$23

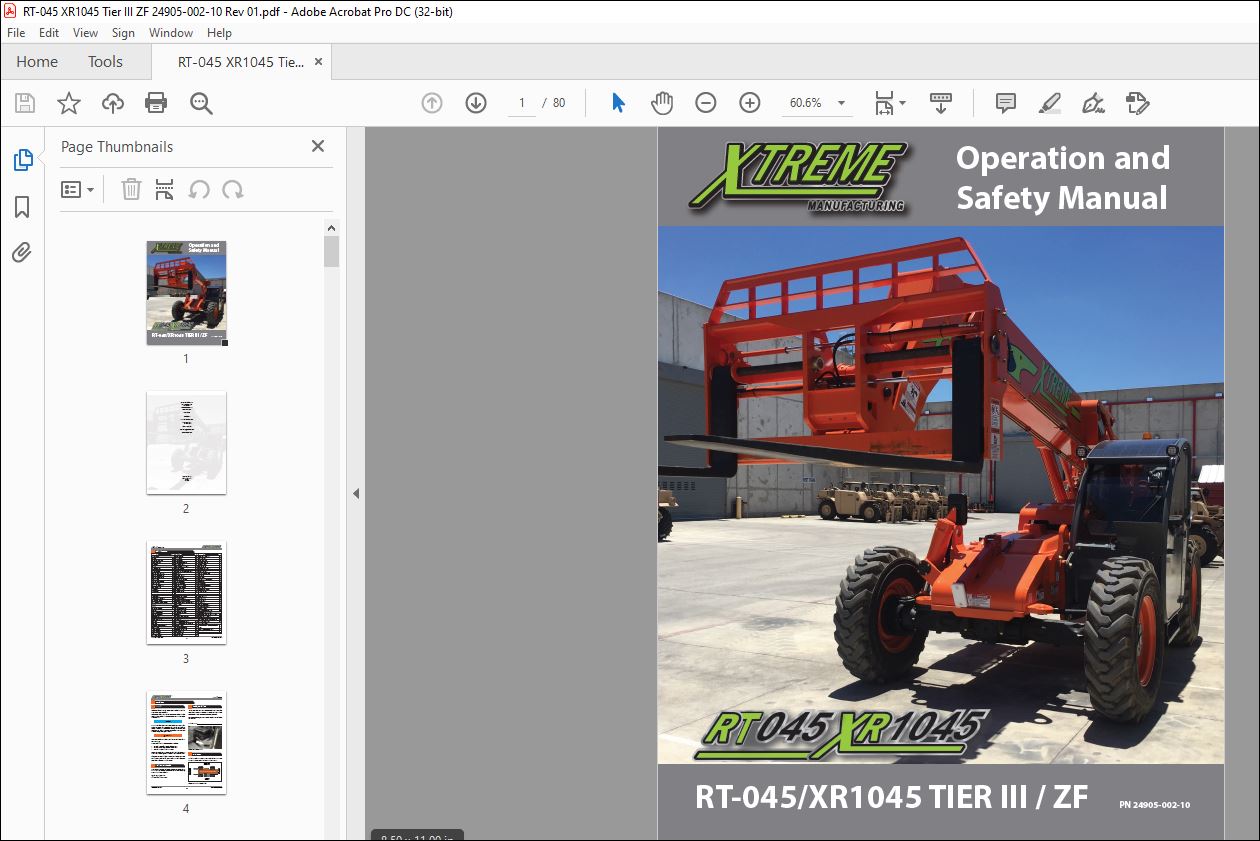

Xtreme RT-045 / XR1045 TIER III / ZF Operation & Safety Manual PDF

Xtreme RT-045 / XR1045 TIER III / ZF Operation & Safety Manual – PDF DOWNLOAD

Xtreme RT-045 / XR1045 TIER III / ZF Operation & Safety Manual is a downloadable PDF providing essential guidelines for safe operation and maintenance. Detailed instructions ensure proper handling and adherence to safety protocols.

FILE DETAILS:

Xtreme RT-045 / XR1045 TIER III / ZF Operation & Safety Manual – PDF DOWNLOAD

Language : English

Pages : 80

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Xtreme RT-045 / XR1045 TIER III / ZF Operation & Safety Manual – PDF DOWNLOAD

Introduction

General 4

Replacement Manuals 4

Model/Serial Plate 4

Orientation 4

Safety

Safety Disclaimer 5

Signal Words 5

Safety Symbols 5

Employer Responsibility 8

Operator Responsibility 8

Operator Qualifications 8

Modifications 8

Mounting/Dismounting 9

Work Site Safety 9

Before Starting Forklift 10

Operation Safety 11

Load Safety 13

Attachments 13

Shut Down Procedure 13

Forklift Maintenance 14

Jump Starting 15

Jump Starting Procedure 15

Dead Engine Towing 16

Parking Brake – Manual Release 16

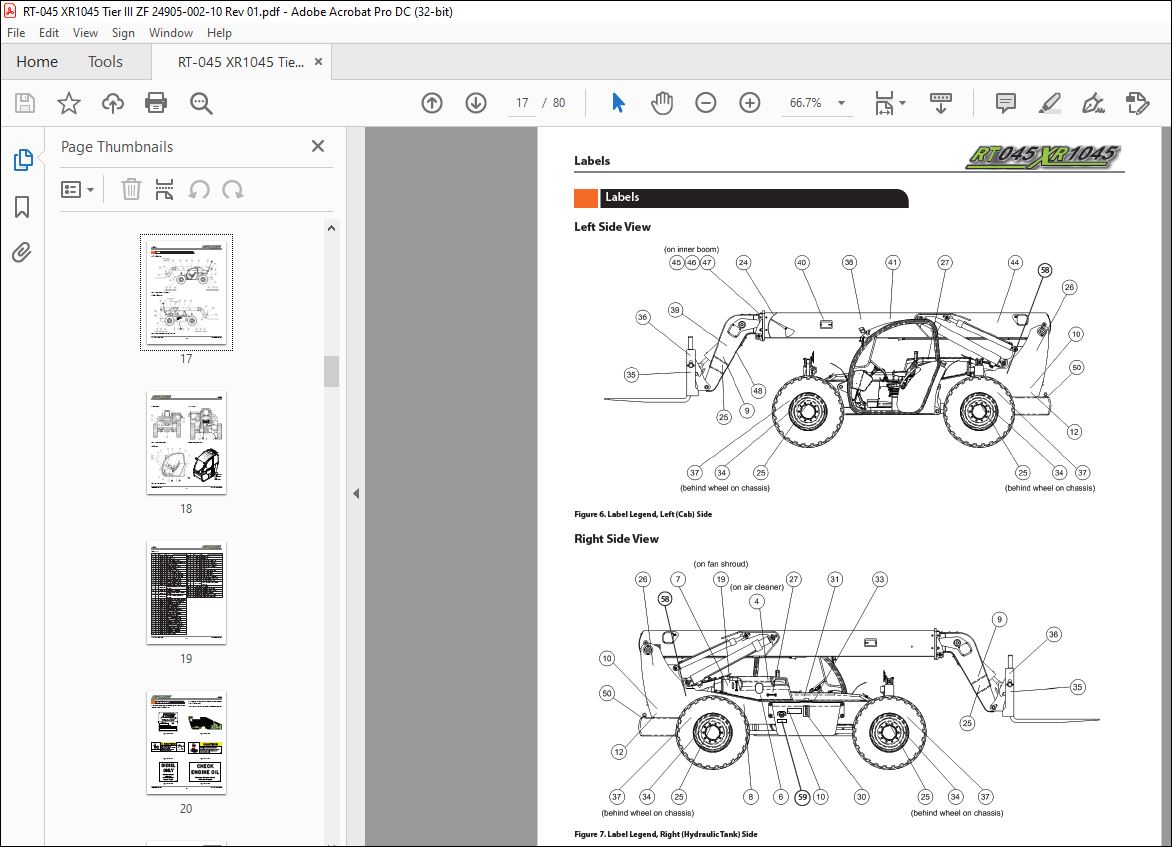

Labels

Labels 17

Replacement Labels 20

Features

Standard Equipment 29

Optional Equipment 29

Specifications

Specifications 30

Major Components

Rear View 32

Front View 33

Major Standard Components 33

Operator Cab

Ignition Switch 34

Accessory Outlet 34

Accelerator Pedal 34

Service Brake Pedal 34

Steering Wheel 35

Horn Button 35

Operator Seat 35

Operator Seat Controls 35

Fire Extinguisher 35

Weight Suspension Lever 36

Lumbar Support 36

Fore and Aft Adjustment Lever 36

Backrest Angle Adjustment Lever 36

Seat Belt 37

Rear View Mirrors 37

Emergency Stop 38

Controls and Indicators 38

Travel Select Lever 38

Gear Select Switch 38

Parking Brake Switch 39

Load Capacity Charts 39

Display Indicators 39

Display Features 41

Steering Select Switch 44

Boom Control 44

Attachment Tilt Switch 45

Frame Sway Control 46

Auxiliary Attachment Control 46

Fork Positioning Carriage Operation 47

Work Lights 47

Wiper 48

Boom Angle Indicator 48

Boom Extend Letters 48

Frame Level Indicator 48

Solargizer 49

Boom Maintenance Stand 49

Forklift Lifting Points 49

Operation

Pre-Operation Inspection 50

Pre-Operation Inspection Checklist 52

Functional Tests 53

Operator Maintenance 54

Before Starting Forklift 55

Starting Forklift 56

Normal Starting 56

Jump Starting 57

Description Page

Operating the Engine 58

Forklift Travel 58

Steering Modes 58

Wheel Alignment 59

Starting Travel 59

Shifting Gears 59

Warning Indicators 59

Changing Travel Direction 60

Stopping Travel 60

Shut Down Procedure 61

Refueling 61

Fuel Types 61

Engine Protection System 61

Pintle Hook 61

Attachments 62

Attachment Disclaimer 62

Fork Ratings 62

Quick Attach System 63

Load Handling 66

Boom Lift Point 67

Suspended Loads 67

Pick Up a Load 67

Carry a Load 68

Place a Load 68

Load Shift 68

Elevating Personnel 68

Load Capacity Charts 70

Frame Leveling 71

Boom Maintenance Stand 72

Preventive Maintenance

Establishing a Maintenance Program 73

Maintenance Schedule 73

Engine Diagnostic Fault Codes 74

Boom Emergency Lower Down Valve 75

Lubrication Diagram 76

Lockout / Tagout

Do Not Operate – Accident Prevention

New or Additional Operators 78

Lockout/Tagout Procedure 78

“Do Not Operate” Tags 79