$25

XTREME Telehandler XR2045 Operation & Safety Manual 24938-000-01 PDF

XTREME Telehandler XR2045 Operation & Safety Manual 24938-000-01 – PDF DOWNLOAD

FILE DETAILS:

XTREME Telehandler XR2045 Operation & Safety Manual 24938-000-01 – PDF DOWNLOAD

Language : English

Pages : 80

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

XTREME Telehandler XR2045 Operation & Safety Manual 24938-000-01 – PDF DOWNLOAD

Introduction 3

General 3

Replacement manuals 3

Model/Serial Number Plate 3

Orientation 3

Safety 4

Safety Disclaimer 4

Signal Words 4

Safety Symbols 4

Employer Responsibility 7

Operator Responsibility 7

Operator Qualifications 7

Modifications 7

Mounting/Dismounting 8

Work Site Safety 8

Before Starting Forklift 9

Operation Safety 10

Load Safety 13

Attachments 13

Shut Down Procedure 13

Forklift Maintenance 14

Dead Engine Towing 16

Parking Brake Release (Front Axle) 16

Re-activating Parking Brakes (Front Axle) 16

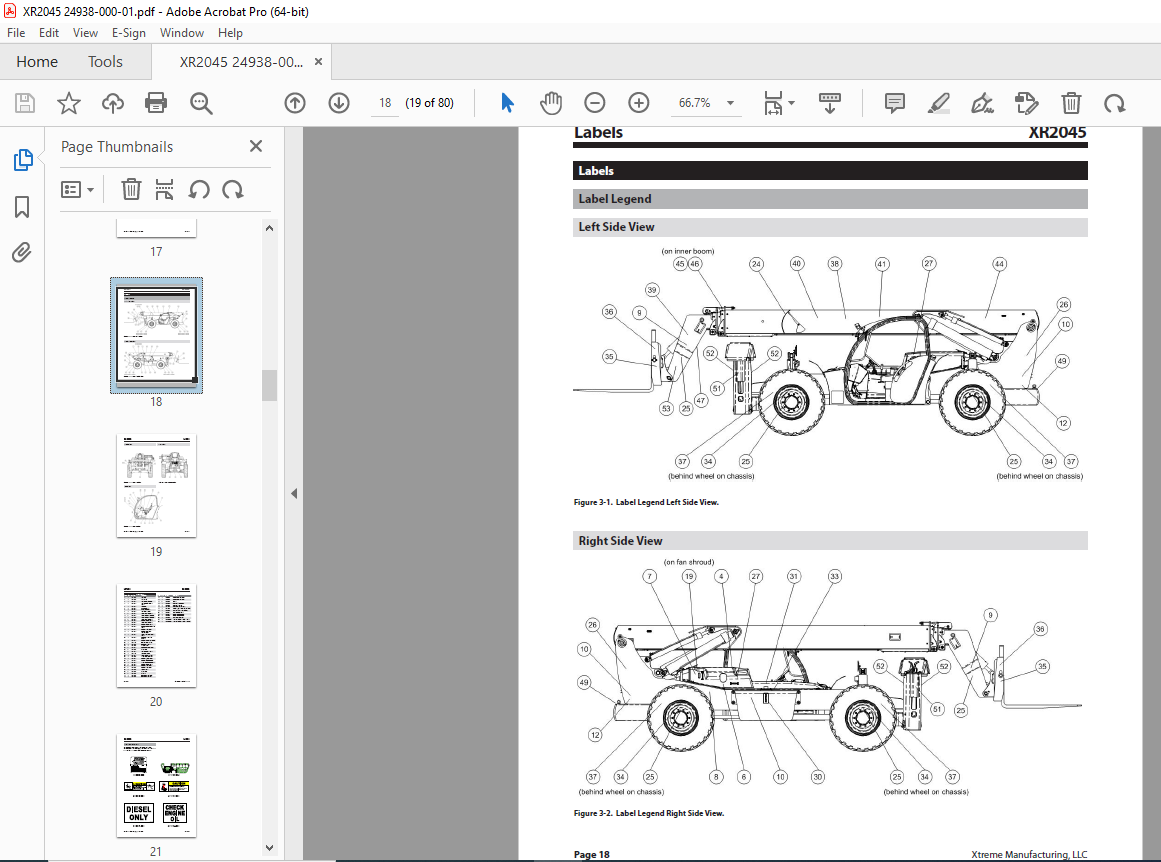

Labels 18

Label Legend 18

Left Side View 18

Right Side View 18

Front View 19

Rear View 19

Cab View 19

Replacement Labels 21

Features 30

Standard Equipment 30

Optional Equipment 30

Specifications 31

Operator Cab 32

Ignition Switch 32

Accessory Outlet 32

Accelerator Pedal 32

Service Brake Pedal 33

Steering Wheel 33

Horn Button 33

Operator Seat 33

Operator Seat Controls 33

Weight Suspension Lever 33

Lumbar Support 34

Fore and Aft Adjustment Lever 34

Backrest Angle Adjustment Lever 34

Seat Belt 34

Rear View Mirrors 35

Controls and Indicators 35

Travel Select Lever 35

Gear Select Switch 36

Parking Brake Switch 36

Load Capacity Charts 36

Hydraulic Oil Temperature Indicator 36

Low Brake Pressure Indicator 37

Rear Axle Lock Indicator 37

Hourmeter 37

Voltage Gauge 37

Fuel Gauge 38

Oil Gauge 38

Coolant Gauge 38

Light Switches 38

Work Light Switch 38

Rear Axle Centering Indicator 39

Steering Select Switch 39

Declutch Indicator 39

Declutch Switch 39

Tier 4 Interim Digital Display (Optional)

Activate Elevated Idle

Deactivate Elevated Idle

Summary of the Regeneration Process

Outrigger Toggle Switches

Boom Control

Attachment Tilt Switch Frame Sway Control Handle

Auxiliary Attachment Control

Optional Controls and Indicators

Two Wheel Rear (2WR) Steering Switch Boom Angle Indicator

Boom Extend Letters

Frame Level Indicator 51

Fuel Types 44

Tier 4 Interim Engines

Engine Warning Indicator

Engine Stop Indicator

Glow Plugs wait to Start Indicator

Starting Forklift

Starting

T4i Digital Display

Main Menu Options 41

Display Setup 43

Service Reminders 43

Engine Speed Contr o l 44

Access and Clearing Fault Codes 44

Operation 52

Pre-Operation Inspection

Pre-Operation Inspection Checklist

Functional Tests

Functional Test

Checklist

Operator Maintenance

Before Starting Forklift

Attachment Connection 66

Attachment Removal

Load Handling

Suspended Loads

Pick Up A Load

Carry A Load

Place A Load

Load Shift

Elevating Personnel

Frame Leveling

Load Capacity Charts 70

Using Load Capacity Charts

Reading Load Capacity Charts

Standard Carriage Load Capacity Chart 72

Preventive Maintenance 73

Establishing A Maintenance Program

Maintenance Schedules

Boom Emergency Lower Down Valve

Do Not Operate – Accident Prevention Tags

New or Additional Operators 75

Lockout / Tagout 76

Lockout/Tag out Procedure 76

Removing Forklift From Service 76

Returning Forklift To Service 76

“Do Not Operate” Tags 77

Steering Modes 61

Crab Steering Two Wheel Steering (2W) Four Wheel Steering (4W) Two Wheel Rear Steering (2WR) (Optional) 61

Maximum Fork Sweep

Starting Travel

Shifting Gears

Stopping Travel

Changing Travel Direction Shut Down Procedure

Warning Indicators and Gauges

Refueling

Attachments

Attachment Disclaimer

Fork Ratings

Standard Carriage Operation

Swing Carriage Operation

Quick Attach System

Starting Forklift 58

Normal Starting 58

Cold Starting 58

Soft Starting 58

Excessive Idling 58

Jump Starting 59

Forklift Travel 61