$39

Wacker Neuson Track Excavator 6003 Service Manual_1000129840 – PDF DOWNLOAD

Wacker Neuson Track Excavator 6003 Service Manual_1000129840 – PDF DOWNLOAD

FILE DETAILS:

Wacker Neuson Track Excavator 6003 Service Manual_1000129840 – PDF DOWNLOAD

Language : English

Pages :342

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Wacker Neuson Track Excavator 6003 Service Manual_1000129840 – PDF DOWNLOAD

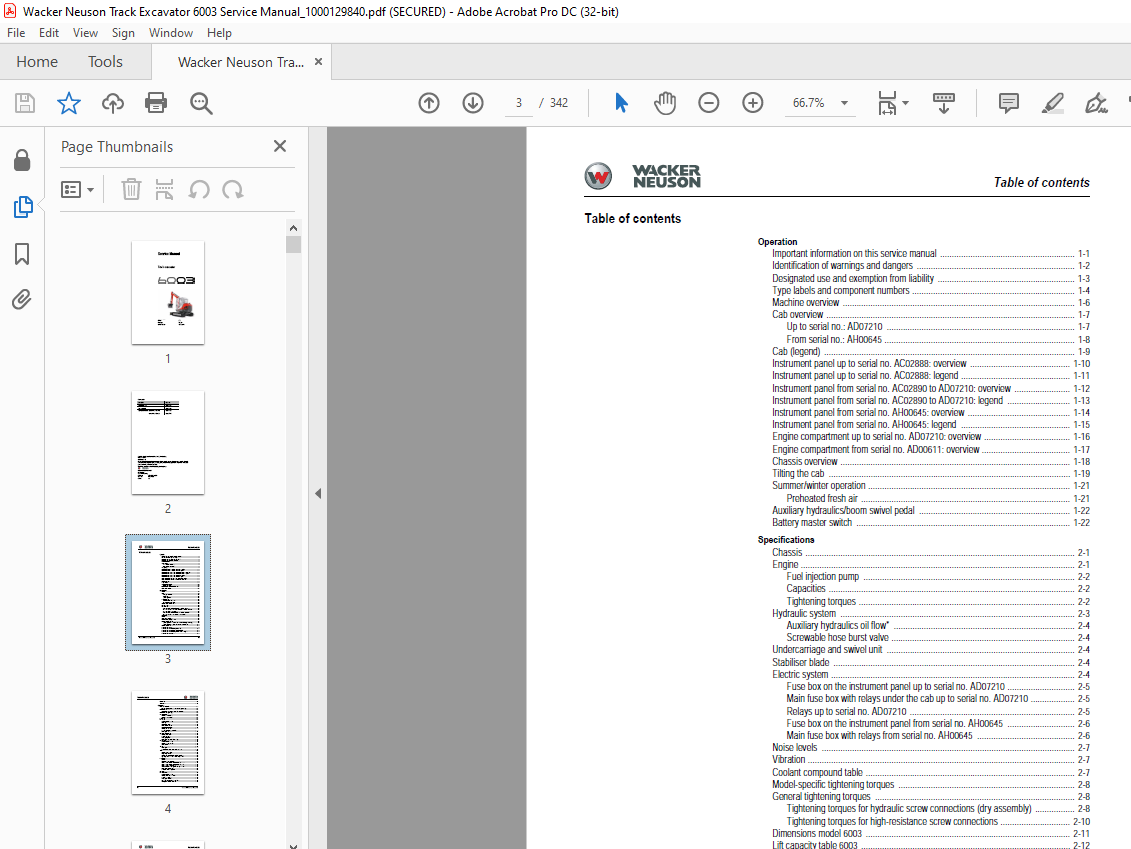

Operation

Important information on this service manual 1-1

Identification of warnings and dangers 1-2

Designated use and exemption from liability 1-3

Type labels and component numbers 1-4

Machine overview 1-6

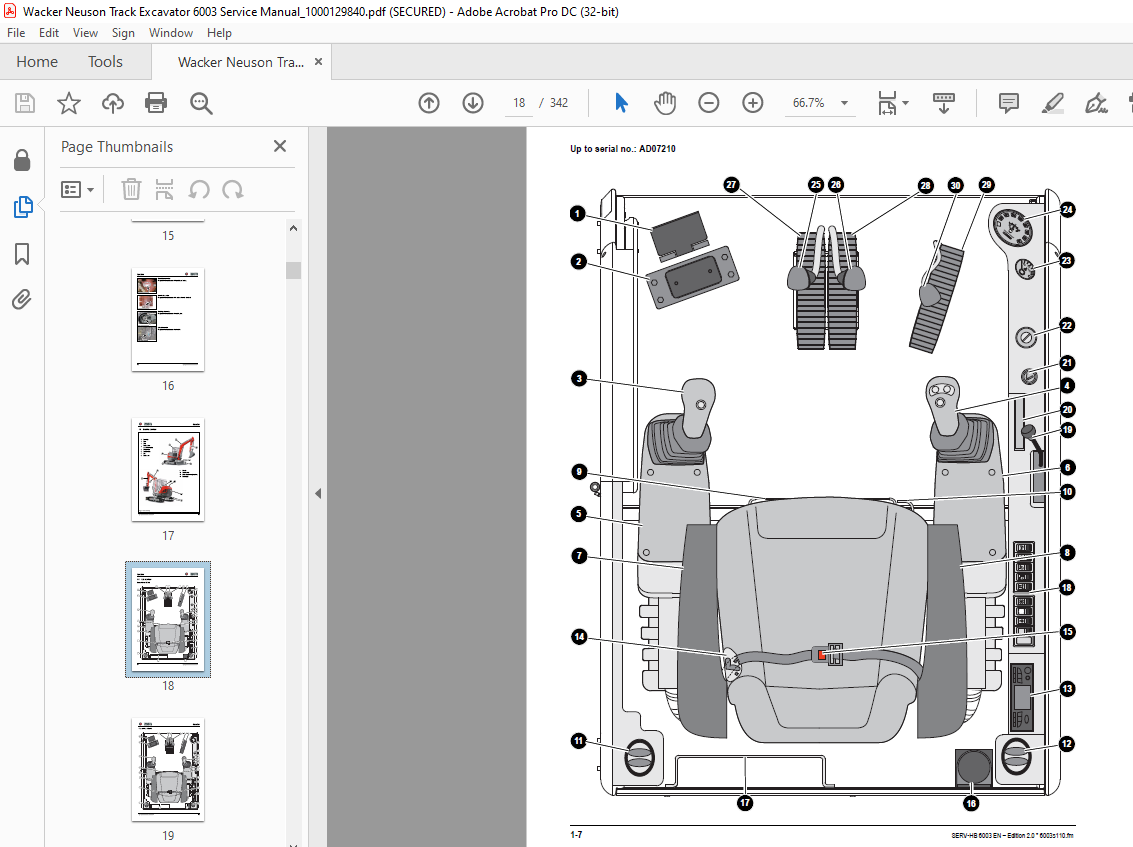

Cab overview 1-7

Up to serial no: AD07210 1-7

From serial no: AH00645 1-8

Cab (legend) 1-9

Instrument panel up to serial no AC02888: overview 1-10

Instrument panel up to serial no AC02888: legend 1-11

Instrument panel from serial no AC02890 to AD07210: overview 1-12

Instrument panel from serial no AC02890 to AD07210: legend 1-13

Instrument panel from serial no AH00645: overview 1-14

Instrument panel from serial no AH00645: legend 1-15

Engine compartment up to serial no AD07210: overview 1-16

Engine compartment from serial no AD00611: overview 1-17

Chassis overview 1-18

Tilting the cab 1-19

Summer/winter operation 1-21

Preheated fresh air 1-21

Auxiliary hydraulics/boom swivel pedal 1-22

Battery master switch 1-22

Specifications

Chassis 2-1

Engine 2-1

Fuel injection pump 2-2

Capacities 2-2

Tightening torques 2-2

Hydraulic system 2-3

Auxiliary hydraulics oil flow* 2-4

Screwable hose burst valve 2-4

Undercarriage and swivel unit 2-4

Stabiliser blade 2-4

Electric system 2-4

Fuse box on the instrument panel up to serial no AD07210 2-5

Main fuse box with relays under the cab up to serial no AD07210 2-5

Relays up to serial no AD07210 2-5

Fuse box on the instrument panel from serial no AH00645 2-6

Main fuse box with relays from serial no AH00645 2-6

Noise levels 2-7

Vibration 2-7

Coolant compound table 2-7

Model-specific tightening torques 2-8

General tightening torques 2-8

Tightening torques for hydraulic screw connections (dry assembly) 2-8

Tightening torques for high-resistance screw connections 2-10

Dimensions model 6003 2-11

Lift capacity table 6003 2-12

Lift capacity table 6003 with long stick option 2-13

Lift capacity table 6003 with counterweight option 2-14

Lift capacity table 6003 with long stick and counterweight 2-15

Lift capacity table 6003 Vario 2-16

Table of contents

I-2 SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm

Table of contents

Kinematics 2-17

Attachments 2-18

Maintenance

Fluids and lubricants 3-1

Additional oil change and filter replacement (hydraulics) 3-2

Maintenance label 3-3

Explanation of symbols on the maintenance label 3-3

Maintenance plan (overview) 3-5

Service package 3-8

Up to serial no AD07210 3-8

From serial no AH00645 3-8

Introduction 3-8

Fuel system 3-9

Specific safety instructions 3-9

Refuelling 3-9

Stationary fuel pumps 3-10

Diesel fuel specification 3-10

Bleeding the fuel system 3-10

Emptying the fuel tank 3-11

Fuel prefilter with water separator 3-11

Replacing the fuel filter 3-12

Engine lubrication system 3-13

Checking the oil level 3-13

Filling up engine oil 3-14

Changing engine oil 3-15

Replacing the engine oil filter cartridge 3-16

Cooling system 3-17

Specific safety instructions 3-17

Checking/filling up coolant 3-18

Draining coolant 3-19

Air filter 3-20

Replacing the filter 3-21

Functional check once a week of the dust valve 3-22

V-belt 3-23

Checking V-belt tension 3-23

Retightening the V-belt 3-24

Checking the V-belt of the air conditioning system 3-25

Tightening the V-belt of the air conditioning system 3-25

Pressure check 3-26

General 3-26

Checking pilot control pressure 3-26

Pressure check of variable displacement pump P1 3-27

Pressure check of variable displacement pump P2 3-28

Pressure check of gear pump P3 3-29

Secondary pressure limiting valve of the gear motor 3-30

Measuring ports: overview 3-30

Primary pressure limiting valves 3-30

Test report 3-31

Hydraulic system 3-34

Specific safety instructions 3-34

Checking the hydraulic oil level 3-35

Filling up hydraulic oil 3-36

Changing hydraulic oil 3-37

Monitoring the hydraulic oil reflux filter 3-37

Checking hydraulic pressure lines 3-38

SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm I-3

Table of contents

Travelling drive 3-38

Checking the oil level and filling up oil 3-39

Draining oil 3-39

Chains 3-40

Checking chain tension 3-40

Setting the chains 3-41

Lubrication work 3-42

Stabiliser blade 3-42

Lubrication points on the swivelling console 3-42

Boom lubrication points 3-43

Lubrication points on the stick 3-43

Lubrication strip 3-44

Maintenance of attachments 3-44

Electric system 3-45

Specific safety instructions 3-45

Service and maintenance work at regular intervals 3-45

Instructions concerning specific components 3-46

Alternator 3-46

Battery 3-47

Jump-starting the engine 3-47

Cab 3-48

Replacing the cab filter 3-48

General maintenance work 3-49

Cleaning 3-49

General instructions for all areas of the machine 3-49

Inside the cab 3-50

Exterior of the machine 3-50

Engine compartment 3-50

Screw connections and attachments 3-50

Pivots and hinges 3-50

Engine

Engine 4TNV98-VNS (Tier 2 up to serial no AD07210) 4-1

Fuel system 4-3

Removing the valve cover 4-4

Checking and adjusting valve clearance 4-4

Checking valve clearance 4-4

Setting zero play of the valve bridge 4-5

Setting valve clearance 4-5

Tightening order for cylinder head bolts 4-6

Checking the injection nozzles 4-7

Pressure check 4-7

Checking the nozzle jet 4-7

Injection time 4-8

Checking injection time 4-8

Setting injection time 4-8

Replacement of fuel injection pump 4-9

Adjusting engine revs 4-10

Compression 4-10

Checking the coolant thermostat 4-11

Checking the thermal switch 4-11

Oil pressure switch 4-12

Checking the coolant circuit 4-12

Engine 4TNV98-ZVNS from serial no AH00645 4-13

Fuel system 4-15

Removing the valve cover 4-16

I-4 SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm

Table of contents

Checking and adjusting valve clearance 4-16

Checking valve clearance 4-16

Setting zero play of the valve bridge 4-17

Setting valve clearance 4-17

Tightening order for cylinder head bolts 4-18

Checking the injection nozzles 4-19

Pressure check 4-19

Checking the nozzle jet 4-19

Injection time 4-20

Checking injection time 4-20

Setting injection time 4-21

Replacement of fuel injection pump 4-22

Compression 4-23

Checking the coolant thermostat 4-23

Checking the thermal switch 4-24

Oil pressure switch 4-24

Checking the coolant circuit 4-24

Engine trouble 4-25

Electronic engine control unit (E-ECU) 4-27

Features 4-27

Engine error codes 4-28

Error diagnosis 4-32

E-ECU connector assignment 4-32

Important information on the ECU maintenance wiring harness 4-33

Flash code 7 – proportional injection pump solenoid (control rack) 4-34

Related DTC (Diagnostic Trouble Codes) 4-34

Diagnosis description 4-36

Flash code 5 – manual throttle 4-38

Related DTC 4-38

Work description 4-40

Flash code 4-1 ECU internal 4-41

Related DTC 4-41

Work description 4-42

Flash code 4-1 ECU temperature sensor and 2-5 ECU temperature rise alarm

4-43

Related DTC 4-43

Work description 4-44

Flash code 4 coolant temperature sensor and 3-6 coolant temperature rise alarm

4-45

Related DTC 4-45

Work description 4-47

Flash code 2-4 – sensor 5 V 4-49

Related DTC 4-49

Work description 4-50

Flash code 2-3 – power supply voltage 4-52

(1) P0562/1: power supply voltage error (voltage too low) 4-52

DTC detection conditions 4-52

Troubleshooting 4-52

Diagnosis description 4-52

(2) P0563/0: power supply voltage error (voltage too high) 4-53

DTC detection conditions 4-53

Troubleshooting 4-53

Diagnosis description 4-53

Flash code 6 – revs sensor 4-54

Work description 4-56

Flash code 1-1 – backup revs sensor 4-57

Related DTC 4-57

SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm I-5

Table of contents

Work description 4-59

Flash code 9 – overspeed error 4-60

(1) P0219/0: overspeed error 4-60

DTC detection conditions 4-60

Troubleshooting 4-60

Diagnosis description 4-60

Flash code 1-7 – proportional solenoid relay of the injection pump (control rack)

4-61

Related DTC 4-61

Work description 4-63

Flash code 1-5 – preheating relay 4-65

Related DTC 4-65

Work description 4-66

Flash code 1-4 – CSD (cold start device) solenoid coil 4-69

Related DTC 4-69

Work description 4-70

Flash code 1-3 – EGR (exhaust gas recirculation) valve 4-72

Related DTC 4-72

Work description 4-74

Flash code 2-1 – oil pressure switch and 3-1 – oil pressure drop error 4-76

Related DTC 4-76

Work description 4-78

Flash code 8 – proportional injection pump solenoid (control rack) 4-80

Related DTC 4-80

Work description 4-82

Flash code 1-6 – main relay 4-84

Related DTC 4-84

Work description 4-86

Flash code 1-2 – CAN (Controller Area Network) communication 4-88

Related DTC 4-88

Work description 4-89

Automatic revs setting 4-90

How it works 4-90

Hydraulic system

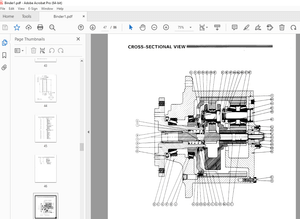

Hydraulic pump PVD-3B-56P-21G5-4626F 5-1

Pump unit: exploded view 5-3

Pilot oil supply unit 5-5

Main valve block with 3rd control circuit and triple articulation boom 5-6

Ports 5-6

Legend 5-7

Main valve block diagram 5-8

Pressure limiting valves 5-9

Pump assignment 5-10

Drive counterbalancing system 5-11

Pump assignment for drive counterbalancing 5-11

Drive counterbalancing diagram 5-12

Regeneration – stick section 5-13

Bucket pre-tension 5-13

Boom summation – raise 5-14

Check valve (load retaining valve) 5-15

Flow rate adjustment of auxiliary hydraulics 5-16

Pilot valves 5-17

Joystick 5-17

Pilot valve (driving) 5-19

Pilot valve for auxiliary hydraulics 5-21

Pilot valve for stabiliser blade 5-22

I-6 SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm

Table of contents

Valves 5-23

7/2 directional valve (changeover valve) 5-23

4/3 directional valve 5-24

Shuttle valve block 5-25

Changeover valve for SAE/ISO controls (option) 5-26

Travelling drive 5-27

Function 5-28

2nd speed range function 5-28

Swivel unit 5-31

Parking brake/multidisc brake function 5-32

Swivel joint 5-37

Breather filter 5-38

Troubleshooting in the hydraulic system 5-39

Hydraulics diagram A4 5-40

Hydraulics diagram (legend) 5-41

Hydraulics diagram A3 5-42

Options diagrams 1 (from serial no AC04070) 5-43

Options diagrams 2 (from serial no AC04070) 5-44

Main valve block A3 diagram 5-45

Electric system

Ohm’s Law (current, voltage, resistance); power 6-1

Measuring equipment, measuring methods 6-1

Cable colour coding 6-2

Relays 6-2

Use, mode of function 6-2

Electric units 6-3

Fuse box on the instrument panel up to serial no AD07210 6-3

Main fuse box with relays up to serial no AD07210 6-3

Relays 6-4

Fuse box on the instrument panel from serial no AH00645 6-4

Main fuse box with relays from serial no AH00645 6-5

ECU from serial no AH00645 6-5

Socket 6-6

Joystick tip switches 6-6

Joystick (left) 6-6

Joystick (right) 6-6

Instrument panel overview 6-7

Switches: overview 6-8

Alternator 6-8

Starter 6-8

Wiring diagram A4 up to serial no AC02888 (legend) 6-10

Wiring diagram A4 up to serial no AC02888 6-11

Wiring diagram A4 from serial no AC02890 (legend) 6-12

Wiring diagram A4 from serial no AC02890 6-13

Wiring diagram A4 from serial no AH00645 (legend) 6-14

Wiring diagram A4 (1) from serial no AH00645 6-15

Wiring diagram A4 (2) from serial no AH00645 6-16

Engine – chassis A4 wiring harness 1000109624 up to AD07210 (legend) 6-17

Engine – chassis A4 wiring harness 1000109624 up to AD07210 6-18

Engine – chassis A4 wiring harness 1000173970 from AH00645 (legend) 6-19

Engine – chassis A4 wiring harness 1000173970 from AH00645 6-20

Switches A4 wiring harness 1000109630 up to serial no AC02888 (legend) 6-21

Switches A4 wiring harness 1000109630 up to serial no AC02888 6-22

Switches A4 wiring harness from serial no AC02890 (legend) 6-23

Switches A4 wiring harness from serial no AC02890 6-24

Wiring harness 1000109629: cab roof 6-25

SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm I-7

Table of contents

Wiring harness 1000109628: armrest 6-26

Wiring harness 1000116138: boom working light 6-27

Wiring diagram A3 up to serial no AC02888 (legend) 6-29

Wiring diagram A3 up to serial no AC02888 6-30

Wiring diagram A3 from serial no AC02890 – AD07210 (legend) 6-31

Wiring diagram A3 from serial no AC02890 – AD07210 6-32

Wiring diagram A4 from serial no AH00645 (legend) 6-33

Wiring diagram A4 (1) from serial no AH00645 6-34

Wiring diagram A4 (2) from serial no AH00645 6-35

Engine – chassis A3 wiring harness 1000109624 (legend) 6-36

Engine – chassis A3 wiring harness 1000109624 6-37

Engine – chassis A3 wiring harness 1000173970 from serial no AH00611 (legend)

6-38

Engine – chassis A3 wiring harness 1000173970 from serial no AH00611 6-39

Switches A3 wiring harness 1000109630 up to serial no AC02888 (legend) 6-40

Switches A3 wiring harness 1000109630 up to serial no AC02888 6-41

Switches A3 wiring harness from serial no AC02890 (legend) 6-42

Switches A3 wiring harness from serial no AC02890 6-43

Wiring harness 1000109629: cab roof A3 6-44

Wiring harness 1000109628: armrest A3 6-45

Wiring harness 1000116138: boom working light A3 6-46

Options

Air conditioning 7-1

Specific safety instructions 7-1

Specifications 7-1

Installation: overview 7-2

Components 7-3

Filling up the air conditioning system 7-5

Maintenance 7-6

Troubleshooting 7-7

Air-suspension seat 7-9

Ports 7-9

Counterweight 7-9

Specifications 7-9

Long stick 7-9

Specifications 7-9

Control circuit (pipework) connections for grab 7-10

3rd control circuit connections 7-10

Auxiliary hydraulics connections 7-11

Quickhitch couplings 7-11

Attachments 7-12

Neuson Vario 7-13

Using the Neuson Vario feature 7-13

Vario diagram 7-14

Function 7-14

Neuson Vario warning device 7-15

Ports 7-16

Fuel-filling pump 7-17

Connections up to serial no AD07210 7-18

Central lubrication system 7-19

Position 7-19

Connections 7-19

Function 7-20

Adjusting breaks and lubrication times 7-21

Repair in case of clogging 7-21

I-8 SERV-HB 6003 EN – Edition 20 * 6003s2_0IVZfm

Table of contents

Service valve 7-23

Function 7-23

Safe load indicator D (safety valve for boom) 7-24

Position 7-24

Function 7-24

Diagram 7-25

Safe load indicator F (safety valves for boom and stick) 7-26

Position 7-26

Function 7-27

Diagram 7-28

3rd control circuit 7-29

Function 7-29

Diagram 7-30

Triple articulation boom 7-31

Function 7-31

Diagram 7-32

Electric auxiliary hydraulics 7-33

Function 7-33

Auxiliary hydraulics shock cartridge 7-35

3rd control circuit shock cartridge 7-36

Drive interlock (antitheft protection) 7-37

Position 7-37

Disabling the drive interlock 7-37

Enabling the drive interlock 7-37

Programming 7-37

Quickhitch 7-39

Proportional controls 7-40

Function 7-40

Ports 7-40

Overview of auxiliary hydraulics controls 7-41

Hammer operation 7-41

Adjusting control response 7-41

Characteristic curve – status display 7-41

Wiring harness 7-42

Control unit 7-42

Control valve plug assignment 7-43

Safety features 7-44

Measures to be taken in case of malfunctions 7-44

Diagnosis display 7-44

IMAGES PREVIEW OF THE MANUAL: