$38

Wacker Neuson Wheel Loaders 750, 850 Service Manual_1000183988 – PDF DOWNLOAD

Wacker Neuson Wheel Loaders 750, 850 Service Manual_1000183988 – PDF DOWNLOAD

FILE DETAILS:

Wacker Neuson Wheel Loaders 750, 850 Service Manual_1000183988 – PDF DOWNLOAD

Language : English

Pages :256

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Wacker Neuson Wheel Loaders 750 850 Service Manual_1000183988 – PDF DOWNLOAD

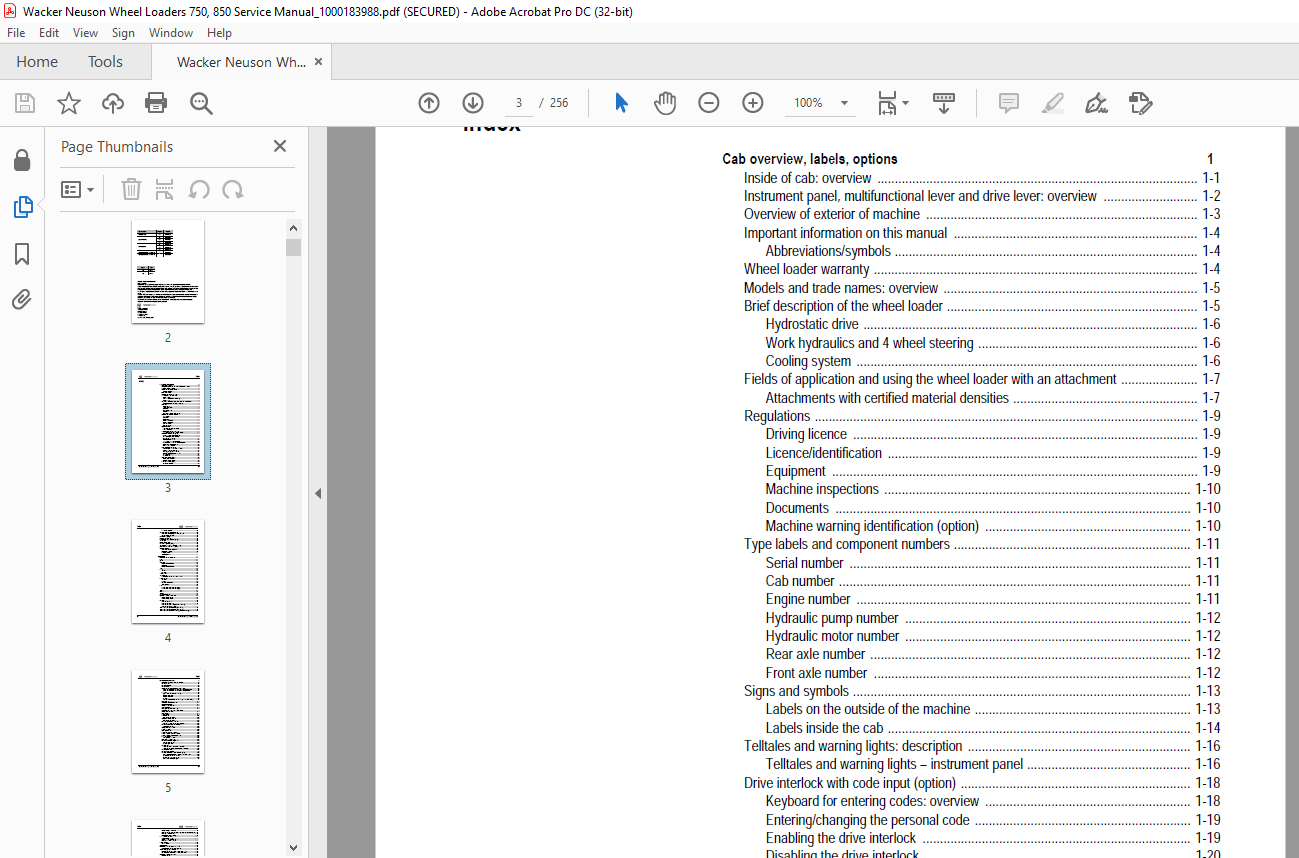

Cab overview, labels, options 1

Inside of cab: overview 1-1

Instrument panel, multifunctional lever and drive lever: overview 1-2

Overview of exterior of machine 1-3

Important information on this manual 1-4

Abbreviations/symbols 1-4

Wheel loader warranty 1-4

Models and trade names: overview 1-5

Brief description of the wheel loader 1-5

Hydrostatic drive 1-6

Work hydraulics and 4 wheel steering 1-6

Cooling system 1-6

Fields of application and using the wheel loader with an attachment 1-7

Attachments with certified material densities 1-7

Regulations 1-9

Driving licence 1-9

Licence/identification 1-9

Equipment 1-9

Machine inspections 1-10

Documents 1-10

Machine warning identification (option) 1-10

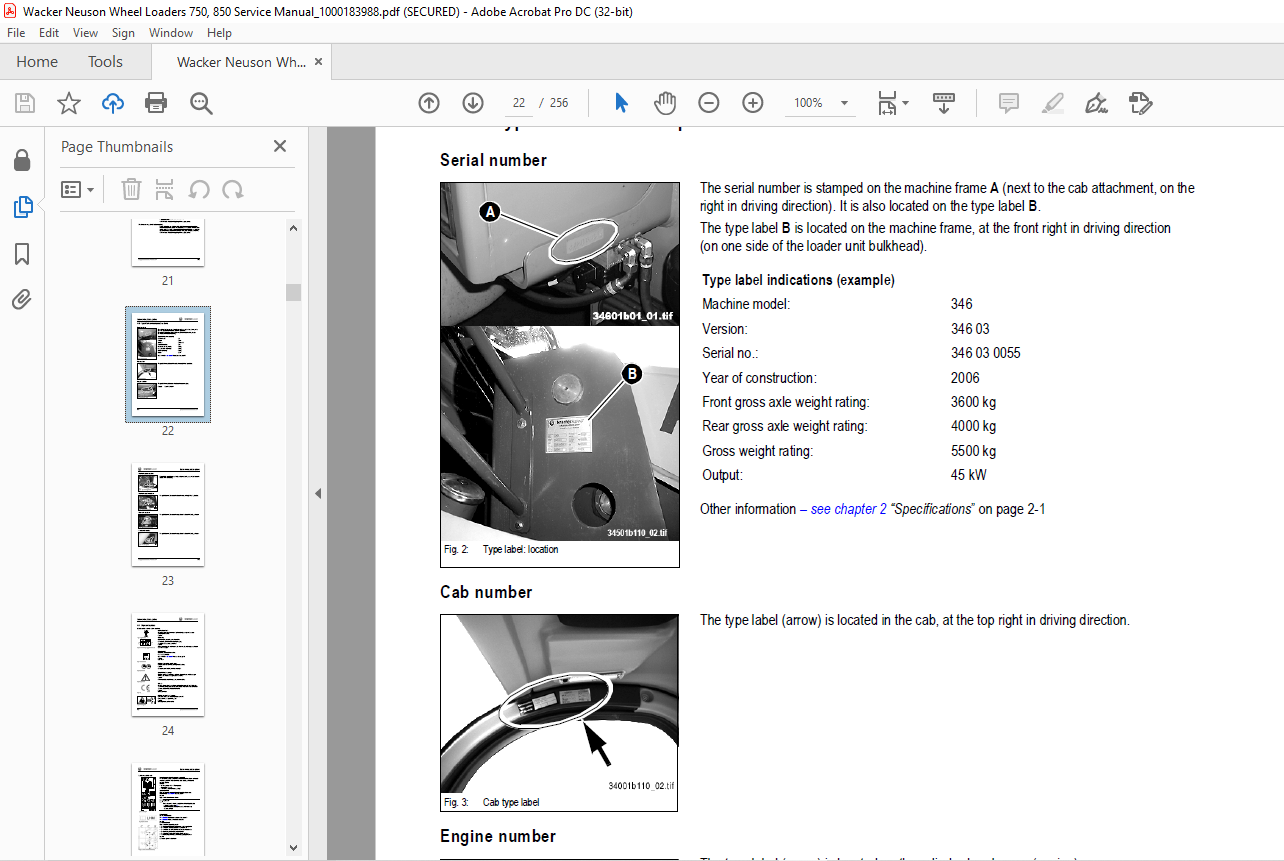

Type labels and component numbers 1-11

Serial number 1-11

Cab number 1-11

Engine number 1-11

Hydraulic pump number 1-12

Hydraulic motor number 1-12

Rear axle number 1-12

Front axle number 1-12

Signs and symbols 1-13

Labels on the outside of the machine 1-13

Labels inside the cab 1-14

Telltales and warning lights: description 1-16

Telltales and warning lights – instrument panel 1-16

Drive interlock with code input (option) 1-18

Keyboard for entering codes: overview 1-18

Entering/changing the personal code 1-19

Enabling the drive interlock 1-19

Disabling the drive interlock 1-20

Taking the drive interlock out of service 1-21

Putting the drive interlock back into service again 1-21

Interruption of drive interlock power 1-21

Drive interlock maintenance 1-21

Key-based drive interlock (option) 1-22

Key-based drive interlock: scope of delivery 1-22

Coding (“training”) new ignition keys 1-22

Enabling (locking) the drive interlock 1-23

Disabling (releasing) the drive interlock 1-23

