$40.95

Yale Forklift A814 (ERC_ERP16-20AAF) Service Manual – PDF DOWNLOAD

Yale Forklift A814 (ERC_ERP16-20AAF) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A814 (ERC_ERP16-20AAF) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1260

Downloadable : Yes

File Type : PDF

PART NO. 524150790

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A814 (ERC_ERP16-20AAF) Service Manual – PDF DOWNLOAD

524150790-2100YRM0103-(03-2007)-UK-EN 1

toc 1

Tilt Cylinders 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Tilt Cylinder Repair 5

Remove 5

Disassemble 5

Clean 5

Assemble 6

Tilt Cylinders With O-Ring or Single-Lip Seals 6

Tilt Cylinders 7

Install 8

Tilt Cylinder Leak Check 10

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 11

Torque Specifications 11

Piston Rod Nut 11

Retainer 11

Troubleshooting 12

tables 1

Table 1 Movement Rates (Maximum) for Tilt Cylinders 10

524150797-8000YRM0231-(02-2023)-UK-EN 17

General 23

Threaded Fasteners 23

Nomenclature, Threads 23

Strength Identification 24

Cotter (Split) Pins 25

Fastener Torque Tables 30

Conversion Table 32

524158040-2240YRM0001-(01-2023)-UK-EN 39

General 45

Battery Type 45

Lead-Acid Batteries 45

Lithium-Ion Batteries 46

Specific Gravity 46

Chemical Reaction in a Cell 46

Electrical Terms 48

Battery Selection 49

Battery Voltage 50

Battery as a Counterweight 50

Battery Ratings 50

Kilowatt-Hours 50

Battery Maintenance 51

Safety Procedures 51

Maintenance Records 51

New Battery 51

Cleaning Battery 52

Adding Water to Battery 54

Hydrometer 54

Battery Temperature 55

Charging Battery 56

Types of Battery Charges 57

Methods of Charging 58

Troubleshooting Charger 59

Knowing When Battery Is Fully Charged 59

Where to Charge Batteries 59

Equipment Needed 59

Battery Connectors 60

Battery Care 60

Troubleshooting 62

524158753-1600YRM0720-(11-2006)-UK-EN 67

toc 67

Steering Housing and Control Unit 67

Safety Precautions Maintenance and Repair 68

General 71

Description 71

Operation 72

Steering Wheel and Column Assembly Repair 73

Assembly Components, Remove 73

Steering Control Unit, Disassemble 78

Steering Control Unit, Clean 78

Steering Control Unit, Assemble 78

Assembly Components, Install 80

System Air Removal 82

Troubleshooting 82

524158757-2200YRM0514-(01-2004)-UK-EN 87

toc 87

Instrument Cluster 87

Safety Precautions Maintenance and Repair 88

General 91

Description 91

Instrument Cluster Display Panel, Internal Combustion Lift Truck 91

Instrument Cluster Display Panel, Electric Lift Truck Models 98

Optional Basic Display Panel 98

Features of the Optional Basic Display Panel 98

Description of Features on the Optional Basic Display Panel 98

Standard Display Panel 99

Features of the Standard Display Panel 99

Description of Features on the Standard Display Panel 99

Premium Display Panel 100

Features on the Premium Display Panel 100

Description of Features on the Premium Display Panel 101

Curtis 1215 Display Panel 103

Description and Features 103

Operation 104

Cluster-Type Display Panel (Internal Combustion) Replacement 105

Remove 105

Install 105

Cluster Display Panel (Electric Lift Truck) Replacement 108

Curtis 1215 Display Panel Replacement 113

