$43.95

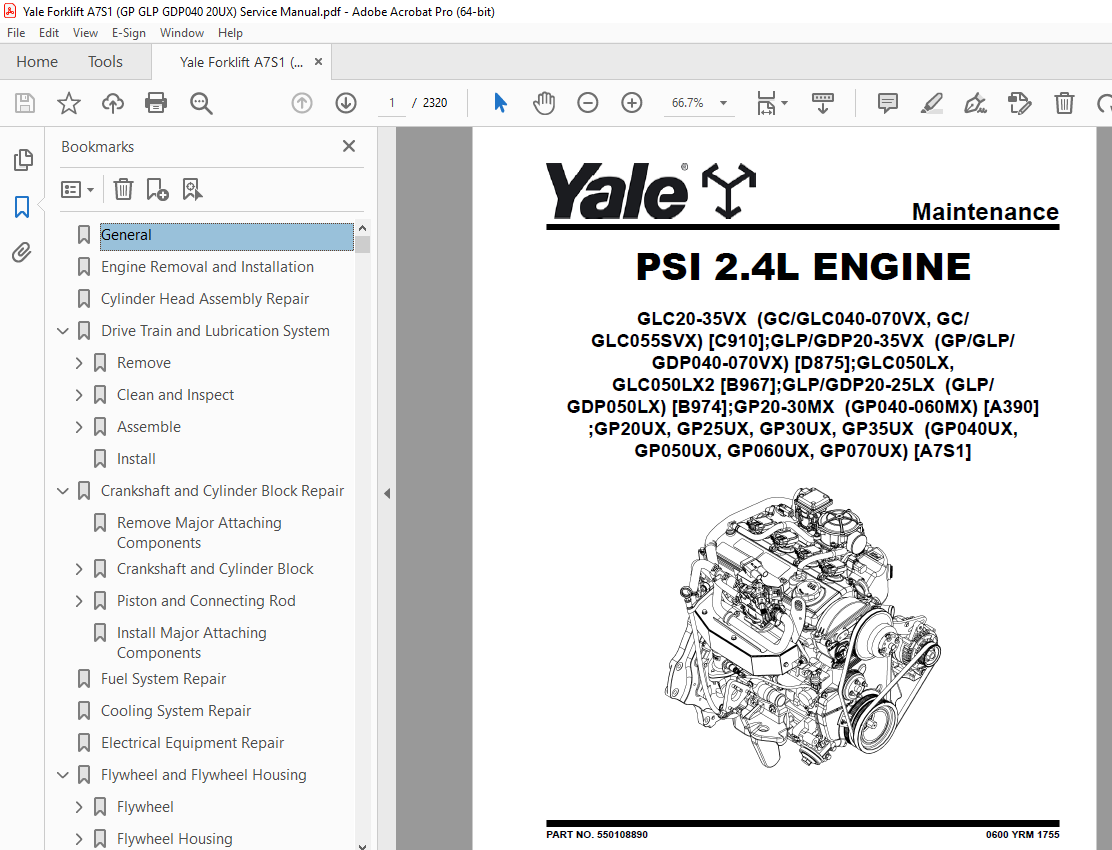

Yale Forklift A7S1 (GP GLP GDP040 20UX) Service Manual – PDF DOWNLOAD

Yale Forklift A7S1 (GP GLP GDP040 20UX) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A7S1 (GP GLP GDP040 20UX) Service Manual – PDF DOWNLOAD

Language : English

Pages : 2320

Downloadable : Yes

File Type : PDF

PART NO. 550108890

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A7S1 (GP GLP GDP040 20UX) Service Manual – PDF DOWNLOAD

General 9

Engine Removal and Installation 13

Cylinder Head Assembly Repair 14

Drive Train and Lubrication System 55

Remove 55

Disassemble 55

Oil Pan 55

Oil Pump (Front Cover) 58

Clean and Inspect 59

Front Case 59

Oil Seal 59

Counterbalance Shaft 59

Oil Pump 59

Assemble 60

Counterbalance Shaft Bearings 60

Oil Pump (Front Cover) 61

Oil Pan 63

Install 63

Crankshaft and Cylinder Block Repair 65

Remove Major Attaching Components 65

Crankshaft and Cylinder Block 65

Remove 65

Clean and Inspect 66

Boring Cylinder 67

Install 68

Piston and Connecting Rod 70

Remove 70

Disassemble 71

Clean and Inspect 71

Assemble 72

Install 74

Piston 74

Rod Bearing 75

Install Major Attaching Components 76

Fuel System Repair 77

Cooling System Repair 78

Electrical Equipment Repair 79

Flywheel and Flywheel Housing 80

Flywheel 80

Remove 80

Install 81

Flywheel Housing 81

Remove 81

Install 81

POWER TAKE OFF (PTO), REMOVE AND INSTALL 82

REMOVE COVER 82

INSTALL COVER 82

Engine Specifications 84

Engine Data 84

Engine Tuning 85

Cylinder Head 86

Intake/Exhaust Valve and Guide 86

Valve Spring 86

Gear Train and Camshaft 87

Camshaft 87

Idle Gear Shaft and Bushing 87

Cylinder Block 87

Crankshaft 87

Piston 87

Piston Ring 88

Connecting Rod 88

Oil Pump 88

Engine Oil Pressure 88

Drive Gear Clearance 88

Driven Gear Clearance 88

Torque Specifications 89

Special Tools 91

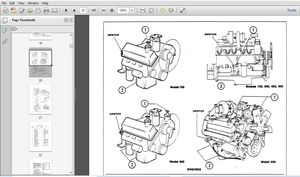

General 103

Engine Identification 103

Major Engine Component Identification 103

Location of Labels 103

Engine Removal and Installation 104

Cylinder Head Assembly Repair 105

Valve Covers and Fuel Injectors 105

Remove 105

Clean and Inspect 108

Install 109

Rocker Arm Assembly 109

Remove 109

Disassemble 110

Clean and Inspect 111

Push Rods 111

Rocker Arm Assembly 111

Assemble 111

Install 112

Valve Clearance Adjustments 112

Compression Test 113

Cylinder Head Assembly 113

Remove 113

Disassemble 123

Valves and Valve Springs, Remove 123

Valve Guides, Remove 124

Clean and Inspect 124

Cylinder Head 125

Valve Guides 125

Valves 125

Valve Sink 126

Valve Seat 126

Valve Springs 127

Assemble 127

Valve Guides, Install 127

Valves and Valve Springs, Install 128

Install 129

Timing Gear Case and Timing Gears Repair 133

Timing Gear Case Cover 133

Remove 133

Clean and Inspect 134

Install 134

Timing Gears 135

Oil Pump Driven Gear 135

Remove 135

Install 135

Crankshaft Gear 135

Remove 135

Install 136

Idler Gear 136

Remove 136

Inspect 136

Install 137

Camshaft Gear 137

Remove 137

Install 137

Drive Train, Camshaft, and Cylinder Block Repair 138

Remove 138

Disassemble 138

Pistons and Connecting Rods 138

Crankshaft 139

Camshaft 141

Remove 141

Install 141

Clean and Inspect 141

Cylinder Block 142

Honing and Boring 142

Cylinder Correction (Oversize) 143

Pistons 144

Piston Ring Gap 144

Piston Ring Groove 144

Connecting Rod and Piston Pin 145

Crankshaft 147

Camshaft 148

Assemble 149

Camshaft 149

Crankshaft 149

Pistons and Connecting Rods 150

Install 151

Lubrication System Repair 152

Engine Oil and Oil Filter Change 152

Oil Pan 152

Remove 152

Install 153

Oil Suction Tube 153

Remove 153

Clean 153

Install 153

Oil Pump 153

Remove 153

Clean and Inspect 154

Outer Rotor Outside Clearance 154

Outer Rotor to Inner Rotor Tip Clearance 154

Rotor Cover Clearance 155

Install 155

Fuel System Repair 156

Fuel Injectors 156

Remove 156

Inspect 156

Clean 156

Replace 156

Install 156

Test 156

Fuel Injection Pump/Supply Pump 157

Remove 157

Clean and Inspect 159

Install 159

Cooling System Repair 161

Accessory Drive Belt 161

Remove 161

Inspect 161

Install 162

Accessory Drive Belt, Adjustment 162

Water Pump 162

Remove 162

Install 164

Thermostat 164

Remove 164

Inspect 165

Install 165

Flywheel and Flywheel Housing 167

Flywheel 167

Remove 167

Install 167

Flywheel Housing 167

Remove 167

Install 167

Electrical Equipment Repair 168

Alternator 168

Remove 168

Install 168

Starter 169

Remove 169

Install 169

Engine Specifications 170

Engine Data 170

Engine Tuning 171

Cylinder Head 171

Intake/Exhaust Valve and Guide 171

Valve Spring 172

Rocker Arm and Shaft 172

Push Rod 172

Gear Train and Camshaft 172

Camshaft 172

Idle Gear Shaft and Bushing 172

Backlash of Each Gear 173

Cylinder Block 173

Crankshaft 173

Piston 173

Piston Ring 174

Connecting Rod 174

Rod Small End 174

Tappet 174

Oil Pump 175

Engine Oil Pressure 175

Outer Rotor Outside Clearance 175

Outer Rotor Side Clearance 175

Inner Rotor to Cover 175

Standard Torque Specifications 176

Standard Torque Chart 176

Special Torque Specifications 177

Special Tools 178

Forklift Truck Main Parts 191

Description of Forklift Truck Main Parts 191

Forklift Main Technical Parameters 192

Main Technical Parameters 192

Power System 195

Engine System 195

Engine Overview 195

Fuel System 196

Fuel Tank 197

Fuel Level Sensor 198

Maintenance of Fuel System 199

Fuel filter service 199

Hydraulic Transmission Case and Torque Converter 200

Overview 200

Torque Converter 201

Hydraulic Clutch 202

Control Valve, Safety Valve, and Inching Valve 203

Transmission Case 205

Transmission Pump 205

Transmission hydraulic schematic 205

Speed Reducer and Speed Differential 206

Speed Reducer 206

Speed Differential 207

Towing the Lift Truck 207

Oil Inlet/Outlet Connection Location 207

Drive Axle 208

Overview 208

Maintenance of Drive Axle 209

Steering System 210

Steering System 210

Overview 210

Hydraulic Steering Gear Assembly 210

Steering Cylinder 211

Inspection of Reassembled Steering System 212

Troubleshoot Steering System 213

Steering and Drive Axle Information 214

Steering Axle 214

Overview 214

Steering Knuckle and Steering King Pin 215

Steering Wheel Bearing Pre-load Information 216

Brake System 216

Overview 217

Brake Master Cylinder 217

Wheel Brake 217

Automatic Brake Adjuster 221

Manual Brake 222

Adjustment of Brake Pedal 222

Maintenance 222

Examination of Wheel Brake 225

Assemble, Wheel Brake 226

Operating Test Automatic Clearance Regulator 228

Troubleshoot Wheel Brake 229

Hydraulic System 231

Overview 231

Steering Control Unit 232

Multi-way Valve and Priority spool 232

Operation of Spool Valve 232

Neutral Position 232

Spool Valve (Pushed In): 233

Spool Valve (Pulled out): 233

Primary Relief Valve and Priority Spool 233

Inclined Auto-Lock Valve 234

Hydraulic System Main Oil Circuit 235

Lift Cylinder 237

Velocity Fuse 239

Tilt Cylinder 240

Maintenance of Hydraulic Pump 241

Disassemble, Main Oil Pump 241

Inspection and Repair 241

Assemble, Main Oil Pump 244

Test 245

Troubleshoot Hydraulic System 249

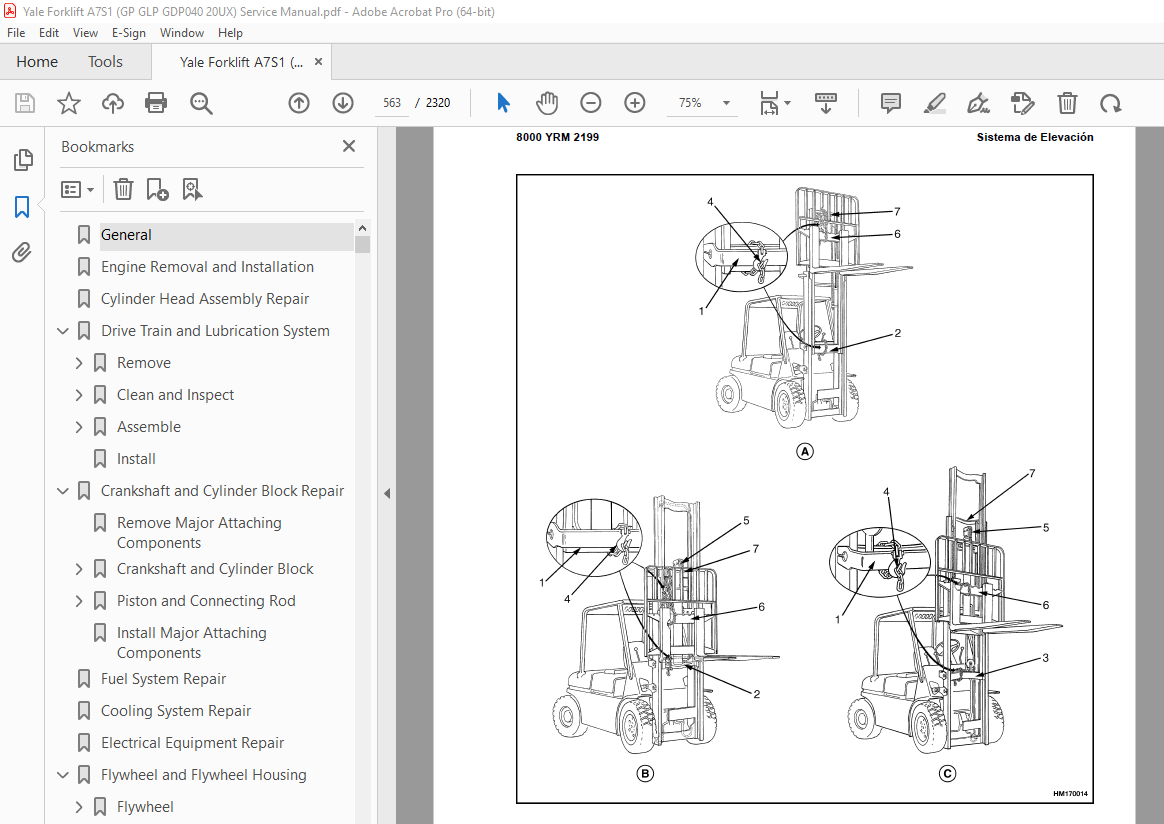

Lifting System 250

Safety Procedures When Working Near Mast 250

Overview 252

Inside and Outside Masts 252

Carriage 253

Adjustment of Lifting System 253

Electrical System 254

Overview 254

Power supply system 254

Starting system 254

Ignition system (ICE forklift truck) 254

Preheating system (diesel forklift truck) 254

Dash Instrument Display System 255

Lighting, sound and alarm system 255

Electrical Box 255

Battery 255

Description and Summary of Basic Truck Operations 255

Introduction to the Power Distribution Module (PDM) 257

Electrical Schematics 257

Troubleshoot Electrical System 271

Troubleshooting 271

Drive, Operation, and Routine Maintenance of Forklift Truck 272

Cooling System Troubleshooting and Service 272