Deleting coded keys 1-23

Safety functions 1-23

Battery master switch (option) 1-24

Interrupting power supply 1-24

Switching on power supply: 1-24

Oil and fuel preheater (option) 1-24

Oil preheater operation 1-24

Index

I-2 Serv-HB 34603_04 EN – Ausgabe 20 * 34603_04s20_enIVZfm

Index

Fuel preheater operation 1-24

Jump-starting the engine (external battery) 1-25

Safety instructions regarding external starting aids 1-25

Providing external starting aid 1-25

Manual throttle (option) 1-26

Low-speed control (option) 1-26

Electric connection – front socket (option) 1-27

Working lights 1-27

Rotating beacon (option) 1-27

Backup warning system (option) 1-28

Additional control circuit for attachments (option) 1-28

“Hose burst valve” safety feature (option) 1-29

Towing the machine 1-30

Safety instructions for towing away 1-30

Getting ready for towing 1-30

Towing the machine 1-31

Once towing is over 1-31

Specifications 2

Models and trade names: overview 2-1

Frame 2-1

Engine 2-1

Power train 2-2

Variable displacement pump 2-2

Boost pump 2-2

Variable displacement motor 2-2

Axles 2-3

Brakes 2-3

Service brake 2-3

Parking brake 2-3

Steering system 2-4

Work hydraulics 2-4

Hydraulic pump, control valve, lift and tilt rams 2-4

Electrical system 2-5

Electric units 2-5

Fuse box 2-5

Main fuse box with relays 2-6

Switching relays 2-6

Tyres 2-7

Tyres for wheel loader model 346-03 (750) 2-7

Tyres for wheel loader model 346-04 (850) 2-7

Weights 2-7

Noise levels 2-8

Vibration 2-8

Coolant compound table 2-8

Tightening torques, conversion tables 2-9

General tightening torques 2-9

Specific tightening torques 2-9

Payloads 2-10

Loader unit with bucket 2-10

Loader unit with pallet forks 2-10

Loader unit with pallet forks (foldable fork arms option) 2-11

Loader unit with load hook (option) 2-11

Wheel loader dimensions with bucket (model 346-03) 2-12

Wheel loader dimensions with bucket (model 346-04) 2-13

Wheel loader dimensions with pallet forks (models 346-03/346-04) 2-14

Serv-HB 34603_04 EN – Ausgabe 20 * 34603_04s20_enIVZfm I-3

Index

Maintenance and service work 3

Explanation of symbols on the maintenance label 3-1

Maintenance label 3-2

Fluids and lubricants 3-3

Maintenance plan 3-4

Important information on maintenance and service work 3-7

Service and maintenance work according to the maintenance plan 3-7

Service and maintenance work on the separate components 3-7

Fuel system 3-8

General safety instructions for refuelling 3-8

Diesel fuel specification 3-8

Stationary fuel pumps 3-8

Refuelling 3-9

Checking/cleaning the additional fuel filter (water separator, option) 3-9

Replacing the fuel filter 3-10

Cleaning the fuel pump screen filter 3-11

Bleeding the fuel system 3-12

Checking/filling up the engine oil 3-13

Changing engine oil 3-14

Replacing the engine oil filter cartridge 3-15

Cleaning the radiator fins of the oil/water radiator 3-16

Checking the coolant level 3-17

Draining coolant 3-18

Filling up coolant 3-19

Hydraulic system 3-20

Specific safety instructions 3-20

Checking hydraulic pressure lines 3-21

Specific safety instructions 3-21

Monitoring the hydraulic oil reflux filter 3-22

Important information for the use of biodegradable oil 3-22

Maintenance of the hydraulic oil reflux filter 3-23

Changing the filter insert 3-23

Checking the hydraulic oil level 3-24

Filling up hydraulic oil 3-24

Replacing hydraulic oil 3-25

Oil levels: rear axle transfer gearbox 3-26

Oil levels: front and rear axle differentials 3-27

Oil levels: front and rear axle planetary drives 3-28

Air filter maintenance 3-29

Checking the air filter for dirt 3-29

Replacing the air filter cartridge 3-30

Maintenance of the diesel engine V-belt 3-31

Checking V-belt tension 3-31

Retightening the V-belt 3-31

Lubrication work 3-32

Lubricating the rear axle oscillation-type bearing 3-32

Lubricating the front and rear axle planetary drive bearings 3-32

Lubricating the loader unit 3-33

Maintenance of attachments 3-33

Lubricating with the central lubrication system (option) 3-34

General functional description of the central lubrication system 3-34

Setting the lubrication and break times 3-35

Filling the central lubrication system 3-35

Central lubrication system diagram 3-36

I-4 Serv-HB 34603_04 EN – Ausgabe 20 * 34603_04s20_enIVZfm

Index

Mounting the high-pressure hoses 3-37

Instructions for troubleshooting in case of central lubrication system blocking 3-38

Repairing a blocked distributor 3-39

Troubleshooting table (overview) 3-40

Brake system maintenance 3-41

Specific safety instructions 3-41

Checking/filling up the brake fluid level 3-41

Repair work on the brake system 3-41

Tyre maintenance 3-42

Daily tyre checks 3-42

Changing wheels 3-43

Maintenance of cab heating and fresh air filter 3-44

Cleaning the dust filter of the heating system 3-44

Air conditioning (option): maintenance 3-45

General instructions regarding the air conditioning system 3-45

Daily functional and visual checks of the air conditioning 3-46

Maintenance of the electrical system 3-47

General instructions 3-47

Safety instructions regarding the electrical system and the battery 3-47

Battery maintenance 3-48

Service and maintenance work at regular intervals 3-49

Electric lines, bulbs, ignition lock, relays and fuses 3-49

Alternator 3-49

General maintenance work 3-50

Specific safety instructions 3-50

Cleaning with washing solvents 3-50

Cleaning with compressed air 3-50

Cleaning with a high-pressure cleaner or steam jet 3-50

Cleaning with volatile and flammable anticorrosion agents and sprays 3-50

Cleaning inside the cab 3-51

Cleaning the seat belt 3-51

Cleaning the exterior of the machine 3-51

Cleaning the engine compartment 3-52

Screw connections, hinges 3-52

Maintenance work “Aggressive Media” (option) 3-53

Anticorrosion protection applied in the factory 3-53

Components coated with anticorrosive wax 3-53

Measures for maintaining anticorrosive protection 3-54

Applying the protective anticorrosion coating 3-55

Treatment of oxidised surfaces 3-55

Engine 4

Engine designation 4-1

Fuel specification 4-1

Coolant specification 4-1

Electrical components (overview) 4-2

Diesel engine D 2011 L04 W overview 4-3

Engine oil cooling 4-4

Belt drive with cooling ports 4-5

Fuel system 4-6

Checking and adjusting valve clearance 4-7

Replacing the fuel injection pump 4-8

Switching off minus compensation 4-13

Heating connection 4-13

Removing/mounting the cylinder head 4-14

Sealing the bleed valve 4-17

Sealing the intake/exhaust manifold 4-17

Serv-HB 34603_04 EN – Ausgabe 20 * 34603_04s20_enIVZfm I-5

Index

Replacing the toothed belt and the tensioning pulley 4-18

General instructions 4-18

Removing the toothed belt and the tensioning pulley 4-18

Checking engine control times 4-25

Engine trouble 4-27

Notes: 4-29

Power train 5

Variable displacement pump test ports (20 kph) 5-1

Variable displacement pump 20 kph 5-2

Variable displacement pump test ports (30 kph) 5-3

Variable displacement pump 30 kph 5-4

Variable displacement motor (20/30 kph) 5-5

Inching valve overview 5-6

Inching valve circuit 5-7

Inching valve diagram 5-8

Drive circuit 5-9

Drive diagram 5-10

Towing and transporting the machine 5-11

Safety instructions 5-11

Getting ready for towing 5-11

Test report: 20 kph power train 5-12

Test report: 30 kph power train 5-13

Adjustment instructions 5-14

Tools required 5-14

Adjusting boost pressure 5-14

Adjusting starting engine speed/control pressure 5-15

Setting high pressure/drive pressure 5-16

Setting the secondary valves for forwards/reverse driving 5-17

Checking/setting the hydraulic resistance (characterisic curve) of the pump 5-17

Check engine droop 5-18

Setting control initiation on the variable displacement motor 5-18

Setting the wheel speed 5-19

Axles 6

Axle overview 6-1

Front axle screw connections 6-2

Sealing work (joint housing/axle carrier) 6-3

Sealing the rear axle in case of oil migration (axle/gearbox) 6-14

Assembly 6-17

Setting the gear drive 6-20

Removing the gearbox 6-24

Input shaft version 1 sealing: overview 6-30

Assembling the gearbox 6-31

Brakes 7

Brake circuit 7-1

Brake diagram 7-2

Service brake/inching valve function 7-2

Parking brake circuit 7-3

20 kph inching valve circuit 7-4

Service brake 7-5

Important information on the brake system 7-5

Brake calliper maintenance 7-5

Bleeding the brake system with bleed equipment 7-6

Notes: 7-7

I-6 Serv-HB 34603_04 EN – Ausgabe 20 * 34603_04s20_enIVZfm

Index

Steering system 8

Steering circuit 8-1

Steering circuit 8-2

Steering system adjustment 8-3

Function 8-3

Hydraulic ports on servostat 8-3

Pressure relief valve: adjustment 8-3

Sealing steering rams 8-4

Checking a steering ram 8-5

Overview of steering ram setting 8-5

Necessary tools 8-5

How to check and set the steering rams 8-6

Checking the track setting (1) 8-7

Correcting the track setting (2) 8-7

Setting the steering limit (3) 8-8

Checking steering synchronisation (4) 8-9

Checking the bypass 8-9

Bleeding the steering rams 8-10

Setting steering synchronisation (5) 8-11

Final check/test run 8-11

Hydraulic system 9

Work hydraulics test report 9-1

Work hydraulics oil supply 9-2

Control valve ports 9-3

Priority valve ports 9-3

Priority valve diagram 9-4

Load stabiliser ports 9-4

Load stabiliser circuit 9-5

Load stabiliser diagram 9-5

Lift ram: sealing work 9-6

Tilt ram: sealing work 9-7

Control ram (quickhitch frame): sealing work 9-8

Notes: 9-9

Work hydraulics diagram 9-10

Hose burst valve hydraulics diagram (option) 9-11

Serv-HB 34603_04 EN – Ausgabe 20 * 34603_04s20_enIVZfm I-7

Index

Electrical system 10

Ohm’s Law (current, voltage, resistance); power 10-1

Measuring equipment, measuring methods 10-1

Terminal description 10-2

Colour coding of electric lines 10-6

Extract from DIN 72551, sheet 4 10-6

Other colour codes (identical to IEC 757) 10-8

Switching relay function 10-8

Use, mode of function 10-8

Terminal description on relay 10-8

Starter, battery, alternator 10-9

Fuse box 10-9

Main fuse box with relays 10-10

Switching relays 10-10

Description of blocking diodes 10-11

Blocking diodes V8, V9 10-11

Blocking diode V10 10-11

Blocking diode V11 10-11

Blocking diodes V16, V17 10-11

Blocking diodes V20, V21 10-11

Overview of switch assignment 10-12

Retrofitting a rotating beacon 10-13

Retrofitting the backup warning system 10-13

Retrofitting 2 front working lights 10-14

Retrofitting 2 front working lights and 1 rear working light 10-14

Retrofitting 2 front working lights and 2 rear working lights 10-15

Electric diagram legend 10-16

Electric diagram sheet 1 10-17

Electric diagram sheet 2 10-18

Notes: 10-19

IMAGES PREVIEW OF THE MANUAL: