$33

XTREME XR842/1045/1245/1254/1267 (Tier III) Forward Reach Forklift Service Manual PDF

XTREME XR842/1045/1245/1254/1267 (Tier III) Forward Reach Forklift Service Manual – PDF DOWNLOAD

FILE DETAILS:

XTREME XR842/1045/1245/1254/1267 (Tier III) Forward Reach Forklift Service Manual – PDF DOWNLOAD

Language : English

Pages : 275

Downloadable : Yes

File Type : PDF

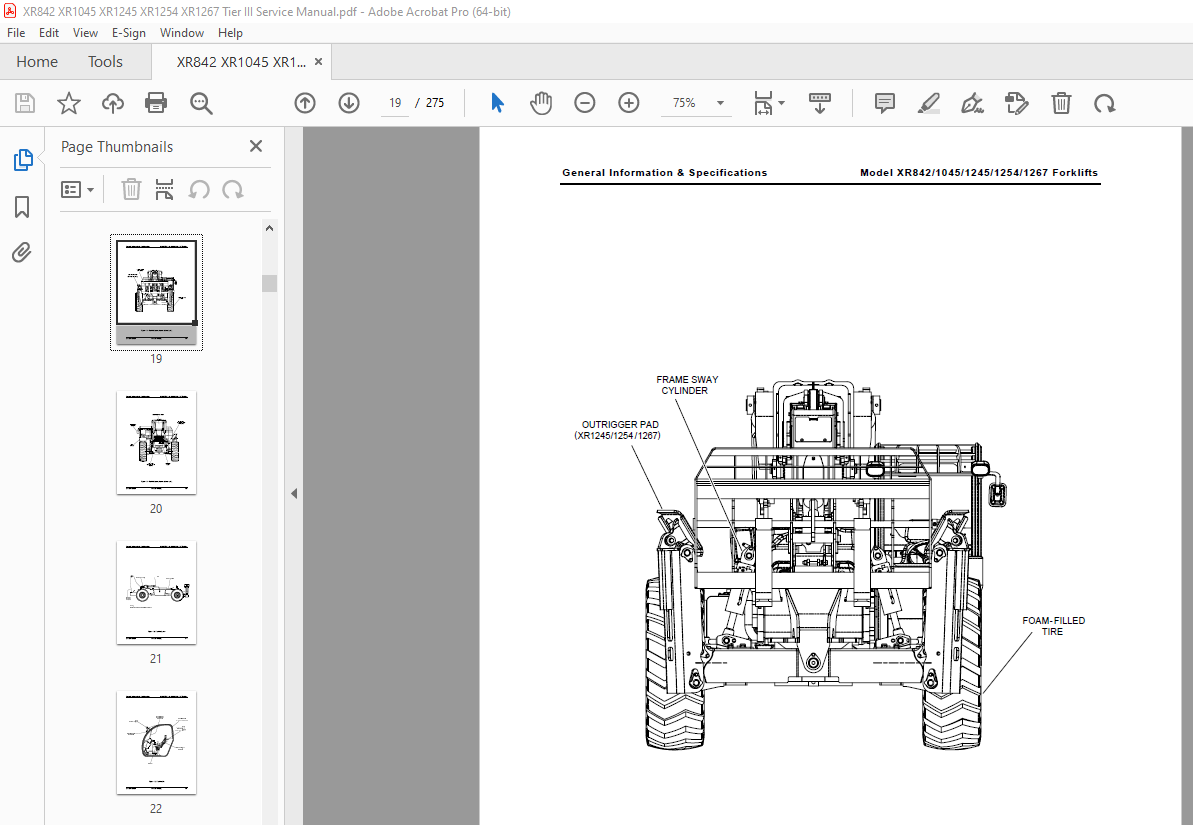

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

XTREME XR842/1045/1245/1254/1267 (Tier III) Forward Reach Forklift Service Manual – PDF DOWNLOAD

List of Effective Pages A

Service Bulletins B

Table of Contents i

List of Illustrations vi

List of Tables ix

SECTION 1 – GENERAL INFORMATION & SPECIFICATIONS 1-1

1-1 Scope of Manual 1-1

1-2 Applicability 1-1

1-3 Service Bulletins 1-1

1-4 Related Technical Documentation 1-2

1-5 Forklift Nomenclature 1-2

1-6 Component Data Plates 1-10

1-7 Lubricants and Fluids 1-14

1-8 Filters and Strainers 1-15

1-9 Forklift and Engine Specifications 1-16

1-10 Torque Wrench Use 1-24

1-11 Cap Screw Torque Values 1-24

SECTION 2 – MAINTENANCE & OPERATION SAFETY 2-1

2-1 General 2-1

2-2 Safety Signal Words 2-1

2-3 Notes 2-1

2-4 Safety Symbols 2-2

2-5 Lockout/Tagout Procedure 2-6

2-6 General Maintenance Precautions 2-7

2-7 Viton Seals 2-7

2-8 Using Compressed Air Safely 2-8

2-9 Battery Handling and Maintenance 2-8

2-10 Engine Operation and Maintenance 2-10

2-11 Fuel Handling and Maintenance 2-11

2-12 California Proposition 65 Warnings 2-11

2-13 Functional Tests 2-11

2-14 Safe Operation Checklist 2-12

2-15 Functional Test Checklist 2-13

2-16 Load Handling 2-14

Table of Contents Model XR842/1045/1245/1254/1267 Forklifts

Service Manual Rev 00 – (9/2/08) ii

Table of Contents – Cont

PARA TITLE PAGE

2-17 Picking Up a Load 2-16

2-18 Carrying a Load 2-16

2-19 Placing a Load 2-16

2-20 Load Shift 2-17

2-21 Proper Use of Forks 2-17

2-22 Prohibited Practices 2-17

2-23 Operator Hand Signals 2-18

2-24 Safety Decals 2-19

SECTION 3 – MAINTENANCE SCHEDULE 3-1

3-1 Establishing a Preventive Maintenance Program 3-1

3-2 Long-Interval Maintenance Requirements 3-5

SECTION 4 – AXLE CYLINDER AND OUTRIGGER LUBRICATION 4-1

4-1 General Maintenance Safety 4-1

4-2 Using a Grease Gun 4-1

4-3 Lubricate Axle Cylinders and Outriggers 4-2

SECTION 5 – ENGINE 5-1

5-1 General Maintenance Safety 5-1

5-2 Check Engine Oil Level 5-1

5-3 Check Engine Coolant Level 5-3

5-4 Check for Oil and Coolant Leaks 5-5

5-5 Check for Water in Fuel-Water Separator 5-6

5-6 Empty Air Filter Dust Cup 5-8

5-7 Check Condition and Tension of Drive Belts 5-10

5-8 Change Engine Oil 5-10

5-9 Replace Oil Filter 5-13

5-10 Replace Fuel Filter 5-15

5-11 Check Specific Gravity of Coolant 5-17

5-12 Drain and Flush Cooling System 5-19

5-13 Replace Air Filter 5-21

5-14 Check Air Filter 5-23

5-15 Check Condition and Tension of Drive Belts 5-24

5-16 Check and Adjust Valve Tip Clearances 5-26

5-17 Check Engine Hoses and Connections 5-28

Table of Contents Model XR842/1045/1245/1254/1267 Forklifts

Service Manual Rev 00 – (9/2/08) iii

Table of Contents – Cont

PARA TITLE PAGE

5-18 Check Radiator Hoses and Connections 5-29

5-19 Check Engine Wiring and Connections 5-30

5-20 Check for Oil, Coolant, and Fuel Leaks 5-31

SECTION 6 – TRANSMISSION, AXLES, & DRIVE SHAFTS 6-1

6-1 General Maintenance Safety 6-1

6-2 Using a Grease Gun 6-1

6-3 Lubricate Axle Grease Fittings 6-2

6-4 Lubricate Drive Shafts 6-4

6-5 Replace Transmission Filters and Fluids (XR1045/1245/1254) 6-6

6-6 Replace Transmission Filters and Fluids (XR842/1267) 6-8

6-7 Check Axle Oil Level 6-10

6-8 Check Wheel-End Oil Level 6-12

6-9 Drain and Fill Axle Wheel-End 6-14

SECTION 7 – WHEELS & TIRES 7-1

7-1 General Maintenance Safety 7-1

7-2 Check Wheel Lug Nut Torque 7-1

7-3 Inspect Wheel/Tire Assembly 7-3

7-4 Replace Wheel/Tire Assembly 7-4

7-5 Replace Tire 7-7

SECTION 8 – HYDRAULIC SYSTEM 8-1

8-1 General Maintenance Safety 8-1

8-2 Hydraulics Maintenance Safety and Precautions 8-1

8-3 Handling Hydraulic Fluid 8-2

8-4 Making Leak-Free Connections 8-2

8-4-1 Hose and Tubing Installation Practices 8-2

8-4-2 Operating Conditions 8-2

8-4-3 Maintenance Practices 8-3

8-5 Keeping the Hydraulic System Clean 8-4

8-6 Check Hydraulic Fluid Level 8-6

8-7 Change Hydraulic Fluid 8-8

8-8 Replace Suction Strainer 8-10

8-9 Clean Hydraulic Reservoir Strainer 8-13

8-10 Replace Air Breather 8-15

8-11 Replace High-Pressure Filter 8-17

Table of Contents Model XR842/1045/1245/1254/1267 Forklifts

Service Manual Rev 00 – (9/2/08) iv

Table of Contents – Cont

PARA TITLE PAGE

8-12 Replace Return Line Filter 8-20

8-13 Taking Hydraulic Fluid Sample 8-22

8-14 Replacing a Hose 8-25

8-15 Tightening Loose Fittings 8-28

8-16 Replace Cartridge Valve 8-28

8-17 Replace Cartridge Valve Solenoid 8-31

8-18 Location of Hydraulic Components 8-33

8-19 Distribution Manifold Hose Connections 8-33

8-20 Maintenance Requirements for Failed Pump 8-50

SECTION 9 – ELECTRICAL SYSTEM 9-1

9-1 General Maintenance Safety 9-1

9-2 Battery Safety 9-1

9-3 Battery Description 9-3

9-4 Battery Cable Description 9-3

9-5 Check Condition of Battery and Cables 9-3

9-6 Replace Battery 9-4

9-7 Inspect and Clean Battery 9-7

9-8 Install Auxiliary Battery 9-9

9-9 Electrical Center Assembly 9-11

9-10 Engine Relay Assembly 9-16

9-11 Replace a Relay 9-18

9-12 Replace a Fuse 9-20

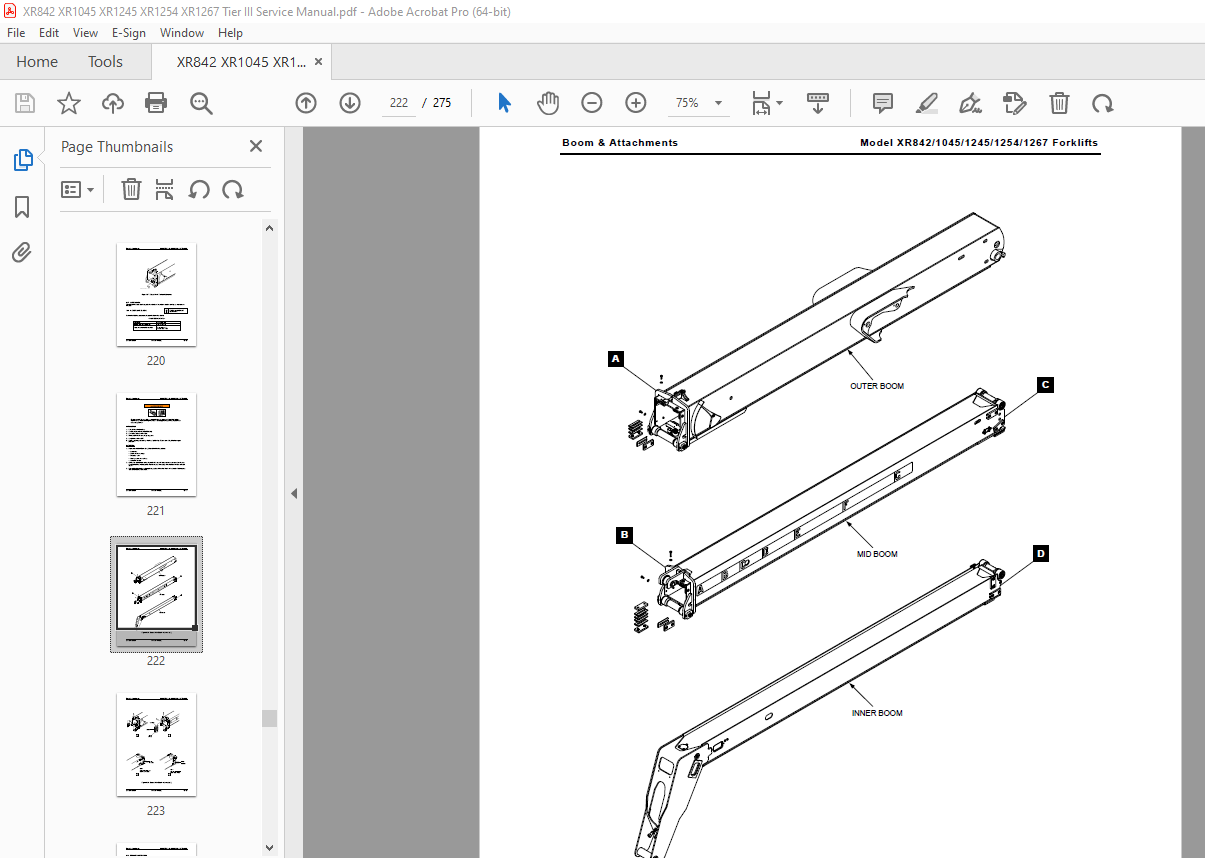

SECTION 10 – BOOM & ATTACHMENTS 10-1

10-1 General Maintenance Safety 10-1

10-2 Using a Grease Gun 10-1

10-3 Boom and Attachment Lubrication 10-2

10-4 Lubricate Boom Extend Chain 10-6

10-5 Inspect Boom Chains 10-7

10-5-1 Chain Nomenclature 10-8

10-5-2 Visually Inspect Chain 10-8

10-5-3 Measure Chain Edge Wear 10-11

10-5-4 Measure Chain Elongation 10-13

10-6 Check and Adjust Boom Chain Tension 10-15

10-7 Slide Blocks 10-16

10-8 Slide Block Inspection 10-16

Table of Contents Model XR842/1045/1245/1254/1267 Forklifts

Service Manual Rev 00 – (9/2/08) v

Table of Contents – Cont

PARA TITLE PAGE

10-9 Replace Slide Blocks 10-20

10-10 Inspect Boom Rollers 10-21

10-11 Fork Nomenclature 10-24

10-12 Measure Fork Flank Wear 10-26

10-13 Fork Inspection 10-28

10-14 Manually Retracting and Lowering Boom 10-29

SECTION 11 – CHECK-OUT PROCEDURES 11-1

11-1 Check Operation of Rear Axle Stabilization System 11-1

SECTION 12 – STORAGE & TRANSPORTATION 12-1

12-1 General Maintenance Safety 12-1

12-2 Preparing Engine for Long-Term Storage 12-1

12-3 Preparing Forklift for Long-Term Storage 12-4

12-4 Transporting Forklift 12-5

APPENDIX – MAINTENANCE FORMS AND SAFETY TAGS A-1

A-1 Preventive Maintenance and History Logs A-1

A-2 Pre-Operation Checklist A-1

A-3 Safety Tags A-1

Maintenance Schedule A-2

Maintenance History Log A-8

Fork Inspection Log A-11

Pre-Operation Checklist A-13

Grease Fittings List A-15

Danger Tags A-16

Condition Tags A-17

Notes A-18