Coolant level check 272

Flushing the cooling system 272

Adding antifreeze/coolant 272

Cleaning the radiator 272

Oils Used for Forklift Truck 273

Hydraulic Oil Gauge and Hydraulic Oil fill 273

General inspection requirements 273

Fill Level Requirements 273

Lubrication System 273

PDM Schematics 275

Principaux éléments du chariot élévateur 291

Description des principaux éléments du chariot élévateur 291

Principales caractéristiques techniques du chariot élévateur 292

Principales caractéristiques techniques 292

Système de traction 295

Circuit moteur 295

Vue d’ensemble des moteurs 295

Système de carburant 296

Réservoir de carburant 297

Capteur du niveau de carburant 298

Maintenance du circuit de carburant 299

Entretien du filtre à carburant 299

Carter de transmission hydraulique et convertisseur de couple 299

Vue d’ensemble 300

Convertisseur de couple 301

Embrayage hydraulique 302

Distributeur, clapet de sécurité et clapet de marche lente 303

Carter de transmission 305

Pompe de transmission 305

Schéma hydraulique de transmission 305

Réducteur de vitesse et différentiel 307

Réducteur de vitesse 307

Différentiel de vitesse 307

Remorquage du chariot élévateur 308

Emplacement des raccords d’entrée/sortie d’huile 308

Pont moteur 308

Vue d’ensemble 309

Maintenance du pont moteur 309

Système de direction 310

Système de direction 310

Vue d’ensemble 310

Ensemble boîtier de direction hydraulique 310

Vérin de direction 311

Contrôle du système de direction remonté 312

Dépannage du système de direction 312

Essieu directeur et pont moteur 313

Essieu directeur 313

Vue d’ensemble 314

Porte-fusée de direction et pivot central de direction 316

Précharge du roulement de roue directrice 316

Circuit de freins 316

Vue d’ensemble 317

Maître-cylindre de frein 317

Frein de roue 318

Système de réglage automatique de frein 322

Frein manuel 323

Réglage de la pédale de frein 323

Maintenance 324

Contrôle du frein de roue 326

Montage du frein de roue 327

Test de fonctionnement du système de réglage automatique du jeu 329

Dépannage du frein de roue 330

Circuit hydraulique 332

Vue d’ensemble 332

Boîtier de direction 333

Distributeur multivoie et tiroir prioritaire 333

Fonctionnement du clapet à tiroir 333

Position neutre 334

Clapet à tiroir (enfoncé) : 334

Clapet à tiroir (tiré) : 334

Clapet de décharge principal et tiroir prioritaire 335

Clapet de verrouillage automatique de l’inclinaison 336

Circuit d’huile principal du système hydraulique 337

Vérin de levage 339

Limiteur de débit 341

Vérin d’inclinaison 342

Maintenance de la pompe hydraulique 343

Démontage de la pompe à huile principale 343

Contrôle et réparation 343

Montage de la pompe à huile principale 346

Test 347

Dépannage du circuit hydraulique 351

Système de levage 352

Mesures de sécurité lors du travail à proximité du mât 352

Vue d’ensemble 355

Mâts intérieur et extérieur 356

Tablier 356

Réglage du système de levage 356

Circuit électrique 358

Vue d’ensemble 358

Système d’alimentation 358

Système de démarrage 358

Système d’allumage (chariot élévateur à moteur thermique) 358

Système de préchauffage (chariot élévateur diesel) 358

Système d’afficheur tableau de bord 358

Système d’éclairage, de son et d’alarme 358

Boîtier électrique 359

Batterie 359

Description et synthèse du fonctionnement de base du chariot 359

Présentation du module de distribution électrique 360

Schémas électriques 361

Procédez au diagnostic du circuit électrique 375

Détection des pannes 376

Conduite, utilisation et maintenance courante du chariot élévateur 376

Dépannage et entretien du circuit de refroidissement 376

Contrôle du niveau de liquide de refroidissement 376

Rinçage du circuit de refroidissement 377

Ajout d’antigel/liquide de refroidissement 377

Nettoyage du radiateur 377

Huiles utilisées sur les chariots élévateurs 377

Jauge d’huile hydraulique et remplissage de l’huile hydraulique 377

Exigences de contrôle général 377

Exigences de niveau de remplissage 377

Système de lubrification 378

Schéma de principe du module de distribution électrique 380

Hauptkomponenten des Gabelstaplers 395

Beschreibung der Hauptkomponenten des Gabelstaplers 395

Technische Hauptparameter des Gabelstaplers 396

Technische Hauptparameter 396

Antriebssystem 399

Motorsystem 399

Überblick über den Motor 399

Kraftstoffsystem 400

Kraftstofftank 401

Kraftstoffstandsensor 402

Wartung des Kraftstoffsystems 403

Wartung des Kraftstofffilters 403

Hydraulikgetriebegehäuse und Drehmomentwandler 403

Überblick 404

Drehmomentwandler 405

Hydraulikkupplung 406

Regelventil, Überdruckventil und Kriechgangventil 407

Getriebegehäuse 409

Getriebepumpe 409

Schaltplan Getriebehydraulik 409

Drehzahlminderer und Differenzial 411

Drehzahlminderer 411

Differenzial 411

Abschleppen des Staplers 411

Lage des Öleinlass-/-auslassstutzens 411

Antriebsachse 412

Überblick 412

Wartung der Antriebsachse 413

Lenksystem 413

Lenksystem 413

Überblick 414

Baugruppe hydraulisches Lenkgetriebe 414

Lenkzylinder 415

Überprüfung des wieder zusammengebauten Lenksystems 416

Fehlerbehebung beim Lenksystem 416

Angaben zur Lenk- und Antriebsachse 417

Lenkachse 417

Überblick 418

Achsschenkel und Lenkkönigszapfen 419

Angaben zur Lagervorspannung am Lenkrad 420

Bremssystem 420

Überblick 421

Hauptbremszylinder 421

Radbremse 422

Automatischer Bremseinsteller 426

Manuelle Bremse 427

Einstellen des Bremspedals 427

Wartung 428

Überprüfung der Radbremse 430

Zusammenbauen der Radbremse 431

Betriebstest automatischer Abstandseinsteller 433

Fehlerbehebung bei der Radbremse 434

Hydrauliksystem 435

Überblick 436

SCU 437

Mehrwegeventil und Vorrangschieber 437

Funktionsweise des Schieberventils 437

Neutralstellung 438

Schieberventil (verschlossen): 438

Schieberventil (geöffnet): 438

Primärüberdruckventil und Vorrangschieber 439

Neigeselbstsperrventil 440

Hauptölkreislauf des Hydrauliksystems 441

Hubzylinder 443

Hydrauliksicherung 445

Neigezylinder 446

Wartung der Hydraulikpumpe 447

Zerlegen der Hauptölpumpe 447

Überprüfung und Reparatur 447

Zusammenbauen der Hauptölpumpe 450

Test 451

Fehlerbehebung beim Hydrauliksystem 455

Hubsystem 456

Sicherheitsvorkehrungen bei Arbeiten in der Nähe des Hubgerüsts 456

Überblick 459

Inneres und äußeres Hubgerüst 460

Gabelträger 460

Einstellen des Hubsystems 460

Elektrisches System 462

Überblick 462

Stromversorgung 462

Startsystem 462

Zündsystem (Gabelstapler mit Verbrennungsmotor) 462

Vorglühanlage (Gabelstapler mit Dieselmotoren) 462

Instrumentenanzeigesystem 462

System für Beleuchtung, Akustik und Warnmeldungen 462

Elektrokasten 463

Batterie 463

Beschreibung und Zusammenfassung der wichtigsten Staplerfunktionen 463

Einführung in das PDM 465

Schaltpläne 465

Fehlersuche im elektrischen System 479

Fehlersuche 479

Fahren, Betrieb und regelmäßige Wartung des Gabelstaplers 480

Kühlsystem – Fehlersuche und Wartung 480

Prüfung Kühlmittelstand 480

Spülen des Kühlsystems 480

Nachfüllen von Frostschutzmittel/Kühlmittel 481

Reinigen des Kühlers 481

Für Gabelstapler verwendete Öle 481

Hydraulikölfüllstandsanzeige und Nachfüllen von Hydrauliköl 481

Allgemeine Überprüfung 481

Vorgaben für den Füllstand 481

Schmiersystem 482

PDM-Schaltplan 484

Partes Principales de la Carretilla Elevadora 499

Descripción de las Partes Principales de la Carretilla Elevadora 499

Parámetros Técnicos Principales de la Carretilla Elevadora 500

Parámetros Técnicos Principales 500

Sistema de Propulsión 503

Sistema del Motor 503

Visión General del Motor 503

Sistema de combustible 504

Depósito de combustible 504

Sensor de nivel de combustible 506

Mantenimiento del Sistema de Combustible 507

Intervención de servicio del filtro de combustible 507

Caja de la Transmisión Hidráulica y Convertidor de Par 507

Visión General 508

Convertidor de par 509

Embrague Hidráulico 510

Válvula de Control, Válvula de Seguridad y Válvula de Marcha Lenta 511

Caja de transmisión 513

Bomba de la Transmisión 513

Esquema hidráulico de la transmisión 513

Reductor de Velocidad y Diferencial de Velocidad 515

Reductor de velocidad 515

Diferencial de Velocidad 515

Remolcado de la carretilla elevadora 516

Ubicación de la Conexión de Entrada/Salida de Aceite 516

Árbol propulsor 516

Visión General 517

Mantenimiento del Árbol Propulsor 517

Sistema de dirección 518

Sistema de dirección 518

Visión General 518

Conjunto de Engranaje de Dirección Hidráulica 518

Cilindro de dirección 520

Inspección del Sistema de Dirección una vez Rearmado 521

Efectúe la Localización de Averías en el Sistema de Dirección 521

Información de la Dirección y del Árbol Propulsor 522

Eje de dirección 522

Visión General 523

Rótula de la Dirección y Pasador Principal de la Dirección 525

Información de Precarga del Cojinete de la Rueda de Dirección 525

Sistema de freno 525

Visión General 526

Cilindro maestro del freno 526

Freno de la Rueda 527

Ajustador Automático del Freno 531

Freno Manual 532

Ajuste del Pedal del Freno 532

Mantenimiento 533

Examen del Freno de la Rueda 535

Montaje, Freno de la Rueda 536

Prueba de Funcionamiento del Regulador de Holgura Automático 538

Efectúe el procedimiento de Localización de Averías del Freno de la Rueda 539

Sistema hidráulico 540

Visión General 541

Unidad de control de dirección 542

Válvula Múltiple y Carrete de Prioridad 542

Funcionamiento de la Válvula de Carrete 543

Posición neutra 543

Válvula de Carrete (Presionada Hacia Dentro): 543

Válvula de Carrete (Extraída Hacia Fuera): 543

Válvula de Alivio Primaria y Carrete de Prioridad 544

Válvula de Bloqueo Automático de Inclinación 545

Circuito de Aceite Principal del Sistema Hidráulico 546

Cilindro de elevación 548

Fusible de velocidad 550

Cilindro de inclinación 551

Mantenimiento de la Bomba Hidráulica 552

Desmontaje, Bomba de Aceite Principal 552

Inspección y Reparación 552

Montaje, Bomba de Aceite Principal 555

Prueba 556

Localización de Averías del Sistema Hidráulico 560

Sistema de Elevación 561

Procedimientos de seguridad cuando se trabaja cerca del mástil 561

Visión General 564

Mástiles Interiores y Exteriores 565

Tablero 565

Ajuste del Sistema de Elevación 565

Sistema eléctrico 567

Visión General 567

Sistema de Alimentación 567

Sistema de arranque 567

Sistema de encendido (carretilla elevadora con Motor de CI) 567

Sistema de precalentamiento (carretilla elevadora diésel) 567

Sistema de Pantalla de Instrumentos del Tablero de Instrumentos 567

Sistema de alumbrado, de sonido y de alarmas 567

Caja Eléctrica 568

Batería 568

Descripción y Resumen de Operaciones Básicas de la Carretilla 568

Introducción del Módulo de Distribución de Alimentación (PDM) 569

Esquemas eléctricos 570

Efectúe la Localización de Averías en el Sistema Eléctrico 584

Localización de averías 584

Conducción, Empleo y Mantenimiento de Rutina de la Carretilla Elevadora 585

Localización de Averías y Servicio del Sistema de Refrigeración 585

Comprobación del nivel de refrigerante 585

Limpieza del sistema de refrigeración 586

Adición de anticongelante/refrigerante 586

Limpieza del radiador 586

Aceites Utilizados para la Carretilla Elevadora 586

Indicador de Aceite Hidráulico y Llenado de Aceite Hidráulico 586

Requisitos de inspección general 586

Requisitos de Nivel de Llenado 586

Sistema de lubricación 587

Esquema del PDM 589

Componenti principali del carrello elevatore a forche 605

Descrizione dei componenti principali del carrello elevatore a forche 605

Principali parametri tecnici del carrello elevatore a forche 606

Principali parametri tecnici 606

Sistema di alimentazione 609

Impianto motore 609

Panoramica del motore 609

Impianto di alimentazione 610

Serbatoio carburante 611

Sensore livello carburante 612

Manutenzione dell’impianto di alimentazione 613

Manutenzione del filtro del carburante 613

Scatola del cambio idraulico e convertitore di coppia 613

Panoramica 614

Convertitore di coppia 615

Frizione idraulica 616

Valvola di comando, valvola di massima pressione e valvola di avanzamento progressivo 617

Scatola trasmissione 619

Pompa della trasmissione 619

Schema idraulico trasmissione 619

Riduttore di velocità e differenziale di velocità 621

Riduttore di velocità 621

Differenziale di velocità 621

Traino del carrello elevatore 621

Posizione collegamento ingresso/uscita olio 621

Assale di trazione 622

Panoramica 622

Manutenzione dell’assale di trazione 623

Sistema sterzante 623

Sistema sterzante 623

Panoramica 624

Assieme ingranaggio dello sterzo idraulico 624

Cilindro sterzo 625

Ispezione e rimontaggio dell’impianto sterzante 626

Ricerca e risoluzione guasti al sistema sterzante 626

Specifiche assale sterzante e di trazione 627

Assale sterzante 627

Panoramica 628

Fuso a snodo e perno fuso a snodo sterzo 629

Informazioni sul precarico dei cuscinetti del volante 630

Impianto freni 630

Panoramica 631

Pompa di comando dei freni 631

Freno ruote 632

Regolatore automatico freno 636

Freno manuale 637

Regolazione del pedale del freno 637

Manutenzione 638

Controllo del freno delle ruote 640

Montaggio del freno ruote 642

Test di funzionamento del regolatore automatico del gioco 643

Ricerca e risoluzione guasti al freno ruote 644

Impianto idraulico 645

Panoramica 646

Unità di comando dello sterzo 647

Valvola multidirezionale e bobina prioritaria 647

Funzionamento della valvola a bobina 647

Posizione di neutro 648

Valvola a bobina (push-in): 648

Valvola a bobina (pull out): 648

Valvola di massima primaria e bobina prioritaria 649

Valvola autobloccante inclinata 650

Impianto idraulico (circuito dell’olio principale) 651

Cilindro di sollevamento 653

Fusibile di velocità 655

Cilindro di inclinazione 656

Manutenzione della pompa idraulica 657

Smontaggio della pompa dell’olio principale 657

Controllo e riparazione 657

Montaggio pompa dell’olio principale 660

Test 661

Ricerca e risoluzione guasti all’impianto idraulico 665

Sistema di sollevamento 666

Precauzioni di Sicurezza da Adottare in Prossimità del Montante 666

Panoramica 669

Montanti interni ed esterni 670

Piastra portaforche 670

Regolazione del sistema di sollevamento 670

Impianto elettrico 672

Panoramica 672

Sistema di alimentazione elettrica 672

Sistema di avviamento 672

Sistema di accensione (carrello elevatore a benzina) 672

Sistema di preriscaldamento (carrello elevatore a forche diesel) 672

Sistema del display del cruscotto 672

Sistema di illuminazione, suono e allarme 672

Scatola di derivazione elettrica 672

Batteria 672

Descrizione e riassunto del funzionamento di base del carrello 673

Introduzione al Modulo di distribuzione dell’alimentazione (PDM) 674

Schemi elettrici 674

Eseguire la ricerca guasti per l’impianto elettrico 688

Individuazione dei guasti 688

Guida, funzionamento e manutenzione ordinaria del carrello elevatore a forche 689

Risoluzione dei problemi e manutenzione dell’impianto di raffreddamento 689

Controllo del livello del refrigerante 689

Lavaggio dell’impianto di raffreddamento 690

Aggiunta di antigelo/liquido di raffreddamento 690

Pulizia del radiatore 690

Oli usati per il carrello elevatore 690

Indicatore olio idraulico e rabbocco olio idraulico 690

Requisiti di ispezione generale 690

Requisiti livello di riempimento 690

Sistema di lubrificazione 691

Schema del modulo PDM 693

General 707

Description 708

Hood, Seat, and Side Covers Replacement 709

Disassemble 709

Re-assemble 712

Steering Column 713

Description 713

Steering Column Repair 713

Remove 713

Disassemble 715

Clean 715

Inspect 715

Re-assemble 716

Counterweight Replacement 717

Remove 717

Install 718

Overhead Guard Replacement 719

Remove and Install 719

Operator Restraint System Replacement 722

Description 722

Emergency Locking Retractor (ELR) 722

Engine and Transmission Replacement 723

Remove 723

Engine and Transmission Disassembly 723

Exhaust System Repair 725

Remove and Re-assemble 725

Inspect 726

Cooling System 727

Description 727

Hydraulic Filter Assembly Repair 728

Disassemble 728

Clean and Inspect 729

Re-assemble 729

Fuel and Hydraulic Tanks Repair 730

Inspect 730

Clean 730

Steam Method of Cleaning 730

Chemical Solution Method of Cleaning 731

Additional Preparations for Repair 731

Small Leaks, Repair 731

Large Leaks, Repair 732

Preparations for Use After Repair 732

Safety Labels 733

General 743

Cooling System Checks 743

Exhaust Leaks Into Cooling System 743

Water Flow Restrictions in Radiator 743

Radiator Hoses 743

Water Pump 743

Flushing the Cooling System 744

Cooling System, Clean 744

Radiator Replacement 746

Radiator, Remove 746

Radiator, Install 749

Fan Assembly Replacement 750

Fan Removal 750

Inspect 750

Fan Installation 751

General 759

Intake-Air System 760

Intake-Air System Manifold Vacuum Check 760

Throttle Body 761

Remove 761

Install 762

Intake Manifold 762

LPG Tank and Bracket Replacement with Swing-Out Bracket 763

Remove LPG Tank 763

Install LPG Tank 765

Remove LPG Bracket 765

Install LPG Bracket 765

Fuel Filter and Fuel Level Sensor Repair 766

FUEL FILTER ELEMENT 766

Remove 766

Install 767

Fuel Level Sensor 767

Remove 767

Install 767

Electronic Throttle Body Repair 768

Remove 768

Install 769

LPG Fuel Mixer With Direct Electronic Pressure Regulator (DEPR) Repair 771

Remove 771

Install 773

Control System 774

Engine Control Module (ECM) 774

Remove 774

Install 774

LPG Converter 775

LPG Lock-Off Valve 777

Remove 777

Install 778

Exhaust System 780

Counterweight Exhaust System 780

Remove and Disassemble 780

Inspect 781

Assemble and Install 781

Oxygen Sensor 782

Remove 782

Install 782

GENERAL 791

Transmission 793

REMOVE 793

CLEAN AND INSPECT 800

INSTALL 800

Pedal Repair 802

REMOVE AND DISASSEMBLE 802

CLEAN AND INSPECT 803

ASSEMBLE AND INSTALL 803

General 811

Drive Axle Repair 811

Remove and Disassemble 811

Clean and Inspect 813

Re-assemble and Install 813

General 823

Steering Axle Assembly Repair 824

Remove 824

Disassemble 824

Clean 826

Inspect 826

Re-assemble 826

Install 827

Spindles, Bearings, and Tie Rods Repair 828

Remove and Disassemble 828

Steering Spindle Removal 828

Clean 828

Inspect 828

Install and Assemble 828

Steering Cylinder Repair 830

Remove and Disassemble 830

Clean and Inspect 831

Assemble and Install 831

GENERAL 839

SERVICE BRAKE REPAIR 840

REMOVE AND DISASSEMBLE 840

CLEAN 841

INSPECT 842

ASSEMBLE AND INSTALL 843

ADJUST 845

PARKING BRAKE REPAIR 846

REMOVE AND DISASSEMBLE 846

ASSEMBLE AND INSTALL 846

ADJUST 846

MASTER CYLINDER REPAIR 847

REMOVE 847

DISASSEMBLE 847

CLEAN AND INSPECT 848

ASSEMBLE 848

BENCH BLEED MASTER CYLINDER 848

INSTALL 848

SERVICE BRAKE ADJUSTMENT 849

SERVICE BRAKE AIR REMOVAL 849

Cylinder 857

General 857

Safety Procedures When Working Near Mast 857

Integral Sideshift Cylinder Repair 857

Remove 857

Disassemble 858

Clean 858

Inspect 859

Re-assemble 859

Install 859

INTEGRAL SIDE-SHIFT CYLINDER GLAND LEAK CHECKS 859

Free-Lift Cylinder 860

Remove 860

Disassemble and Re-assemble 862

Clean 863

Inspect 863

Install 865

Main Lift Cylinder Repair 865

Remove 865

Disassemble and Re-assemble 866

Clean 867

Inspect 867

Install 867

MAIN LIFT CYLINDER LEAK CHECK 867

Tilt Cylinder Repair 868

Remove 868

Disassemble and Re-assemble 870

Clean 871

Inspect 871

Install 871

Hydraulic Gear Pump 872

General 872

Hydraulic Gear Pump Repair 873

Remove 873

Disassemble 873

Re-assemble 874

Examination and Repair 875

Pump Body 875

Bearing 876

Gear 877

Oil Seal 877

Main Control Valve 878

General 878

Main Control Valve 878

Description 878

Remove 880

Clean and Inspect 883

Install 883

General 893

Combination Switch 893

Remove and Install 893

Display and Rocker Switch 895

Remove and Install 895

Battery and Power Distribution Module 897

Remove and Install 897

Auxiliary Relay and Fuse Box 898

Remove and Install 898

Sensors and Switches 899

General 899

Accelerator Pedal Position Sensor 899

Remove and Install 899

Parking Brake Sensor 899

Remove and Install 899

Fuel Level Sensor 900

Remove and Install 900

Torque Converter Temperature Sensor 901

Remove and Install 901

Engine Coolant Temperature Sensor 901

Remove and Install 901

CAM Sensor 901

Remove and Install 901

Crank Sensor 902

Remove and Install 902

Map Sensor 902

Remove and Install 902

Oil Pressure Sensor 902

Remove and Install 902

Oxygen Sensors 903

Fuel Shut-off Valve, Fuel filter, Fuel Pump, and Fuel Temperature Sensor 903

Remove and Install 903

Lights 905

Remove and Install 905

Main Harness and OPS Harness 905

General 913

Safety Procedures When Working Near Mast 914

Fork Replacement 915

Standard Carriage and Integral Sideshift Carriage 915

Remove 915

Install 916

Checks 916

Carriages Repair, Three-Stage FFL Mast 918

Standard Carriage 918

Remove 918

Clean and Inspect 918

Install 919

Integral Sideshift Carriage 919

Remove 919

Disassemble 921

Clean and Inspect 921

Assemble 922

Install 922

Three-Stage Mast With Full Free-Lift Repair 923

Remove 923

Disassemble and Re-assemble 924

Clean and Inspect 925

Carriage Adjustments 926

Lift Chains Adjustment 927

Mast Adjustments 928

Load Roller, Adjust 928

Mast Side Kicking, Adjust 929

Electrical Schematics 937

Hydraulic Schematics 955

Operator Presence System (OPS) Schematic 956

Power Distribution Module (PDM) Schematics 958

General 975

How to Move a Disabled Lift Truck 975

How to Tow Lift Truck 975

How to Put a Lift Truck on Blocks 976

How to Raise Drive Tires 976

How to Raise Steering Tires 976

HOW TO CLEAN A LIFT TRUCK 977

Maintenance Schedule 979

Maintenance Procedures Every 8 Hours or Daily 995

How to Make Checks With Engine Stopped 995

Tires and Wheels 995

Safety Labels 995

Mast, Carriage, Lift Chains, Header Hoses, and Attachment 995

Emergency Locking Retractor (ELR) 996

Adjust Seat – Standard Full Suspension 996

Hood and Seat Latches 997

Engine Compartment 997

Fuel, Oil, and Coolant Leaks, Check 997

Hydraulic Hoses 998

Coolant Hoses 998

Steering Column 998

Transmission 998

Hydraulic System Oil 998

Engine Oil 998

Air Filter 998

Forks 999

Inspect 999

Remove 1000

Adjust 1000

How to Make Checks With Engine Running 1000

Indicator Lights, Horn, Fuses, and Relays 1000

Service Brakes 1002

Operation, Check 1002

Parking Brake 1002

Engine Oil Pressure 1002

Cooling System 1003

Steering System 1003

Control Levers and Pedals 1003

Lift System, Operate 1003

Maintenance Procedures Every 250 Hours or 3 Months 1005

ENGINE OIL AND OIL FILTER 1005

Maintenance Procedures Every 500 Hours or 6 Months 1006

Hydraulic System Oil 1006

Battery 1007

Clean Debris From Radiator Core 1007

Transmission Oil Level 1007

Fuel Filter Element, Replace 1008

Forks 1008

Header Hose Checks 1008

Lift Chain Lubrication 1009

Tilt Cylinder Lubrication 1009

Master Brake Cylinder Rod End Pin Lubrication 1009

Manual Hydraulic Levers Lubrication 1009

Brake Fluid 1009

Tie Rod Lubrication 1010

Differential and Drive Axle Oil 1010

Maintenance Procedures Every 1000 Hours or 1 Year 1011

PCV VALVE 1011

DRIVE BELT CHECK 1011

GASOLINE FUEL SYSTEM 1011

SPARK PLUGS 1011

Lift Chains Wear Check 1011

Lift Chain Lubrication 1011

STEERING AXLE 1011

Control Levers, Pedals, and Parking Brake 1011

Maintenance Procedures Every 2000 Hours or 1 Year 1012

Hydraulic System 1012

Return and Suction Filters, Replace 1012

Air Filter Element, Replace 1012

PCV VALVE 1012

Oxygen Sensor 1012

Forks, Inspect 1013

Integral Sideshift Carriage 1013

Bearings, Replace 1013

Service Brakes (DRY Brake) 1013

Transmission Oil and Filter, Replace 1013

Brake Fluid (Master Cylinder), Change 1014

Brake Fluid, Remove 1014

Maintenance Procedures Every 4000 Hours or 2 Years 1015

COOLING SYSTEM 1015

TIMING BELT CHANGE 1015

Maintenance Procedures Every 6000 Hours or 2 Years 1016

CAMSHAFT BELT, BALANCE SHAFT BELT, IDLER AND TENSINOER PULLLEY 1016

Safety Procedures When Working Near Mast 1017

Periodic Maintenance for YANMAR Engine 1018

Maintenance Schedule 1018

Periodic Maintenance Procedures 1022

Daily 1023

Drain Fuel Filter/Water Separator 1023

Check Fuel Hoses and Engine Coolant Hoses 1024

Every 250 Hours of Operation 1024

Check and Clean Radiator Fins 1024

Check and Adjust Cooling Fan V-belt 1024

Check Battery 1024

Clean Air Filter Element 1025

Every 500 Hours of Operation 1026

Replace Engine Oil and Engine Oil Filter 1026

Check and Adjust the Governor Lever and Engine Speed Control 1026

Every 1000 Hours of Operation 1027

Adjust Intake/Exhaust Valve Clearance 1027

Clean Fuel/Water Separator 1027

Replace Fuel Filter 1028

Every 2000 Hours of Operation 1029

Replace Air filter Element 1029

Inspect, Clean and Test Fuel Injectors 1030

Every 4000 Hours of Operation 1030

Drain, Flush, and Re-fill the Coolant System with New Coolant 1030

Replace Fuel Hoses and Engine Coolant Hoses 1031

Periodic Maintenance Procedures 1031

After Initial 50 Hours of Operation 1031

Every 50 Hours of Operation 1031

Every 250 Hours of Operation 1031

Drain Fuel Tank 1032

Check and Clean Radiator Fins 1032

Clean and Adjust Cooling Fan V-belt 1032

Check and Adjust the Governor Lever and Engine Speed Control 1033

Clean Air Filter Element 1033

Every 500 Hours of Operation 1033

Replace Air Filter Element 1033

Replace Fuel Filter 1033

Clean Fuel Filter/Water Separator 1033

Replace Engine Oil and Engine Oil Filter 1033

Every 1000 Hours of Operation 1033

Every 1500 Hours of Operation 1033

Inspect, Clean and Test Fuel Injectors 1033

Inspect Crankcase Breather System 1033

Every 2000 Hours of Operation 1034

Check and Replace Fuel Hoses and Engine Coolant Hoses 1034

Lap the Intake and Exhaust Valves 1034

Drain, Flush and Re-fill Cooling System with New Coolant 1034

Periodic Maintenance for LS Engine 1035

Maintenance Schedule 1035

Major Function Inspection 1036

Visual Inspection 1036

Engine Oil 1036

Fuel 1036

Coolant 1037

Cooling Fan V-belt 1037

Periodic Maintenance for KUBOTA Engine 1038

Maintenance Schedule 1039

Periodic Maintenance Procedure 1041

Daily Check 1041

Check engine oil level 1041

Check fuel level 1042

Check coolant level 1043

Antifreeze 1044

Check fan belt 1044

For the air filter with a dust cup (optional) 1045

Dust indicator (optional) 1045

Every 50 Hours of Service 1045

Check fuel pipes and clamp bands 1045

Drain water separator (Type 1) 1045

Every 250 Hours of Service 1046

Precaution at overheating 1046

Clean air filter element 1046

Adjust fan belt tension 1047

Check intake air line 1047

Every 250 Hours or 6 Months of Service 1048

Check radiator hoses and clamp bands 1048

Every 500 Hours of Service 1048

Change engine oil 1048

Replace oil filter cartridge 1048

Replace fuel filter cartridge 1049

Remove sediment in fuel tank 1049

Clean radiator core (Outside) 1049

Clean radiator inside 1049

Replace fan belt 1049

Clean water separator (Type 1) 1049

Every 500 Hours or 1 Year of Service 1049

Replace water separator (Type 2) 1049

Every 1000 Hours of Service 1050

Check valve clearance 1050

Every 1500 Hours of Service 1050

Check injector tip 1050

Check EGR cooler 1050

Change oil separator element 1050

Check PCV valve (Positive Crankcase Ventilation valve) 1050

Check head cover valve 1050

Every 3000 Hours of Service 1050

Check turbo charger 1050

Check EGR system 1050

Every 3000 to 6000 Hours of Service 1050

Clean DPF 1050

Remove ash 1050

Annual Service 1051

Replace air filter element 1051

Check DPF related piping 1051

Check EGR piping 1051

Check intake air line 1051

Check exhaust manifold for cracks or gas leak and for looseness or damage 1051

Check exhaust heating catalyst (EHC) and exhaust throttle valve for cracks or gas leak and for looseness or damage 1051

Check intake air line 1051

Biennial Service 1051

Replace rubber piping related to oil separator 1051

Replace DPF related rubber piping 1051

Replace intake air line and suction airpressure takeout rubber piping 1051

Replace boost sensor pressure rubber piping 1051

Replace EGR cooler rubber piping 1051

Replace water rubber piping 1051

Replace exhaust throttle valve piping 1051

Replace lubricant rubber piping 1051

Change radiator coolant (LLC) 1051

Remedies for quick decrease of coolant 1051

Replace radiator hoses and clampbands 1052

Replace fuel pipes and clamp bands 1052

Replace intake air line 1052

Replace fan belt 1052

Service as required 1052

Drain water separator (Type 2) 1052

Periodic Maintenance For HYUNDAI Engine 1053

Maintenance Schedule 1053

Daily Check 1055

Before starting the Engine 1055

Starting the Engine 1055

Running the Engine 1055

Stopping the Engine 1056

When using the Engine only during a particular period of the year 1056

During in-use period 1056

During out-of-use period 1056

Periodic Maintenance Procedures 1056

Test Fuel System for Leaks 1056

Inspect Engine for Fluid Leaks 1057

Inspect Vacuum Lines and Fittings 1057

Inspect Electrical System 1057

Inspect Foot Pedal Operation 1057

Check Coolant Level 1057

Inspect Coolant Hoses 1057

Inspect Battery System 1057

Inspect Ignition System 1057

Replace Spark Plugs 1057

Replace LP Fuel Filter Element 1057

Test Fuel Lock-off Operation 1058

Pressure Regulator/Converter Inspection 1059

Fuel Trim Valve Inspection (FTV) 1059

Inspect Air/Fuel Valve Mixer Assembly 1059

Inspect for Intake Leaks 1059

Inspect Throttle Assembly 1059

Check the TMAP Sensor 1059

Inspect Engine for Exhaust Leaks 1059

Lift Truck Lifting Capacity 1067

Counterweight Weights 1067

Tire Sizes 1067

Forklift Main Technical Parameters 1068

Main Technical Parameters 1068

Capacities 1084

Recommended Lubricants 1087

Lubricant Specifications 1087

Electrical System 1088

Transmission Oil Pressures 1089

Hydraulic System Relief Pressures 1089

Steering System 1089

Mast Speeds 1090

Tilt Angles 1092

Engine Specifications 1092

Torque Specifications 1102

Frame 1102

Mast 1102

Steering System, Cushioned Tire Trucks 1102

Steering System, Pneumatic Tire Trucks 1102

Drive Axle (Dry Brake) 1102

Transmission – Iron Housing 1102

Engine 1103

Yanmar Engine 1103

LS Engine 1104

Standard Bolt and Nut Tightening Torque 1106

Hyundai Engine 1107

Operator Station General Description and Principles of Operation 1117

General Description and Location 1117

Display Switch Cluster 1118

Dash Display 1118

Control Inputs, Right Side 1120

Control Input, Left Side 1120

Manual Hydraulic Control Levers 1121

General Description 1121

System Components 1121

Lift/Lower 1121

Tilt 1121

Auxiliary 1 1121

Auxiliary 2 1121

Hydraulic Principle of OPS 1122

General 1122

Mast Lowering Function 1123

Mast Tilt Function 1124

Sequential Seatbelt Module 1125

General Description 1125

Seat Switch/Sensor 1125

Seat Belt Switch 1125

Sequential Seatbelt Module 1125

Lighting 1126

Front End, Mast 1126

Description 1126

Carriages 1127

Description 1127

Principles of Operation 1127

Integral Sideshift Carriage 1127

Fork Positioning 1127

Mast Mounts 1128

Description 1128

Principles of Operation 1128

Two-Stage Limited Free-Lift (LFL) Mast 1129

Description 1129

Principles of Operation 1129

Two-Stage Full Free-lift (FFL) Mast 1130

Description 1130

Principles of Operation 1130

Three-Stage Full Free-Lift (FFL) Mast 1132

Description 1132

Principles of Operation 1132

Lift Cylinders 1134

Description 1134

Tilt and Sideshift Cylinders 1136

Description 1136

Tilt Cylinder 1136

Sideshift Cylinder 1136

Lowering Control Valves 1137

Description 1137

Principles of Operation 1137

Chassis 1139

Description 1139

Examination and Maintenance 1140

Leakage of Hydraulic Oil and Transmission Case Oil 1140

Tire Air Pressure (Pneumatic Tire) 1140

Wheel Hub Nut Torque 1141

Overhead Guard 1141

Brake Fluid Level 1141

Coolant Level 1142

Engine Oil Level 1142

Fan Belt Tension Level 1142

Rear Combination Light 1142

Hysdraulic Oil Level 1142

Pipeline Cylinder 1142

Transmission Oil Level 1142

Backrest 1142

Fork and Fork Positioning Pin 1142

Front Headlight and Front Combination Light 1143

Reversing Handle 1143

Multi-way Valve Operating Handle 1143

Parking Brake Operation 1143

Lamplights 1143

Turn Signal 1143

Horn Pushbutton 1143

Idle Stroke of Brake Pedal 1143

Mast Operation 1143

Lifting Chain Tension 1143

Steering Wheel Free Stroke 1143

Exhaust Gas 1144

Inching Pedal (Hydraulic Transmission lift truck) 1144

Brake 1144

Steering Wheel 1144

Parking Brake 1144

Reversing light and Reversing Buzzer 1144

Troubleshooting 1145

Troubleshooting for Functionl systems 1145

Steering System 1145

Wheel Brake 1146

Hydraulic System 1147

Electrical System 1148

Cooling system 1149

Coolant level check 1149

Flushing the cooling system 1149

Adding antifreeze/coolant 1149

Cleaning the radiator 1149

Diagnostic Fault Codes 1149

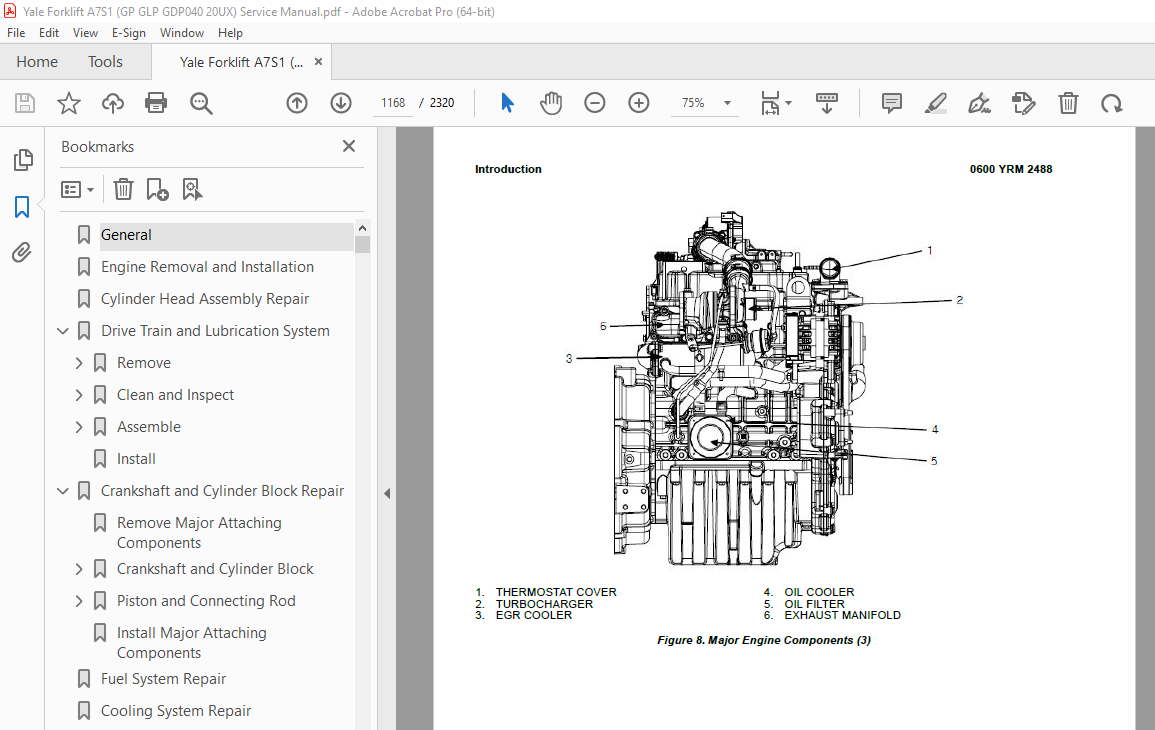

Introduction 1161

Engine Identification 1161

Major engine component identification 1161

L4CRTV4 ENGINE 1161

L3CRTV4 ENGINE 1166

Main Specificaitons 1170

Engine Labels 1172

Engine Repair 1174

Maintenance Data 1174

General Engine Parts Maintenance Data 1174

Lubrication System 1177

Cooling System 1178

Electrical System 1178

Overview for Disassembly and Service 1179

When to Overhaul the Engine 1179

Test Compression Pressure 1179

Preparation and Inspection before Disassembly 1180

Prepare for Disassembly 1180

Disassembly Procedure 1180

Disassembly of Auxiliary Components 1180

Disassembly of Engine Body 1180

Disassembly, Structure, and Inspection of Major Systems 1182

Cylinder Head and Valve 1182

Engine Rear Parts 1183

Moving System 1184

Fuel System 1186

Remove Water from Pre Fuel Filter 1188

Bleed Pre Fuel Filter 1188

Assemble Pre Fuel Filter 1188

Assemble Main Fuel Filter 1189

Lubrication System 1191

Disassemble and Inspect Oil Filter, Relief Valve, Oil Cooler 1191

Lubrication System Description 1192

Disassemble and Inspect Oil Pump 1192

Disassembly Order 1194

Relief Valve 1194

Oil Pump 1194

Cooling System 1196

Disassemble and Inspect Cooling Fan, Fan Pulley, V-belt 1196

Disassemble and Adjust V-belt Tension 1197

Inspect V-belt 1197

Adjust V-belt Tension 1197

Inspect Water Pump 1197

Inspect Thermostat 1198

Electrical System 1199

Inspection before Starter Disassembly 1199

Inspect Magnetic Switch 1199

Continuity Test between Terminals S and M (Pull-in Test) 1199

Continuity Test between Terminal S and Start Motor Body (Holding Test) 1199

Continuity Test between Terminal M and Start Motor Body (Return Test) 1199

Test at No Load 1199

Disassemble and Inspect Starter 1200

Pinion Set Disassembly 1202

Magnetic Switch Disassembly 1203

Rear Bracket Disassembly 1203

Brush Holder and Brush Disassembly 1203

Armature and Yoke Disassembly 1203

Overrunning Clutch Disassembly 1204

Inspect and Repair Starter 1204

Inspect Magnetic Switch Coil 1204

Check Brush for Wear 1204

Inspect Brush Spring Load 1205

Inspect Brush Holder for Insulation 1205

Inspect Yoke Assembly for Conduction 1205

Measure Commutator O D (Outside Diameter) 1205

Commutator Runout – Check and Measure 1206

Commutator Undercut Depth – Measure 1206

Inspect Front Bracket 1206

Inspect Armature Coil 1206

Inspect Rear Bracket 1207

Inspect Overrunning Clutch 1207

Inspect Starter Gear 1207

Starter Assembly 1207

Disassemble and Inspect Alternator 1208

Measuring Alternator Output Voltage with Engine Running (With Ignition (I) and Indicator (L) Wires Connected to Regulator) 1210

No Indicator Illumination before Running Engine (Key ON ) 1210

Indicator Illuminated with Engine Running 1211

Stator 1211

Conduction between Lead Wires (Stator Conductive) 1211

Insulation between Lead Wire and Core (Coil Ground) 1211

Rotor 1211

Important Parts Inspect and Repair 1212

Piston 1212

Measure Piston O D 1212

Inspect Piston and Piston Ring 1212

Measure Piston Ring End Gap 1213

Measure Pin Hole and Piston Pin 1213

Measure Clearance between Connecting Rod Bushing and Piston Pin 1214

Measure Twist of Connecting Rod 1215

Inspect Big End of the Connecting 1215

Crankshaft 1215

Inspect Main Bearing Oil Clearance 1216

Measure the Crankshaft Deflection 1217

Assemble the Crankshaft Gear 1218

Assemble the Drive Gear 1218

Crankcase 1218

Measure Cylinder I D 1218

Boring the Cylinder 1219

Tappet 1220

Inspect the Mating Surface with the Tappet and Cam 1220

Install the Rear Oil Seal 1220

Install the Flywheel Housing 1220

Install the Flywheel 1221

Clean the Cylinder Head Bottom Surface 1221

Install the Stem Seal 1222

Install the Valve and Valve Spring 1222

Inspect and Repair Cylinder Head and Valve Mechanism 1222

Clearance between the Bushing and Rocker Shaft 1222

Inspect Valve Face 1223

Lap the Valve and Valve Seat 1224

Measure the Squareness and Free Length of Valve Spring 1225

Measure the Distortion of Cylinder Head Bottom Surface 1225

Measure Each Gear Play 1226

Measure the Idle Gear End Play 1226

Measure the Camshaft End Play 1226

Measure the Camshaft 1227

Measure the Camshaft Lift 1227

Measure the Camshaft Journal O D and Camshaft Journal Hole I D 1227

Measure the Camshaft Deflection 1227

Remove the Camshaft Gear 1228

Assemble the Camshaft Gear and Thrust Plate 1228

Engine Components Disassembly 1228

Engine Oil 1228

Exhaust Connector 1229

Electrical Components 1229

Fuel System 1229

Cooling System 1230

Intake and Hose and Pipe 1230

EGR Pipe 1230

ACV (Air Mass Flow) 1230

Fuel Pipe 1231

Return Hose 1231

Injector Clamp 1231

Injector 1231

Glow Plug 1231

Common Rail 1232

EGR Valve 1232

Intake Manifold 1232

Turbocharger 1232

EGR Cooler 1232

Exhaust Manifold 1233

Rocker Arm Cover 1233

Rocker Arm Shaft Assembly 1233

Cylinder Head 1233

Flywheel 1234

Flywheel Housing 1234

Crankshaft V-Pully 1234

Timing Gear Case Front (FR) 1234

Hydraulic Pump Drive Gear 1235

Idle Gear (A) 1235

High Pressure Pump Gear 1235

High Pressure Pump 1235

Idle Gear (B) 1236

Oil Pump Assembly 1236

Camshaft Assembly 1236

Rear Gear Case 1236

Oil Pan Assembly 1237

Piston and Connecting Rod Assembly 1237

Crankshaft Assembly 1237

Tappet and Piston Cooling Jet 1238

Engine Components Assembly 1238

Precaution Before Assembly 1238

Install Crankcase 1238

Install Piston Cooling Jet 1239

Crankshaft Assembly 1239

Install Crankshaft Sub-assembly 1239

Install Crankshaft 1239

Install Crankshaft Piston Sensor 1240

Piston Assembly and Connecting Rod 1240

Install Piston Sub-assembly 1240

Install Connecting Rod Sub-assembly 1241

Install Piston Assembly and Connecting Rod 1241

Install Piston Assembly and Connecting Rod 1242

Oil Pan Assembly 1242

Install Oil Strainer Sub-assembly 1242

Install Oil Pan 1243

Install Rear Gear Case 1243

Camshaft Assembly 1244

Oil Pump Assembly 1245

Install Idle Gear (B) 1245

Install High-pressure Pump 1246

Install High-pressure Pump Gear 1246

Install Idle Gear (A) 1246

Install Hydraulic Pump Drive Gear 1247

Install Front Gear Case 1247

Install Camshaft Position Sensor 1247

Install Oil Filler 1247

Install Crankshaft V-pulley 1248

Install Flywheel Housing 1248

Install Flywheel 1248

Cylinder Head 1249

Install Cylinder Head Sub-assembly 1249

Install Cylinder Head 1249

Install Push Rod 1250

Install Rocker Shaft Assembly 1250

Adjust Valve Clearance 1251

Check Cylinder No 1 Top Dead Center (TDC) on Compression Stroke 1251

Adjust Valve Clearance 1251

Adjust Four-cylinder Engine 1252

Adjust Three-cylinder Engine 1252

Install Rocker Arm Cover 1253

Install Exhaust Manifold 1253

Install Exhaust Gas Recirculation (EGR) Cooler 1253

Install Turbocharger 1254

Install Turbocharger Lubrication Pipe 1254

Install Intake Manifold 1254

Install EGR Valve 1255

Install Common Rail 1255

Install Glow Plug 1255

Install Injector 1255

Install Injector Clamp 1256

Install Return Hose 1256

Fuel Pipe 1256

Install Fuel Pipe 1256

ACV 1257

Install EGR Passage and EGR Pipe B 1257

Install Injector Wiring 1257

Install Intake Hose and Pipe 1257

Fuel Filter 1258

Install Knock Sensor 1258

Assemble the Water Pump Assembly 1258

Thermostat and Cover 1258

Install EGR Cooler and Oil Cooler Hose 1259

Install Alternator 1259

Install Cooling Fan Pully and V-belt 1259

Install Starter 1259

Install Exhaust Connection (Option) 1260

Install Oil Cooler and Oil Filter 1260

Install Oil Guage and Oil Drain Bolt 1260

Replenish Oil 1260

Install Sensor 1261

Install Intake Pressure (P2) Sensor 1261

Install Intake Temperature (T2) Sensor 1261

Install Exhaust Temperature (T3) Sensor 1261

Install DPF Temperature (T5) Sensor 1261

Install Coolant Temperature Sensor 1262

Install Oil Pressure Switch 1262

Install Differential Pressure Sensor 1262

Install Mass Air Flow (MAF) Sensor 1263

Appendix 1264

Special Tools 1264

General 1275

Engine Identification 1275

Precautions for maintenance operation 1275

Removal, Disassembling 1275

Special service tools 1275

Replacement parts 1275

Replacement parts 1276

Connection 1276

Rubber parts and tubes 1276

Checking the cables and wiring 1276

Electrical System Checking 1277

Check Fuses 1277

Inspect the Electrical System 1277

Engine Removal and Installation 1280

Cylinder Head Assembly Repair 1281

Cylinder Head Assembly 1281

Removal and Disassembly 1282

Inspection 1285

Cylinder head 1285

Valve and valve springs 1285

MLA 1286

Camshaft 1287

Reassembly 1288

Compression Test 1291

Valve Clearance Adjustments 1292

Intake manifold 1295

Removal 1297

Installation 1297

Exhaust manifold 1298

Removal 1300

Installation 1300

Timing Gear Case and Timing Gears Repair 1301

Timing Gear Case Cover 1301

Remove 1301

Clean and Inspect 1301

Install 1301

Timing Gears 1302

Remove 1305

Inspection 1307

Sprocket, Chain tensioner, Chain guide, Chain tensioner arm 1307

Belt, Idler, Belt tensioner, Pulley 1307

Installation 1307

Drive Train, Flywheel and Cylinder Block Repair 1312

Remove 1312

Inspection 1316

Connecting rod and Crankshaft 1316

Cylinder block 1322

Piston and piston rings 1323

Piston pin 1325

Installation 1325

Lubrication System Repair 1331

Engine Oil and Oil Filter Change 1331

Removal 1331

Inspection 1331

Selection of Engine Oil 1332

Oil Pump 1332

Removal 1332

Inspection 1333

Installation 1333

Cooling System Repair 1335

Water pump 1338

Removal 1338

Installation 1338

Inspection 1338

Thermostat 1339

Removal 1339

Inspection 1339

Installation 1340

Water pump troubleshooting 1341

Electrical Equipment Repair 1343

Engine Electrical System 1343

Specification 1343

Troubleshooting 1344

Ignition system 1346

Description 1346

Removal and Installation 1346

Ignition coil 1346

Inspection 1346

Spark test procedure 1347

Inspect spark plug 1347

Ignition coil Inspection 1348

Charging system 1348

Description 1348

Inspection 1349

Battery voltage inspection 1349

Check for Drive belt 1349

Check for alternator wiring and abnormal noises 1349

Check for discharge warning light circuit 1349

Check for charging system 1350

Output Current test 1350

Regulated voltage test 1351

Alternator 1352

Disassembly and Reassembly 1354

Inspection 1355

Battery 1355

Battery diagnostic test (1) 1355

Load test 1356

Battery diagnostic test (2) 1356

Starting system 1357

Description 1357

Starter circuit troubleshooting 1357

Starter motor solenoid inspection 1357

Performance test (Free running test) 1359

Starter Components 1360

Disassembly and reassembly 1360

Inspection 1363

Electrical Control System 1366

Basic inspection procedure 1366

Resistance inspection conditions 1366

Intermittent problem inspection 1366

Simulation (I) – Vibration 1366

Simulation (II) – Heat 1366

Simulation (III) – Moisture (Water) 1366

Simulation (IV) – Electrical load 1366

Connector inspection procedure 1367

Wire harness inspection procedure 1368

Electrical circuit inspection procedure 1368

Short circuit 1369

Troubleshooting 1370

Input/Output signal 1372

MAP sensor (Manifold Absolute Pressure) 1373

Intake Air Temperature Sensor (ITS) 1375

Engine Coolant Temperature Sensor (ECTS) 1378

Oxygen sensor (HO2S) 1380

Description 1380

Function and Roles 1380

Inspect Connectors and Terminals 1381

Inspect component 1381

Knock sensor (KS) 1382

Description 1382

Crankshaft Position Sensor (CKPS) 1383

Description and Functions 1383

Camshaft Position Sensor (CMPS) 1385

Description 1385

Injector 1386

Description 1387

Functions and Roles 1387

Inspection 1388

Removal 1389

Residual fuel removal procedure 1389

Installation 1390

Assembly 1390

Cleaning 1390

Icing tube 1391

Engine Specifications 1392

Standard Torque Specifications 1397

Special Torque Specification 1398

Troubleshooting 1400

Special Tools 1403

Engine Troubleshooting Guide 1429

LS Engine Troubleshooting Guide 1429

Abnormal Situation and Solution 1429

Diagnostic System 1432

Components (LS Stage V ScanTool) 1432

Diagnostic System Installation Layout (LS Stage V ScanTool) 1432

Fault Code Table 1433

Fault code P0401 1439

Truck Behavior 1439

Circuit and connector diagrams 1439

Troubleshooting procedure 1441

Component locators 1442

Fault code P0402 1443

Truck behavior 1443

Circuit and connector diagrams 1443

Troubleshooting procedure 1445

Component locators 1446

Fault code P0403 1447

Truck Behavior 1447

Circuit and connector diagrams 1447

Troubleshooting procedure 1450

Fault code P0404 1451

Truck Behavior 1451

Circuit and connector diagrams 1451

Troubleshooting procedure 1453

Fault code P0406 1456

Truck behavior 1456

Circuit and connector diagrams 1456

Troubleshooting procedure 1458

Component locators 1458

Fault code P0407 1460

Truck behavior 1460

Circuit and connector diagrams 1460

Troubleshooting procedure 1462

Component locators 1462

Fault code P046D 1464

Truck Behaviour 1464

Circuit and connector diagrams 1464

Troubleshooting procedure 1467

Fault code P0C18 1469

Truck behavior 1469

Circuit and connector diagrams 1469

Troubleshooting procedure 1471

Component locators 1471

Fault code P060E 1473

Truck behavior 1473

Circuit and connector diagrams 1473

Troubleshooting procedure 1477

Fault code P060F 1478

Truck behavior 1478

Circuit and connector diagrams 1478

Troubleshooting procedure 1482

Fault code P2120 1483

Truck behavior 1483

Circuit and connector diagrams 1483

Troubleshooting procedure 1487

Fault code P2125 1488

Truck behavior 1488

Circuit and connector diagrams 1488

Troubleshooting procedure 1492

Fault code P2138 1493

Truck behavior 1493

Circuit and connector diagrams 1493

Troubleshooting procedure 1497

Fault code P02E0 1498

Truck behavior 1498

Circuit and connector diagrams 1498

Troubleshooting procedure 1501

Fault code P02E1 1502

Truck behavior 1502

Circuit and connector diagrams 1502

Troubleshooting procedure 1505

Fault code P02E2 1506

Truck behavior 1506

Circuit and connector diagrams 1506

Troubleshooting procedure 1509

Fault code P02E3 1510

Truck behavior 1510

Circuit and connector diagrams 1510

Troubleshooting procedure 1513

Fault code P02E7 1514

Truck behavior 1514

Circuit and connector diagrams 1514

Troubleshooting procedure 1517

Fault code P02E8 1518

Truck behavior 1518

Circuit and connector diagrams 1518

Troubleshooting procedure 1521

Fault code P02E9 1522

Truck behavior 1522

Circuit and connector diagrams 1522

Troubleshooting procedure 1525

Fault code P02EB 1526

Truck behavior 1526

Circuit and connector diagrams 1526

Troubleshooting procedure 1529

Fault code P02FA 1530

Truck behavior 1530

Circuit and connector diagrams 1530

Troubleshooting procedure 1533

Fault Code P242F 1534

Truck behavior 1534

DOC/DPF and Exhaust system diagrams 1534

Troubleshooting procedure 1536

Fault Code P2458 1537

Truck behavior 1537

DOC/DPF and Exhaust system diagrams 1537

Troubleshooting procedure 1539

Fault Code P2463 1540

Truck behavior 1540

DOC/DPF and Exhaust system diagrams 1540

Troubleshooting procedure 1542

Fault code P0120 1543

Truck behavior 1543

Circuit and connector diagrams 1543

Troubleshooting procedure 1547

Fault code P0220 1548

Truck behavior 1548

Circuit and connector diagrams 1548

Troubleshooting procedure 1552

Fault code P060C 1553

Truck behavior 1553

Circuit and connector diagrams 1553

Troubleshooting procedure 1557

Fault code P060D 1558

Truck behavior 1558

Circuit and connector diagrams 1558

Troubleshooting procedure 1562

Fault code P2135 1563

Truck behavior 1563

Circuit and connector diagrams 1563

Troubleshooting procedure 1567

Fault Code P0088 1568

Truck behavior 1568

Circuit and connector diagrams 1568

Troubleshooting procedure 1571

Fault Code P2264 1573

Truck behavior 1573

Circuit and connector diagrams 1573

Troubleshooting procedure 1576

Fault Code P2269 1577

Truck behavior 1577

Circuit and connector diagrams 1577

Troubleshooting procedure 1580

Fault Code P0522 1581

Truck behavior 1581

Circuit and connector diagrams 1581

Troubleshooting procedure 1583

Fault code P0111 1584

Truck Behavior 1584

Circuit and connector diagrams 1584

Troubleshooting procedure 1586

Component locators 1587

Fault code P0112 1588

Truck Behavior 1588

Circuit and connector diagrams 1588

Troubleshooting procedure 1590

Component locators 1591

Fault code P0113 1592

Truck Behavior 1592

Circuit and connector diagrams 1592

Troubleshooting procedure 1594

Component locators 1594

Fault code P0114 1596

Truck Behavior 1596

Circuit and connector diagrams 1596

Troubleshooting procedure 1598

Component locators 1598

Fault code P0106 1600

Truck Behavior 1600

Circuit and connector diagrams 1600

Troubleshooting procedure 1602

Component locators 1603

Fault code P0107 1604

Truck Behavior 1604

Circuit and connector diagrams 1604

Troubleshooting procedure 1606

Component locators 1607

Fault code P0108 1608

Truck Behavior 1608

Circuit and connector diagrams 1608

Troubleshooting procedure 1610

Component locators 1611

Fault code P2228 1612

Truck Behavior 1612

Circuit and connector diagrams 1612

Troubleshooting procedure 1613

Component locators 1613

Fault code P2229 1614

Truck Behavior 1614

Circuit and connector diagrams 1614

Troubleshooting procedure 1615

Component locators 1615

Fault code P0115 1616

Truck Behavior 1616

Circuit and connector diagrams 1616

Troubleshooting procedure 1618

Component locators 1619

Fault code P0116 1621

Truck Behavior 1621

Circuit and connector diagrams 1621

Troubleshooting procedure 1623

Component locators 1624

Fault code P0117 1626

Truck Behavior 1626

Circuit and connector diagrams 1626

Troubleshooting procedure 1628

Component locators 1629

Fault code P0118 1631

Truck Behavior 1631

Circuit and connector diagrams 1631

Troubleshooting procedure 1633

Component locators 1634

Fault code P0119 1636

Truck Behavior 1636

Circuit and connector diagrams 1636

Troubleshooting procedure 1638

Component locators 1639

Fault code P0100 1641

Truck Behavior 1641

Circuit and connector diagrams 1641

Troubleshooting procedure 1643

Component locators 1645

Fault code P0101 1646

Truck Behavior 1646

Circuit and connector diagrams 1646

Troubleshooting procedure 1648

Component locators 1650

Fault code P0102 1651

Truck Behavior 1651

Circuit and connector diagrams 1651

Troubleshooting procedure 1653

Component locators 1655

Fault code P0103 1656

Truck Behavior 1656

Circuit and connector diagrams 1656

Troubleshooting procedure 1658

Component locators 1659

Fault code P0087 1661

Truck Behavior 1661

Circuit and connector diagrams 1661

Troubleshooting procedure 1664

Component locators 1664

Fault code P0089 1666

Truck Behavior 1666

Circuit and connector diagrams 1666

Troubleshooting procedure 1669

Component locators 1669

Fault code P0093 1671

Truck Behavior 1671

Circuit and connector diagrams 1671

Troubleshooting procedure 1673

Component locators 1673

Fault code P0190 1674

Truck Behavior 1674

Circuit and connector diagrams 1674

Troubleshooting procedure 1676

Component locators 1676

Fault code P0191 1677

Truck Behavior 1677

Circuit and connector diagrams 1677

Troubleshooting procedure 1679

Component locators 1679

Fault code P0192 1680

Truck Behavior 1680

Circuit and connector diagrams 1680

Troubleshooting procedure 1682

Component locators 1682

Fault code P0193 1683

Truck Behavior 1683

Circuit and connector diagrams 1683

Troubleshooting procedure 1685

Component locators 1685

Fault code P0562 1686

Truck Behavior 1686

Circuit and connector diagrams 1686

Troubleshooting procedure 1688

Fault code P0563 1689

Truck Behavior 1689

Circuit and connector diagrams 1689

Troubleshooting procedure 1691

Fault code P0072 1692

Truck Behavior 1692

Circuit and connector diagrams 1692

Troubleshooting procedure 1695

Component locators 1696

Fault code P0073 1697

Truck Behavior 1697

Circuit and connector diagrams 1697

Troubleshooting procedure 1700

Component locators 1701

Fault code P0074 1702

Truck Behavior 1702

Circuit and connector diagrams 1702

Troubleshooting procedure 1705

Component locators 1706

Fault code P242A 1707

Truck Behavior 1707

Circuit and connector diagrams 1707

Troubleshooting procedure 1709

Component locators 1710

Fault code P242B 1711

Truck Behavior 1711

Circuit and connector diagrams 1711

Troubleshooting procedure 1713

Component locators 1714

Fault code P242C 1715

Truck Behavior 1715

Circuit and connector diagrams 1715

Troubleshooting procedure 1717

Component locators 1718

Fault code P242D 1719

Truck Behavior 1719

Circuit and connector diagrams 1719

Troubleshooting procedure 1721

Component locators 1722

Fault code P242E 1723

Truck Behavior 1723

Circuit and connector diagrams 1723

Troubleshooting procedure 1725

Component locators 1726

Fault code P0181 1727

Truck Behavior 1727

Circuit and connector diagrams 1727

Troubleshooting procedure 1729

Component locators 1729

Fault code P0182 1731

Truck Behavior 1731

Circuit and connector diagrams 1731

Troubleshooting procedure 1733

Component locators 1734

Fault code P0183 1736

Truck Behavior 1736

Circuit and connector diagrams 1736

Troubleshooting procedure 1738

Component locators 1739

Fault code P060B 1741

Truck behavior 1741

ECU position and Shape 1741

Troubleshooting procedure 1744

Fault code P0602 1746

Truck Behavior 1746

Troubleshooting procedure 1746

Component Locators 1746

Injector Change and Code Saving 1747

Fault code P0603 1748

Truck behavior 1748

Circuit and Connector Diagrams 1748

Troubleshooting procedure 1750

Component Locators 1750

Fault code P0604 1751

Truck behavior 1751

Circuit and Connector Diagrams 1751

Troubleshooting procedure 1753

Component Locators 1753

Fault code P0605 1754

Truck behavior 1754

Circuit and Connector Diagrams 1754

Troubleshooting procedure 1756

Component Locators 1756

Fault code P062F 1757

Truck behavior 1757

Circuit and Connector Diagrams 1757

Troubleshooting procedure 1759

Component Locators 1759

Fault code P0335 1760

Truck Behavior 1760

Circuit and connector diagrams 1760

Troubleshooting procedure 1763

Component locators 1765

Fault code P0371 1766

Truck Behavior 1766

Circuit and connector diagrams 1766

Troubleshooting procedure 1768

Component locators 1770

Fault code P0372 1771

Truck Behavior 1771

Circuit and connector diagrams 1771

Troubleshooting procedure 1773

Component locators 1775

Fault code P0374 1776

Truck Behavior 1776

Circuit and connector diagrams 1776

Troubleshooting procedure 1778

Component locators 1780

Fault code P0340 1781

Truck Behavior 1781

Circuit and connector diagrams 1781

Troubleshooting procedure 1783

Component locators 1785

Fault code P0341 1786

Truck Behavior 1786

Circuit and connector diagrams 1786

Troubleshooting procedure 1788

Component locators 1790

Fault code P0201 1791

Truck Behavior 1791

Circuit and connector diagrams 1791

Troubleshooting procedure 1792

Component Locators 1793

Injector change and code saving 1794

Fault code P0261 1795

Truck Behavior 1795

Circuit and connector diagrams 1795

Troubleshooting procedure 1797

Component Locators 1797

Injector change and code saving 1798

Fault code P0262 1799

Truck Behavior 1799

Circuit and connector diagrams 1799

Troubleshooting procedure 1801

Component Locators 1801

Injector change and code saving 1802

Fault code P029A 1803

Truck Behaviour 1803

Circuit and connector diagrams 1803

Troubleshooting procedure 1806

Fault code P029B 1808

Truck Behaviour 1808

Circuit and connector diagrams 1808

Troubleshooting procedure 1811

Fault code P0202 1813

Truck Behavior 1813

Circuit and connector diagrams 1813

Troubleshooting procedure 1814

Component Locators 1815

Injector change and code saving 1816

Fault code P0264 1817

Truck Behavior 1817

Circuit and connector diagrams 1817

Troubleshooting procedure 1819

Component Locators 1819

Injector change and code saving 1820

Fault code P0265 1821

Truck Behavior 1821

Circuit and connector diagrams 1821

Troubleshooting procedure 1823

Component Locators 1823

Injector change and code saving 1824

Fault code P029E 1825

Truck Behaviour 1825

Circuit and connector diagrams 1825

Troubleshooting procedure 1828

Fault code P029F 1830

Truck Behaviour 1830

Circuit and connector diagrams 1830

Troubleshooting procedure 1833

Fault code P0203 1835

Truck Behavior 1835

Circuit and connector diagrams 1835

Troubleshooting procedure 1836

Component Locators 1837

Injector change and code saving 1838

Fault code P0267 1839

Truck Behavior 1839

Circuit and connector diagrams 1839

Troubleshooting procedure 1841

Component Locators 1841

Injector change and code saving 1842

Fault code P0268 1843

Truck Behavior 1843

Circuit and connector diagrams 1843

Troubleshooting procedure 1845

Component Locators 1845

Injector change and code saving 1846

Fault code P02A2 1847

Truck behavior 1847

Circuit and connector diagrams 1847

Troubleshooting procedure 1850

Fault code P02A3 1852

Truck Behaviour 1852

Circuit and connector diagrams 1852

Troubleshooting procedure 1855

Fault code P0204 1857

Truck Behavior 1857

Circuit and connector diagrams 1857

Troubleshooting procedure 1859

Component Locators 1859

Injector change and code saving 1860

Fault code P0270 1861

Truck Behavior 1861

Circuit and connector diagrams 1861

Troubleshooting procedure 1863

Component Locators 1863

Injector change and code saving 1864

Fault code P0271 1865

Truck Behavior 1865

Circuit and connector diagrams 1865

Troubleshooting procedure 1867

Component Locators 1867

Injector change and code saving 1868

Fault code P02A6 1869

Truck Behaviour 1869

Circuit and connector diagrams 1869

Troubleshooting procedure 1872

Fault code P02A7 1874

TRUCK BEHAVIOR 1874

Circuit and connector diagrams 1874

Troubleshooting procedure 1877

Fault code P2687 1879

Truck Behavior 1879

Circuit and connector diagrams 1879

Troubleshooting procedure 1881

Fault code P0380 1882

Truck Behavior 1882

Circuit and connector diagrams 1882

Troubleshooting procedure 1885

Fault code P0383 1886

Truck Behavior 1886

Circuit and connector diagrams 1886

Troubleshooting procedure 1889

Fault code P0384 1890

Truck Behavior 1890

Circuit and connector diagrams 1890

Troubleshooting procedure 1893

Fault code P0615 1894