$34.95

Yale Forklift A7T0 (GP110UX, GP135UX, GP155UX) Service Manual PDF

Yale Forklift A7T0 (GP110UX, GP135UX, GP155UX) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A7T0 (GP110UX, GP135UX, GP155UX) Service Manual – PDF DOWNLOAD

Language : English

Pages : 406

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

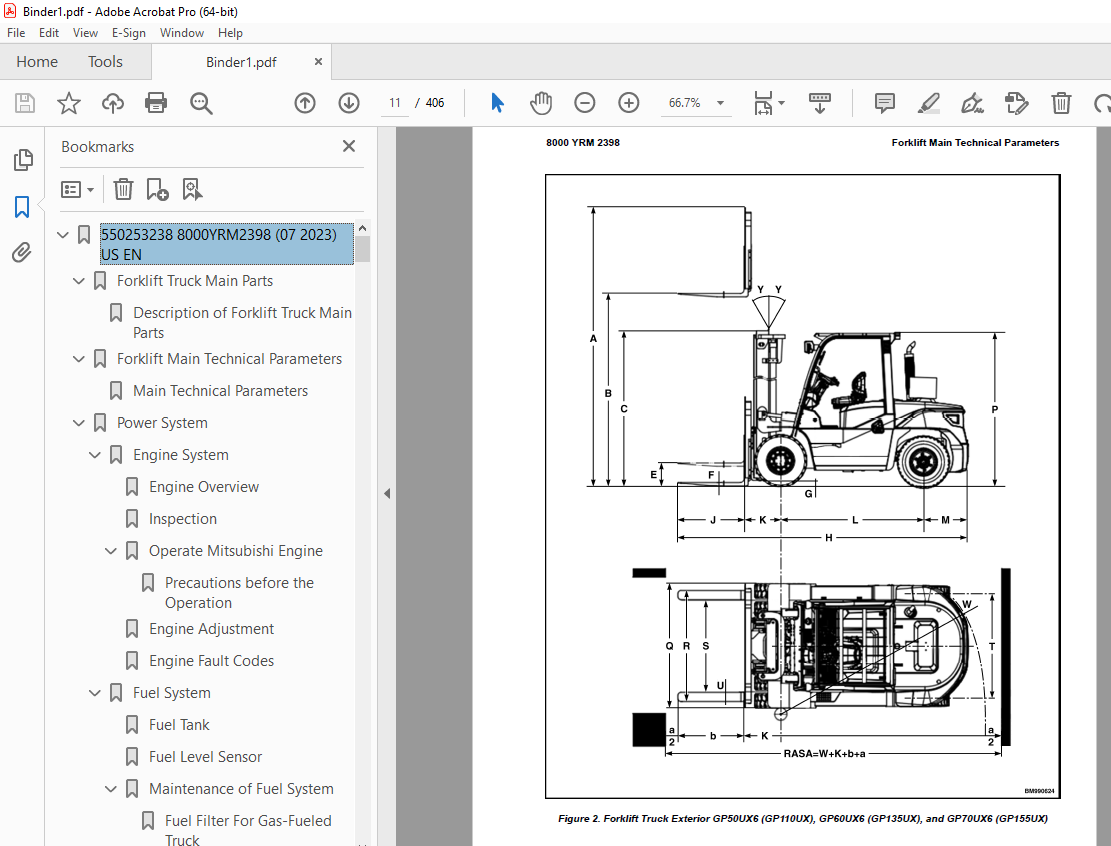

TABLE OF CONTENTS:

Yale Forklift A7T0 (GP110UX, GP135UX, GP155UX) Service Manual – PDF DOWNLOAD

550253238 8000YRM2398 (07 2023) US EN 1

Forklift Truck Main Parts 9

Description of Forklift Truck Main Parts 9

Forklift Main Technical Parameters 10

Main Technical Parameters 10

Power System 26

Engine System 26

Engine Overview 26

Inspection 36

Operate Mitsubishi Engine 36

Precautions before the Operation 36

Engine Adjustment 37

Engine Fault Codes 38

Fuel System 47

Fuel Tank 47

Fuel Level Sensor 50

Maintenance of Fuel System 50

Fuel Filter For Gas-Fueled Truck 50

Fuel Filter For Diesel-Fueled Truck 50

Fuel-Water Separator (Sediment Bowl) 51

Clean Fuel Tank 51

Maintenance of the Air Filter 51

Hydraulic Transmission Case and Torque Converter 52

Overview 54

Torque Converter 54

Hydraulic Clutch Unit 55

Control Valve 55

Transmission Case 56

Transmission Pump 56

Transmission Hydraulic Schematic 56

Speed Differential 59

Towing of Forklift Truck to be Repaired 60

Oil Inlet/Outlet Connection Location 60

Precautions in case of forklift failure 61

Trouble Shooting 61

Oil Port 64

Drive Axle 66

4-5T 66

5-7T 67

Steering System 74

Steering Axle 78

Brake System 82

Overview 83

Brake Master Cylinder 83

Wheel Brake 84

Automatic Clearance Regulator 85

Manual Brake 85

Adjustment of Brake Pedal 86

Maintenance 86

Disassemble, Wheel Brake 86

Inspect 88

Assemble, Wheel Brake 88

Test Automatic Clearance Regulator 90

Troubleshoot Wheel Brake 92

Hydraulic System 93

Main Pump 95

Multi-way Valve 95

Operation of Spool Valve 95

Primary Relief Valve 96

Steering relief valve 96

Action of Inclined Auto-lock Valve 97

Control Levers of Multi-way Control Valve 98

Hydraulic Oil Tank 98

Hydraulic System Main Oil Circuit 98

Lift Cylinder 102

Shut-off Valve 103

Speed Limit Valve 104

Tilting Cylinder 105

Main Oil Pump 105

Disassemble, Main Oil Pump 105

Assemble, Oil Pump 110

Test 110

Oil Filling Instructions 111

General Inspection Requirements 111

Inspection 111

Fill Level Requirements 111

Troubleshoot Hydraulic System 112

Lifting System 113

Inside and Outside Masts 114

Bracket 114

Safety Procedures When Working Near Mast 115

Adjustment for Lifting System 117

Lifting Cylinder 117

Carriage 117

Installation of Roller 118

Electrical System 120

Overview 120

Truck Operations 120

Start and Stop 120

Driving Operations 121

Combination Switch 121

Horn Button 121

Reverse Light and Signal 121

Light Controls 121

Steering Signal 121

Brake Signal 122

Dash Display 122

Introduction to PDM 127

Battery 127

Truck Safety System (OPS/Park Brake Alarm System) 128

Overview 128

Truck Will Not Start 129

Lift, Lowering and Tilt Functions are not Working 129

Forward and Back Functions are not Working 130

USB 130

Electrical Schematics 130

Troubleshoot with Electrical System 141

Diesel Particulate Filter (DPF) Regeneration Control (Only for the Trucks Equipped with Kubota V3800 Engine) 142

DPF Status 142

DPF Operation Instructions 143

DPF System Status Transiton 143

DPF Indicator Status 145

Drive, Operation, and Routine Maintenance of Forklift Truck 147

Transporting the Forklift Truck 147

Towing 147

Long-Term Storage of Forklift Truck 147

Procedures Prior to Operation 148

Precautions for Use 148

Cooling System 149

Oils Used for Forklift Truck 149

Hydraulic Oil Gauge Clarification and Oil Filling Instruction 152

General inspection requirements 152

Inspection method 152

Technical Requirements for filling Hydraulic Oil reservoir 152

Periodical Maintenance 153

550277201 0100YRM5001 (09 2023) US EN 181

General 187

Description 188

Hood, Seat, Floor Plate and Covers Replacement 190

Disassemble (4-5T Trucks) 190

Re-assemble 196

Steering Column 197

Description 197

Steering Column Repair 197

Disassemble 197

Disassemble Steering Hoses 199

Clean 200

Inspect 200

Re-assemble 200

Counterweight Replacement 201

Remove (4-5T Trucks) 201

Remove (5-7T Trucks) 203

Install (4-5T Trucks) 205

Install (5-7T Trucks) 205

Overhead Guard Replacement 206

Remove and Install 206

Operator Restraint System Replacement 209

Description 209

Emergency Locking Retractor (ELR) 209

Engine and Transmission Replacement 210

Remove 210

Disassemble (4-5T Trucks) 210

Disassemble (5-7T Trucks) 211

Re-assemble (4-5T Trucks) 213

Re-assemble (5-7T Trucks) 213

Exhaust System Repair 214

Remove and Disassemble Exhaust System 214

Inspect 214

Re-assemble Exhaust System 214

Cooling System 215

Description 215

Hydraulic Filter Assembly Repair 216

Disassemble 216

Clean and Inspect 217

Re-assemble 218

Fuel and Hydraulic Tanks Repair 219

Inspect 219

Clean 219

Steam Method of Cleaning 219

Chemical Solution Method of Cleaning 220

Additional Preparations for Repair 221

Small Leaks, Repair 221

Large Leaks, Repair 221

Preparations for Use After Repair 221

Safety Labels 222

550277204 0900YRM5004 (07 2023) US EN 227

Air-Intake and Exhaust System 233

Air-Intake and Exhaust System (Mitsubishi S6S and Mitsubishi S6S-T Engine) 233

Remove 233

Inspect 233

Install 233

Air-intake System (Kubota Engine) 235

Remove 235

Install 235

LPG Tank and Bracket Replacement with Swing-Out Bracket (Kubota WG3800 Engine) 236

Remove LPG Tank 236

Install LPG Tank 237

Remove LPG Bracket 237

Install LPG Bracket 238

Fuel Filter and Fuel Level Sensor Repair 239

FUEL FILTER ELEMENT (4-5T Trucks) 239

Remove 239

Install (4-5T Trucks) 240

Fuel Level Sensor (4-5T Trucks) 240

Remove (4-5T Trucks) 240

Install (4-5T Trucks) 240

FUEL FILTER ELEMENT (5-7T Trucks) 240

Remove 240

Install (5-7T Trucks) 241

Fuel Level Sensor (5-7T Trucks) 241

Remove (5-7T Trucks) 241

Install (5-7T Trucks) 241

LPG Converter (Kubota WG3800 Dual Fuel Engine) 242

Remove 242

Exhaust System 245

Remove (4-5T Trucks) 245

Install (4-5T Trucks) 247

Remove (5-7T Trucks) 251

Install (5-7T Trucks) 256

550286761 1600YRM5007 (09 2023) US EN 259

General 265

Steering Axle Assembly Repair 267

Remove 267

Disassemble (4-5T Trucks) 268

Disassemble (5-7T Trucks) 270

Clean 272

Inspect 272

Re-assemble (4-5T Trucks) 272

Re-assemble (5-7T Trucks) 273

Reinstall 274

Steering Cylinder Repair 275

Remove and Disassemble (4-5T Trucks) 275

Remove and Disassemble (5-7T Trucks) 276

Clean and Inspect 277

Assemble and Install (4-5T Trucks) 277

Assemble and Install (5-7T Trucks) 278

550286763 1900YRM5009 (07 2023) US EN 281

Cylinder 287

General 287

Safety Procedures When Working Near Mast 287

Integral Sideshift Cylinder Repair 287

Remove 287

Disassemble 289

Clean 289

Inspect 290

Re-assemble 290

Install 290

Check Integral Sideshift Cylinder Guide Sleeve Leak 290

Free-Lift Cylinder 291

Remove 291

Disassemble and Re-assemble 293

Clean 293

Inspect 294

Install 296

Main Lift Cylinder Repair 296

Remove 296

Disassemble and Re-assemble 298

Clean 298

Inspect 298

Install 299

MAIN LIFT CYLINDER LEAK CHECK 299

Tilt Cylinder Repair 299

Remove 299

Disassemble and Re-assemble 302

Clean 302

Inspect 302

Install 302

Hydraulic Gear Pump 303

General 303

Hydraulic Gear Pump Repair 304

Remove 304

Disassemble 306

Re-assemble 307

Examination and Repair 308

Pump Body 308

Bearing 309

Gear 310

Oil Seal 310

Main Control Valve 311

General 311

Main Control Valve 311

Description 311

Remove 313

Clean and Inspect 317

Install 317

550286764 2200YRM5010 (09 2023) US EN 319

General 325

Combination Switch 325

Remove and Install 325

Display and Rocker Switch 327

Remove and Install 327

Battery and Power Distribution Module 329

Remove and Install (4-5T Trucks) 329

Remove and Install (5-7T Trucks) 330

Auxiliary Relay and Fuse Box 331

Remove and Install 331

Sensors and Switches 332

General 332

Accelerator Pedal Position Sensor 332

Remove and Install 332

Parking Brake Sensor 332

Remove and Install 332

Fuel Level Sensor (4-5T Trucks) 333

Remove and Install 333

Fuel Level Sensor (5-7T Trucks) 334

Remove and Install 334

Torque Converter Temperature Sensor 335

Remove and Install 335

Engine Coolant Temperature Sensor 336

Remove and Install 336

Oil Pressure Sensor 338

Remove and Install 338

Lights 341

Lights 341

Remove and Install 341

550286765 4000YRM5011 (09 2023) US EN 343

General 349

Safety Procedures When Working Near Mast 350

Fork Replacement 351

Standard Carriage and Integral Sideshift Carriage 351

Remove 351

Install 352

Checks 352

Carriages Repair, Three-Stage FFL Mast 354

Standard Carriage 354

Remove 354

Clean and Inspect 354

Install 355

Integral Sideshift Carriage 355

Remove 355

Clean and Inspect 359

Assemble 359

Install 359

Three-Stage Mast With Full Free-Lift Repair 360

Remove 360

Disassemble and Re-assemble 361

Clean and Inspect 363

Carriage Adjustments 364

Lift Chains Adjustment 365

Mast Adjustments 366

Load Roller, Adjust 366

Mast Side Kicking, Adjust 367

550286769 8000YRM5015 (07 2023) US EN 369

Operator Station General Description and Principles of Operation 375

General Description and Location 375

Display Switch Cluster 377

Dash Display 377

Manual Control Levers 379

General Description 379

System Components 379

Lift/Lower 379

Tilt 379

Sideshift 379

Sideshift Fork Positioner 379

Accelerator Control 380

Description 380

Remove and Install 380

Combination Switch 380

Sequential Seatbelt Module 382

General Description 382

Seat Switch/Sensor 382

Buckle Switch 382

Sequential Seatbelt Module 382

Lighting 382

Front End, Mast 383

Description 383

Carriages 383

Description 383

Principles of Operation 383

Integral Sideshift Carriage 383

Mast Mounts 384

Description 384

Principles of Operation 384

Two-Stage Limited Free-Lift (LFL) Mast 386

Description 386

Principles of Operation 386

Two-Stage Full Free-lift (FFL) Mast 388

Description 388

Principles of Operation 388

Three-Stage Full Free-Lift (FFL) Mast 389

Description 389

Principles of Operation 389

Lift Cylinders 391

Description 391

Tilt and Sideshift Cylinders 394

Description 394

Tilt Cylinder 394

Sideshift Cylinder 394

Lowering Control Valves 394

Description 394

Chassis 395

Description 395

Examination and Maintenance 396

Leakage of Hydraulic Oil and Transmission Case Oil 396

Tire Air Pressure (Pneumatic Tire) 396

Wheel Hub Nut Torque 396

Overhead Guard 398

Coolant Level (Mitsubishi S6S Engine) 398

Engine Oil Level 398

Fan Belt Tension Level 398

Rear Combination Light 399

Hydraulic Oil Level 399

Pipeline Cylinder 399

Transmission Oil Level 399

Backrest 401

Fork and Fork Positioning Pin 402

Headlights 402

Gear-shift Handle 402

Multi-way Valve Operating Handle 402

Parking Brake Operation 402

Display Panel 402

Fuel Level 402

Lights 402

Turn Signal 403

Horn Pushbutton 403

Idle Stroke of Brake Pedal 403

Mast Operation 403

Lifting Chain Tension 403

Steering Wheel Free Stroke 403

Exhaust Gas 404

Inching Pedal (Hydraulic Transmission lift truck) 404

Brake 404

Steering Wheel 404

Parking Brake 404

Reversing light and Reversing Buzzer 404

Troubleshooting 405