Remove 113

Install 113

tables 87

Table 1 Instrument Cluster, Internal Combustion 92

524158890-4000YRM0521-(03-2006)-UK-EN 117

toc 117

Mast 117

Safety Precautions Maintenance and Repair 118

General 121

Description and Operation 121

Carriages 121

Mast Mounts 123

Two-Stage Mast, Limited Free-Lift (LFL) 124

Description and Operation 124

Two-Stage Mast, Full Free-Lift (FFL) 126

Description and Operation 126

Three-Stage Mast, Full Free-Lift (FFL) 128

Description and Operation 128

Four-Stage Mast 130

Description and Operation 130

Cylinder Cushion During Lifting Sequence 134

Cylinder Cushion During Lowering Sequence 135

524158891-4000YRM0522-(07-2010)-UK-EN 139

toc 139

Mast 139

Safety Precautions Maintenance and Repair 140

General 143

Safety Procedures When Working Near Mast 144

Fork Repair 146

Remove 146

Install 146

Carriages Repair 148

Standard Carriage, Remove 148

Hang-On Sideshift Carriage, Remove 149

Standard Carriage and Hang-On Sideshift Carriage, Repair 150

Standard Carriage, Install 151

Hang-On Sideshift Carriage, Install 152

Integral Sideshift Carriage 152

Remove 152

Clean and Inspect 156

Repair 157

Install 158

Mast Repair 159

Remove 159

Two-Stage LFL and Two-Stage FFL Masts, Disassemble 161

Three-Stage FFL Mast 169

Disassemble 169

Mast and Chains, Clean and Inspect 172

Two-Stage LFL and Two-Stage FFL Mast, Assemble 173

Three-Stage FFL Mast, Assemble 174

Install 175

Lift Cylinders Repair 177

Main Lift Cylinders, Remove 177

Free-Lift Cylinder, Remove 177

Cylinders, Disassemble 178

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 178

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 180

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 180

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 181

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 182

Clean and Inspect 183

Cylinders, Assemble 183

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 183

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 184

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 185

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 185

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 186

Main Lift Cylinders, Install 187

Free-Lift Cylinder, Install 187

Header Hose Arrangements 188

Two-Stage LFL Mast, New Hose Install 188

Two-Stage LFL Mast, Adjust Hoses After Installation 193

Two-Stage FFL Mast, New Hose Install 193

Two-Stage FFL Mast, Adjust Hoses After Installation 201

Three-Stage FFL Mast, New Hose Install 201

Three-Stage FFL Mast, Adjust Hoses After Installation 212

Header Hose Arrangement 213

Two-Stage LFL Mast, New Hose Install 213

Two-Stage LFL Mast, Adjust Hoses After Installation 218

Two-Stage FFL Mast, New Hose Install 218

Two-Stage FFL Mast, Adjust Hoses After Installation 224

Three-Stage FFL Mast, New Hose Install 224

Three-Stage FFL Mast, Adjust Hoses After Install 233

Lift and Tilt System Leak Check 234

Lift Cylinders Leak Check 234

Tilt Cylinders Leak Check 234

Tilt Cylinders Adjustment 235

Lift Chains Adjustment 237

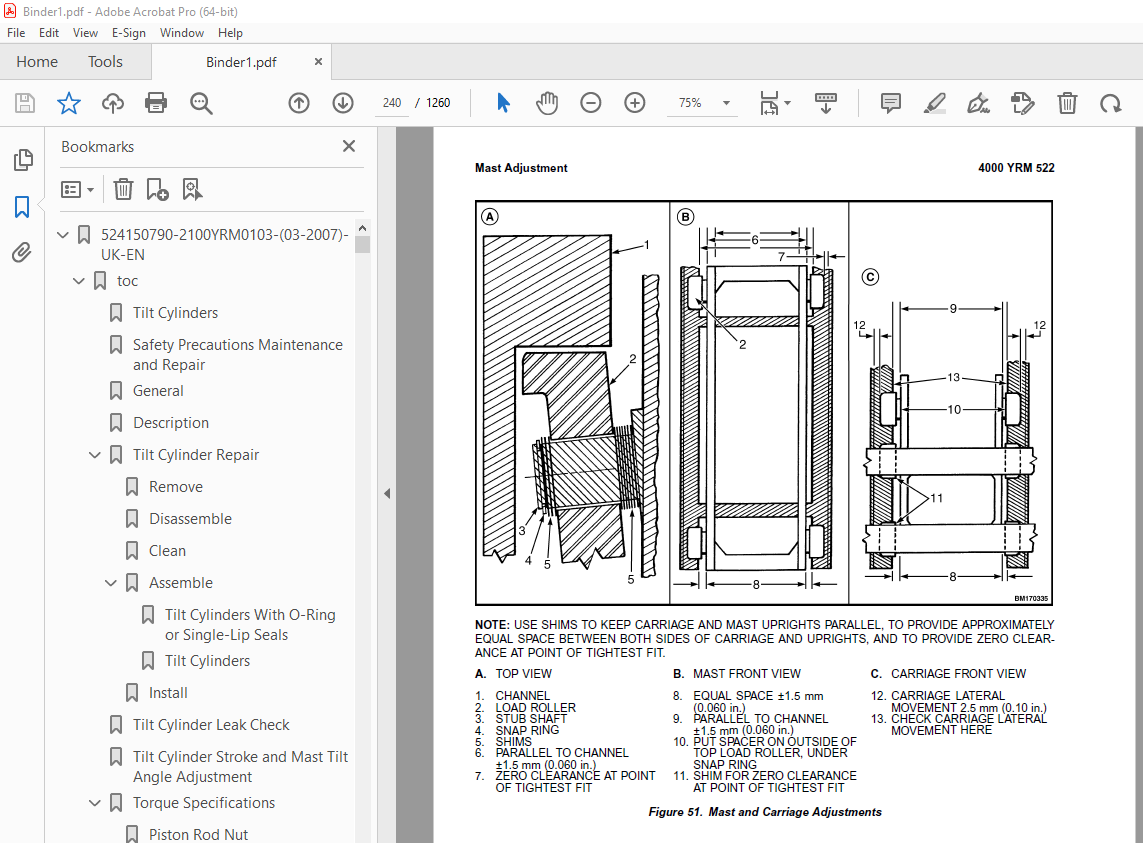

Mast Adjustment 239

Carriage Adjustment 241

Troubleshooting 242

tables 139

Table 1 Hook-Type Carriage Chain Adjustment 237

Table 2 Pin-Type Carriage Chain Adjustment 238

524166836-1600YRM0485-(07-2003)-UK-EN 245

toc 245

Steering System for Electric Lift Trucks 245

Safety Precautions Maintenance and Repair 246

General 249

Description 251

Steering Wheel and Column Assembly Repair 252

Assembly Components, Remove 252

Assembly Components, Install 256

Power Steering Motor and Pump 257

Description 257

Remove and Disassemble, Models ERC 20-30AGF (ERC040-065RF/ZF, RG 258

Remove and Disassemble, Models ERC35-55HG (ERC70-120HD, ERC70-12 259

Remove and Disassemble, Models ERP20-30ALF 262

Remove and Disassemble, Models ERC/P16-20AAF (ERC040-065AF, AG/B 262

Assemble and Install, All Models With A Vertical Mount Except ER 263

Assemble and Install, Models ERP20-30ALF 263

Assemble and Install, Models ERC/P16-20AAF (ERC030-040AF, AG/BG) 264

Power Steering Pump, Repair 264

Seal, Replace 265

Hydraulic Steering Motor 266

Steering System Air Removal 266

Steering Pressure Check 266

Optical Encoder and Activator Circuits Check 267

Troubleshooting 269

524166840-2200YRM0560-(07-2005)-UK-EN 273

toc 273

Electrical System 273

Safety Precautions Maintenance and Repair 274

General 279

Description 280

ZX Series Display Panels 280

Optional Basic Display Panel 280

Features of the Optional Basic Display Panel 280

Description of Features on the Optional Basic Display Panel 280

Standard Display Panel 281

Features of the Standard Display Panel 281

Description of Features on the Standard Display Panel 281

Premium Display Panel 282

Features on the Premium Display Panel 282

Description of Features on the Premium Display Panel 283

Curtis 1215 Display Panel 285

Description and Features 285

Operation 285

SEM Display Panels – Features 286

Descriptions of Common Features 287

LED Symbol Indicators – SEM 287

LCD Screen 287

Battery Discharge Indicator (BDI) 287

Service Reminder 288

Status Codes 288

Hourmeter 288

Additional Features of Premium Display Panel 289

Descriptions of Additional Features 289

LCD Screen 289

Operator Passwords 289

Daily Checklist and Service Items 289

Performance Modes 289

Status Code Lists 290

Adjustment of BDI 290

SEM Display Panel Indicators 290

All Indicator Symbols 290

Hourmeter Indicator Symbol 290

Wrench Symbol 290

Battery Symbol 290

Battery Discharge Indicator (BDI) 290

Brake Fluid Too Low Symbol 290

Parking Brake Symbol 290

Fasten Seat Belt Symbol 291

LCD Screen (Standard Display Panel) 291

Additional Components of Premium Display Panel 291

Alpha Numerical Screen 291

STAR Push Button 291

Push Buttons ##1 Through ##5 – SEM 291

Other Control Components 291

Display Panel Components – ZX, and Curtis Replacement 292

ZX Panel Replacement 292

Curtis 1215 Display Panel Replacement 297

Remove 297

Install 297

SEM Display Panel Replacement 298

Motor Controller (SR or SP) Replacement 298

Remove 298

Install 298

Control Components Replacement 300

Start Switch, Replace 300

Brake Light Switch, Replace 301

Seat Switch, Replace 301

External Seat Switch, Adjust 302

Switch for Optional Seat Brake, Replace 303

Parking Brake Switch, Replace 303

Direction Switches Foot Directional Control Replace 304

Direction Control Switches (Steering Column), Replace 305

