraulics, parallel 8-93, 8-95

Steering system 8-81

Tilt cylinder 8-79

Variant 1 8-55

Variant 2 8-57

Variant 3 8-59

Variant 4 8-61

Variant 5 8-63

I

Inflating the tires 1-55

L

Lift cylinder

Disassemble 8-25

Install 8-27

Limit switch

Adjust 9-9

Load sensor

Install 9-10

Loader unit control lever B-52

Loader unit stabilizer B-92

Locking the loader unit B-57

M

Machine

Cleaning 1-21

Lubrication 1-22

Maintenance

Air conditioning 1-49

Attachments 1-57

Axles 1-52

Bleed the fuel system 1-28

Braking system 1-53

Cabin breather filter 1-48

Checking the brake-fluid level 1-53

Cleaning the condenser of the air conditioning system

1-49

Engine air filter 1-36

Fuel/water separator 1-25, 1-27

Inflating the tires 1-55

Lubrication plan 1-15

Tires 1-54

Washer system 1-51

Maintenance access

Transmission tunnel cover 10-5, 10-7

Malfunctions

of the machine electronics (363 kW engine) 9-13

of the machine electronics (447 kW engine) 9-15

Manual inching B-91

O

Operation

Central lubrication system B-94

Differential lock B-44

Electric power outlet on the loader unit B-86

Emergency lowering B-84

Engine speed setting B-91

Fan B-50

Horn B-48

Locking the loader unit B-57

Low/high beam B-46

Manual speed control adjustment B-91

Travel mode B-38

Working lights B-45

Operator seat

Disassemble 11-2

Install 11-3

Overview

Switch assignment 13-2

P

Parking brake B-35

Planetary drive housing

Tightening torques 5-33

Plug

Tightening torques 5-31

Push-out cylinder

Disassemble 8-31

Install 8-34

Q

Quickhitch

Disassemble 8-8, 8-11

Install 8-11

S-4 SHB TH522 30 * SHB_TH522_V2_enSIXfm

S

R

Rear axle

Check plug 5-36

Disassemble 5-12

Drain plug 5-36

Filler plug 5-36

Install 5-18

Threaded fittings 4-13, 5-29

Type label 4-11, 5-27

Rear cover

disassemble 10-7

Rear hydraulic connection B-26

Rear hydraulic connections B-96

Rear wiper B-49

Reduction gear

Screw lock 5-29

Tightening torques 5-29

Refueling with diesel fuel 1-23

Relays 9-4

Repair book

handling E-2

Repair Instructions

Cause of Damage E-4

Diesel engine E-4

Gearbox E-4

Spare Parts E-4

Technical Specifications E-4

Replacing brake linings

Parking brake 6-2

Service brake 6-4

Residual pressure in hydraulic system B-85

Reverse warning system B-48

Rotating beacon B-47

S

Safe load indicator

0%-point calibration 9-6

100%-point calibration 9-6

calibrate 9-5

Safety E-19

Safety regulations

general information E-20

Screw connections E-5

Screw dimensions E-7

Self-securing coupling

Disassemble 12-18

Install 12-18

Signal words E-19

Starter

Disassemble 2-31, 2-63

Install 2-32, 2-64

Steering cylinder

Tightening torques 5-30

Steering modes B-31

Switch assignment

Overview 13-2

T

Technical data

Electrical components 9-4

Telematik B-104

Telescopic boom

Disassemble 8-16

Install 8-20

Tightening torques

adjustable hydraulic screw struts E-16

brake line screw connections E-18

climate screw fixtures E-10

general information E-7

hollow screws E-15

hydraulic screw connections E-10, E-11

hydraulic screw struts E-12

hydraulic swivel screw fittings E-15

metric fine threads E-9

metric regulation threads E-8

specific E-7

worm drive clips E-18

Tilt cylinder

Disassemble 8-40

Install 8-43

Tools E-5

Transfer case 20 km/h

Check plug 4-15

Drain plug 4-15

Filler plug 4-15

Tightening torques 4-13

Transfer case 30 km/h

Check plug 4-16

Drain plug 4-16

Filler plug 4-16

Screw lock 4-14

Tightening torques 4-14

Transfer gearbox

Type label 4-11

Transmission tunnel cover

Install 10-7

Travel direction selection B-37

Travel mode B-38

Turn indicators B-46

U

Underride protection

Disassemble 10-5

Install 10-6

V

Variable displacement motor

Disassemble 4-8

Install 4-9

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: