$38

Wacker Neuson Track Excavator 50Z³ 6003 50Z3(2) 6003(2) Operator’s Manual – PDF DOWNLOAD

Wacker Neuson Track Excavator 50Z³ 6003 50Z3(2) 6003(2) Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Wacker Neuson Track Excavator 50Z³ 6003 50Z3(2) 6003(2) Operator’s Manual – PDF DOWNLOAD

Language : English

Pages :282

Downloadable : Yes

File Type : PDF

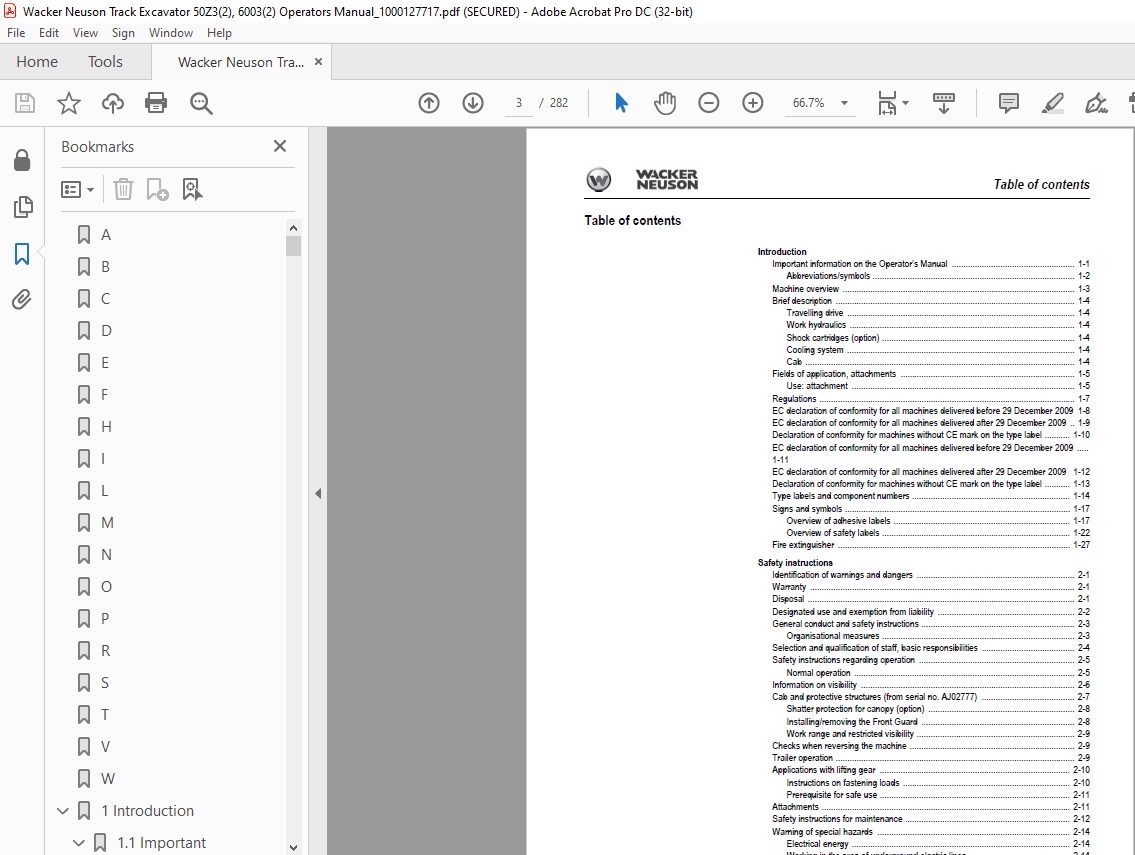

TABLE OF CONTENTS:

Wacker Neuson Track Excavator 50Z³ 6003 50Z3(2) 6003(2) Operator’s Manual – PDF DOWNLOAD

Introduction

Important information on the Operator’s Manual 1-1

Abbreviations/symbols 1-2

Machine overview 1-3

Brief description 1-4

Travelling drive 1-4

Work hydraulics 1-4

Shock cartridges (option) 1-4

Cooling system 1-4

Cab 1-4

Fields of application, attachments 1-5

Use: attachment 1-5

Regulations 1-7

EC declaration of conformity for all machines delivered before 29 December 2009 1-8

EC declaration of conformity for all machines delivered after 29 December 2009 1-9

Declaration of conformity for machines without CE mark on the type label 1-10

EC declaration of conformity for all machines delivered before 29 December 2009

1-11

EC declaration of conformity for all machines delivered after 29 December 2009 1-12

Declaration of conformity for machines without CE mark on the type label 1-13

Type labels and component numbers 1-14

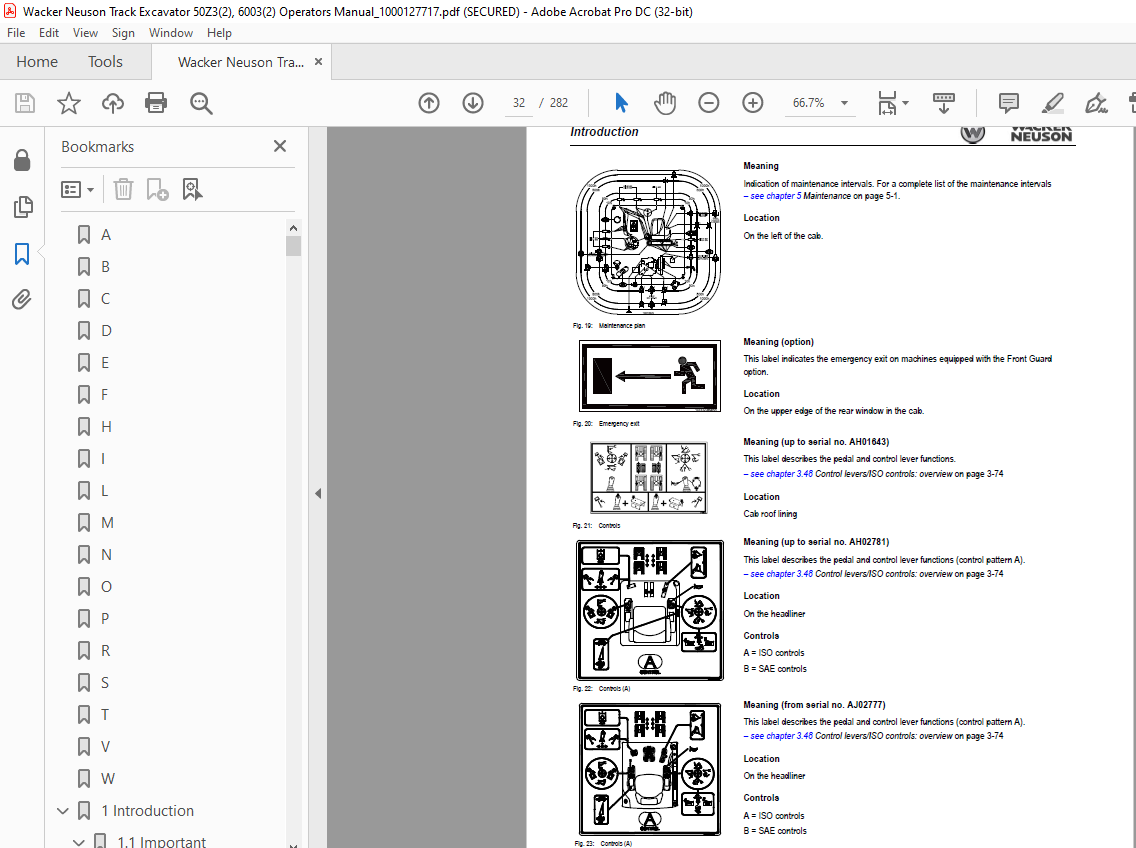

Signs and symbols 1-17

Overview of adhesive labels 1-17

Overview of safety labels 1-22

Fire extinguisher 1-27

Safety instructions

Identification of warnings and dangers 2-1

Warranty 2-1

Disposal 2-1

Designated use and exemption from liability 2-2

General conduct and safety instructions 2-3

Organisational measures 2-3

Selection and qualification of staff, basic responsibilities 2-4

Safety instructions regarding operation 2-5

Normal operation 2-5

Information on visibility 2-6

Cab and protective structures (from serial no AJ02777) 2-7

Shatter protection for canopy (option) 2-8

Installing/removing the Front Guard 2-8

Work range and restricted visibility 2-9

Checks when reversing the machine 2-9

Trailer operation 2-9

Applications with lifting gear 2-10

Instructions on fastening loads 2-10

Prerequisite for safe use 2-11

Attachments 2-11

Safety instructions for maintenance 2-12

Warning of special hazards 2-14

Electrical energy 2-14

Working in the area of underground electric lines 2-14

Working near overhead electric lines 2-14

Gas, dust, steam, smoke 2-15

Hydraulics 2-15

Noise 2-15

Table of contents

I-2 BA 50Z3/6003 en – Edition 42 * * Ba5003en4_1IVZfm

Table of contents

Oil, grease and other chemical substances 2-15

Using the quickhitches in water 2-15

Battery 2-16

Tracks 2-16

Hammer operation 2-16

Safety instructions 2-16

Working with a hammer 2-17

Transport and towing 2-17

Towing 2-17

Transport 2-17

Operation

Cab 50Z3/6003 (up to serial no AH02781) 3-2

Cab 50Z3 2 / 6003 2 (from serial no AJ02777) 3-4

Control elements 50Z3 (up to serial no AH02781) / 6003 (up to serial no AH00578)

3-6

Control elements 6003 (serial nos AH00579 to AH02750) 3-7

Control elements 50Z3 2 / 6003 2 (from serial noAJ02777) 3-9

Indicator lights and warning lights: overview 3-11

Putting into operation 3-14

Safety instructions 3-14

Putting the machine into operation for the first time 3-14

Running-in period 3-14

Check lists 3-15

Start-up checklist 3-15

Operation checklist 3-16

Parking checklist 3-16

Driving the machine 3-17

Preheating start switch 3-17

Throttle 3-17

Automatic engine speed setting 3-18

Before starting the engine 3-19

Starting the engine: general 3-20

Starting with the drive interlock – internal transponder (option) (from serial no AJ02777)

3-21

Jump-starting the engine (supply battery) 3-22

Starting at low temperatures 3-23

When the engine has started 3-23

Special instructions for driving on public roads 3-24

Drive position 3-24

Drive levers 3-24

High speed 3-25

Moving off 3-25

Hydraulic brake 3-25

Mechanical brake 3-25

Working on slopes 3-26

Stabiliser blade operation 3-28

Parking the machine 3-29

Parking the machine on slopes 3-29

Light system 3-30

Working light 3-30

Roof lights (option) 3-31

Interior light 3-31

Rotating beacon (option) 3-32

Cab heating and ventilation 3-33

Summer/winter operation (up to serial no AD04650) 3-34

Heating controls (from serial no AD04651) 3-34

BA 50Z3/6003 en – Edition 42 * Ba5003en4_1IVZfm I-3

Table of contents

Air conditioning (option) 3-35

Recirculated air mode 3-35

Wiper/wash system 3-36

Tank for washer system 3-36

Seat (50Z3) 3-37

Weight adjustment 3-38

Height adjustment 3-38

Horizontal adjustment 3-38

Backrest adjustment 3-38

Seat (6003) 3-39

Weight adjustment 3-40

Horizontal adjustment 3-40

Seat depth adjustment 3-40

Backrest adjustment 3-40

Head rests 3-41

Height adjustment 3-41

Seat (air suspension option) 3-42

Weight adjustment 3-43

Height adjustment 3-43

Horizontal adjustment 3-43

Seat depth adjustment 3-43

Backrest adjustment 3-44

Adjusting the head rest 3-44

Horizontal suspension 3-44

Seat belt 3-45

Retracting lap belt (option) 3-46

Mirrors (option) 3-47

Safety instructions 3-47

Adjusting the mirrors 3-48

Emergency exit 3-49

Emergency exit on machines equipped with protective Front Guard structures

(option) 3-49

Front window (up to serial no AD06526) 3-50

Front window (from serial no AD06527) 3-51

Opening the front window 3-51

Closing the front window 3-52

Opening the lower front window 3-53

Closing the lower front window 3-53

Opening the whole front window 3-54

Closing the whole front window 3-55

Opening the front window to a gap 3-56

Opening and closing the side window 3-56

Mounting/removing the canopy shatter protection (option) 3-57

Door 3-58

Door 50Z3 3-58

Door 6003 3-58

Exit through the door (up to serial no AH02764) 3-60

Exit through the door (from serial no AJ02777) 3-61

Armrest adjustment (up to serial no AH02764) 3-62

Armrest adjustment (from serial no AJ02777) 3-63

Engine cover 3-63

Battery master switch 3-64

Tilting the cab 3-65

Towing the machine 3-68

Crane handling the machine 3-69

Loading and transporting the machine 3-71

Safety instructions 3-71

I-4 BA 50Z3/6003 en – Edition 42 * * Ba5003en4_1IVZfm

Table of contents

Tying down the machine 3-72

Driving signal (option) 3-72

Working with the machine 3-73

General safety instructions 3-73

Control levers/ISO controls: overview 3-74

Left-hand control lever 3-74

Hammer pedal lock (up to serial no AH02781) 3-74

Boom/triple articulation boom operation (up to serial no AH02781) 3-75

Hammer pedal lock (from serial no AJ02777) 3-75

Boom/triple articulation boom operation (from serial no AJ02777) 3-76

Right-hand control lever 3-76

Lowering the boom with the engine stopped 3-76

Rotating the upper carriage 3-77

Swivel unit brake 3-77

Changeover valve for SAE/ISO controls (option) 3-78

Left-hand control lever 3-78

Right-hand control lever 3-78

Directional valve position 3-78

Directional valve 3-79

Control lever with proportional controls (option): overview 3-80

Function 3-80

Left-hand control lever 3-81

Changeover between auxiliary hydraulics and boom swivel 3-81

Switching the status indicator on/off for auxiliary hydraulics/boom swivel 3-81

Operating the boom/auxiliary hydraulics 3-82

Hammer operation 3-82

Adjusting control response 3-83

Characteristic curves – status indicator 3-83

Lowering the boom with the engine stopped 3-84

Releasing pressure 3-84

Control lever if equipped with 3rd control circuit (option): overview 3-85

Left-hand control lever 3-85

Boom swivel controls (up to serial no AH02781) 3-85

Boom swivel controls (from serial no AJ02777) 3-86

Right-hand control lever 3-86

Right-hand control lever if equipped with proportionally controlled 3rd control circuit

(option) 3-87

Lowering the boom with the engine stopped 3-87

Releasing pressure 3-87

Tilting the upper carriage – Vertical Digging System (option) 3-88

Operation (up to serial no AH02781) 3-89

Operation (from serial no AJ02777) 3-89

Vario (6003 option) 3-90

Vario operation 3-90

Driving across slopes with the Vario feature 3-90

Danger zone of the Vario feature 3-91

Working with the Vario feature 3-92

Improved reach with the Vario feature 3-92

Releasing the pressure on the work hydraulics 3-93

Releasing pressure 3-93

Pressure release with proportional controls (option) 3-93

Re-equipping attachments 3-94

Specific safety instructions 3-94

Removing a bucket 3-94

Mounting a bucket 3-95

BA 50Z3/6003 en – Edition 42 * Ba5003en4_1IVZfm I-5

Table of contents

Quickhitch (option) 3-95

Hydraulic Easy Lock quickhitch (option) 3-97

Powertilt (option) 3-101

Re-equipping 3-101

Operation 3-102

Right-hand control lever (Powertilt) 3-102

Connections for auxiliary hydraulics 3-103

Quickhitch couplings 3-103

Safe load indicator (option) 3-104

Safety feature “Hose burst valve” (option) 3-105

Applications with lifting gear 3-105

Lifting gear applications 3-106

Fastening loads 3-106

Work area assessment and preparation 3-106

Examining the site 3-106

Preparing the ground 3-106

Working with the machine 3-107

Working with the standard bucket 3-107

Inadmissible work 3-107

Work position of machine 3-108

Bucket position when digging 3-109

Excavating trenches 3-109

Loading 3-110

Grading 3-110

Excavating trenches sideways 3-110

Working alongside trenches 3-111

Stabiliser blade at rear 3-111

Further practical hints for digging 3-112

Loading vehicles 3-112

Freeing the machine 3-112

Grading 3-112

Grading 3-112

Troubleshooting

Troubleshooting the engine 4-1

Indicator lights 4-3

Seals, hoses 4-3

Undercarriage 4-4

Engine error codes 4-5

Malfunctions of the Powertilt unit 4-9

Troubleshooting the central lubrication system (option) 4-10

Proportional controls (option) diagnosis display 4-11

Maintenance

Introduction 5-1

Safety-relevant parts 5-1

Fuel system 5-2

Refuelling 5-3

Fuel-filling pump (option) (up to serial no AD04862) 5-3

Fuel-filling pump (option) (from serial no AD04863) 5-4

Stationary fuel pumps 5-4

Diesel fuel specification 5-5

Bleeding the fuel system 5-5

Fuel prefilter with water separator 5-6

Engine lubrication system 5-7

Checking the engine oil level 5-7

Filling up engine oil 5-8

I-6 BA 50Z3/6003 en – Edition 42 * * Ba5003en4_1IVZfm

Table of contents

Engine and hydraulics cooling system 5-9

Specific safety instructions 5-9

Checking/filling up coolant 5-10

Air filter 5-12

Replacing the air filter 5-13

Air intake 5-14

Change cab air filter 5-14

Replacing the filter element of the air conditioning system (option) 5-15

Diesel particulate filter (option) 5-16

Main components of diesel particulate filter system 5-16

How the diesel particulate filter works 5-17

Machine operation with diesel particulate filter 5-17

Display 5-19

Temperature scale 5-19

Exhaust gas back pressure scale 5-19

Alarm messages 5-20

Maintenance 5-23

Oils and fuels 5-24

Troubleshooting 5-24

Warranty 5-24

V-belt 5-25

Checking V-belt tension 5-25

Retightening the V-belt 5-26

Checking the V-belt of the air conditioning system (option) 5-27

Tightening the V-belt of the air conditioning system 5-27

Hydraulic system 5-28

Specific safety instructions 5-28

Checking the hydraulic oil level 5-29

Filling up hydraulic oil 5-30

Important information for the use of biodegradable oil 5-31

Checking hydraulic pressure lines 5-32

Tracks 5-33

Checking the track tension of the rubber tracks 5-33

Checking the track tension of the steel tracks (option) and hybrid tracks (option)

5-34

Adjusting track tension 5-34

Travelling drive 5-36

Checking the oil level and filling up oil 5-36

Draining oil 5-36

Maintenance of attachments 5-37

Electrical system 5-37

Service and maintenance work at regular intervals 5-37

Instructions concerning specific components 5-37

Alternator 5-37

Battery 5-38

General maintenance work 5-40

Cleaning 5-40

General instructions for all areas of the machine 5-40

Inside the cab 5-40

Cleaning the seat belt 5-41

Exterior of the machine 5-41

Engine compartment 5-41

Screw connections and attachments 5-41

Pivots and hinges 5-41

Overview of lubrication points 5-42

Parking the machine 5-43

Lubrication points on the boom, bucket and stick rams 5-43

BA 50Z3/6003 en – Edition 42 * Ba5003en4_1IVZfm I-7

Table of contents

Lubrication points on the boom and stick 5-44

Joint rod lubrication point 5-45

Lubrication points on the stabiliser blade and stabiliser blade ram 5-45

Lubrication points on the slewing ram and swivelling console 5-46

Lubrication points of ball bearing race of live ring 5-47

Lubrication points of live ring teeth 5-48

Powertilt lubrication points (option) 5-49

Lubrication points of hydraulic quickhitch (option) 5-49

Lubrication points of control lever base (from serial no AJ02777) 5-50

VDS lubrication points (option) 5-50

Central lubrication system (option) 5-51

Function 5-51

Status LEDs 5-51

Adjusting cycle time and lubrication time 5-52

Repair in case of clogging 5-52

Preparatory work before taking the machine out of service 5-53

Maintenance if the machine is out of service for a longer period of time 5-53

Putting into operation again 5-53

Fluids and lubricants 5-54

Oil grades for the diesel engine, depending on temperature 5-55

Additional oil change and filter replacement (hydraulic system) 5-55

Oil grades for the hydraulic system, depending on temperature 5-56

Maintenance plan (overview) 5-57

Maintenance label 5-62

Explanation of symbols on the maintenance label 5-62

Specifications

Chassis 6-1

Engine 6-1

Hydraulic system 6-2

Work hydraulics 6-2

Undercarriage and swivel unit 6-2

Stabiliser blade 6-2

Electrical system, model 50Z3 6-3

Fuse box in instrument panel 6-3

Main fuse box with relays underneath the cab 6-3

Relays 6-4

Electrical system, model 6003 (from serial no AH0611) 6-4

Fuse box on instrument panel (up to serial no AH02750) 6-4

Main fuse box with relays 6-5

Fuse box on instrument panel (from serial no AJ02777) 6-5

I-8 BA 50Z3/6003 en – Edition 42 * * Ba5003en4_1IVZfm

Table of contents

ECU control unit (6003 from serial no AH00611) 6-6

Noise levels 6-6

Vibration 6-6

Coolant compound table 6-7

Powertilt 6-7

Weight indications 6-8

Dimensions model 50Z3 6-9

Dimensions model 50Z3 VDS 6-11

Dimensions model 6003 standard boom, Vario (option) 6-13

Dimensions model 6003 triple articulation boom (option) 6-15

Lift capacity table 50Z3 6-17

Lift capacity table 50Z3 counterweight (option) 6-18

Lift capacity table 50Z3 long stick (option) 6-19

Lift capacity table 50Z3 long stick, counterweight (option) 6-20

Lift capacity table 50Z3 VDS short stick (option) 6-21

Lift capacity table 50Z3 VDS short stick, counterweight (option) 6-22

Lift capacity table 50Z3 VDS long stick (option) 6-23

Lift capacity table 50Z3 VDS long stick, counterweight (option) 6-24

Lift capacity table 6003 6-25

Lift capacity table 6003 counterweight (option) 6-26

Lift capacity table 6003 long stick (option) 6-27

Lift capacity table 6003 long stick, counterweight (option) 6-28

Lift capacity table 6003 long stick, triple articulation boom (option) 6-29

Lift capacity table 6003 long stick, triple articulation boom, counterweight (option)

6-30

Lift capacity table 6003 triple articulation boom (option) 6-31

Lift capacity table 6003 triple articulation boom, counterweight (option) 6-32

Lift capacity table 6003 Vario (option) 6-33

Abbreviations 1-2

Air filter 5-12

Air intake 5-14

Applications with lifting gear 2-10

Battery master switch 3-64

Biodegradable oil 5-31

Cab air filter 5-14, 5-15

Cab entry and exit 3-61

Check lists 3-15

Craning operation 3-69

Designated use and exemption from liability 2-2

Diesel particulate filter (option) 5-16

Driving on public roads 3-24

Driving the excavator 3-17

Emergency exit

Front Guard (option) 3-49

Fire extinguisher 1-27

Fluids and lubricants 5-54

Heating 3-33

Hose burst valve (option) 3-105

Important information

On this Operator’s Manual 1-1

Indicator lights and warning lights 3-11

Interior light 3-31

Legal regulations 1-7

Light system 3-30

Lowering the boom with the engine stopped 3-76, 3-84, 3-87

Machine

Brief description 1-4

Fields of application 1-5

Loading and transporting 3-71

Overview 1-3

Maintenance

Air filter 5-13, 5-14

Biodegradable oil 5-31

Bleeding the fuel system 5-5

Cab air filter 5-14

Central lubrication system (option) 5-51

Checking the coolant level 5-10

Checking the engine oil level 5-7

Checking the hydraulic oil level 5-29

Cleaning 5-40

Diesel particulate filter (option) 5-16

Electrical system 5-37

Engine and hydraulics cooling system 5-9

Engine lubrication system 5-7

Filling in engine oil 5-8

Filling up coolant 5-10

Filling up hydraulic oil 5-30

Filter element of air conditioning system (option) 5-15

Fluids and lubricants 5-54

Fuel system 5-2

General maintenance work 5-40

Hydraulic pressure lines 5-32

Hydraulic system 5-28

Instructions concerning specific components 5-37

Maintenance plan 5-57

Pivots and hinges 5-41

Screw connections 5-41

Service and maintenance work at regular intervals 5-37

Track maintenance 5-33

V-belt 5-25

Noise levels 1-18

Operation 3-1

3rd control circuit (option) 3-85

Before starting the engine 3-19

Moving off 3-24

Parking the machine 3-29

Seat belt height adjustment 3-45

Starting the engine 3-20

Triple articulation boom (option) 3-75, 3-76, 3-102

Vario (option) 3-90

Preheating start switch 3-17

Putting into operation 3-7, 3-9

Check lists 3-15

Putting the machine into operation for the first time 3-14

Safety instructions 3-14

Refuelling 5-3

Rotating beacon 3-32

Running-in period 3-14

Index

I-10 BA 50Z3/6003 en – Edition 42 * * Ba5003en4_1SIXfm

Index

Safety instructions 2-1

Applications with lifting gear 2-10

General conduct 2-3

Identification 2-1

Maintenance 2-12

Operation 2-5

Special hazards 2-14

Trailers and attachments 2-11

Transport 2-12

Seat (air suspension option) 3-42

Seat (standard) 3-39

Seat adjustment 3-37

Backrest adjustment 3-38, 3-40

Horizontal adjustment 3-38, 3-40, 3-43

Seat depth adjustment 3-40, 3-43

Weight adjustment 3-38, 3-40, 3-43

Seat belt 3-45

Seat belt height adjustment 3-45

Shatter protection 2-8, 3-57

Side window 3-56

Specifications 6-1

Chassis 6-1

Dimensions 6-9

Electrical system 6-3

Engine 6-1

Noise levels 6-6

Vibration 6-6

Work hydraulics 6-2

Starting aid 3-22

Tilting the upper carriage 3-88

Track maintenance 5-33

Ventilation 3-33

Ventilation, fresh air 3-33

Warranty 2-1

Washer system 3-36

Tank 3-36

Wiper 3-36

Working

Freeing the machine 3-112

Practical hints 3-112

IMAGES PREVIEW OF THE MANUAL: