$38

Wacker Neuson Track Excavators 75Z3 75Z32 8003 80032 Operator’s Manual - PDF DOWNLOAD

Wacker Neuson Track Excavators 75Z3 75Z32 8003 80032 Operator’s Manual - PDF DOWNLOAD

FILE DETAILS:

Wacker Neuson Track Excavators 75Z3 75Z32 8003 80032 Operator’s Manual - PDF DOWNLOAD

Language : English

Pages :270

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Wacker Neuson Track Excavators 75Z3 75Z32 8003 80032 Operator’s Manual - PDF DOWNLOAD

1 Introduction 13

11 Important information on the Operator’s Manual 13

Abbreviations/symbols 13

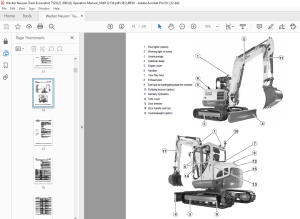

12 Machine overview 14

13 Brief description 15

Travelling drive 15

Work hydraulics 15

Shock cartridges (option) 15

Cooling system 15

Cab 15

14 Fields of application, attachments 16

Use: attachment 16

15 Regulations 18

16 EC declaration of conformity for all machines delivered before 29 December 2009 19

17 EC declaration of conformity for all machines delivered after 29 December 2009 20

18 Declaration of conformity for machines without CE mark on the type label 21

19 Type labels and component numbers 22

110 Signs and symbols (up to serial no AH01658) 25

on the outside of the machine 25

111 Signs and symbols (from serial no AH01659) 29

Safety labels 34

112 Fire extinguisher 39

2 Safety instructions 41

21 Identification of warnings and dangers 41

22 Warranty 41

23 Disposal 41

24 Designated use and exemption from liability 42

25 General conduct and safety instructions 43

Organisational measures 43

26 Selection and qualification of staff, basic responsibilities 44

27 Safety instructions regarding operation 45

Normal operation 45

28 Information on visibility 46

29 Cab and protective structures (from serial no AJ02793) 47

Installing/removing the Front Guard 47

Work range and restricted visibility 48

210 Checks when reversing the machine 48

211 Trailer operation 48

212 Applications with lifting gear 49

Instructions on fastening loads 49

Prerequisite for safe use 50

213 Attachments 50

214 Safety instructions for maintenance 51

215 Warning of special hazards 53

Electrical system 53

Working in the area of underground electric lines 53

Working near overhead electric lines 53

Gas, dust, steam, smoke 54

Hydraulics 54

Noise 54

Oil, grease and other chemical substances 54

Using the quickhitches in water 54

Battery 54

Tracks 55

216 Hammer operation 55

Safety instructions 55

Working with a hammer 56

217 Transport and towing 57

Towing 57

Transport 57

3 Operation 59

31 Cab 75Z3/8003 (up to serial no AH00610) 60

32 Control elements 75Z3/8003 (up to serial no AH00610) 62

33 Cab 75Z3/8003 (serial nos AH00611 to AH02749) 64

34 Control elements 75Z3/8003 (serial nos AH00611 to AH02749) 66

35 Cab 75Z3 2/8003 2 (from serial no AJ02793) 68

36 Control elements 75Z3 2/8003 2 (from serial no AJ02793) 70

37 Indicator lights and warning lights: overview 72

38 Putting into operation 75

Safety instructions 75

Putting the machine into operation for the first time 75

Running-in period 75

Check lists 75

Start-up checklist 76

Operation checklist 76

Parking checklist 77

39 Driving the machine 78

Preheating start switch 78

Throttle 78

310 Automatic engine speed setting 79

311 Before starting the engine 80

Starting the engine: general 81

312 Starting with the drive interlock (option) 82

Drive interlock (up to serial no AH02749) 82

Drive interlock – internal transponder (from serial no AJ02793) 83

313 Jump-starting the engine (supply battery) 84

314 Starting at low temperatures 85

315 When the engine has started 85

316 Special instructions for driving on public roads 86

Drive position 86

Drive levers 86

High speed 87

Moving off 87

Hydraulic brake 87

Mechanical brake 87

317 Working on slopes 88

318 Stabiliser blade operation 90

319 Parking the machine 91

Parking the machine on slopes 91

320 Light system 92

Working light 92

Front and rear roof lights (option) (up to serial no AH02749) 93

Rotating beacon (option) 94

Interior light 94

321 Cab heating and ventilation 95

Summer/winter operation (up to serial no AD04617) 96

Heating controls (from serial no AD04618) 96

322 Air conditioning (option) 97

Recirculated air mode 97

323 Wiper/wash system 98

Tank for washer system 98

324 Seat (standard) 99

Seat depth adjustment100

Horizontal adjustment100

Weight adjustment100

Adjusting the head rest100

Backrest adjustment101

Height adjustment101

325 Seat (air suspension option)102

Seat depth adjustment103

Horizontal adjustment103

Weight adjustment103

Height adjustment103

Adjusting the head rest104

Backrest adjustment104

Horizontal suspension104

326 Seat belt105

327 Retracting lap belt (option)106

328 Mirrors (option)107

Safety instructions107

Adjusting the mirrors108

329 Emergency exit109

Emergency exit on machines equipped with protective Front Guard structures (option)109

330 Front window (up to serial no AD06526)110

331 Front window (from serial no AD06527)111

Opening the front window111

Closing the front window112

Opening the lower front window112

Closing the lower front window113

Opening the whole front window113

Closing the whole front window114

Opening the front window to a gap115

332 Opening the side window115

333 Engine cover115

334 Battery master switch116

335 Tilting the cab117

336 Door120

Door 75Z3120

Door 8003120

337 Exit through the door (up to serial no AH02749)122

338 Exit through the door (from serial no AJ02793)123

339 Armrest adjustment (75Z3/8003 up to serial no AH02749)124

340 Armrest adjustment (75Z3/8003 from serial no AJ02793)124

341 Towing the machine125

342 Crane handling the machine126

343 Loading and transporting the machine128

Safety instructions128

344 Tying down the machine129

345 Driving signal (option)129

346 Working with the machine130

General safety instructions130

347 Control levers/ISO controls: overview131

Left-hand control lever131

Hammer pedal lock (up to serial no AH02749)131

Boom/triple articulation boom operation (up to serial no AH02749)132

Hammer pedal lock (from serial no AJ02793)132

Boom/triple articulation boom operation (from serial no AJ02793)133

Right-hand control lever133

Lowering the boom with the engine stopped134

Rotating the upper carriage134

Swivel unit brake135

348 Changeover valve for SAE/ISO controls (option)136

Left-hand control lever136

Right-hand control lever136

Directional valve position136

Directional valve137

349 Control lever with proportional controls (option): overview138

Function138

Left-hand control lever139

Changeover between auxiliary hydraulics and boom swivel139

Switching the status indicator on/off for auxiliary hydraulics/boom swivel139

Operating the boom/auxiliary hydraulics140

Hammer operation140

Adjusting control response140

Characteristic curves – status indicator141

Right-hand control lever141

Releasing pressure141

350 Control lever if equipped with 3rd control circuit (option): overview142

Left-hand control lever142

Boom swivel (up to serial no AH02749)142

Boom swivel (from serial no AJ02793)143

Right-hand control lever143

Releasing pressure143

351 Vario (8003 option)144

Vario operation144

Driving across slopes with the Vario feature144

Vario warning device145

Warning ranges145

Working with the Vario feature146

Improved reach with the Vario feature146

352 Releasing the pressure on the work hydraulics147

Releasing pressure147

Pressure release with proportional controls (option)147

353 Re-equipping attachments148

Specific safety instructions148

Removing a bucket148

Mounting a bucket149

354 Quickhitch (option)149

355 Hydraulic quickhitch – Easy Lock (option)150

Picking up an attachment151

Setting down an attachment152

Shovel bucket operation153

356 Powertilt (option)153

Re-equipping154

Operation154

Right-hand control lever (Powertilt)154

357 Connections for auxiliary hydraulics155

Quickhitch couplings155

358 Safe load indicator (option)156

359 Safety feature “Hose burst valve” (option)157

360 Applications with lifting gear157

Lifting gear applications158

Fastening loads158

361 Work area assessment and preparation158

Examining the site158

Preparing the ground158

362 Working with the machine159

Working with the standard bucket159

Inadmissible work procedures159

Work position of machine160

Bucket position when digging160

Excavating trenches161

Loading161

Grading162

Excavating trenches laterally162

Working alongside trenches163

Stabiliser blade at rear163

Further practical hints for digging164

Loading vehicles164

Freeing the machine164

363 Grading164

Grading164

364 Increased volume of auxiliary hydraulics 8003 (from serial no AJ02782)165

4 Troubleshooting167

41 Troubleshooting the engine167

Indicator lights169

Seals, hoses169

Undercarriage170

42 Engine error codes:171

43 Malfunctions of the Powertilt unit175

44 Troubleshooting the central lubrication system (option)176

45 Proportional controls (option) diagnosis display177

5 Maintenance179

51 Introduction179

52 Safety-relevant parts179

53 Fuel system180

Refuelling181

Fuel-filling pump (option) (75Z3 up to serial no AD07209; 8003 up to serial no AD07187)181

Fuel-filling pump (option) (75Z3 from serial no AH00646; 8003 from serial no AH00611)182

Stationary fuel pumps182

Diesel fuel specification183

Bleeding the fuel system183

Fuel prefilter with water separator184

54 Engine lubrication system185

Checking the engine oil level185

Filling up engine oil186

55 Engine and hydraulics cooling system187

Specific safety instructions187

Checking/filling up coolant188

56 Air filter190

Replacing the air filter191

Air intake192

57 Change cab air filter192

58 Replacing the filter element of the air conditioning system (option)193

59 Diesel particulate filter (option)194

Main components of diesel particulate filter system194

How the diesel particulate filter works195

Machine operation with diesel particulate filter195

Display197

Temperature scale197

Exhaust gas back pressure scale197

Alarm messages198

Maintenance201

Oils and fuels202

Troubleshooting202

Warranty202

510 V-belt203

Checking V-belt tension203

Retightening the V-belt204

Checking the V-belt of the air conditioning system (option)205

Tightening the V-belt of the air conditioning system (option)205

511 Hydraulic system206

Specific safety instructions206

Checking the hydraulic oil level207

Filling up hydraulic oil208

Important information for the use of biodegradable oil209

Checking hydraulic pressure lines210

512 Tracks211

Checking the track tension of the rubber tracks211

Checking the track tension of the steel tracks (option) and hybrid tracks (option)212

Adjusting track tension212

513 Travelling drive214

Checking the oil level and filling up oil214

Draining oil214

514 Maintenance of attachments215

515 Electrical system215

Service and maintenance work at regular intervals215

Instructions concerning specific components215

Alternator215

Battery216

516 General maintenance work218

Cleaning218

General instructions for all areas of the machine218

Inside the cab218

Cleaning the seat belt219

Exterior of the machine219

Engine compartment219

Screw connections and attachments219

Pivots and hinges219

517 Overview of lubrication points220

Parking the machine221

Lubrication points on the boom, bucket and stick rams221

Lubrication points on the boom and stick222

Joint rod lubrication point223

Lubrication points on the stabiliser blade and stabiliser blade ram 75Z3223

Lubrication points of stabiliser blade ram 8003224

Lubrication points on the slewing ram and swivelling console224

Lubrication points of ball bearing race of live ring225

Lubrication points of live ring teeth226

Powertilt lubrication points (option)227

Lubrication points of hydraulic quickhitch (option)227

Lubrication points of control lever base (from serial no AJ02793)228

518 Central lubrication system (option)229

Function229

Status LEDs229

Adjusting cycle time and lubrication time230

Repair in case of clogging230

519 Preparatory work before taking the machine out of service231

520 Maintenance if the machine is out of service for a longer period of time231

Putting into operation again231

521 Fluids and lubricants232

Oil grades for the diesel engine, depending on temperature233

Additional oil change and filter replacement (hydraulic system)233

Oil grades for the hydraulic system, depending on temperature234

522 Maintenance plan (overview)235

523 Maintenance label240

Explanation of symbols on the maintenance label240

6 Specifications243

61 Chassis243

62 Engine243

63 Hydraulic system244

64 Work hydraulics244

65 Undercarriage and swivel unit244

66 Stabiliser blade245

67 Electrical system245

Fuse box on instrument panel (75Z3/8003 up to serial no AD07209/AD07187)245

Main fuse box with relays (75Z3/8003 up to serial no AD07209/AD07187)245

Fuse box on instrument panel (75Z3/8003 serial nos AH00646/AH00611 to AH02749/AH02747)246

Main fuse box with relays (75Z3/8003 from serial no AH00646/AH00611)246

Fuse box on instrument panel (75Z3/8003 from serial no AJ02793 /AH02798)247

68 ECU control unit (75Z3/8003 from serial no AH00646/AH00611)247

69 Noise levels248

610 Vibration248

611 Coolant compound table248

612 Powertilt249

613 Weight indications249

614 Dimensions model 75Z3250

615 Dimensions model 8003 Vario (option)252

616 Dimensions model 8003 triple articulation boom (option)254

617 Lift capacity table 75Z3256

618 Lift capacity table 75Z3 counterweight (option)257

619 Lift capacity table 75Z3 long stick (option)258

620 Lift capacity table 75Z3 long stick, counterweight (option)259

621 Lift capacity table 8003260

622 Lift capacity table 8003 counterweight (option)261

623 Lift capacity table 8003 long stick (option)262

624 Lift capacity table 8003 long stick, counterweight (option)263

625 Lift capacity table 8003 triple articulation boom (option)264

626 Lift capacity table 8003 triple articulation boom, counterweight (option)265

627 Lift capacity table 8003 long stick, triple articulation boom (option)266

628 Lift capacity table 8003 long stick, triple articulation boom, counterweight (option)267

629 Lift capacity table 8003 Vario (option)268

IMAGES PREVIEW OF THE MANUAL: