$35

Wacker Neuson Wheel Loaders 750T Operators Manual – PDF DOWNLOAD

Wacker Neuson Wheel Loaders 750T Operators Manual – PDF DOWNLOAD

FILE DETAILS:

Wacker Neuson Wheel Loaders 750T Operators Manual – PDF DOWNLOAD

Language : English

Pages :182

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Wacker Neuson Wheel Loaders 750T Operators Manual – PDF DOWNLOAD

Index I-8

Introduction 1

Important information on this Operator’s Manual 1-1

Abbreviations/symbols 1-1

Machine overview 1-2

Models and trade names: overview 1-3

Brief description of the wheel loader 1-3

Hydrostatic travel 1-4

Work hydraulics and 4 wheel steering 1-4

Cooling system 1-4

Fields of application and using the wheel loader with an attachment 1-5

Attachments with certified material densities 1-5

EC declaration of conformity, model 346-11 (750T) 1-7

Type labels and component numbers 1-8

Serial number 1-8

Cab certification number 1-8

Engine serial number 1-8

Hydraulic pump serial number 1-9

Hydraulic motor serial number 1-9

Rear axle serial number 1-9

Front axle serial number 1-9

Labels overview 1-10

Signs and symbols 1-11

Labels on the outside of the machine 1-11

Labels inside the cab 1-12

Engine compartment labels 1-15

Safety Information 2

Safety symbols found in this manual 2-1

Designated use 2-2

General conduct and safety instructions 2-2

Conditions for use 2-2

User training and knowledge 2-3

Preparing for use 2-3

Modifications and spare parts 2-3

Operator/technician qualifications and basic responsibilities 2-4

User/owner responsibility 2-4

Repair person qualifications 2-4

Safety instructions regarding operation 2-4

Preparing for use 2-4

Startup and shutdown 2-4

Work area awareness 2-5

Danger area awareness 2-5

Operating the machine 2-5

Carrying passengers 2-6

Mechanical integrity 2-6

Traveling 2-6

Applications with lifting gear 2-7

General Information 2-7

Safety criteria 2-7

Conditions for safe operation 2-7

Trailers and attachments 2-8

General information regarding attachments 2-8

Installation notes 2-8

Transport and towing 2-9

Table of contents

I-2 BA 34611 US – Edition 10 * 34611b10_usIVZfm

Table of contents

Towing 2-9

Transporting 2-9

Safety guidelines for maintenance 2-9

General maintenance notes 2-9

Personal safety measures 2-10

Preparing for maintenance and repair work 2-10

Performing maintenance and repairs 2-11

Special hazards 2-11

Battery 2-11

Tires 2-11

Electrical energy 2-12

Hydraulics 2-12

Noise 2-12

MSDS 2-12

Safety guidelines while using internal combustion engines 2-13

Running the engine 2-13

Fueling the engine 2-13

Operation 3

Description of control elements 3-1

Cab overview 3-2

Instrument panel, multifunctional lever and travel lever: overview 3-4

Indicators and warning lights: description 3-5

Putting the machine into service for the first time 3-7

Safety instructions 3-7

Important information 3-7

Running-in period 3-7

Check lists 3-8

Start-up checklist 3-8

Operation checklist 3-9

Parking checklist 3-9

Cab 3-10

Locking/unlocking the door 3-10

Locking and unlocking the right-hand side cab window 3-11

Side window emergency exit 3-12

Opening/closing the engine cover 3-12

Starting the engine 3-13

General instructions regarding engine start 3-13

Starting the engine 3-14

Travel interlock with code input (option) 3-15

Keyboard for entering codes: overview 3-15

Entering/changing the personal code 3-16

Enabling the travel interlock 3-16

Disabling the travel interlock 3-17

Taking the travel interlock out of service 3-18

Putting the travel interlock back into service again 3-18

Interruption of travel interlock power 3-18

Travel interlock maintenance 3-18

Key-based travel interlock (option) 3-19

Key-based travel interlock: scope of delivery 3-19

Coding (“training”) new starting keys 3-19

Enabling (locking) the travel interlock 3-20

Disabling (releasing) the travel interlock 3-20

Deleting coded keys 3-20

Security functions 3-20

Battery master switch (option) 3-21

Interrupting power supply 3-21

BA 34611 US – Edition 10 * 34611b10_usIVZfm I-3

Table of contents

Switching on power supply 3-21

Oil and fuel preheater (option) 3-21

Oil preheater operation 3-21

Fuel preheater operation 3-21

Jump-starting the engine (external battery) 3-22

Safety instructions regarding external starting aids 3-22

Providing external starting aid 3-22

Before operating 3-23

Special instructions regarding travel on public roads 3-23

Locking the control lever (joystick) and the 3rd control circuit (attachments)

when traveling on roads 3-24

Steering system 3-24

Checking the steering system 3-24

Synchronous wheel position 3-25

Differential lock 3-25

Switching the differential lock on and off 3-25

Accelerator pedal 3-25

Speed control with the accelerator pedal 3-25

Brake/inching pedal 3-26

Specific instructions regarding brake/inching pedal actuation 3-26

Braking with the brake/inching pedal 3-26

Inching with the brake/inching pedal 3-26

Parking brake 3-27

General instructions regarding the parking brake 3-27

Applying the parking brake 3-27

Moving the machine 3-28

Selecting a speed range 3-28

Changing direction (forward/reverse) 3-28

Load stabilizer 3-29

General instructions regarding the load stabilizer function 3-29

Switching the load stabilizer on and off 3-30

Backup warning system (option) 3-30

Backup warning system feature 3-30

Manual throttle (option) 3-31

Setting the travel speed with the manual throttle 3-31

Low-speed control (option) 3-32

Setting the travel speed with the low-speed control 3-32

Electric connection – front socket (option) 3-32

Location of fire extinguisher (option) 3-32

Putting the machine out of operation 3-33

Stopping/parking the machine 3-33

Machine lights 3-34

Machine lights operation 3-34

Working lights operation 3-35

Interior light operation 3-35

Signalling system 3-36

Turn indicator operation 3-36

Rotating beacon (option) 3-37

Rotating beacon operation 3-37

Cab heating and ventilation 3-37

Heating and ventilation system operation 3-37

Air conditioning (option) 3-38

Air conditioning operation 3-38

Washer system 3-39

Wiper controls 3-39

Tank for washer system 3-39

Seat 3-40

I-4 BA 34611 US – Edition 10 * 34611b10_usIVZfm

Table of contents

Seat adjustment: overview 3-40

Weight adjustment 3-40

Height adjustment 3-41

Backrest adjustment 3-41

Horizontal adjustment 3-41

Armrest adjustment 3-41

Seat belt (lap belt) 3-42

Specific instructions regarding the seat belt 3-42

Fastening the seat belt 3-42

Unfastening the seat belt 3-43

Longer/shorter lap belt adjustment 3-43

Towing the machine 3-44

Safety instructions for towing away 3-44

Getting ready for towing 3-44

Towing the machine 3-45

Once towing is over 3-45

Crane handling the machine 3-46

Safety instructions regarding crane handling 3-46

Crane handling the machine 3-46

Loading and transporting the machine on a transport vehicle 3-47

General safety instructions 3-47

Loading and strapping down the machine 3-48

Telescopic boom operation: overview 3-49

Safety instructions regarding the safe load indicator 3-49

Safe load indicator display unit: overview 3-50

Functional check of the safe load indicator 3-50

Control lever (joystick) for lift, tilt and push-out cylinders: overview 3-51

Locking/unlocking the quickhitch 3-51

Operation: control lever for 3rd control circuit 3-52

Operation of 3rd control circuit in continuous operation 3-52

Raising/extending the telescopic boom 3-53

Retracting/lowering the telescopic boom 3-53

Lowering the telescopic boom with the engine stopped 3-54

Lower the telescopic boom as follows: 3-54

Pressure relief on the quick couplers and the quickhitch 3-54

Releasing the pressure 3-54

Equipping the machine with a standard bucket 3-55

Fitting a standard bucket onto the quickhitch 3-55

Removing a standard bucket from the quickhitch 3-56

Working with the standard bucket 3-57

Fields of application of the standard bucket 3-57

General safety instructions for working with the bucket 3-57

Recommendations for digging 3-58

Tilt position of the bucket 3-58

Transport position of the bucket when loaded 3-58

Transporting with a full bucket 3-59

Loading loose material 3-59

Loading if the material is hard to penetrate 3-60

Removing material/digging in soft soil 3-61

Removing material/digging in hard soil 3-62

Loading heaped material (non-compacted material) 3-62

Loading heaped material (compacted material) 3-63

Grading 3-63

Recommendations for loading vehicles 3-63

Freeing the machine 3-63

“Load holding control valve” safety feature 3-64

Fitting a multipurpose bucket 3-65

BA 34611 US – Edition 10 * 34611b10_usIVZfm I-5

Table of contents

Removing the multipurpose bucket from the quickhitch 3-65

Hydraulic connections on the multipurpose bucket 3-65

Connecting hydraulic lines to the machine 3-66

Removing the multipurpose bucket from the quickhitch 3-67

Working with the multipurpose bucket 3-68

Traveling on public roads with the multipurpose bucket 3-68

Grading and scraping 3-69

Stripping in thin layers (scraper) 3-69

Spreading material in thin layers 3-70

Pulling out material from slopes 3-70

Moving material with longer reach 3-70

Picking up remaining material completely 3-71

Grabbing bulky material 3-71

Grabbing large objects 3-71

Pulling out and setting posts 3-71

Precise unloading 3-72

Backfilling round gravel into drainage ditches 3-72

Unloading from the bottom of the bucket for increased dump heights 3-72

Fitting pallet forks 3-73

Fitting an attachment onto the quickhitch 3-73

Removing the pallet forks from the quickhitch 3-73

Traveling on public roads 3-73

Adjusting the fork arms 3-74

Working with the pallet forks 3-75

General safety instructions regarding the pallet forks 3-75

Brief instructions for fork arms 3-77

Specific safety instructions for picking up loads with the pallet forks 3-78

Pallet forks load diagram 3-79

Picking up loads with the pallet forks 3-80

Lowering the telescopic boom and setting down the load 3-81

Transporting loads with the pallet forks 3-82

Troubleshooting 4

Engine trouble 4-1

Maintenance 5

Important information on maintenance and service work 5-1

Fuel system 5-2

General safety instructions for refueling 5-2

Diesel fuel specification 5-2

Stationary fuel pumps 5-2

Refueling 5-3

Bleeding the fuel system 5-3

Engine lubrication system 5-4

Checking the oil level once a day 5-4

Filling up engine oil 5-4

Engine and hydraulics cooling system 5-5

Specific safety instructions 5-5

Cleaning the radiator fins of the oil/water radiator 5-6

Checking the coolant level 5-7

Filling up coolant 5-8

Air filter 5-9

Checking the air filter for dirt 5-9

Replacing the air filter cartridge 5-10

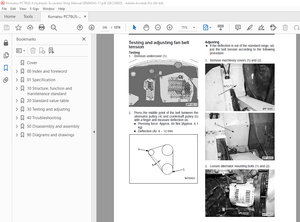

V-belt 5-11

Checking V-belt tension 5-11

Retightening the V-belt 5-11

Hydraulic system 5-12

I-6 BA 34611 US – Edition 10 * 34611b10_usIVZfm

Table of contents

Specific safety instructions regarding the hydraulic system 5-12

Monitoring the hydraulic oil return filter 5-13

Important information for the use of biodegradable oil 5-13

Checking the hydraulic oil level 5-14

Filling up hydraulic oil 5-14

Checking hydraulic pressure lines 5-15

Specific safety instructions regarding pressure line checks 5-15

Lubrication work 5-16

Lubricating the rear axle oscillation-type bearing 5-16

Lubricating the front and rear axle planetary drive steering joint bearings 5-16

Lubricating the telescopic boom 5-17

Checking the wear pads 5-17

Lubricating with the central lubrication system (option) 5-18

General functional description of the central lubrication system 5-18

Pushbutton switch for intermediate lubrication 5-18

Setting the lubrication and break times 5-19

Filling the central lubrication system 5-19

Maintenance of the brake system 5-20

Specific safety instructions regarding the brake system 5-20

Checking/filling up the brake fluid level 5-20

Tires 5-21

Daily tire checks 5-21

Wheel change 5-22

Heating and ventilation system maintenance 5-23

General instructions regarding the heating system 5-23

Cleaning the dust filter of the heating system 5-23

Air conditioning (option): maintenance 5-24

General instructions regarding the air conditioning system 5-24

Daily functional and visual checks of the air conditioning 5-25

Electric system 5-26

Specific safety instructions regarding the electric system 5-26

Service and maintenance work at regular intervals 5-26

Cables, bulbs, starting lock, relays and fuses 5-27

Alternator 5-27

Checking the battery 5-28

General cleaning and maintenance work 5-29

Specific safety instructions regarding cleaning 5-29

When using washing solvents 5-29

When using compressed air 5-29

When using a high-pressure cleaner or steam jet 5-29

When using volatile and flammable anticorrosion agents and sprays 5-29

Cleaning inside the cab 5-30

Cleaning the seat belt 5-30

Cleaning the exterior of the machine 5-30

Cleaning the engine compartment 5-31

Checking screw connections 5-31

Checking pivots and hinges 5-31

Maintenance of attachments and of the work equipment 5-31

Maintenance work “Aggressive Media” (option) 5-32

Anticorrosion protection applied in the factory 5-32

Components coated with anticorrosive wax 5-32

Measures for maintaining anticorrosive protection 5-33

Applying the protective anticorrosion coating 5-34

BA 34611 US – Edition 10 * 34611b10_usIVZfm I-7

Table of contents

Treatment of oxidised surfaces 5-34

Fluids and lubricants 5-35

Explanation of symbols on the maintenance label 5-36

Maintenance label 5-37

Maintenance plan model 346-11 (overview) 5-38

Specifications 6

Models and trade names: overview 6-1

Frame 6-1

Engine 6-1

Travel 6-2

Variable displacement pump 6-2

Boost pump 6-2

Variable displacement motor 6-2

Axles 6-3

Brakes 6-3

Service brake 6-3

Parking brake 6-3

Steering system 6-4

Work hydraulics 6-4

Hydraulic pump, control valve, lift and tilt cylinders 6-4

Electric system 6-5

Electric units 6-5

Fuse box 6-5

Main fuse box with relays 6-6

Switching relays 6-6

Tires 6-7

Weights 6-7

Noise levels 6-8

Vibration 6-8

Coolant compound table 6-8

Tightening torques 6-9

General tightening torques 6-9

Specific tightening torques 6-9

Conversion table: DIN standard – USA standard 6-10

Payloads 6-11

Telescopic boom with bucket 6-11

Telescopic boom with pallet forks 6-11

Dimensions with bucket 6-12

Dimensions with pallet forks 6-13

I-8 BA 34611 US – Edition 10 * 34611b10_usSIXfm

Index

Index

Symbols

“Hose burst valve” safety feature (option) 3-64

A

Abbreviations 1-1

Accelerator pedal 3-25

Air conditioning 5-24

Air conditioning (option) 3-38

Air filter 5-9

Cleaning the dust valve 5-9

B

Battery 5-28

Battery master switch (option) 3-21

Biodegradable oil 5-13

Brake system 5-20

Brake fluid 5-20

Safety instructions 5-20

Brake/inching pedal 3-26

Brief description of the wheel loader 1-3

Brief instructions for fork arms 3-77

C

Cab 3-10

Central lubrication system (option) 5-18

Check lists 3-8

Control circuit in continuous operation 3-52

D

Daily tire checks 5-21

Dimensions with bucket 6-12

Driving on public roads

With the multipurpose bucket 3-68

With the pallet forks 3-73

E

Electric units 6-5

F

Filling the central lubrication system 5-19

Fire extinguisher (option) 3-32

Fitting pallet forks 3-73

Fitting the multipurpose bucket onto the quickhitch 3-65

Fluids and lubricants 5-35

Front socket (option) 3-32

Fuel preheater (option) 3-21

Fuel system

Refueling 5-3

Fuse box 6-5

G

General safety instructions regarding the pallet forks 3-75

H

Hazard warning system 3-36

Heating 3-37

Fine-dust filter 5-23

Heating system dust filter 5-23

HInts for digging, loading or pushing material 3-58

Hose burst valve 3-64

Hydraulic connections 3-66

I

Important information

On this Operator’s Manual 1-1

Indicator 3-5

Instructions for driving on public roads 3-23

Interior light 3-35

K

Key-based drive interlock 3-19

L

Light system 3-34

Load stabilizer (option) 3-29

Loading tie-bar 3-46

Locking and unlocking the right-hand side cab window 3-11

Locking the control lever (joystick) and the 3rd control circuit

(attachments) when driving on roads 3-24

Locking/unlocking the door 3-10

Locking/unlocking the quickhitch 3-51

Lowering the telescopic boom with the engine switched off 3-54

Low-speed control (option) 3-32

Index

BA 34611 US – Edition 10 * 34611b10_usSIXfm I-9

Index

M

Machine

Brief description 1-3

Fields of application 1-5

Loading and transporting 3-47

Overview 1-2

Maintenance

Air filter cartridge 5-10

Biodegradable oil 5-13

Brake system 5-20

Checking the coolant level 5-7

Checking the engine oil level 5-4

Checking the hydraulic oil level 5-14

Cleaning 5-29

Electric system 5-26

Engine and hydraulics cooling system 5-5

Engine lubrication system 5-4

Fill up the hydraulic oil 5-14

Filling in engine oil 5-4

Filling up coolant 5-8

Fluids and lubricants 5-35

Fuel system 5-2

General cleaning and mainentance work 5-29

Heating and ventilation system 5-23

Hydraulic pressure lines 5-15

Hydraulic system 5-12

Maintenance of attachments 5-31

Maintenance plan 5-38

Maintenance work if the machine is used in a saline environment

5-32

Pivots and hinges 5-31

Screw connections 5-31

Service and maintenance work at regular intervals 5-26

Tire care 5-21

V-belt 5-11

Manual throttle (option) 3-31

Models and trade names

overview 1-3

N

Noise levels 1-11

O

Oil preheater (option) 3-21

Operation 3-1

3rd control circuit control lever 3-52

Before starting the engine 3-13

Cab overview 3-2

Control lever (joystick) for lift, tilt and push-out rams 3-51

Hose burst valve on tilt ram (option) 3-64

Instrument panel overview 3-4

Load stabilizer (option) 3-29

Moving off 3-28

Parking the machine 3-33

Selecting a speed range 3-28

Starting the engine 3-13

Telescopic boom 3-49

P

Pallet forks 3-75

Adjusting the fork arms 3-74

Pallet forks load diagram 3-79

Parking brake 3-27, 6-3

Picking up loads with the pallet forks 3-80

Putting into service

Check lists 3-8

Safety instructions 3-7

Q

Quickhitch 3-55

R

Re-equipping the telescopic boom 3-55

Removing

The multipurpose bucket from the quickhitch 3-67

Rotating beacon 3-37

Running-in period 3-7

S

Safe load indicator 3-49

Functional check 3-50

Measures to be taken if 3-50

Safe load indicator (overview) 3-50

Safety instructions regarding the safe load indicator 3-49

Seat 3-40

Armrest adjustment 3-41

Backrest adjustment 3-41

Height adjustment 3-41

Horizontal adjustment 3-41

Seat adjustment 3-40

Seat belt 3-42

Weight adjustment 3-40

Seat belt 3-42

Service brake 3-26, 6-3

Setting down the material 3-81

Side window emergency exit 3-12

Signalling system 3-36

Signs and symbols 1-11

Specific safety instructions for picking up loads with the

pallet forks 3-78

I-10 BA 34611 US – Edition 10 * 34611b10_usSIXfm

Index

Specifications 6-1

Axles 6-3

Brakes 6-3

Dimensions 6-12

Electric system 6-5

Engine 6-1

Frame 6-1

Noise levels 6-8

Pallet forks (standard) 6-11

Pilot control 6-4

Steering system 6-4

Telescopic boom with bucket 6-11

Tightening torques 6-9

Tires 6-7

Vibration 6-8

Weights 6-7

Work hydraulics 6-4

Starting aid 3-22

Steering system 3-24

Synchronous wheel position 3-25

T

Telescopic boom

Checking the tilt position of the bucket 3-58

Checking the transport position of the bucket 3-58

Lowering with the engine switched off 3-54

Lubrication 5-17

Releasing the pressure on the quick couplers 3-54

Telescopic wheel loader dimensions with pallet forks 6-13

Tires 5-21

Towing the machine 3-44

Transport 3-59

Transporting loads with the pallet forks 3-82

Turn indicators 3-36

V

Ventilation 3-37

Ventilation, fresh air 3-37

W

Washer system 3-39

Tank 3-39

Wheel change 5-22

Wipers 3-39

Working

Freeing the machine 3-63

Grading 3-63

Loading heaped material 3-62

Loading loose material 3-59

Removing material/digging in hard soil 3-62

Removing material/digging in soft soil 3-61

With the multipurpose bucket 3-68

With the pallet forks 3-75

Working light 3-35

Working with the telescopic boom 3-57

IMAGES PREVIEW OF THE MANUAL: