$36.95

Yale Forklift A7S6 (GP080UX, GP090UX, GP100UX) Service Manual PDF

Yale Forklift A7S6 (GP080UX, GP090UX, GP100UX) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A7S6 (GP080UX, GP090UX, GP100UX) Service Manual – PDF DOWNLOAD

Language : English

Pages : 620

Downloadable : Yes

File Type : PDF

PART NO. 550253238

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A7S6 (GP080UX, GP090UX, GP100UX) Service Manual – PDF DOWNLOAD

550253238 8000YRM2398 (07 2023) US EN 1

Forklift Truck Main Parts 9

Description of Forklift Truck Main Parts 9

Forklift Main Technical Parameters 10

Main Technical Parameters 10

Power System 26

Engine System 26

Engine Overview 26

Inspection 36

Operate Mitsubishi Engine 36

Precautions before the Operation 36

Engine Adjustment 37

Engine Fault Codes 38

Fuel System 47

Fuel Tank 47

Fuel Level Sensor 50

Maintenance of Fuel System 50

Fuel Filter For Gas-Fueled Truck 50

Fuel Filter For Diesel-Fueled Truck 50

Fuel-Water Separator (Sediment Bowl) 51

Clean Fuel Tank 51

Maintenance of the Air Filter 51

Hydraulic Transmission Case and Torque Converter 52

Overview 54

Torque Converter 54

Hydraulic Clutch Unit 55

Control Valve 55

Transmission Case 56

Transmission Pump 56

Transmission Hydraulic Schematic 56

Speed Differential 59

Towing of Forklift Truck to be Repaired 60

Oil Inlet/Outlet Connection Location 60

Precautions in case of forklift failure 61

Trouble Shooting 61

Oil Port 64

Drive Axle 66

4-5T 66

5-7T 67

Steering System 74

Steering Axle 78

Brake System 82

Overview 83

Brake Master Cylinder 83

Wheel Brake 84

Automatic Clearance Regulator 85

Manual Brake 85

Adjustment of Brake Pedal 86

Maintenance 86

Disassemble, Wheel Brake 86

Inspect 88

Assemble, Wheel Brake 88

Test Automatic Clearance Regulator 90

Troubleshoot Wheel Brake 92

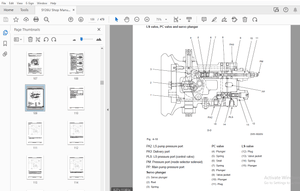

Hydraulic System 93

Main Pump 95

Multi-way Valve 95

Operation of Spool Valve 95

Primary Relief Valve 96

Steering relief valve 96

Action of Inclined Auto-lock Valve 97

Control Levers of Multi-way Control Valve 98

Hydraulic Oil Tank 98

Hydraulic System Main Oil Circuit 98

Lift Cylinder 102

Shut-off Valve 103

Speed Limit Valve 104

Tilting Cylinder 105

Main Oil Pump 105

Disassemble, Main Oil Pump 105

Assemble, Oil Pump 110

Test 110

Oil Filling Instructions 111

General Inspection Requirements 111

Inspection 111

Fill Level Requirements 111

Troubleshoot Hydraulic System 112

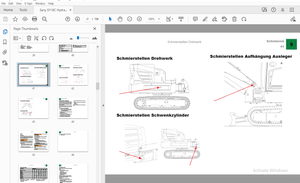

Lifting System 113

Inside and Outside Masts 114

Bracket 114

Safety Procedures When Working Near Mast 115

Adjustment for Lifting System 117

Lifting Cylinder 117

Carriage 117

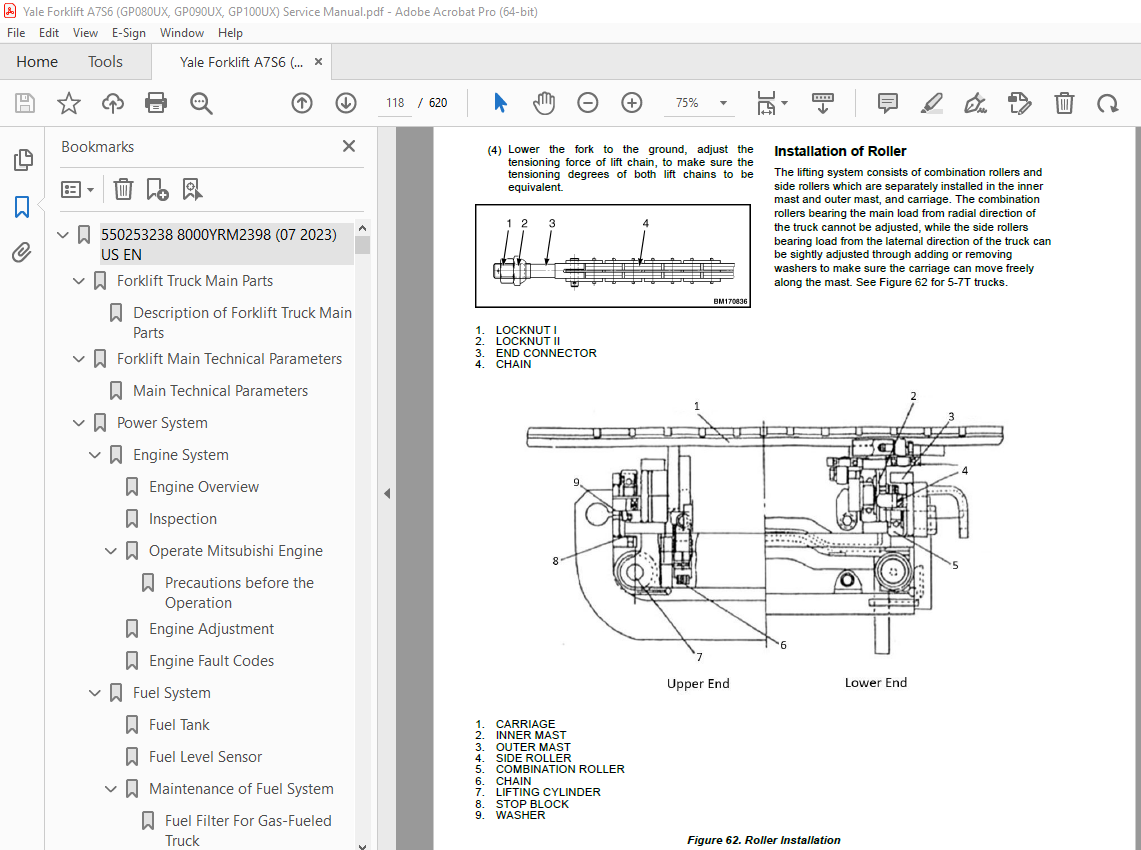

Installation of Roller 118

Electrical System 120

Overview 120

Truck Operations 120

Start and Stop 120

Driving Operations 121

Combination Switch 121

Horn Button 121

Reverse Light and Signal 121

Light Controls 121

Steering Signal 121

Brake Signal 122

Dash Display 122

Introduction to PDM 127

Battery 127

Truck Safety System (OPS/Park Brake Alarm System) 128

Overview 128

Truck Will Not Start 129

Lift, Lowering and Tilt Functions are not Working 129

Forward and Back Functions are not Working 130

USB 130

Electrical Schematics 130

Troubleshoot with Electrical System 141

Diesel Particulate Filter (DPF) Regeneration Control (Only for the Trucks Equipped with Kubota V3800 Engine) 142

DPF Status 142

DPF Operation Instructions 143

DPF System Status Transiton 143

DPF Indicator Status 145

Drive, Operation, and Routine Maintenance of Forklift Truck 147

Transporting the Forklift Truck 147

Towing 147

Long-Term Storage of Forklift Truck 147

Procedures Prior to Operation 148

Precautions for Use 148

Cooling System 149

Oils Used for Forklift Truck 149

Hydraulic Oil Gauge Clarification and Oil Filling Instruction 152

General inspection requirements 152

Inspection method 152

Technical Requirements for filling Hydraulic Oil reservoir 152

Periodical Maintenance 153

550277201 0100YRM5001 (09 2023) US EN 181

General 187

Description 188

Hood, Seat, Floor Plate and Covers Replacement 190

Disassemble (4-5T Trucks) 190

Re-assemble 196

Steering Column 197

Description 197

Steering Column Repair 197

Disassemble 197

Disassemble Steering Hoses 199

Clean 200

Inspect 200

Re-assemble 200

Counterweight Replacement 201

Remove (4-5T Trucks) 201

Remove (5-7T Trucks) 203

Install (4-5T Trucks) 205

Install (5-7T Trucks) 205

Overhead Guard Replacement 206

Remove and Install 206

Operator Restraint System Replacement 209

Description 209

Emergency Locking Retractor (ELR) 209

Engine and Transmission Replacement 210

Remove 210

Disassemble (4-5T Trucks) 210

Disassemble (5-7T Trucks) 211

Re-assemble (4-5T Trucks) 213

Re-assemble (5-7T Trucks) 213

Exhaust System Repair 214

Remove and Disassemble Exhaust System 214

Inspect 214

Re-assemble Exhaust System 214

Cooling System 215

Description 215

Hydraulic Filter Assembly Repair 216

Disassemble 216

Clean and Inspect 217

Re-assemble 218

Fuel and Hydraulic Tanks Repair 219

Inspect 219

Clean 219

Steam Method of Cleaning 219

Chemical Solution Method of Cleaning 220

Additional Preparations for Repair 221

Small Leaks, Repair 221

Large Leaks, Repair 221

Preparations for Use After Repair 221

Safety Labels 222

550277203 0700YRM5003 (08 2023) US EN 227

General 233

Cooling System Checks 233

Water Flow Restrictions in Radiator 233

Radiator Hoses 233

Water Pump 233

Flushing the Cooling System 234

Cooling System, Clean 234

Radiator Replacement (4-5T Trucks) 236

Remove Radiator 236

Install Radiator 240

Radiator Replacement (5-7T Trucks) 241

Remove Radiator 241

Install Radiator 245

Fan Assembly Replacement 246

Fan Removal 246

Inspect 247

Fan Installation 247

550277204 0900YRM5004 (07 2023) US EN 249

Air-Intake and Exhaust System 255

Air-Intake and Exhaust System (Mitsubishi S6S and Mitsubishi S6S-T Engine) 255

Remove 255

Inspect 255

Install 255

Air-intake System (Kubota Engine) 257

Remove 257

Install 257

LPG Tank and Bracket Replacement with Swing-Out Bracket (Kubota WG3800 Engine) 258

Remove LPG Tank 258

Install LPG Tank 259

Remove LPG Bracket 259

Install LPG Bracket 260

Fuel Filter and Fuel Level Sensor Repair 261

FUEL FILTER ELEMENT (4-5T Trucks) 261

Remove 261

Install (4-5T Trucks) 262

Fuel Level Sensor (4-5T Trucks) 262

Remove (4-5T Trucks) 262

Install (4-5T Trucks) 262

FUEL FILTER ELEMENT (5-7T Trucks) 262

Remove 262

Install (5-7T Trucks) 263

Fuel Level Sensor (5-7T Trucks) 263

Remove (5-7T Trucks) 263

Install (5-7T Trucks) 263

LPG Converter (Kubota WG3800 Dual Fuel Engine) 264

Remove 264

Exhaust System 267

Remove (4-5T Trucks) 267

Install (4-5T Trucks) 269

Remove (5-7T Trucks) 273

Install (5-7T Trucks) 278

550286759 1300YRM5005 (07 2023) US EN 281

General 287

Serial Number 288

Transmission 289

Remove and Install 289

Remove 289

Remove Transmission 289

Remove Torque Converter 291

Remove Speed Differential 291

Remove Speed Reducer 292

Disassemble Output Shaft 292

Remove Control Valve and Solenoid Valve 298

Remove Transmission Box 298

Remove Clutch I 298

Remove Clutch II 300

Remove Torque Converter Housing 302

Remove Torque Converter 302

Installation 302

Install Torque Converter 302

Install Clutch I 302

Install Clutch II 303

Install Torque Converter Housing 303

Install Transmission Box 303

Install Speed Differential 303

Re-assemble Output Shaft 303

Install Speed Reducer 303

Install Control Valve and Solenoid Valve 303

Install Torque Converter 304

Clean and Inspect 304

Pedal 305

Remove and Install 305

Remove Pedal 305

Install Pedal 306

Clean and Inspect 306

550286760 1400YRM5006 (07 2023) US EN 309

General 315

Drive Axle Repair 315

Remove and Disassemble 315

Clean and Inspect 320

Re-assemble and Install 320

550286761 1600YRM5007 (09 2023) US EN 323

General 329

Steering Axle Assembly Repair 331

Remove 331

Disassemble (4-5T Trucks) 332

Disassemble (5-7T Trucks) 334

Clean 336

Inspect 336

Re-assemble (4-5T Trucks) 336

Re-assemble (5-7T Trucks) 337

Reinstall 338

Steering Cylinder Repair 339

Remove and Disassemble (4-5T Trucks) 339

Remove and Disassemble (5-7T Trucks) 340

Clean and Inspect 341

Assemble and Install (4-5T Trucks) 341

Assemble and Install (5-7T Trucks) 342

550286762 1800YRM5008 (07 2023) US EN 345

GENERAL 351

SERVICE BRAKE REPAIR 352

REMOVE AND DISASSEMBLE 352

CLEAN 354

INSPECT 354

ASSEMBLE AND INSTALL 355

ADJUST 355

PARKING BRAKE REPAIR 356

REMOVE AND DISASSEMBLE 356

ASSEMBLE AND INSTALL 357

ADJUST 357

MASTER CYLINDER REPAIR 358

REMOVE 358

INSTALL 359

BRAKE SYSTEM TROUBLESHOOTING 360

SERVICE BRAKE ADJUSTMENT 361

SERVICE BRAKE AIR REMOVAL 361

550286763 1900YRM5009 (07 2023) US EN 363

Cylinder 369

General 369

Safety Procedures When Working Near Mast 369

Integral Sideshift Cylinder Repair 369

Remove 369

Disassemble 371

Clean 371

Inspect 372

Re-assemble 372

Install 372

Check Integral Sideshift Cylinder Guide Sleeve Leak 372

Free-Lift Cylinder 373

Remove 373

Disassemble and Re-assemble 375

Clean 375

Inspect 376

Install 378

Main Lift Cylinder Repair 378

Remove 378

Disassemble and Re-assemble 380

Clean 380

Inspect 380

Install 381

MAIN LIFT CYLINDER LEAK CHECK 381

Tilt Cylinder Repair 381

Remove 381

Disassemble and Re-assemble 384

Clean 384

Inspect 384

Install 384

Hydraulic Gear Pump 385

General 385

Hydraulic Gear Pump Repair 386

Remove 386

Disassemble 388

Re-assemble 389

Examination and Repair 390

Pump Body 390

Bearing 391

Gear 392

Oil Seal 392

Main Control Valve 393

General 393

Main Control Valve 393

Description 393

Remove 395

Clean and Inspect 399

Install 399

550286764 2200YRM5010 (09 2023) US EN 401

General 407

Combination Switch 407

Remove and Install 407

Display and Rocker Switch 409

Remove and Install 409

Battery and Power Distribution Module 411

Remove and Install (4-5T Trucks) 411

Remove and Install (5-7T Trucks) 412

Auxiliary Relay and Fuse Box 413

Remove and Install 413

Sensors and Switches 414

General 414

Accelerator Pedal Position Sensor 414

Remove and Install 414

Parking Brake Sensor 414

Remove and Install 414

Fuel Level Sensor (4-5T Trucks) 415

Remove and Install 415

Fuel Level Sensor (5-7T Trucks) 416

Remove and Install 416

Torque Converter Temperature Sensor 417

Remove and Install 417

Engine Coolant Temperature Sensor 418

Remove and Install 418

Oil Pressure Sensor 420

Remove and Install 420

Lights 423

Lights 423

Remove and Install 423

550286765 4000YRM5011 (09 2023) US EN 425

General 431

Safety Procedures When Working Near Mast 432

Fork Replacement 433

Standard Carriage and Integral Sideshift Carriage 433

Remove 433

Install 434

Checks 434

Carriages Repair, Three-Stage FFL Mast 436

Standard Carriage 436

Remove 436

Clean and Inspect 436

Install 437

Integral Sideshift Carriage 437

Remove 437

Clean and Inspect 441

Assemble 441

Install 441

Three-Stage Mast With Full Free-Lift Repair 442

Remove 442

Disassemble and Re-assemble 443

Clean and Inspect 445

Carriage Adjustments 446

Lift Chains Adjustment 447

Mast Adjustments 448

Load Roller, Adjust 448

Mast Side Kicking, Adjust 449

550286766 8000YRM5012 (07 2023) US EN 451

Electrical Schematics 457

Electrical Schematics 457

Hydraulic Schematics 460

Hydraulic System Main Oil Circuit 460

Power Distribution Module (PDM) Schematics 462

550286767 8000YRM5013 (07 2023) US EN 489

General 495

How to Move a Disabled Truck 495

How to Tow Truck 495

How to Put a Truck on Blocks 496

How to Raise Drive Tires 496

How to Raise Steering Tires 496

HOW TO CLEAN A Truck 497

Maintenance Schedule 499

Periodical Maintenance 499

Oils Used for Truck 520

Maintenance Procedures Every 8 Hours or Daily 521

How to Make Checks With Engine Stopped 521

Tires and Wheels 521

Safety Labels 521

Mast, Carriage, Lift Chains, Header Hoses, and Attachment 521

Emergency Locking Retractor (ELR) 522

Adjust Seat – Standard Full Suspension 522

Hood and Seat Latches 523

Engine Compartment 523

Fuel, Oil, and Coolant Leaks, Check 523

Hydraulic Hoses 524

Coolant Hoses 524

Steering Column 524

Transmission 524

Hydraulic System Oil 524

Engine Oil 524

Check Engine Oil Level 524

Forks 525

Inspect 525

Remove 526

Adjust 526

How to Make Checks With Engine Running 526

Indicator Lights, Horn, Fuses, and Relays 526

Service Brakes 529

Operation, Check 529

Parking Brake 529

Engine Oil Pressure 529

Cooling System 529

Steering System 529

Control Levers and Pedals 529

Lift System, Operate 530

Maintenance Procedures Every 50 Hours or Daily 531

Kubota V3800 Engine 531

Fuel Tank Water Drainage (Mitsubishi Engine S6S) 531

Maintenance Procedures Every 250 Hours or Quarterly 532

Mitsubishi Engine S6S 532

Engine Oil and Oil Filter 532

Drain Engine Oil 532

Refill Engine Oil 532

Change Oil Filter 533

Inspect and Adjust Belt and Tension 534

Inspect Belt 534

Adjust Belt Tension (Alternator Side) 534

Check and Clean Radiator Fins 535

Kubota V3800 Engine and Kubota WG3800 Engine 535

Check Radiator Hose and Clamp Bands 535

Clean Air Cleaner Primay Element 536

Adjust Fan Belt Tension 537

Maintenance Procedures Every 500 Hours or Semi-annually 540

Mitsubishi Engine S6S 540

Replace Fuel Filter 540

Kubota V3800 Engine and Kubota WG3800 540

Change Engine Oil 540

Replace Oil Filter Cartridge 542

Replace Water Separator Filter – Kubota V3800 Engine 542

Cleaning Water Jacket and Radiator Interior – Kubota V3800 Engine 543

Maintenance Procedures Every 1000 Hours or Annually 546

Mitsubishi Engine S6S 546

Inspect Starter 546

Inspect Alternator 546

Kubota V3800 Engine 546

Check Valve Clearance 546

Kubota WG3800 Engine 549

Check Valve Clearance 549

Maintenance Procedures Every 1500 Hours or Annually 550

Kubota V3800 Engine and Kubota WG3800 Engine 550

Replace Air Cleaner Element 550

Kubota WG3800 Engine 550

Clean Water Jacket and Radiator Interior 550

Maintenance Procedures Every 3000 Hours or Two Years 552

Mitsubishi Engine S6S 552

Change Coolant 552

Safety Procedures When Working Near Mast 553

550286768 8000YRM5014 (07 2023) US EN 555

Truck Main Technical Parameters 561

Main Technical Parameters 561

Truck Lifting Capacity 573

Counterweight Weights 573

Tire Sizes 573

Capacities 574

Recommended Lubricants 575

Lubricant Specifications 575

Electrical System 576

Transmission Oil Pressures 577

Hydraulic System Relief Pressures 577

Steering System 578

Mast Speeds 578

Tilt Angles 578

Engine Specifications 579

550286769 8000YRM5015 (07 2023) US EN 583

Operator Station General Description and Principles of Operation 589

General Description and Location 589

Display Switch Cluster 591

Dash Display 591

Manual Control Levers 593

General Description 593

System Components 593

Lift/Lower 593

Tilt 593

Sideshift 593

Sideshift Fork Positioner 593

Accelerator Control 594

Description 594

Remove and Install 594

Combination Switch 594

Sequential Seatbelt Module 596

General Description 596

Seat Switch/Sensor 596

Buckle Switch 596

Sequential Seatbelt Module 596

Lighting 596

Front End, Mast 597

Description 597

Carriages 597

Description 597

Principles of Operation 597

Integral Sideshift Carriage 597

Mast Mounts 598

Description 598

Principles of Operation 598

Two-Stage Limited Free-Lift (LFL) Mast 600

Description 600

Principles of Operation 600

Two-Stage Full Free-lift (FFL) Mast 602

Description 602

Principles of Operation 602

Three-Stage Full Free-Lift (FFL) Mast 603

Description 603

Principles of Operation 603

Lift Cylinders 605

Description 605

Tilt and Sideshift Cylinders 608

Description 608

Tilt Cylinder 608

Sideshift Cylinder 608

Lowering Control Valves 608

Description 608

Chassis 609

Description 609

Examination and Maintenance 610

Leakage of Hydraulic Oil and Transmission Case Oil 610

Tire Air Pressure (Pneumatic Tire) 610

Wheel Hub Nut Torque 610

Overhead Guard 612

Coolant Level (Mitsubishi S6S Engine) 612

Engine Oil Level 612

Fan Belt Tension Level 612

Rear Combination Light 613

Hydraulic Oil Level 613

Pipeline Cylinder 613

Transmission Oil Level 613

Backrest 615

Fork and Fork Positioning Pin 616

Headlights 616

Gear-shift Handle 616

Multi-way Valve Operating Handle 616

Parking Brake Operation 616

Display Panel 616

Fuel Level 616

Lights 616

Turn Signal 617

Horn Pushbutton 617

Idle Stroke of Brake Pedal 617

Mast Operation 617

Lifting Chain Tension 617

Steering Wheel Free Stroke 617

Exhaust Gas 618

Inching Pedal (Hydraulic Transmission lift truck) 618

Brake 618

Steering Wheel 618

Parking Brake 618

Reversing light and Reversing Buzzer 618

Troubleshooting 619