$45

Wacker Neuson Telehandlers TH744 TH750 TH755 Operator's Manual PDF DOWNLOAD

Wacker Neuson Telehandlers TH744 TH750 TH755 Operator’s Manual

FILE DETAILS:

Wacker Neuson Telehandlers TH744 TH750 TH755 Operator’s Manual

Language : English

Pages : 514

Downloadable : YES

Format : PDF

Size : 16.4 MB

DESCRIPTION:

Wacker Neuson Telehandlers TH744 TH750 TH755 Operator’s Manual

PREFACE :

Operator’s manual :

- This Operator’s Manual only applies to the machines on the cover sheet. It provides information on how to use, adjust and operate the machine, and on how to perform maintenance on it, and is therefore only intended for the operator and operating company. Before performing machine travel or operation for the first time, the user must be briefed on this machine and must carefully read and understand this Operator’s Manual, in particular chapter “Safety instructions”.

- Work on the machine may only be performed by trained and instructed personnel that have been authorized by the operating company. Any person involved in operation, inspection, maintenance, servicing, repair work or transport of the machine must read, understand and follow the complete instructions in the Operator’s Manual and in particular the safety instructions.

- The buyer/operating company is responsible for the operators’ training in safe working on and with the machine. The basis for this in the Federal Republic of Germany is the “DGUV principle 308-009.” Get informed on and follow the legal regulations of your country. recommend repeating the training sessions at regular intervals. The buyer/operating company is responsible for ensuring that any additional safety regulations applicable in the country of use of the machine are followed. The machine may only be operated by persons who are physically, mentally and professionally suited for this work. Persons under the influence of alcohol or drugs may not use the machine. The operator is the person performing machine operation and/or travel.

• Before putting the machine into operation, the operator of the machine must ensure that it is in a perfect condition, and during operation, the operator must observe the regulations regarding operation.

• The operator is responsible for ensuring that the machine and its use do not pose a risk.

• Before working with the machine, operators must familiarize themselves with all the control elements and their functions, and with the handling of the machine.

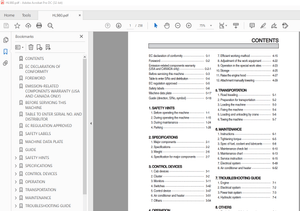

TABLE OF CONTENTS:

Wacker Neuson Telehandlers TH744 TH750 TH755 Operator’s Manual

EC Declaration of Conformity EG-1

EC Declaration of Conformity EG-2

EC Declaration of Conformity EG-3

1 Foreword

1 1 Operator’s Manual 1-1

1 2 Warranty and liability 1-4

2 Safety

2 1 Safety symbols and signal words 2-1

2 2 Conduct and safety instructions 2-2

2 3 Qualification of operating and maintenance personnel 2-3

2 4 Operation 2-4

2 5 Lifting gear applications 2-8

2 6 Trailer operation 2-10

2 7 Attachment operation 2-11

2 8 Towing, loading and transporting 2-12

2 9 Maintenance 2-15

2 10 Measures for avoiding risks 2-18

3 Introduction

3 1 Machine overview 3-1

3 2 Brief description of machine 3-4

3 3 Information and regulations on use 3-5

3 4 Labels 3-16

4 Putting into operation

4 1 Cabin/control stand 4-1

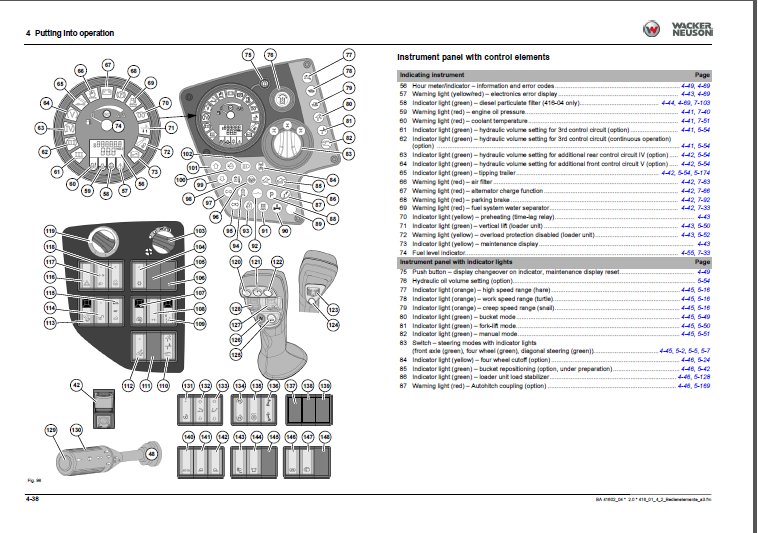

4 2 Overview of control elements 4-35

4 3 Indicator lights and warning lights (overview) 4-41

4 4 Preparatory work 4-56

4 5 Starting and stopping the engine 4-64

5 Operation

5 1 Steering system 5-1

5 2 Accelerator actuation 5-8

5 3 Brakes 5-11

5 4 Travel operation 5-15

5 5 Differential lock 5-25

5 6 Lights/signalling system 5-26

5 7 Wiper/wash system 5-35

5 8 Heating, ventilation and air conditioning system 5-37

5 9 Operating hydraulics 5-39

5 10 Attachments 5-72

5 11 Work operation 5-123

5 12 Emergency lowering 5-160

5 13 Options 5-161

5 14 Putting out of operation/back into operation 5-198

5 15 Permanently putting out of operation 5-200

6 Transport

6 1 Towing the machine 6-1

6 2 Loading the machine 6-6

6 3 Transporting the machine 6-10

Table of contents

I-2 BA 41602_04 * 2 0 * BA_41601_03_07_V2_enIVZ fm

Table of contents

7 Maintenance

7 1 Information on maintenance 7-1

7 2 Maintenance overview 7-3

7 3 Fluids and lubricants 7-12

7 4 Maintenance accesses 7-16

7 5 Cleaning and maintenance 7-19

7 6 Lubrication work 7-24

7 7 Fuel system 7-33

7 8 Engine lubrication system 7-40

7 9 Cooling system 7-51

7 10 Air filter 7-63

7 11 V-belt/toothed belt 7-66

7 12 Hydraulic system 7-71

7 13 Electrical system 7-77

7 14 Heating, ventilation and air conditioning system 7-83

7 15 Washer system 7-90

7 16 Axles/travelling drive 7-91

7 17 Braking system 7-92

7 18 Tyres 7-94

7 19 Maintenance of attachments 7-97

7 20 Maintenance of options 7-98

7 21 Exhaust gas treatment 7-101

7 22 Machine preservation 7-106

8 Malfunctions

8 1 Diesel engine malfunctions 8-1

8 2 Drive malfunctions 8-4

8 3 Malfunctions of the hydraulic system 8-4

8 4 Malfunctions of the electrical system 8-5

8 5 Malfunctions in the air conditioning system (option) 8-17

9 Technical data

9 1 Model and trade names 9-1

9 2 Engine 9-1

9 3 Travelling drive/axles 9-3

9 4 Brakes 9-5

9 5 Tyres 9-6

9 6 Steering system 9-7

9 7 Operating hydraulics 9-8

9 8 Electrical system 9-11

9 9 Tightening torques 9-19

9 10 Coolant 9-19

9 11 Noise emissions 9-20

9 12 Vibration 9-20

9 13 Weight 9-20

9 14 Payload/lift capacity/stability 9-21

9 15 Dimensions 9-28

Index

Index S-1

INDEX:

Abbreviations 1-3

Accelerator actuation 5-8

Accelerator pedal 5-8

Accident prevention regulations 3-9

Acoustic warnings 4-52

Additional control circuit 5-61

Additional control circuit IV 5-64

Additional control circuit V 5-69

Additional electrical functions 5-158

Additional equipment 5-161

Additional front/rear hydraulic control circuit 5-64, 5-69

Adjusting the mirror on the left 4-13

Adjusting the mirror on the right 4-14

Adjusting the wide-angle mirror (option)

on the right 4-15

Agricultural or forestry registration 3-6

Air conditioning 5-37, 5-38

Air filter 7-63

Cleaning the dust collector 7-65

Airing the cabin 4-3

Air-suspension seat 4-24

Alternator 7-79, 9-15

Anticorrosion agents 7-20

Anticorrosion protection 7-19, 7-106

Area of obstructed vision 4-8, 4-10, 4-11, 4-12

Attachment

Locking 5-58

Overview 3-11

Safety 2-11

Unlocking 5-58

Attachment lights 5-158

Attachments from

other manufacturers 5-87, 5-99, 5-111

Inspection plan 5-98, 5-110, 5-122

Quickhitch 5-87

Autohitch trailer coupling (option) 5-169

Automatic trailer coupling 5-161

Axles 7-91, 9-3

B

Backfilling round gravel 5-138

Backrest 4-21

Backrest adjustment 4-21

Backup warning system 5-34

Ball trailer coupling ø 80 mm (option) 5-165

Battery 2-19, 9-15

Battery master switch 4-27

Behaviour during thunderstorm 2-22

Biodegradable oils 7-15

Bleeding the fuel system and refuelling 2-19

Boost pressure drop 5-14

Brake discs

Disabling 6-2

Enabling 6-5

Brake hose 5-182

Brake/inching pedal 5-11

Brakes 5-11, 5-12, 9-5

Braking system 7-92

Safety instructions 7-92

Breakout force 9-21

Brief description of machine 3-4

Bucket mode 5-49

Bucket repositioning 5-44, 5-155

Buzzer

Backup warning system 4-53

Machine electronics 4-53

Steering system 4-53

Index

S-2 BA 41602_04 * 2 0 * BA_41601_03_07_V2_enSIX fm

Index

C

Cabin 3-21, 4-1, 4-2

Calculation for attachments from

other manufacturers 5-96, 5-108, 5-120

Camera 4-18, 5-185

Carrying passengers 2-6

Central lubrication system 7-30

Certified attachments 3-11

Changing speed range 5-17

Check number of EC approval 3-20

Checking/replacing the battery 7-78

Cleaning 2-22, 7-19

Inside the cabin 7-21

Motor and engine compartment 7-23

On the outside of the machine 7-22

Seat belt 7-21

Cleaning and maintenance 7-19

Cold starter 4-66

Compressed air 7-19

Compressed-air braking system 2-18, 5-177

Compressed-air braking system of trailer 5-177

Compressed-air gauge 5-178

Compressed-air hoses 5-178

Conduct and safety instructions 2-2

control 3rd circuit (additional) plug couplings 5-60

control 3rd circuit changeover valve 5-44

Control circuit III changeover valve

For additional control circuit 5-60

Control circuits

3rd control circuit 5-59

3rd control circuit changeover valve

for additional control circuit 5-60

Additional control circuit IV 5-64

Additional control circuit V 5-69

Continuous operation of 3rd control circuit 5-62

Tipping trailer 5-174

Control elements 4-35

Control lever 4-39, 4-63, 5-44

Control lever base 4-22

Control stand 4-1

Control valve 9-8

Coolant 7-14, 9-19

Coolant preheating 4-32

Cooling system 3-4, 7-51

Crab steering 5-7

Crane jib 5-152

Crane-lifting 2-13, 6-8

D

Danger zone 2-5

Data Confirmation 3-6

Defroster vents 5-37

Description of machine 3-4

Designated use 3-6

Diagonal steering 5-7

Diesel particulate filter 4-69, 7-103

Cleaning/replacing 7-103

Regenerating 7-101, 7-102

Differential lock 5-25, 5-44

Digging 5-132, 5-133

Dimensions 9-28

Disabling the travel direction 5-44

Displacement 9-8

Disposal 5-200

Documents 3-9

Door 4-2

DPF (diesel particulate filter) 4-69

Drawbar load 9-21

Drinks holder 4-34

Driving licence 3-8

Driving the machine 5-15

E

EC approval mark

Cabin 3-21

EC Declaration of Conformity EG-1, EG-2, EG-3

Electric mirror adjustment 4-17

Electrical components 9-15

Electrical system 2-18, 9-11

Electro-hydraulic pilot control 9-9

Emergency exit – emergency hammer 4-6

Emergency hammer 4-6

Emergency lowering 5-160

Engine 4-64, 9-1

Starting 2-6, 4-64

Stopping 2-7, 4-68

Engine cover lock 7-16

Error code

Additional-frame electronics 8-15

Cabin electronics 8-10

Diesel engine electronics 8-7

Drive electronics 8-12

Electronics 8-15

Frame electronics 8-6

Joystick 8-13

Overload control 8-14

Safe load indicator 8-16

Steering electronics 8-14

Error code displays 8-5

Exhaust turbocharger 4-65

Explanation of symbols 1-3

External starting aid 4-67

BA 41602_04 * 2 0 * BA_41601_03_07_V2_enSIX fm S-3

Index

F

Fastening, guiding and removing loads 2-8

Field of application of multipurpose bucket 5-80

Field of application of standard bucket 5-79

Field of vision 4-8, 4-9

Field of vision during work operation 3-12, 4-1

Fields of application 3-11

Fields of application of pallet forks 5-85

Fire extinguisher 4-28

Fire hazard 2-20

Fitting and removing

Attachments from other manufacturers 5-111

Fitting attachments from

other manufacturers onto the quickhitch 5-99, 5-111

Fluids 7-12

FOPS 4-1

Fork-lift mode 5-50

four wheel steering 3-4, 5-6

Four-wheel cutoff 5-24

Front axle 9-4

Front axle steering 5-5

Front socket 5-158

Front wiper 5-35

Front/rear gross axle weight rating 9-20

Front-edge protection 4-61

Fuel preheater 4-33

Fuel system

Bleeding 7-36, 7-37

Functional check

Brakes 4-63

Lights 4-63

Steering system 4-63

Fuse assignment 9-11

G

Grabbing bulky material 5-137

Grading 5-133

Grease 2-20

H

Hazard warning system 5-32

Headlight flasher 5-27

Heated seat 4-23

Heating 5-37

High beam 5-27

High-pressure cleaner 7-20

Horizontal adjustment 4-22

Horizontal suspension 4-22

Horn 5-32

Hose burst valve 5-123

Hydraulic attachment 5-59

Hydraulic lock 5-73

Hydraulic oil and coolant preheating 4-32

Hydraulic oil filter 9-8

Hydraulic oil volume setting 5-54

Hydraulic pump 9-8

Hydraulic ram protection 9-8

Hydraulic system 2-18

3rd control circuit 5-44, 5-57, 5-59, 5-83

Hydrostatic drive 3-4

I

Identification 3-8

Ignition key 4-29, 4-66

Illumination 5-28

Immobilizer 4-29

Important information on the cabin 4-1

Improper use 3-7

Inching 5-11

Increasing speed 5-17

Indicating instrument 4-38

Indicator lights 4-38, 4-39

Information and regulations on use 3-5

Information labels 3-27

Inside the cabin 4-36

Installing and removing

Attachments from other manufacturers 5-87, 5-99

Instrument panel 4-38, 4-39

Interior light 5-31

J

Job site 2-5

Joystick 4-39, 4-63, 5-44

K

Kerb weight 9-20

Key-based system 4-29

Keys 4-2

S-4 BA 41602_04 * 2 0 * BA_41601_03_07_V2_enSIX fm

Index

L

Label

Battery master switch 3-27

Control elements on control lever 3-28

Drawbar load 3-29

Emergency exit 3-29

Ensuring machine stability 3-25

Filler opening for hydraulic oil 3-29

Fuel filler opening 3-27

Load diagram 3-28

Maximum machine speed 3-27

Noise levels 3-29

Stopping the machine 3-27

Tie down points 3-27

Tie-down points 3-27

Tyre pressure table 3-28

Labels 3-16

Front of machine 3-18

Left side of machine 3-16

Rear of machine 3-19

Right side of machine 3-17

Lap belt 4-25

Lift capacity 9-21

Lift ram 9-8, 9-9

Lifting gear applications 2-8, 2-9

Lights 5-26

Limited field of vision 4-8, 4-10, 4-11, 4-12

Load 5-145

Load diagram 5-145

Load diagrams 9-22

Load on diesel particulate filter 4-70

Load stabilizer 5-128

Load transport 5-142

Loader unit

Spraying oil onto the slide plates 7-28

Loader unit attachments 5-72

Loading 5-131, 5-133

Low accesses 5-33

Low beam 5-26

Low-load operation 4-68

Low-speed control 5-23

Lubricants 7-12

Lubrication plan label 7-11

Lubrication points

Door 7-25

Planetary drive bearing of axle 7-24

Rear axle oscillation-type bearing 7-24

Telescopic boom 7-26

Lubrication work 7-24

Lumbar support 4-22

M

Machine

Crane-lifting 6-9

Loading on a transport vehicle 6-6

Park 5-21

Stopping 5-20, 5-21

Stopping and securing 2-7

Towing 6-1

Transport 6-10

Tying down 6-10

Machine fuses 7-18

Machine inspections 3-9

Machine keys 4-2

Machine lights 5-26

Machine operation 2-6, 3-5

Machine overview 3-1

Machine preservation 7-106

Machine speed 5-8

Machine travel

on public roads 2-7, 4-60, 4-61, 5-124, 5-154

Main components of machine 3-4

Main fuse box 9-13

Maintenance 2-15, 7-1, 7-19

Adding coolant 7-55, 7-56

Adding engine oil 7-43, 7-44

Adding hydraulic oil 7-74

Air-filter cartridge 7-64

Anticorrosive protection 7-107

Attachments 7-97

Axles/travelling drive 7-91

Braking system 7-92

Changing wheels 7-95

Checking the coolant level 7-53, 7-54

Checking the engine oil level 7-41, 7-42

Checking the hydraulic oil level 7-73

Compressed-air braking system 7-93

Diesel particulate filter 7-103

Electrical system 7-77

Engine and hydraulics cooling system 7-51

Engine lubrication system 7-40

Fuel system 7-33

Heating 7-83

Hydraulic pressure lines 7-75

Hydraulic system 7-71

Options 7-98

Pivots and hinges 7-23

Requirements 7-1

Responsibilities 7-1

Safety instructions 7-1

Servicing and maintenance

at regular intervals 7-79

Slide plates 7-27

Threaded fittings 7-23

Trailer coupling 7-98, 7-100

Tyre care 7-94

V-belt 7-66

Washer system 7-90

BA 41602_04 * 2 0 * BA_41601_03_07_V2_enSIX fm S-5

Index

Work description 7-3, 7-4, 7-7, 7-8, 7-9

Maintenance “Aggressive Media” 7-106

Maintenance access

Engine vat 7-16

Rear of machine 7-17

Maintenance accesses 7-16

Maintenance label 7-10

Maintenance overview 7-3

Maintenance plan 7-3

Malfunctions 8-1

Air conditioning 8-17

Diesel engine 8-1

Manual mode 5-51

Manual throttle 5-9

Measures for avoiding risks 2-18

Measures for performing maintenance 2-16

Mechanical integrity 2-6

Mechanical oscillating axle interlock 5-159

Mirror adjustment 4-13

Mirror heating 4-19

Model designation 3-3

Modifications and spare parts 2-17

Moving material 5-136

Multifunctional lever 4-40

Multipurpose bucket 5-80

N

National Type Approval (Germany) 3-6

Neutral 5-20, 5-44

Noise 2-22

Noise emissions 9-20

O

Oil 2-20

Oil volume setting 5-54

3rd control circuit 5-57

Oil/water fan 9-3

Operating hydraulics 3-4, 5-39, 9-8

Operation 5-1

Operator seat 4-20

Options 5-161

Other substances 2-20

Overload control 5-39, 5-47

Disabling 5-52

Overview

Control elements 4-35, 4-36

Inside the cabin 4-36

Instrument panel 4-38

Lubricants 7-12

Lubrication plan 7-10

Model and trade names 9-1

Overview of speed ranges 5-16

Owner’s duties 2-3

P

Pallet forks 5-85, 9-30

Adjusting the fork arms 5-147

Picking up loads 5-148

Transporting loads 5-149

Pallet forks transport position 5-141

Parking brake 5-13, 9-5

Payload 9-21

Permanently putting out of operation 5-200

Permissible maximum weight 9-20

Personal safety measures 2-15

Picking up a load 5-148

Picking up remaining material completely 5-137

Plug coupling of hydraulic trailer brake 5-181

Plug couplings of additional control circuit IV 5-64

Plug couplings of additional control circuit V 5-69

Precise unloading 5-138

Preheating 4-32

Preheating start switch 4-66

Preparatory measures 2-16

Preparatory measures for the operator 2-3

Prerequisites for operation 2-2

Preserving the diesel engine 5-199

Pressure indicator 5-178

Pressure relief 5-67, 5-82

Protective structures 2-17

Pulling out and setting posts 5-138

Pulling out material from slopes 5-136

Push-out ram 9-8, 9-9

Putting back into operation 5-198

Putting into operation 4-1

Putting out of operation 5-198

Putting the machine out of operation 5-199

Q

Qualifications 2-3

Quick couplers 5-67, 5-82

Quickhitch 5-44, 5-57, 5-73, 5-86

With mechanical lock 5-74

Quickhitch ram (3rd control circuit) 9-8

S-6 BA 41602_04 * 2 0 * BA_41601_03_07_V2_enSIX fm

Index

R

Ramp mirror on the right (option) 4-16

Rear axle 9-4

Rear mirrors (option) 4-17

Rear towing gear 6-3

Rear window 4-4

Rear window emergency exit 4-5

Rear window heating 4-19

Rear wiper 5-35

Reducing travel speed 5-17

Regulations on use 3-5

Removing and fitting attachments 2-11

Removing and spreading material in thin layers 5-136

Removing material 5-132, 5-133

Required knowledge of operator 2-3

Reservoir 5-36

Retracts/extends the telescopic boom 5-44

Reversing fan 5-184

Reversing operation 5-19

Right switch panel 4-40

Rotating beacon 5-33

S

SAE grade 7-12, 7-13

Safe load indicator 5-39

Safe machine operation 3-5

Safety instructions

Attachment operation 2-11

Cooling system 7-51

For internal combustion engines 2-19

Lifting gear applications 2-8

Maintenance 2-15, 7-1

Operation 2-4

Towing, loading and transporting 2-12

Trailer operation 2-10

Working with a bucket 5-125

Safety prop for telescopic boom 7-2

Safety symbols 2-1

Screw dimensions 9-19

Seat adjustment 4-21

Seat belt 4-25

Adjustment 4-26

Seat suspension 4-23

Self-propelled work machine 3-6

Serial number

Cabin number 3-21

Drive variable displacement motor 3-23

Drive variable displacement pump 3-22

Engine number 3-22

Front and rear axles 3-23

Gearbox (30/40 kph option) 3-23

Gearbox (standard 20 kph) 3-23

Hydraulic work pump 3-22

Serial number 3-20

Service brake 5-11, 9-5

Setting down a load 5-150

Setting down loads 5-143

Setting engine speed 5-9

Side marker lights 5-26

Signal transmitter 5-34

Signal transmitter of backup warning system 4-53

Signal words 2-1

Signalling system 5-26

Slopes 5-22

Smart Handling 5-47

Sound power level 9-20

Specification 7-12, 7-13

Diesel fuel 7-14

Speed

Lift, tilt and push-out rams 9-9

Push-out ram 9-9

Tilt ram 9-9

Speed control 5-16

Stability 9-21

Stability calculation 5-91, 5-103, 5-115

Standard bucket 5-79

Start repeat interlock 4-64

Starter 9-15

Starting aid 4-67

Starting the engine 4-66

Steam jet 7-20

Steering column 5-1

Angle adjustment 5-1

Height adjustment 5-1

Steering system 5-1, 9-7

Synchronization 5-2

Storage bin with cooling 4-34

Storage bin with ventilation 4-34

Storage bins 4-33

Storage bins (option) 4-33

Storage bins and storage places in the cabin 4-34

Storage bins on outside of machine 4-33

Storage net for machine documentation 4-34

Storage net for Operator’s Manual 4-34

Switch panel on cabin roof 4-40

Switching relay assignment 9-14

Symbols 3-20

BA 41602_04 * 2 0 * BA_41601_03_07_V2_enSIX fm S-7

Index

T

Technical data 9-1

Axles 9-3

Brakes 9-5

Bucket payload 9-21

Coolant 9-19

Dimensions 9-28

Drawbar load 9-21

Electrical components 9-15

Electrical system 9-11

Electro-hydraulic pilot control 9-9

Engine 9-1

Front axle 9-4

Fuse assignment 9-11

Hydraulic pump 9-8

Hydraulic ram protection 9-8

Lift capacity 9-21

Noise emissions 9-20

Oil/water fan 9-3

Operating hydraulics 9-8

Pallet forks 9-30

Parking brake 9-5

Payload 9-21

Rear axle 9-4

Service brake 9-5

Stability 9-21

Steering system 9-7

Switching relay assignment 9-14

Tightening torques 9-19

Trailer weight 9-21

Travelling drive 9-3

Tyres 9-6

Usable consumer pressure

At additional control circuit 9-10

Variable displacement motor 9-4

Variable displacement pump 9-3

Weight 9-20

Telescopic boom 5-42, 5-44

Threaded fittings 7-23

Tightening torque 9-19

Tilt ram 9-8, 9-9

Tilt ram lock 5-157

Tipping trailer connection 5-174

Towing 2-12

Tracks 2-18

Trade name 3-3

Trailer coupling 5-161, 5-165, 5-169, 7-98, 7-100

Checking for wear 7-99

Cleaning 7-98, 7-100

Lubricate 7-98, 7-100

Trailer operation 2-10, 4-62

Trailer weight 9-21

Transport 2-14, 5-127, 6-1

With loaded pallet forks 5-149

Travel direction 5-18, 5-44

Travel operation 5-15

Travel speed 5-16

Travelling drive 7-91, 9-3

Turn indicator system 5-31

Turn indicators 5-31

Type labels 3-20

Tyre care 7-94

Tyre pressure 9-6

Tyre pressure table 3-28

Tyre size 9-6

Tyres 2-18, 9-6

U

Unauthorized attachments 3-12

Unloading from the bottom of the bucket

for increased tilt-out heights 5-139

Upper door 4-3

Usable consumer pressure at additional

control circuit 9-10

Use of fork arms 5-144

V

Validity of Operator’s Manual 1-1

Variable displacement motor 9-4

Variable displacement pump 9-3

Disabling 6-1

Enabling 6-5

Ventilation 5-37

IMAGES PREVIEW OF THE MANUAL: