$41.95

Yale (E876) (GDP 190DC, 210DC, 230DC, 230DCS, 250DC, 280DC) Service Manual PDF

Yale Forklift E876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift E876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1500

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift E876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

524150779 1400YRM0046 (08 2012) US EN 1

toc 1

Differential 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Differential Repair 5

Remove 5

Differential Carrier From Axle Housing, Remove 5

Differential and Ring Gear From Differential Carrier, Remove 9

Drive Pinion and Pinion Carrier From Differential Carrier, Remov 11

Disassemble 12

Differential and Ring Gear Assembly, Disassemble 12

Drive Pinion and Pinion Carrier, Disassemble 13

Clean and Inspect 16

Assemble 17

Pinion, Bearings, and Pinion Carrier, Assemble 17

Pinion Bearings, Adjust Preload 17

Press Method 17

Yoke or Flange Method 18

Triple-Lip Seal, Install 19

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion) 20

Differential and Ring Gear, Assemble 22

Differential Gears Rotating Torque, Check 24

Differential and Ring Gear Assembly, Install 25

Differential Bearings, Preload Adjust 26

Ring Gear, Runout Check 27

Ring Gear Backlash, Adjust 28

Gear Set, Tooth Contact Pattern Check 30

Thrust Screw, Install and Adjust 33

Install 33

Differential Assembly Into Axle Housing, Install 33

Specifications 34

Troubleshooting 38

tables 1

Table 1 Ring Gear Backlash Adjustment Specifications 29

Table 2 Ring and Pinion Tooth Contact Adjustment 30

Table 3 General Specifications 34

Table 4 Rivet Installation Pressure 34

Table 5 Pinion Adjustment 34

Table 6 Pinion Preload Pressure 35

Table 7 Torque Specifications 36

Table 8 Torque Specifications for Metric Hardware 37

Table 9 Torque Specifications for Metric (Fine) Hardware 37

524150780 1400YRM0944 (08 2012) US EN 41

toc 41

Planetary Drive Axle 41

Safety Precautions Maintenance and Repair 42

General 45

Description 45

Operation 47

Identification 47

Removal 48

Disassembly 48

Planetary Spider and Gearing Assembly GDP80-120DB (GP170-280DB) 49

Planetary Spider and Gearing Assembly GDP130-160EB (GP300-360EB) 50

Wheel End 52

Spindle and Piston Housing 53

Cleaning 54

Clean Ground or Polished Parts 54

Clean Parts With Rough Finish 54

Clean Axle Assemblies 54

Drying Cleaned Parts 54

Corrosion Prevention 54

Parts Inspection 55

Tapered Roller Bearings 55

Bevel Pinion and Ring Gear Sets 56

Main Differential Assembly 56

Axle Shafts 56

Yoke 56

Brakes 56

Repair or Replace Parts 56

Repair Welding 57

Apply Silicone Gasket Material 57

Assembly 57

Spindle and Piston Housing to Axle Housing 57

Wet Disc Brakes 58

Adjust Wheel Bearing Preload 59

Planetary Spider and Gearing Assembly GDP80-120DB (GP170-280DB) 60

Planetary Spider and Gearing Assembly GDP130-160EB (GP300-360EB) 60

Planetary Spider Assembly 61

Installation 62

Fill Wet Disc Brakes With Hydraulic Fluid 62

Torque Specifications 63

Lubrication Specification 64

524150781 1400YRM0945 (08 2011) US EN 67

toc 67

Planetary Drive Axle 67

Safety Precautions Maintenance and Repair 68

General 71

Description 71

Operation 73

Identification 73

Removal 74

Disassembly 75

Brake Drum 75

Planetary Spider and Gearing Assembly GDP/GLP80-120DB (GDP/GLP17 76

Dry Brakes 76

Planetary Spider and Gearing Assembly GDP/GLP130-160EB (GDP/GLP3 78

Spindle and Brake Spider 80

Cleaning 80

Ground or Polished Parts 80

Parts With Rough Finish 81

Axle Assemblies 81

Drying Cleaned Parts 81

Corrosion Prevention 81

Parts Inspection 81

Tapered Roller Bearings 81

Bevel Pinion and Ring Gear Sets 82

Main Differential Assembly 83

Axle Shafts 83

Yoke 83

Brakes 83

Repair or Replace Parts 83

Repair Welding 83

Apply Silicone Gasket Material 83

Assembly 84

Spindle, Brake Spider, and Brake 84

Wheel End 85

Adjust Wheel Bearing Preload 85

Planetary Spider and Gearing Assembly GDP/GLP80-120DB (GDP/GLP17 86

Planetary Spider and Gearing Assembly GDP/GLP130-160EB (GDP/GLP3 87

Planetary Spider Assembly 87

Installation 88

Torque Specifications 89

Lubrication Specification 90

524150797 8000YRM0231 (02 2023) US EN 93

General 99

Threaded Fasteners 99

Nomenclature, Threads 99

Strength Identification 100

Cotter (Split) Pins 101

Fastener Torque Tables 106

Conversion Table 108

524150797 8000YRM0231 (03 2020) US EN 115

General 119

Threaded Fasteners 119

Nomenclature, Threads 119

Strength Identification 120

Cotter (Split) Pins 121

Fastener Torque Tables 126

Conversion Table 128

524211827 0600YRM1101 (11 2018) US EN 135

Series Code / Model Designation Reference Table 139

General 139

Fault Codes 140

Normal Mode 140

Fault Log Mode 141

Access 141

Exit 141

Clear 141

Electronic Throttle Calibration 141

Electronic Throttle Calibration Procedure 142

Stationary Regeneration Procedure 142

524300813 0700YRM1350 (05 2012) US EN 171

toc 171

Cooling System 171

Safety Precautions Maintenance and Repair 172

General 175

Cooling System Description 175

Cooling Cores 175

Fan and Shroud 176

Engine Cooling System 176

Water Pump 177

Thermostat 177

Expansion Tank And Radiator Cap 178

Cab Heater 178

Coolant 178

Charge Air Cooling System 180

Transmission Oil Cooling System 180

Hydraulic Oil Cooling System 180

Hydraulic Oil Cooling, D876/D877 Trucks 181

Hydraulic Oil Cooling, E876/E877 Trucks 181

Brake Cooling 182

Oil Filtration and Oil Cooling 182

Hydraulic Control System 182

Service and Repair 183

Cooling System Checks 183

Basic Checks 183

Coolant Quality Checks 183

Coolant Flow Checks 184

Thermostat 184

Water Pump 185

Cooling Core Efficiency 185

Cooling Core Flow Restrictions 185

Engine Leak Tests 186

External Leak Test 186

Check for Coolant Leak Into The Engine Oil Sump 187

Combustion Leak Test 187

Engine Cooling System Maintenance 188

Draining the Engine Cooling System 188

Filling the Engine Cooling System 189

Flushing the Engine Cooling System 189

Cleaning the Engine Cooling System 190

Remove and Replace Procedures 190

Drive Belt 190

Remove 190

Install 190

Belt Tensioner 190

Inspect 190

Remove 190

Install 191

Water Pump 191

Inspect 191

Remove 191

Install 191

Thermostat 192

Remove 192

Inspect 192

Install 192

Cooling Core Assembly 192

Removal 192

Cooling Cores 195

Disassembly 195

Assembly 195

Install 195

tables 171

Table 1 Limiting Values 179

Table 2 Thermostat Operating Temperatures 184

Table 3 Temperature Differences Between Core Entry and Core Exi 185

524302733 1300YRM1356 (01 2016) US EN 201

Series Code / Model Designation Reference Table 205

General 205

Transmission Repair 205

Remove 205

Disassemble 209

Reverse and Second-Speed Clutch 239

Clean and Inspect 255

Housings 255

Oil Seals and Gaskets 256

Bearings 256

Gears and Shafts 256

Assemble 256

Reverse and Second-Speed Clutch 266

Install 307

Control Valve Removal and Installation 310

Remove 310

Install 310

Control Valve Components 311

Control Valve Disassemble and Assemble 311

Remove 311

Control Valve Cover 311

Control Valve Components 312

Install 312

Control Valve Components 312

Control Valve Cover 312

Transmission Frame Bracket 313

Torque Specifications 313

Torque Specifications for Lubricated or Plated Screw Threads 313

Troubleshooting 315

524304019 1300YRM1358 (01 2016) US EN 319

Series Code / Model Designation Reference Table 325

General 326

Description 326

General 326

Operation 329

Hydraulic Operation 329

1st/3rd Selector Valve 332

Cooling and Lubrication 334

Control System 335

General 336

APC200 Controller 336

Self Test 336

Protection Modes 336

Limp Home Mode 336

Shut Down Mode 336

Transmission Exceed Codes 337

Fault Codes 337

Description 337

Fault Log Mode 337

Access 337

Exit 338

Clear 338

Fault Rectification 338

Hydraulic Control Valve 340

Hydraulic Control Valve Repair 342

Solenoid Replacement 342

Pressure Check 342

Pressure Specifications 343

Pressure, Speed, and Temperature Sensors 343

Pressure Switch 348

Test 348

Speed Sensor 349

Test 349

Temperature Sensors 350

Test 350

Transmission Test and Calibration 351

Precautions 351

Stall Test 351

Description 351

Stall Test Procedure 351

Clutch Calibration 352

Description 352

Procedure 353

Inching Calibration 353

Description 353

Brake and Inching Pedal Adjustment 354

Inching Sensor Adjustment 354

Inching Sensor Calibration 355

Electrical Specifications 355

APC200 Display information 355

General 356

General Information Group 356

Fault Codes 357

Indication of Protection Modes 357

Test Function Group 358

Digital Input Test 360

Analog Input Test 361

Speed Sensor Test 362

Output Test 363

Voltage Test 364

Calibration Group 366

Calibration Mode 366

Clutch Filling Calibration 366

Heat Up Mode 367

Inching Sensor Calibration 367

Inching Pedal Sensor Adjustment 367

Inching Sensor Calibration 367

TE-Userlink 368

Description 368

Connection 368

368

Diagrams, Schematics, or Arrangements 368

550022606 1300YRM1435 (01 2016) US EN 405

Series Code / Model Designation Reference Table 409

General 409

Transmission Exceed Codes 409

Clutch Calibration Condition Messages 409

Fault Codes During Clutch Calibration 409

APC200 Fault Codes 410

Limp Home Mode 410

Shut Down Mode 410

Pressure Feedback Sensor 410

APC200 Fault Codes 411

Transmission Exceed Codes 411

Clutch Calibration Condition Messages 415

Fault Codes During Clutch Calibration 415

APC200 Fault Codes 418

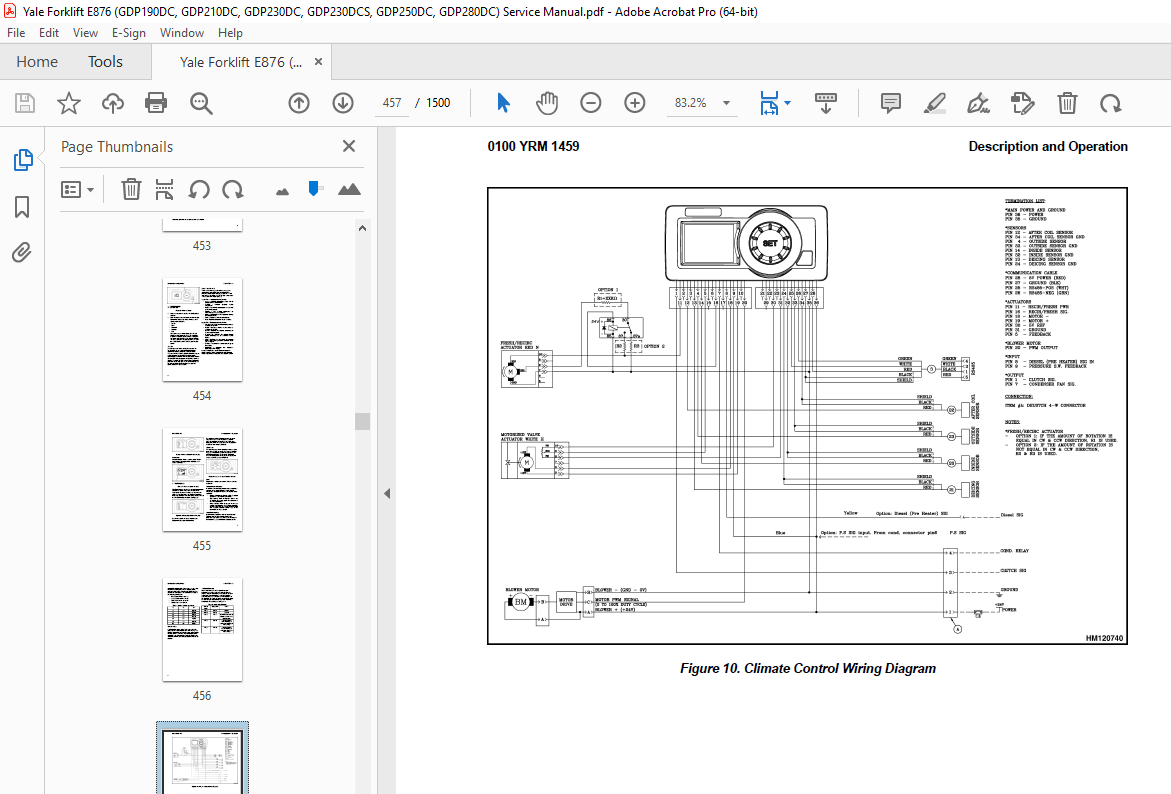

550033398 0100YRM1459 (12 2018) US EN 445

Series Code / Model Designation Reference Table 449

Description and Operation 449

Heater System 449

General 449

Air Conditioning 450

General 450

Dryer 451

Compressor Lubrication 452

Control Systems, Sensors, and Switches 452

Climate Control 453

Description 453

Service Menu 453

Set Up 454

View 1 and View 2 454

Error List 455

Statistics 455

Exit 455

Temperature Sensors 455

Troubleshooting 455

Water Valve 456

Troubleshooting 456

Remove and Replace 458

Standard Heater Assembly 459

Access 459

Remove 459

Install 460

Standard Heater Parts 461

Heater Core 461

Remove 461

Install 462

Blower 462

Remove 462

Install 463

Water Valve 464

Remove 464

Install 464

Push/Pull Cable 465

Water Valve Cable 465

Remove 465

Install 465

Heater/Air Conditioner Assembly 466

Remove 466

Install 467

Heater/Air Conditioner Parts 467

Vent Door 467

Remove 467

Install 468

Heater Core 468

Remove 468

Install 469

Evaporator Core 470

Remove 470

Install 471

Blower 472

Remove 472

Install 472

Thermostat 473

Remove 473

Install 474

Water Valve 474

Remove 474

Install 475

Air Conditioning Technical Detail 476

550033400 0100YRM1390 (12 2018) US EN 479

Series Code / Model Designation Reference Table 487

General 487

Description of Operation 489

Cab Structure 489

Cab Tilt System 489

Cab Tip-Up System 491

Tilting the Cab 492

Raising 492

Lowering 493

Remove and Install 494

Cab Door Assembly 494

Cab Door 494

Remove 494

Install 494

Door Hinge 495

Remove 495

Install 495

Door Latch 496

Remove 496

Install 496

Door Handle 496

Remove 496

Install 496

Door Release 497

Remove 497

Install 497

Door Push Button 497

Remove 497

Install 498

Cab Tilt System 498

Electric Tilt Pump 498

Remove 498

Install 498

Hand Tilt Pump 498

Remove 498

Install 499

Cab Tilt Cylinder 500

Remove 500

Disassemble 500

Clean 502

Inspect 502

Assemble 502

Install 503

Latch 503

Remove 503

Install 504

Brake and Inching Pedal 505

Remove 505

Install 505

Accelerator Pedal and Sensor 506

Remove 506

Install 506

Adjust Sensor 506

Seat Assembly 506

Seat 506

Remove 506

Install 507

Seat Cushion 507

Remove 507

Install 508

Back Cushion 508

Remove 508

Install 508

Seat Suspension Replacement 508

Boot Replacement 508

Power Assist Armrest 532

Release Cable 532

Remove 532

Install 532

Gas Spring 532

Remove 532

Install 533

Joystick 533

Remove 533

Install 533

Electrical Levers 533

Remove 533

Install 534

Armrest Rocker Switches 534

Remove 534

Install 534

Armrest Top Cover 534

Remove 534

Install 534

Instrument Panel 535

Key Switch 535

Remove 535

Install 535

12V Power Socket 535

Remove 535

Install 535

Electric-Operated Heat Control and Air Recirculation Control (Airco Only) 536

Remove 536

Install 536

Cable-Operated Heater Control (Heater Only) 537

Remove 537

Install 537

Air Conditioning Switch Replacement 537

Instrument Panel Rocker Switches Replacement 537

Parking Brake Switch 538

Remove 538

Install 538

Indicator Display Replacement 538

Instrument Panel Top Console 538

Remove 538

Install 539

Steering Wheel and Column Assembly 539

Steering Wheel and Horn 539

Remove 539

Install 541

Steering Column Assembly 541

Remove 541

Install 542

Adjustment Handle 542

Remove 542

Install 542

Main Warning Lights 543

Remove 543

Install 543

Shift Lever 543

Remove 543

Install 543

Turn Signal Lever 543

Remove 543

Install 543

Window Wipers 544

Window Wiper Assembly Replacement 544

Remove 544

Install 544

Window Wiper Motor Replacement 544

Front Window Wiper Motor 544

Install 544

Rear Window Wiper Motor Assembly 545

Remove 545

Install 545

Top Window Wiper Motor Assembly 545

Remove 545

Install 545

Window Washer System 546

Window Washer Reservoir and Pumps 546

Remove 546

Install 546

Window Washer Hoses 547

Hoses for Top and Rear Window 547

Install 548

Window Washer Spray Nozzles 548

Front Window 548

Remove 548

Install 548

Rear Window 549

Remove 549

Install 549

Top Window 549

Remove 549

Install 549

Window Replacement 549

Front Window 551

Remove 551

Install 551

Rear Window 551

Remove 551

Install 551

Top Window 552

Remove 552

Install 552

Door, Upper/Lower Window 553

Remove 553

Install 553

Sliding Window and Sliding Tracks 553

Remove 553

Install 555

Weather Strip Replacement 555

Window Stopper Replacement 555

Window Seal Replacement 556

Sliding Window Frame 556

Remove 556

Install 556

Floor Mat 556

Front Floor Mat 556

Remove 556

Install 557

Rear Floor Mat 557

Remove 557

Install 558

Radio Console 558

Remove 558

Install 558

Air Duct Replacement 559

Remove Front 559

Remove Rear 559

Install 560

Accessories 560

Mirror Replacement 560

Sunshade Replacement 560

Top 560

Rear 561

Map Light Replacement 561

Interior Fan Replacement 561

Training Seat 561

Field Installation 561

Remove 561

Label Replacement 562

Checks and Adjustments 562

Check Oil Level for Cab Tilt System 562

Door Striker Pin Adjustment 563

Brake Pedal Adjustment 563

Dry Brake 563

Wet Brake 564

Inching Pedal Adjustment 564

Inching Pedal Sensor Adjustment 564

Sensor Adjustment Using Dana Dashboard Software 564

Sensor Adjustment using the APC200 Display 565

Sensor Adjustment for Trucks with ZF Transmission 566

Inching Pedal Sensor Calibration 566

Sensor Calibration using Dana Dashboard Software 566

Sensor Calibration using APC200 Display 566

Sensor Calibration for Trucks with ZF Transmission 567

550035498 2200YRM1481 (08 2012) US EN 571

toc 571

Hydraulic Control System 571

Safety Precautions Maintenance and Repair 572

General 575

Description 575

Control Valve 575

Analog Inputs 576

Levers and Joysticks 576

Sensors 577

Temperature Sensor 577

Pressure Sensor 577

Digital Inputs 577

Switches 577

Interrupts 577

CAN Bus Communication 578

Output Signals 578

Analog Outputs 578

Digital Outputs 578

Programmed Features 578

Anti-Stall (Standard) 578

Temperature Protection (Standard) 578

Low Temperature Protection (Standard) 579

High Temperature Protection (Optional) 579

Dynamic Control (Optional) 579

Loaded Speed Reduction (Optional) 579

Settings 579

Adjustable Parameters 579

Truck Configuration Screen 579

Mode Definition Responsiveness (Smooth, Medium, and Rapid) 579

Set Default Flow Settings Screen 579

Features Screen 579

Loaded Speed Reduction Screen 579

Flow Settings Screen 580

General Functions of the Interface 580

Main Functional Requirements 580

What is Needed for the Hydraulic User Interface Program 580

Installation of the Program 580

Start Screen 583

Reminder Screen 584

Basic Screen Layout of the Hydraulic User Interface Program 585

Truck Configuration Screen 586

Mode Definition Screen 588

Default Flow Settings Screen 589

Load Moment Interrupt Screen 590

Features Screen 591

Dynamic Control Screen 592

Loaded Speed Reduction Screen 593

Temperature Protection Screen 594

Anti-Stall Screen 595

Calibration Screen 596

Calibrating the Connected Levers/Joystick Without the Interface 596

Calibrating the Connected Levers/Joystick With the Interface Sof 596

Profile Configuration Screen 597

Flow Settings Screen 598

Valve Settings Screen 599

Diagnostic Screen 600

Active Errors Screen 601

Error History Screen 602

All Parameters Screen 603

Installing the Hydraulic Controller Software and Read-Only Param 604

Calibration 607

Calibrating the Lever With the Hydraulic User Interface Program 607

Calibrating the Joystick With the Hydraulic User Interface Progr 607

Calibrating the Lever Without the Hydraulic User Interface Progr 607

Calibrating the Joystick Without the Hydraulic User Interface Pr 607

Fault Codes 608

Controller Pinning 618

tables 571

Table 1 Temperature and Maximum Engine Speed 579

Table 2 Hydraulic User Interface Program Overview 581

Table 3 Parameters 588

Table 4 Temperature/Rpm Table 594

Table 5 Fault Codes 608

Table 6 Fixed PT 618

Table 7 Alternating PT 620

Table 8 Empty Container Handler (ECH) 622

Table 9 XML Parameter File Content 623

550035500 0100YRM1496 (11 2015) US EN 629

General 633

Description 633

Air Cleaner 633

Remove 634

Install 634

Exhaust System 634

Remove 635

Install 635

Hood Assembly 635

Remove 636

Install 637

Hydraulic Tank 637

Remove 637

Inspect 640

Clean 640

Additional Preparations for Repair 640

Repair 641

Small Leaks 641

Large Leaks 641

Preparations for use After Repair 641

Install 641

Fuel Tank 643

Remove 643

Repair 647

Install 647

Cab 647

Raising and Lowering Cab 648

Raise Cab 648

Lower Cab 649

Cab Repair 649

Remove 649

Install 650

Oil Filling for Cab Tilt System 652

Engine 652

Remove 653

Install 660

Counterweight 661

General 662

Remove 662

Install 663

Label Replacement 663

550035502 1300YRM1455 (11 2018) US EN 667

Series Code / Model Designation Reference Table 671

General 671

Description 671

General 671

Clutch 676

Operation 676

Hydraulic Operation 676

Clutch Valve 677

Cooling and Lubrication 678

Control System 679

Transmission Control Unit (TCU) 680

Operating Modes 680

Normal Mode 680

Substitute Clutch Control 680

Limp-Home Mode 680

Transmission Shut Down Mode 680

TCU Shut Down Mode 680

Transmission Exceed Codes 680

Self-Test 681

Fault Codes 681

Description 681

Fault Log Mode 681

Access 681

Exit 682

Clear 682

Fault Log Memory 682

Fault Rectification 682

Hydraulic Control Valve 683

Hydraulic Control Valve Repair 684

Solenoid Replacement 684

Pressure Check 684

Pressure Specifications 685

Speed and Temperature Sensors 685

Speed Sensors 686

Test 687

Temperature Sensors 687

Shift Lever 687

PedalFoot Directional Control 687

ZF Transmission Test and Calibration 688

Transmission Test and Calibration 688

Precautions 688

Stall Test 688

Description 688

Stall Test Procedure 688

Inch Pedal Calibration 689

Description 689

Calibration 689

Brake and Inch Pedal Adjustment 689

Inch Sensor Adjustment 689

Inch Pedal Calibration 690

Preparation 690

Calibration Procedure Using the Calibration Switch 690

Calibration Procedure Using the Testman software 690

Inch Pedal Calibration Fault Codes 690

Clutch Calibration 691

Description 691

Clutch Calibration Procedure 692

Manual Clutch Calibration Procedure 692

Testman Clutch Calibration Procedure 693

Testman 693

Description 693

Connection 694

Truck Configuration 694

Configuration 694

Limitations 694

Capacities and Specifications 695

Electrical Specifications 695

Transmission Control Unit Diagram 695

ZF Transmission Fault Codes 697

Transmission Exceed Codes 697

Testman Fault Codes 698

550035503 1300YRM1456 (12 2015) US EN 709

Series Code / Model Designation Reference Table 713

Special Tools List 714

Transmission Repair 715

Remove 715

Disassemble 719

Clean and Inspect 758

Housings 759

Oil Seals and Gaskets 759

Bearings 759

Gears and Shafts 759

Assemble 760

Transmission Oil Filter Assembly Replacement 807

Clean 808

Inspect 808

Install 809

Control Valve Replacement 814

Remove 814

Install 815

Control Valve Repair 816

Disassemble 816

Clean 820

Inspect 820

Assemble 821

550035504 1600YRM1479 (01 2022) US EN 829

General 835

Basic Principles of Flow Control Systems 835

Basic Principles of Flow Control Systems 835

Orifice (Fixed/Variable) 835

Basic Principle 835

Pressure Compensated Flow Control Valve 836

Basic Principle 836

Pressure Compensated Flow Control Valve Functional Description 836

Priority Valve 837

Basic Principle 837

Priority Valve Functional Description 837

Load Sense (LS) 838

Basic Principle 839

Load Sense Functional Description 839

Example 1 839

Example 2 839

Basic Principles of Pressure Control Systems 840

Basic Principles of Pressure Control Systems 840

Direct Acting Relief Valves 840

Basic Principle 840

Direct Acting Relief Valve Functional Description 840

Two-Stage Relief Valve (Pilot Operated Relief Valve) 841

Basic Principle 841

Two-Stage Relief Valve (Pilot Operated Relief Valve) Functional Description 841

Unloading Valve (Accumulator Charging Valve) 842

Basic Principle 842

Unloading Valve (Accumulator Charging Valve) Functional Description 842

Counterbalance Valve 844

Basic Principle 844

Counterbalance Valve Functional Description 844

Pressure Reducer Valve 844

Basic Principle 844

Pressure Reducer Valve Functional Description 845

Steering System Main Component Identification 846

Description and Operation 850

Steering System 850

Introduction 850

Description 850

Hydraulic Oil Flow Path 850

Priority Valve 850

Fundamentals 850

Description 850

Operation 850

Component Validation for Correct Operation 851

Steering Control Unit 851

Description 851

Steering Control Valve 851

Fundamentals 851

Operation 851

Component Validation for Correct Operation 851

Hand Pump 851

Fundamentals 851

Operation 852

Component Validation for Correct Operation 852

LS Relief Valve 852

Fundamental 852

Operation 852

Component Validation for Correct Operation 852

Shock Valve 852

Fundamental 852

Operation 852

Component Validation for Correct Operation 852

Steering Axle 852

Remove and Replace 854

Steering Control Unit 854

Remove 854

Install 855

Steer Axle (E876/E877) (F876 F877) 855

Remove 855

Install 856

Tie Rod (E876/E877) (F876 F877) 858

Remove 858

Clean and Inspect 858

Install 858

Steering Cylinder (E876/E877) (F876 F877) 858

Remove 858

Clean and Inspect 860

Assemble and Install 861

Hubs (E876/E877) (F876 F877) 861

Remove and Disassemble 861

Clean and Inspect 861

Assemble and Install 862

Spindle (E876/E877) (F876 F877) 862

Remove 862

Clean 863

Assemble and Install 863

Hydraulic Troubleshooting Flowcharts 864

Hydraulic Pressure Checks Preparation 864

Steering Relief Pressure Check 864

Pressure Check, Port MLS1 and MLS2 on the Main Control Valve 865

Steering Wheel Lock to Lock Check 865

Flowchart 866

Hydraulic Pressure Checks for Troubleshooting Flowcharts 867

Hydraulic Pressure Checks Preparation 867

Condition Check, Shuttle Valve L and M in the Main Control Valve 867

Condition Check, Logic Element N in the Main Control Valve 868

Condition Check, Priority Valve on the Main Control Valve 868

Steering Cylinder 869

Remove and Disassemble 869

Clean and Inspect 870

Assemble and Install 870

Steering Axle Assembly 873

Steer Axle 873

Remove 873

Install 873

Wheels and Hubs 875

Remove and Disassemble 875

Clean 876

Inspect 876

Assemble and Install 876

Spindles and Bearings 876

Remove 876

Clean 877

Assemble and Install 877

Tie Rods 877

Remove 877

Clean 878

Install 878

Torque Specifications 880

550035505 1800YRM1498 (03 2013) US EN 883

toc 883

Brake and Hydraulic Cooling System 883

Safety Precautions Maintenance and Repair 884

General 891

Basic Principles of Flow Control Systems 891

Basic Principles of Flow Control Systems 891

Orifice (Fixed/Variable) 892

Basic Principle 892

Pressure Compensated Flow Control Valve 892

Basic Principle 892

Pressure Compensated Flow Control Valve Functional Description 892

Priority Valve 893

Basic Principle 893

Priority Valve Functional Description 893

Load Sense (LS) 894

Basic Principle 894

Load Sense Functional Description 894

Example 1 895

Example 2 895

Basic Principles of Pressure Control Systems 895

Basic Principles of Pressure Control Systems 895

Direct Acting Relief Valves 896

Basic Principle 896

Direct Acting Relief Valve Functional Description 896

Two-Stage Relief Valve (Pilot-Operated Relief Valve) 897

Basic Principle 897

Two-Stage Relief Valve (Pilot Operated Relief Valve) Functional 897

Unloading Valve (Accumulator Charging Valve) 898

Basic Principle 898

Unloading Valve (Accumulator Charging Valve) Functional Descript 898

Counterbalance Valve 899

Basic Principle 899

Counterbalance Valve Functional Description 899

Pressure Reducer Valve 900

Basic Principle 900

Pressure Reducer Valve Functional Description 900

Brake System Main Component Identification 900

Description 906

Brake Pressure System 906

Main System 906

Introduction 906

Service Brakes 906

Park Brake 906

Description 906

Hydraulic Oil Flow Path 906

Brake Accumulator Charging System 906

Service Brake System 907

Park Brake System 907

Priority Valve 907

Fundamentals 907

Description 907

Operation 907

Component Validation for Correct Operation 907

Brake Control Manifold 907

Description 907

Orifice (F) 908

Fundamentals 908

Description 908

Operation 908

Component Validation for Correct Operation 909

Unloading Valve 909

Fundamentals 909

Operation 909

Component Validation for Correct Operation 909

Screen 909

Description 909

Component Validation for Correct Operation 909

Check Valve 909

Description 909

Component Validation for Correct Operation 909

Pressure Reducer Valve 909

Fundamentals 909

Operation 909

Component Validation for Correct Operation 909

Park Brake Selector Valve 909

Fundamentals 909

Operation 909

Component Validation for Correct Operation 909

Brake Accumulator 910

Fundamentals 910

Operation 910

Component Validation for Correct Operation 910

Brake Treadle Valve 910

Fundamentals 910

Description 910

Operation 910

Wet Disc Brake Cooling System 910

Main System 910

Introduction 910

Description 910

Hydraulic Oil Flow Path 910

Gear Pump 911

Fundamentals 911

Operation 911

Brake Cooling Valve 911

Description 911

Operation 911

Thermostatic Bypass Valve 911

Fundamental 911

Operation 911

Component Validation for Correct Operation 911

Brake Flow Distribution Manifold 911

Fundamentals 911

Operation 911

Component Validation for Correct Operation 912

Hydraulic Oil Cooler Core 912

Fundamentals 912

Operation 912

Brake Return Line Filter ( E876 & E877 Only) 913

Operation 913

Cooling System Air Brakes 913

Main System 913

Description 913

Hydraulic Oil Flow Path 913

Component Explanation 913

Brake Treadle Valve Repair 914

Remove 914

Install 914

Accumulator 915

Remove 915

Disassemble 916

Clean 917

Inspect 917

Repair 918

Assemble 918

Install 918

Pre-Charge Filling 919

Parking Brake 920

Parking Brake Caliper 920

Remove 920

Disassemble 921

Clean and Inspect 921

Assemble 923

Install 923

Parking Brake Caliper Pads 923

Remove 923

Install 924

Parking Brake Bleed 924

Parking Brake Emergency Release 925

Brake Flow Distribution Manifold 925

Remove 925

Pressure Relief Valve 927

Disassemble 927

Clean and Inspect 927

Assemble 927

Install 927

Brake Control Manifold 928

Remove 928

Orifices F and G 929

Disassemble 929

Assemble 929

Orifice H 929

Disassemble 929

Assemble 929

Unloading Valve (B) 929

Disassemble 929

Assemble 929

Screen 929

Disassemble 929

Assemble 929

Check Valve (E) 930

Disassemble 930

Assemble 930

Pressure Reducer Valve (C) 930

Disassemble 930

Assemble 930

Park Brake Selector Valve (A) 931

Disassemble 931

Assemble 931

Install 931

Brake Cooling Valve 932

Remove 932

Install 932

Filter Restriction Indicator (Optional) 933

Remove 933

Install 933

Filter 934

Remove 934

Install 934

Brake Return Line Filter ( E876 & E877 Only) 935

Brake Return Line Filter Assembly 935

Remove 935

Install 936

Filter 936

Remove 936

Install 936

Gear Pump 936

Remove 936

Disassemble 936

Clean 938

Inspect 938

Assemble 939

Install 939

Hydraulic Troubleshooting Flowcharts 940

Mechanical Troubleshooting 944

Checks and Adjustments 946

Hydraulic Pressure Checks Preparation 946

Park Brake Selector Valve Check 946

Park Brake Selector Valve Coil Check 946

Accumulator Pre-Charge Check 946

Parking Brake Adjustment 947

Condition Check, Shuttle Valve L in the Main Control Valve 948

Condition Check, Shuttle Valve N in the Main Control Valve 948

Condition Check, Priority Valve on the Main Control Valve 948

Pressure Check, Port MLS1 949

Torque Specifications 949

Hydraulic Hose Torque Specifications 949

tables 883

Table 1 Definition of Terms 891

Table 2 Definition of Terms 895

Table 3 Internal Components of the Brake Control Manifold 908

Table 4 Internal Components of the Brake Cooling Valve 912

Table 5 Low Brake Pressure Warning Is Intermittent or Constantl 941

Table 6 Service Brake Is Soft or Spongy 942

Table 7 Hydraulic Oil is Overheating 943

Table 8 Parking Brake Will Not Disengage With the Parking Brake 943

Table 9 Lining-to-Disc Clearance 948

550035506 1900YRM1478 (11 2018) US EN 953

Series Code / Model Designation Reference Table 961

Fundamentals 961

Basic Principles of Flow Control Systems 961

Orifice (Fixed/Variable) 961

Basic Principle 961

Pressure Compensated Flow Control Valve 962

Basic Principle 962

Pressure Compensated Flow Control Valve Functional Description 963

Priority Valve 963

Basic Principle 963

Priority Valve Functional Description 963

Load Sense (LS) 964

Basic Principle 964

Load Sense Functional Description 965

Example 1 965

Example 2 965

Basic Principles of Pressure Control Systems 965

Direct Acting Relief Valves 966

Basic Principle 966

Direct Acting Relief Valve Functional Description 966

Two-Stage Relief Valve (Pilot-Operated Relief Valve) 966

Basic Principle 966

Two-Stage Relief Valve (Pilot-Operated Relief Valve) Functional Description 967

Pilot-Operated Selector Valves 967

Fundamentals 967

Function Description 968

Pump Pressure Free Flow Side 968

Function Pressure Blocked Flow Side 968

Unloading Valve (Accumulator Charging Valve) 969

Basic Principle 969

Unloading Valve (Accumulator Charging Valve) Functional Description 969

Counterbalance Valve 970

Basic Principle 970

Counterbalance Valve Functional Description 970

Pressure Reducer Valve 971

Basic Principle 971

Pressure Reducer Valve Functional Description 971

Description and Operation 971

Component Location and Identification 972

Main Control Valve 978

Introduction 978

Flow Path 978

Main Manifold 978

Introduction 978

Priority Valve (A) 978

Fundamentals 978

Description 979

Operation 979

Component Functionality Test 979

Check Valve (I) 979

Function Description 979

Function Operation 979

Component Functionality Test 979

Pilot Supply Circuit 979

Function Description 979

Pilot Supply Valve (F) 979

Fundamentals 979

Function Description 979

Function Operation 979

Component Functionality Test 979

Lift Pressure Selector Valve (B) 980

Function Description 980

Function Operation 980

Component Functionality Test 980

Check Valve (K) 980

Function Description 980

Component Functionality Test 980

Check Valve (Q) 980

Function Description 980

Component Functionality Test 980

Screen (O) 980

Function Description 980

Component Functionality Test 980

Relief Valve 980

Function Description 980

Load Sense Relief Valve (H) 980

Fundamentals 980

Functional Operation 980

Component Functionality Test 980

Pressure Controller on Pump 981

Fundamentals 981

Functional Operation 981

Component Functionality Test 981

Full Flow Relief Valve (C) and (G) 981

Fundamentals 981

Functional Operation 981

Component Functionality Test 981

Shuttle Valve (L) and (M) 981

Function Description 981

Component Functionality Test 981

Logic Valve (N) 982

Function Description 982

Function Operation 982

Load Sense Selector Valve (D) 982

Function Description 982

Component Functionality Test 982

Directional Control Valve Section 982

Functional Operation (System Level) 982

Directional Control Valve 983

Fundamentals 983

Description 983

Functional Operation 983

Electrical Actuation Module (Solenoid End Cap) 983

Functional Operation 983

Component Functionality Test 984

Lift Function 984

Function Description 984

Pilot-Operated Check Valve 984

Fundamentals 984

Function Description 985

Function Operation 985

Emergency Lowering Valve (LH Lift Section ONLY) 985

Function Description 985

Lowering Control Valve 985

Fundamentals 985

Function Description 985

Tilt Function 985

Function Description 985

Impact Relief Valve 986

Fundamentals 986

Function Description 986

Counterbalance Valve 986

Fundamentals 986

Function Description 986

Auxiliary Function 986

Function Description 986

Carriage Valve Bank 986

Introduction 986

Functional Operation 987

Inlet Module 987

Directional Control Valve Section 987

Directional Control Valve 987

Electrical Actuation Module (Solenoid End Cap) 988

Variable Displacement Pump 988

Function Description 988

Basic Functional Operation 989

Pressure Control Valve 989

Fundamentals 989

Operation 989

Load Sense Pressure Regulator 989

Fundamentals 989

Functional Operation 989

Repair 990

Main Control Valve 990

Remove 990

Clean 995

Inspect 995

Assemble 995

Install 995

Priority Valve (A) 998

Remove 998

Clean 998

Inspect 999

Component Functionality Test 999

Install 999

Check Valve (K) 999

Remove 999

Clean 999

Inspect 999

Component Functionality Test 999

Install 999

Check Valve (I) 999

Remove 999

Clean 999

Inspect 1000

Component Functionality Test 1000

Install 1000

Check Valve (Q) 1000

Remove 1000

Clean 1000

Inspect 1000

Component Functionality Test 1000

Install 1000

Screen Cartridge (O) 1000

Disassemble 1000

Component Functionality Test 1000

Assemble 1000

Shuttle Valves (L) and (M) 1001

Remove 1001

Clean 1001

Inspect 1001

Component Functionality Test 1001

Install 1001

Logic Valve (N) 1002

Remove 1002

Clean 1002

Inspect 1002

Component Functionality Test 1002

Install 1002

Full Flow Relief Valve ©) (Relief Spool) 1002

Remove 1002

Clean 1002

Inspect 1003

Assemble 1003

Install 1003

Pilot Supply Valve (F) 1003

Remove 1003

Clean 1003

Inspect 1003

Assemble 1003

Component Functionality Test 1003

Install 1003

Load Sense (LS) Relief Valve (H) and Full Flow Relief Valve (G) 1003

Remove 1003

Clean 1003

Inspect 1004

Component Functionality Test 1004

Install 1004

Load Sense Relief Valve (H) Adjustment 1004

Full Flow Relief Valve (G) Adjustment 1004

Load Sense Selector Valve (D) 1004

Remove 1004

Clean 1004

Inspect 1005

Assemble 1005

Install 1005

Lift Pressure Selector Valve (B) 1005

Remove 1005

Clean 1005

Inspect 1006

Assemble 1006

Install 1006

Variable Displacement Pump (Primary and Secondary) 1006

Remove 1006

Clean 1008

Inspect 1008

Assemble 1008

Install 1009

Tilt Cylinder 1010

Remove 1010

Disassemble 1010

Clean 1010

Assemble 1010

Install 1011

Tilt Cylinder Leak Check 1011

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 1012

Counterbalance Valves 1012

Remove 1012

Clean 1013

Inspect 1013

Assemble 1013

Install 1013

Carriage Valve Bank 1013

Remove 1013

Clean 1016

Inspect 1017

Assemble 1017

Install 1017

Electrical Actuation Module 1017

Remove 1017

Clean 1017

Inspect 1017

Assemble 1017

Install 1018

Emergency Lowering Valve (Left Slice Only) 1018

Remove 1018

Clean 1019

Inspect 1019

Install 1019

Load Sense and Pressure Controller Valve on Pump 1019

Remove 1019

Clean 1019

Inspect 1019

Assemble 1020

Install 1020

Adjustment of Pressure Controller on Pump 1020

Adjustment of Load Sense Controller on the Secondary Variable Pump 1021

Adjustment of Load Sense Controller on the Primary Variable Pump 1022

Lowering Control Valve 1023

Remove 1023

Clean 1024

Inspect 1024

Install 1024

Directional Control Valve 1024

Remove 1024

Clean 1024

Inspect 1024

Assemble 1025

Install 1025

Manual End Cap 1025

Remove 1026

Clean 1026

Inspect 1026

Assemble 1026

Install 1026

Troubleshooting 1026

Lift, Tilt, and/or Aux function does not move when applied Steering is operating normal 1026

The truck is not

capable to lift

rated load at expected

max lift

speed 1027

Tilt function

shakes 1027

It is not

possible to

lower the

mast with

ignition key

turned to

ON 1028

Steer and

brake accumulator

charge

function

does not operate 1028

The truck is

hydraulically

loaded

during engine

start

Accumulator

charge

and steering

is possible

during

XMSN calibration 1028

Torque Specifications 1028

Torque Specifications 1028

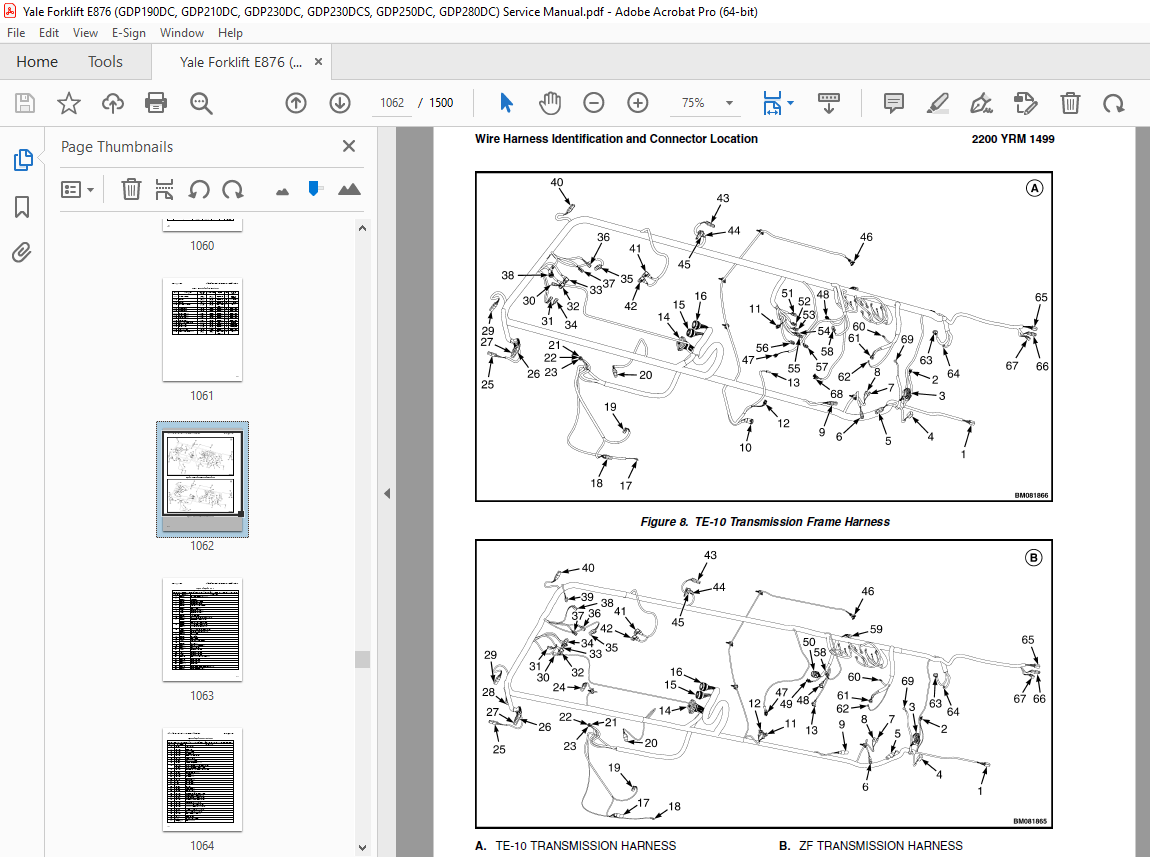

550035507 2200YRM1499 (04 2011) US EN 1031

toc 1031

Electrical System 1031

Safety Precautions Maintenance and Repair 1032

General 1035

Electrical Schematic and System Description 1035

Electrical Schematic 1035

Schematic Location Number 1037

Electrical Components 1037

Electrical Wires 1037

Wire Identification Number 1037

Electrical Wire Colors 1038

Wire Harnesses 1038

Harness Interconnection 1039

Electrical Connectors 1039

Connector Types 1039

Connector Identification 1039

Connector Pin Numbers 1040

Connector Description 1040

Fuses 1040

Relays 1043

Flyback Diodes 1044

CAN (Controller Area Network) 1044

Diagnostic 1045

Troubleshooting 1045

Instrument Panel 1045

General Fault Finding 1048

Preparation 1048

Define the Problem Area 1048

Identify Possible Causes of Malfunction 1048

Determine the Most Probable Cause 1048

Fuse Check 1048

Wiring Check 1048

Component Check 1048

Repair and Test 1048

Wire Harness Identification and Connector Location 1049

tables 1031

Table 1 Electrical Schematic Index 1035

Table 2 Function ID Numbers 1037

Table 3 Electrical Wire Colors 1038

Table 4 Harnesses by Option 1038

Table 5 Connector Types 1039

Table 6 Flyback Diodes ZF and TE-10 Transmissions 1044

Table 7 Connector Overview 1049

550035508 8000YRM1500 (06 2011) US EN 1079

550035509 8000YRM1475 (07 2019) US EN 1147

General 1153

Serial Number Data 1153

Truck Handling Procedures 1154

Moving and Towing a Lift Truck 1154

Precautions 1154

Moving the Truck 1154

Putting a Lift Truck on Blocks 1155

Raising the Drive Tires 1155

Raising the Steering Tires 1155

Cleaning a Lift Truck 1156

Safety Procedures Before Starting Maintenance 1157

Making Checks From the Driver Seat with Engine Running 1157

Fire Hazard 1157

Hydraulic Service Switch 1158

Transmission Calibration Switch 1158

Wait 100 Seconds Before Disconnecting Battery 1158

Periodic Maintenance Schedule 1158

Daily Inspection 1159

Daily Condition Checks 1159

Daily Fluid Level Checks 1160

Daily Checks from the Driver Seat with Engine Running 1161

Initial Inspection 1162

First Inspection after First 100 Hours of Operation 1162

Periodic Maintenance 1162

Inspect and Adjust 1162

Lubricate 1166

Change 1167

Periodic Maintenance Procedures 1168

Air Conditioning System 1168

Attachment 1168

Brake System Accumulator 1168

Cab Air Filter 1169

Cab Door Hinges 1169

Chain Sheave Bearings 1169

Control Levers, Switches, and Pedals 1169

Cooling System 1170

Coolant Hoses 1170

Coolant Level 1170

Coolant Quality 1170

Cooling Fan 1170

Cooling Fan Drive Belts 1171

Cooling Fan Drive Belt Tensioner and Pulleys 1171

Bearing Condition 1171

Pulley Alignment 1171

Tensioner Condition 1171

Drive Axle and Differential 1172

Check Oil level 1172

Change Oil 1173

Drive Shaft 1173

End Beam Slider Pads 1173

Engine Air Filter 1173

Engine Air Intake Piping and Charge Air Piping 1174

Engine and Transmission Mounts 1174

Engine Compartment 1174

Engine Oil 1174

Engine Oil Level 1174

Engine Oil and Engine Oil Filter 1175

Engine Valve Adjustment 1175

Extension Beam Wear Pads 1178

Fault Codes 1179

Forks 1179

Fork Pins, Carriage Pins, and Carriage Sliding Surfaces 1180

Frame, Mast, Carriage and Attachment 1180

Fuel, Oil or Coolant Leaks 1181

Fuel/Water Separator and Final Fuel Filter 1181

Header Hose Assembly 1181

Horn, Gauges, Lights, Alarms and Control System 1182

Hydraulic System Oil 1182

Hydraulic Oil Testing Procedures 1183

Hydraulic Oil Replacement 1183

Hydraulic Tank Breather 1184

Hydraulic Tank Return Filter 1184

Inching Pedal Sensor Calibration 1185

Lift Chains 1185

Check and Lubricate Lift Chains 1185

Adjust Lift Chains 1185

Inspect Lift Chains 1186

Chain Elongation 1186

Lift Chain Wear and Damage 1187

Lift System Accumulator (Optional) 1187

Mast, Carriage, and Attachment 1188

Mast Pivot Pins 1188

Operator Presence System 1188

Operator Restraint System 1188

Seat Belt and Seat Rails 1188

Steering Column Latch 1189

Parking and Service Brakes 1189

Powered Pile Slope Cylinders (Optional) 1190

Radiator Assembly 1190

Side Shift Bearing Pads (ECH) 1190

Signals from the Spreader Control System 1190

Steering Axle Grease Fittings 1190

King Pins 1190

Tie Rod Pins 1190

Steering System 1191

Steering Wheel Hub Bearings 1191

Remove and Disassemble 1191

Clean and Inspect 1191

Assemble and Install 1191

Tilt Cylinder Pivot Pins 1192

Transmission 1192

Transmission Clutch Calibration 1192

Transmission Oil Level 1192

Transmission Oil and Oil Filter For TE-10 Transmissions 1193

Transmission Oil and Oil Filter For ZF Transmissions 1193

Twist locks 1194

Inspect 1194

Lubricate 1195

Replace 1195

Vibration Damper (Rubber) 1195

Warning and Safety Labels 1196

Windows and Mirrors 1196

Windshield Washer Fluid Level 1196

Wheels and Tires 1196

Wheels, Tires, and Tire Pressure 1196

Remove Wheels from Lift Truck 1197

Adding Air Pressure to Pneumatic Tires 1203

Install Wheels on Lift Truck 1207

Capacities and Specifications 1209

Approved Fuel and Engine Oils 1209

Approved Oils, Fluids, and Grease 1209

Engine Oil Viscosity 1210

Lift Chain Lubricant Requirements 1210

Fuses and Relays 1210

Side Console 1211

550035510 8000YRM1501 (07 2013) US EN 1215

toc 1215

Capacities and Specifications 1215

Safety Precautions Maintenance and Repair 1216

Counterweight Weights 1219

Lift Truck Weights 1219

Capacities 1220

Engine Specifications 1220

Hydraulic System 1221

Electrical System 1221

Tire Sizes 1222

Mast Speeds 1222

Torque Specifications, Cummins Diesel 1223

Lubrication System 1223

Torque Specifications, General 1223

Transmission TE-10 1223

Transmission ZF 1224

Driveline and Axle 1224

Counterweight 1224

Differential 1224

Brakes – Wet 1224

Brakes – Dry 1224

Steering 1224

Wheel Nuts 1225

Hydraulic System 1225

Mast 1225

Carriage 1225

Tilt Cylinders 1226

Wiper Arms, Front 1226

tables 1215

Table 1 Counterweight Weights 1219

Table 2 Basic Truck 1219

550036815 1800YRM1477 (05 2012) US EN 1229

toc 1229

Dry Brake System 1229

Safety Precautions Maintenance and Repair 1230

General 1235

Air Brake System Description 1235

Air Compressor 1235

Air Dryer Assembly 1235

Air Pressure Regulation 1235

Discharging the Air Compressor 1235

Filtration of Air Admitted to the System 1236

Reduction of Air Humidity 1236

Silencer 1238

Heater Element 1238

Air Tank 1238

Drum Brakes 1238

Air Chamber 1238

Parking Brake Piston 1238

Service Brake Piston 1239

Manual Brake Release 1240

Parking Brake Valve 1240

Brake Treadle Valve 1240

Quick Release Valve 1241

Double Check Valve 1241

Operational Procedures 1242

Tilting the Operator’s Cab 1242

Manual Brake Release Procedure 1242

Releasing Air Pressure From the Brake System 1242

Checking For Leaks 1242

Air Hose Seal Replacement 1242

Air Pressure Checks 1242

Cleaning 1243

Corrosion Protection 1243

Air Tank Replacement 1244

Removal 1244

Installation 1244

Drain Valve 1245

Air Dryer Assembly 1245

Removal 1245

Installation 1245

Purge Valve Silencer 1245

Removal 1245

Installation 1245

Air Dryer Filter Element 1247

Removal 1247

Installation 1247

Regeneration Valve Assembly 1247

Removal 1247

Installation 1247

Purge Valve 1247

Removal 1247

Installation 1247

Outlet Check Valve Assembly 1247

Removal 1247

Installation 1247

Electrical Heating Element 1247

Removal 1247

Installation 1249

Double Check Valve Assembly 1249

Removal 1249

Installation 1249

Brake Treadle Valve 1250

Remove 1250

Disassembly 1250

Assembly 1251

Install 1251

Air Chambers 1252

Remove 1252

Disassembly 1252

Assembly 1253

Install 1254

Actuator Arm 1254

Removal 1254

Inspection 1254

Installation 1254

Brake Assembly 1255

Brake Drum Remove 1255

Brake Shoes, D876 and E876 Series 1256

Disassemble 1256

Brake Shoes, D877 and E877 Series 1257

Disassemble 1257

Inspection 1259

General 1259

Brake Shoes 1259

Spider Bushings 1259

Brake Drum 1259

Camshaft Bushings 1259

Brake Shoe, Install, D876 and E876 Series 1260

Brake Shoe, Install, D877 and E877 Series 1260

Brake Drum Install 1261

Camshaft 1262

Access 1262

Remove 1262

Cleaning and Inspection 1262

Install 1262

Brake Shoe Adjustment 1264

Piston Rod Travel Measurement 1264

Brake Adjustment 1264

Specifications 1265

Troubleshooting 1266

Service Brakes 1266

Service Brakes, Park Function 1268

550041025 1300YRM1536 (08 2011) US EN 1271

toc 1271

Transmission Repair 1271

Safety Precautions Maintenance and Repair 1272

General 1275

Transmission Repair 1275

Remove 1275

Disassemble 1279

Transmission Case, Disassemble 1280

Torque Converter Housing, Disassemble 1295

Forward Clutch, Disassemble 1300

First-Speed Clutch, Disassemble 1304

Reverse and Second-Speed Clutch 1309

Reverse Clutch, Disassemble 1309

Second-Speed Clutch, Disassemble 1313

Third-Speed Clutch, Disassemble 1316

Third Clutch Shaft, Disassemble 1318

Turbine Shaft, Disassemble 1319

Output Shaft, Disassemble 1320

Turbine, Disassemble 1321

Clean and Inspect 1323

Housings 1323

Oil Seals and Gaskets 1323

Bearings 1324

Gears and Shafts 1324

Assemble 1324

Turbine, Assemble 1324

Impeller, Assemble 1326

Output Shaft, Assemble 1328

Turbine Shaft, Assemble 1330

Third Clutch Shaft, Assemble 1331

Third-Speed Clutch, Assemble 1332

Reverse and Second-Speed Clutch 1335

Second-Speed Clutch, Assemble 1335

Reverse Clutch, Assemble 1338

First-Speed Clutch, Assemble 1342

Forward Clutch, Assemble 1347

Torque Converter Housing, Assemble 1351

Transmission Case, Assemble 1356

Install 1373

Control Valve Removal and Installation 1375

Remove 1375

Install 1376

Control Valve Components 1376

550041030 1300YRM1537 (03 2012) US EN 1381

toc 1381

Transmission Operation and Diagnostics 1381

Safety Precautions Maintenance and Repair 1382

Description 1385

General 1385

Operation 1387

Hydraulic Operation 1387

Clutch Release 1389

Anti-Drain 1389

Cooling and Lubrication 1390

Control System 1392

General 1392

APC200 Controller 1392

Self Test 1392

Protection Modes 1392

Limp Home Mode 1392

Shut Down Mode 1392

Transmission Exceed Codes 1392

Fault Codes 1392

Description 1392

Fault Log Mode 1393

Access 1393

Exit 1393

Clear 1394

Fault Rectification 1394

Hydraulic Control Valve 1394

Pressure Check 1395

Pressure Specifications 1396

Pressure, Speed, and Temperature Sensors 1396

Pressure Sensors 1399

Test 1399

Speed Sensor 1399

Test 1399

Temperature Sensors 1400

Test 1400

Electrical Specifications 1401

Transmission Test and Calibration 1401

Precautions 1401

Stall Test 1402

Description 1402

Stall Test Procedure 1402

Clutch Calibration 1402

Description 1402

Procedure 1403

Inching Calibration 1403

Description 1403

Brake and Inching Pedal Adjustment 1404

Inching Sensor Adjustment 1404

Inching Sensor Calibration 1405

APC200 Display information 1405

General 1405

General Information Group 1405

Fault Codes 1407

Indication of Protection Modes 1407

Test Function Group 1407

Digital Input Test 1408

Analog Input Test 1409

Speed Sensor Test 1410

Output Test 1411

Voltage Test 1411

Calibration Group 1414

Calibration Mode 1414

Clutch Filling Calibration 1414

Heat Up Mode 1415

Inching Sensor Calibration 1415

Inching Pedal Sensor Adjustment 1415

Inching Sensor Calibration 1416

TE-Userlink 1416

Description 1416

Connection 1416

Diagrams, Schematics, and Arrangements 1417

tables 1381

Table 1 Gear Selection and Activated Valves 1390

Table 2 Control Valve Pressure Check Ports 1396

Table 3 Transmission Housing Check Ports 1398

Table 4 Sensors and Switches 1398

Table 5 Speed Sensor Check Values 1400

Table 6 Temperature Sensor (In Speed Sensor) Resistance Versus 1401

Table 7 General Information Group 1406

Table 8 Digital Input Test 1409

Table 9 Analog Input Test 1410

Table 10 Speed Sensor Test 1410

Table 11 Output Test 1411

Table 12 Voltage Test 1412

Table 13 APC200 Wire Number to Yale Wire Number Conversion 1412

550088524 4000YRM1647 (07 2016) US EN 1421

Series Code / Model Designation Reference Table 1427

General 1427

Description And Operation 1427

Mast System 1427

Tilting 1427

Lifting 1428

Operation 1428

Pilot Operated Check Valves 1429

Gland Lubrication 1430

Emergency Lowering Valve 1430

Operation 1430

Lift Chains 1431

Elongation Through Wear 1431

Speed of Wear 1431

Plate Height Wear 1432

Lubrication 1432

Restoring The Oil Film 1432

Maintenance 1432

Maintaining The Presence of Oil 1433

Corrosion Protection 1433

Requirements for Chain Lubricant 1433

Load Rollers 1434

Bearing Blocks 1434

Carriage 1435

Standard Carriage with Manual Fork Positioning 1435

Standard Carriage with Hydraulic Fork Positioning 1435

Dual Function Side Shift and Fork Positioning (DFSSFP) Carriage 1436

Integral Side Shift 1436

Carriage Valve 1437

Alternating Pressure and Tank (P & T) 1437

Fixed Pressure and Tank (P & T) 1437

Flow Divider for Simultaneous Fork Positioning 1437

Valve for Dual Function with Side Shift and Fork Positioning (DFSSFP) 1439

Fixed Pressure and Tank System (Fixed P & T) 1441

Forks 1443

Safety Procedures When Working Near Mast 1444

Before Starting Repairs to the Hydraulic System, Always: 1445

Remove and Replace 1445

Forks 1445

Remove 1445

Install 1446

Fork Guide And Fork Pin 1447

Remove 1447

Install 1447

Carriage 1448

1448

Remove 1448

Install 1449

Carriage Bearing Blocks 1450

Remove 1450

Install 1451

1451

Carriage Load Rollers 1451

Replace 1451

1453

Side Shift Cylinder 1453

Remove 1453

Disassemble 1453

Clean And Inspect 1454

Assemble 1454

Install 1455

Fork Positioner Cylinder 1455

Remove 1455

Disassemble 1456

Clean and Inspect 1456

Assemble 1457

Install 1457

Carriage Valves 1457

Remove 1457

Install 1458

1458

Valve for Fixed P & T Systems 1458

Remove and Disassemble 1458

Clean and Inspect 1460

Assemble and Install 1460

Flow Divider for Simultaneous Fork Positioning Valve 1461

Restrictor Valve and Relief Valve Replacement 1461

Dual Function Valve for Side Shifting and Fork Positioning 1461

Solenoid Valve Replacement 1461

Relief Valve Replacement 1462

Remove 1462

Install 1462

Mast 1462

Lift Chains and Top Chain Anchor 1462

Remove 1462

Install 1462

Chain Anchor On Carriage 1463

Remove 1463

Install 1463

Chain Sheave 1464

Remove 1464

Install 1464

Header Hoses 1465

Remove 1465

Install 1467

Electric Mast Cable 1467

Remove 1467

Install 1467

Hose Sheave 1468

Remove and Disassemble 1468

Assemble and Install 1468

Mast Assembly 1469

Remove 1469

Disassemble 1471

Assemble 1472

Install 1473

Inner Mast Load Rollers 1475

Replace 1475

Mast Bearing Blocks 1476

Remove 1476

Install 1476

Lift Cylinders 1477

Remove 1477

Disassemble 1480

Clean and Inspect 1480

Assemble 1480

Install 1481

Tilt Cylinders 1482

Remove 1482

Disassemble 1483

Clean and Inspect 1483

Assemble 1483

Install 1484

Checks and Adjustments 1485

General Checks 1485

Mast Condition Check 1485

Mast Operation Check 1486

Counterbalance Valve Check (for E876 and E877 Only) 1486

Fork Inspection and Adjustment 1486

Lift Chain Inspection 1487

Lift Chain Lubricant Requirements 1488

Lift Chain Lubrication Procedure 1488

Leak Checks 1488

Mast Vertical Creep 1488

Mast Tilt Drift 1489

Adjustments 1489

Lift Cylinder Shimming 1489

Lift Chain and Fork Height Adjustment 1491

Header Hose Tension Adjustment 1493

Electric Mast Cable Tension Adjustment 1493

Counterbalance Valve Adjustment 1493

Tilt Cylinder Backward Tilt Angle Adjustment 1494

Mast Support Pad Adjustment 1494

Troubleshooting 1494

Introduction 1495

No Hydraulic Movement With Engine Running 1495

Initial Basic Check 1495

1496

Electrical Supply 1496

Hydraulic Supply 1496

Fault Code 1496

No Lowering Possible with Engine OFF 1497

Incorrect Movement 1497

Irregular (shaking) Movement

or

Slight Carriage Movement When Starting Engine

1497

Unequal Movement of Left And Right Tilt Cylinder 1497

Insufficient Lifting Speed 1497

Insufficient Lifting Capacity 1498

Incorrect Lowering Speed 1498

Lift Cylinder Creep 1498

Tilt Cylinder Creep 1498