Direction Control Switches, ERC070-120HG (Steering Column), Repl 306

Brake Fluid Switch, Replace 306

Brush Wear and Overtemperature Sensors 306

Rocker Switches for Lights 307

Accelerator Position Sensor, Replace 307

On-Demand Steering Components 309

Lights, Converter, Relay, and Reverse Alarm 311

Incandescent Brake, Tail, and Reverse Light Assembly, Replace 311

LED Brake, Tail, and Reverse Light Assembly, Replace 313

Remove 313

Install 313

Flashing Light Assembly, Replace 313

Front, Rear Driving Light, or Spot Light Assemblies, Replace 315

Operator Compartment Light Assembly, Replace 315

Converter, Replace 316

Relay, Replace 316

Reverse Alarm, Replace 316

Horn and Horn Button 316

Horn Switch and Cover 317

Hydraulic Pump Switches 317

Control and Power Fuses Check 318

ZX Motor Controllers 318

SEM Motor Controllers 318

SEM Controller Field Diagnostic Procedure 323

Armature FET Test 323

Field FET Test 323

Brush Wear and Overtemperature Sensors Check – ZX Motor Controll 327

Thermal Sensors – SEM Motor Controllers Check 328

Start Switch Adjustment 329

Accelerator Potentiometer and Start Switch, ERC070-120HG Lift Tr 330

ERC070-120HG 330

Direction Switches Foot Directional Control Pedal 331

Brake Light Switch Adjustment 332

Seat Switch Check 333

Optional Seat Brake Switch Adjustment 333

Parking Brake Switch Adjustment 334

Direction Switches Check 334

Foot Directional Control Pedal 334

Steering Column 335

Hydraulic Pump Switch Adjustment 335

Foot Directional Control or Accelerator Pedal Adjustment 335

Accelerator Position Sensor Adjustment 336

524166844-2200YRM0942-(08-2007)-UK-EN 341

toc 341

Display Panel for SEM Controls 341

Safety Precautions Maintenance and Repair 342

General 345

SEM Display Panel Features 345

Descriptions of Common Features 345

LED Symbol Indicators 345

LCD Screen 345

Battery Discharge Indicator (BDI) 346

Service Reminder 346

Status Codes 346

Hourmeter 346

Additional Features of Premium Display Panel 346

Descriptions of Additional Features (Available With Premium Disp 346

LCD Screen 346

Operator Passwords 347

Daily Check List and Service Items 347

Performance Modes 347

Status Code Lists 347

Adjustment of BDI 347

SEM Display Panel Indicators 348

All Indicator Symbols 348

Hourmeter Indicator Symbol 348

Wrench Indicator Symbol 348

Battery Indicator Symbol 348

Battery State-of-Charge (BDI) 348

Brake Fluid Too Low Symbol 349

Parking Brake Symbol 349

Fasten Seat Belt Symbol 349

LCD Screen (Standard Display Panel) 350

Additional Components of Premium Display Panel 350

Alphanumeric Screen 350

STAR Push Button 350

Push Buttons 1 Through 5 350

Adjustments With a Computer 350

Computer System 350

Connect PC to SEM Display Panel 351

ITW Switches Windows Software Program (for SEM Display Panel) 352

Description 352

Getting Help 352

Hardware and Software Requirements 352

Install 352

How to Start ITW Switches Program 352

Menus 356

Sample Sessions 365

Replacement 387

SEM Display Panel 387

Remove and Replace 387

tables 341

Table 1 Adapter Pins (DB25F to DB9) 351

524167640-2200YRM0947-(08-2007)-UK-EN 393

toc 393

Troubleshooting and Adjustments With a Computer 393

Safety Precautions Maintenance and Repair 394

Computer System 397

Connect a PC to a Control Card 398

Installation 399

SMARTSET™ Windows Software Program 399

How to Start the Program 399

DEMO Mode 400

Selecting the Communications Port 402

Verification of Controller and Lift Truck 403

Select Lift Truck Series 405

Controller Card Register Parameter List 406

How to Change a Parameter 407

How to Save a Changed Parameter File 408

How to Load a Saved Parameter File 410

How to Show and Remove Saved Parameter Files 410

How to Return to Factory Default Settings 411

How to Save Changes to Control Card 412

How to View Status Codes 413

Saving Status Codes 414

How to Show and Remove Saved Status Code Files 415

Closing and Clearing Status Code List 416

How to View Saved Register Data and Saved Status Data 417

How to Save Register Data and Status Code Data In RTF and TXT 419

GE Sentry™ Software Program 420

Installation 420

Description 420

How to Start GE SENTRY Program 420

How to Reset MIN and MAX Display 425

Graphing Mode 426

How to Exit GE SENTRY Program 427

tables 393

Table 1 Cable Connections – Computer to Control 397

Table 2 Adapter Pins (DB25F to DB9) 398

Table 3 Plug-Z Connection 399

524179936-0100YRM0617-(03-2006)-UK-EN 431

toc 431

Frame 431

Safety Precautions Maintenance and Repair 432

General 435

Description 435

Main Frame 435

Other Frame Weldments 445

Overhead Guard 446

Overhead Guard Replacement 451

Remove 451

Install 452

Battery and Operator Restraint System, Hood and Seat Brake, and 452

Battery Restraint System 452

Hood and Seat Brake 454

Hood With E-Hydraulics 455

Operator Restraint System and Seat Assembly 456

Automatic Locking Retractor (ALR) 456

Emergency Locking Retractor (ELR) 456

Counterweight Replacement 457

Remove 457

Install 459

Traction Motor Replacement 460

Remove 460

Install 462

Hydraulic Tank Repair 463

Inspect 463

Clean 464

Steam Method 464

Chemical Solution Method 464

Additional Preparations for Repair 465

Small Leaks, Repair 465

Large Leaks, Repair 465

Preparations for Usage After Repair 465

Painting Instructions 465

Safety Label Replacement 467

Battery Specifications 469

tables 431

Table 1 Counterweights 458

524179939-1400YRM0618-(03-2006)-UK-EN 473

toc 473

Drive Axle, Speed Reducer, and Differential 473

Safety Precautions Maintenance and Repair 474

General 477

Description 477

Drive Unit Assembly Repair 477

Remove Complete Drive Unit Assembly as a Unit 477

Traction Motor, Remove 478

Drive Unit and Speed Reducer, Remove 480

Drive Axle, Disassemble 481

Differential and Speed Reducer, Disassemble 481

Clean 484

Inspect 484

Assembly of Drive Unit 484

Find Correct Shim Set for Hypoid Gear 484

Pinion, Assemble and Install 485

Differential and Ring Gear, Assemble and Install 486

Input Gear for Speed Reducer, Assemble 490

Drive Axle and Hub Assembly, Assemble 491

Installation of Drive Unit 492

Drive Unit, Install 492

Traction Motor, Install 493

Torque Specifications 494

Troubleshooting 495

tables 473

Table 1 Shims Adjustment for Pinion 485

Table 2 Ring and Pinion Tooth Contact Adjustment 489

524179940-1600YRM0619-(03-2006)-UK-EN 499

toc 499

Steering Axle 499

Safety Precautions Maintenance and Repair 500

General 503

Description 503

Steering Axle Assembly Repair 504

Remove 504

Install 504

Wheels and Hubs Repair 505

Remove and Disassemble 505

Clean 505

Assemble and Install 505

Spindles, Bearings, and Links Repair 509

Remove and Disassemble; Lift Truck Models ERC/P16-20AAF (A814/B8 509

Clean 509

Assemble and Install; Lift Truck Models ERC/P16-20AAF (A814/B814 509

Remove and Disassemble; Lift Truck Models ERC030-040AF and ERC03 511

Clean 511

Inspect 511

Assemble and Install; Lift Truck Models ERC030-040AF and ERC030- 511

Steering Cylinder Repair 513

Remove and Disassemble 513

Clean and Inspect 513

Assemble and Install 513

Torque Specifications 514

Troubleshooting 515

524179941-1600YRM0512-(07-2003)-UK-EN 519

toc 519

Steering Housing and Control Unit 519

Safety Precautions Maintenance and Repair 520

General 523

Description 523

Operation 524

Steering Wheel and Column Assembly Repair 525

Steering Column Assembly, Remove 525

Steering Control Unit 530

Disassemble 530

Clean 533

Assemble 534

Install 541

Steering Column Assembly, Install 543

System Air Removal 544

Remove 544

Troubleshooting 544

524179944-1800YRM0620-(03-2008)-UK-EN 549

toc 549

Brake System 549

Safety Precautions Maintenance and Repair 550

General 553

Description and Operation 553

Service Brakes 553

Master Cylinder 553

Parking Brake 555

Service Brakes Repair 555

Remove and Disassemble 555

Clean 558

Inspect 558

Assemble and Install 559

Master Cylinder Repair 562

Remove 562

Disassemble 563

Clean and Inspect 565

Assemble 565

Install 568

Parking Brake Repair 568

Remove and Dissemble 568

Assemble and Install 568

Parking Brake Switch Replacement 572

Brake System Air Removal 572

Service Brakes Adjustment 573

Brake Pedal Adjustment 573

Master Cylinder Adjustment 574

Parking Brake Adjustment 574

Parking Brake Switch Adjustment 574

Parking Brake Not Applied Switch Test 574

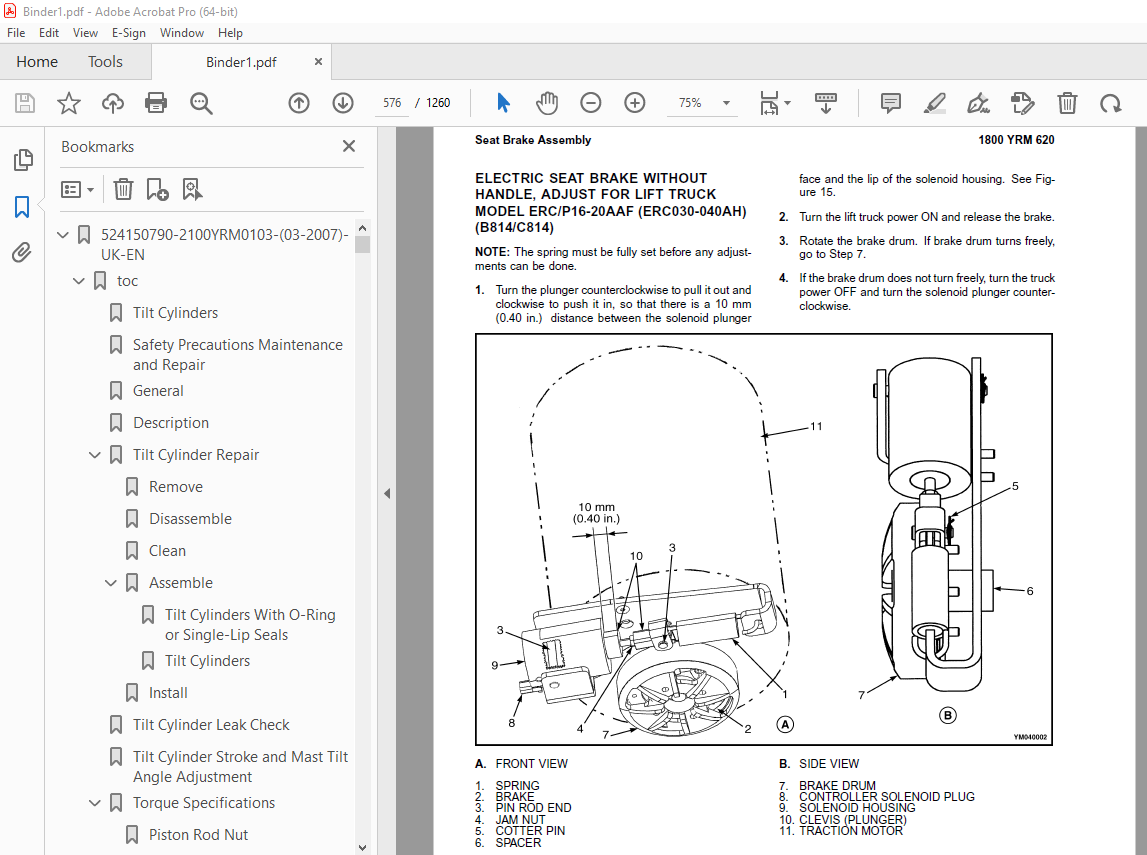

Seat Brake Assembly 574

Seat Brake, Adjust – Lift Truck Models ERC/P16-20AAF (ERC030-040 574

Brake Switch, Adjust – Lift Truck Models ERC/P16-20AAF (ERC030-0 575

Electric Seat Brake Without Handle, Adjust for Lift Truck Model 576

Electric Seat Brake With Handle for Lift Truck Model ERC/P16-20A 577

Remove 577

Clean 577

Inspect 577

Install 579

Adjustments 579

Solenoid Adjustment 579

Traction cutoff Switch Adjustment 579

Cable Adjustment 580

Torque Specifications 582

Troubleshooting 582

524179945-1900YRM0559-(04-2009)-UK-EN 589

toc 589

Hydraulic System 589

Safety Precautions Maintenance and Repair 590

General 593

Description 593

Hydraulic System 593

Operation 601

Hydraulic System 601

Hydraulic Gear Pump 607

Steering Pump 607

Hydraulic Tank Repair 615

Tank, Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P1 615

Tank, Remove [ERP20-30ALF (B216) and ERP20-30ALF (ERP040-060DH) 617

Tank, Remove [ERP20-32ALF (ERP040-065DH) (E216)] 618

Hydraulic Tank [ERC35-55HG (ERC70-120HH) (B839/C839)] 618

Inspect 619

Small Leaks, Repair 620

Large Leaks, Repair 620

Clean 620

Steam Method 620

Chemical Solution Method 621

Additional Methods for Tank Repair 621

Tank, Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P 621

Tank, Install [ERP20-30ALF (B216) and ERP20-30ALF (ERP040-060DH) 622

Tank, Install [ERP20-32ALF (ERP040-065DH) (E216)] 622

Filter Replacement 623

All Lift Trucks Except [ERC35-55HG (ERC70-120HH) (B839/C839); ER 623

Remove 623

Install 624

Lift Truck Models [ERC35-55HG (ERC70-120HH) (B839/C839)] 624

Remove 624

Install 624

Lift truck Models [ERC20-32AGF (ERC040-065GH) (A908) and ERC/P16 625

Remove 625

Install 625

Lift Truck Models [ERP20-32ALF (ERP040-065DH) (E216)] 627

Remove 627

Install 627

Hydraulic Pump Repair 630

Hydraulic Pump, Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A81 630

Hydraulic Pump, Disassemble ERC/P16-20AAF (ERC030-040AF, AG/BG) 630

Inspect 632

Clean 632

Pump Seal Replace and Pump Assemble 632

Assemble Pump on Motor 632

Hydraulic Pump and Motor, Install [ERC/P16-20AAF (ERC030-040AF, 634

Hydraulic Pump, Remove [ERP20-30ALF (B216); ERP20-30ALF (ERP040- 635

Hydraulic Pump, Disassemble [ERC35-55HG (ERC70-120HH) (B839/C839 636

Hydraulic Pump, Inspect [ERC35-55HG (ERC70-120HH) (B839/C839) an 638

Hydraulic Pump, Clean [ERC35-55HG (ERC70-120HH) (B839/C839) and 638

Hydraulic Pump, Assemble [ERC35-55HG (ERC70-120HH) (B839/C839) a 638

Hydraulic Pump and Motor, Install [ERP20-30ALF (B216); ERP20-30A 638

Main Control Valve Repair 640

Steering Pump Repair 640

Pump, Remove and Disassemble [ERC/P16-20AAF (ERC030-040AF, ERC03 640

Pump, Remove and Disassemble [ERP20-30ALF (B216); ERP20-30ALF (E 642

Pump, Assemble and Install 644

Steering Control Unit Replacement 645

Remove 645

Install 645

Steering Cylinder Repair 651

Main Control Valve Check and Adjust 651

Steering Relief Valve Check and Adjust 652

Specifications 652

Relief Valve Pressures* 652

Hydraulic Tank Capacity (dipstick full mark) 653

Hydraulic Pump Capacities – All Models Except ERC35-55HG (ERC70- 653

Hydraulic Pump Capacities – Models ERC35-55HG (ERC70-120HH) (B83 653

Troubleshooting 653

Steering 653

Steering Housing and Steering Control Unit 654

Hydraulic System 655

524179946-2000YRM0562-(02-2009)-UK-EN 661

toc 661

Manual hydraulic Control Valve 661

Safety Precautions Maintenance and Repair 662

General 665

Description 665

Operation 668

ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P16-20AAF (ERC03 668

ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D216) and ERP20- 668

Lift Section 670

Tilt Section 670

Tilt Backward 670

Tilt Forward 670

Relief Valve 672

Main Control Valve Repair 673

Main Control Valve Without OPS Solenoid 673

Remove 673

Disassemble 673

Clean and Inspect 677

Assemble 677

Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P16-20A 678

Install [ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D216) a 678

Main Control Valve With OPS Solenoid 679

Remove 679

Disassemble 679

Clean and Inspect 681

Relief Valve Repair 683

Assemble 684

Install 685

Control Lever Linkage Repair 685

Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814),ERC/P16-20AAF 685

Disassemble [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814),ERC/P16- 685

Assemble and Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814) 687

Control Valve Linkage Repair 687

Remove and Disassemble [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A81 687

Assemble and Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814) 688

Control Lever Linkage Repair 688

Remove [ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D216) an 688

Disassemble [ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D21 690

Assemble and Install [ERP20-30ALF (B216), ERP20-30ALF (ERP040-06 690

Pressure Relief Valve Check and Adjustment 691

Primary Relief Valve 691

Secondary Relief Valve 692

Troubleshooting 693

524179947-2200YRM0557-(07-2003)-UK-EN 697

toc 697

EV-100ZX™ SCR Motor Controller 697

Safety Precautions Maintenance and Repair 698

General 703

Model Number Data For EV-100ZX Controller 704

Register Parameters 718

General 718

Function Numbers 718

Control Card, Checks and Adjustments 718

Handset 719

How to Check and Adjust Registers 719

How to Scroll through Fault Codes and Clear Them 719

Checks and Adjustments on Workbench 720

When Handset Is Connected to Control Card Installed In Lift Truc 721

Function Numbers 1 through 15 722

Function Numbers 16 through 30 722

Function Numbers 48 through 62 722

Control Cards 723

Function Number Descriptions 723

Traction Control Cards (Label Letters – ZH and ZY) 723

Function Number 1 STORED STATUS CODE 723

Function Number 2 CREEP SPEED 723

Function Number 3 CONTROLLED ACCELERATION AND 1A TIME 723

Function Number 4 CURRENT LIMIT 724

Function Number 5 PLUGGING DISTANCE (CURRENT) 724

Function Number 6 1A DROP OUT CURRENT 724

Function Number 7 FIELD WEAKENING PICK UP 724

Function Number 8 FIELD WEAKENING DROP OUT 724

Function Number 9 REGENERATIVE BRAKING CURRENT LIMIT 724

Function Number 10 REGENERATIVE BRAKING START 725

Function Number 13 SPEED LIMIT 3 (SL3) 725

Function Number 14 INTERNAL RESISTANCE COMPENSATION 725

Function Number 15 BATTERY VOLTS 726

Function Numbers GREATER THAN 15 726

Function Number 16 PEDAL POSITION PLUG 726

Function Number 17 CARD TYPE SELECTION 726

Function Number 18 STEERING PUMP TIME DELAY 726

Function Number 19 MAINTENANCE ALERT (Tens/Units) 727

Function Number 20 MAINTENANCE ALERT (Thousands/Hundreds) 727

Function Number 21 MAINTENANCE SPEED LIMIT 727

Function Numbers 22 Through 28 TEMPORARY DATA REGISTERS 727

Function Number 29 HOURMETER (Tens/Units) 727

Function Number 30 HOURMETER (Thousands/Hundreds) 727

Function Number 48 Through 62 SET LIFT TRUCK PERFORMANCE 727

Function Number 48 CONTROLLED ACCELERATION AND 1A TIME 728

Function Number 49 FIELD WEAKENING PICK UP 728

Function Number 50 SPEED LIMIT 1 728

Function Number 52 CONTROLLED ACCELERATION AND 1A TIME 728

Function Number 53 FIELD WEAKENING PICK UP 728

Function Number 54 SPEED LIMIT 1 729

Function Number 56 CONTROLLED ACCELERATION AND 1A TIME 729

Function Number 57 FIELD WEAKENING PICK UP 729

Function Number 58 SPEED LIMIT 1 729

Function Number 60 CONTROLLED ACCELERATION AND 1A TIME 729

Function Number 61 FIELD WEAKENING PICK UP 729

Pump Control Card (Label Letter ZP) 729

Function Number 1 STORED STATUS CODE 730

Function Number 2 INTERNAL RESISTANCE COMPENSATION START 730

Function Number 3 CONTROLLED ACCELERATION 730

Function Number 4 CURRENT LIMIT 730

Function Number 7 CONTROLLED ACCELERATION COMPENSATION 730

Function Number 11 SPEED LIMIT 1 (SL1) (Slow Speed) – Tilt and S 730

Function Number 12 SPEED LIMIT 2 (SL2) (Medium Speed) – Slow Lif 730

Function Number 13 SPEED LIMIT 3 (SL3) 730

Function Number 14 SPEED LIMIT 4 (SL4) Fast Lift 731

Function Numbers Greater Than 15 731

Function Number 16 INTERNAL RESISTANCE COMPENSATION 731

Function Number 17 CARD TYPE SELECTION 731

Function Numbers 18 through 28 TEMPORARY DATA REGISTERS 731

Function Number 29 HOURMETER (Tens/Units) 731

Function Number 30 HOURMETER (Thousands/Hundreds) 731

Function Number 48 CONTROLLED ACCELERATION 732

Function Number 49 SPEED LIMIT 2 732

Function Number 50 SPEED LIMIT 3 732

Function Number 52 CONTROLLED ACCELERATION 732

Function Number 53 SPEED LIMIT 2 732

Function Number 54 SPEED LIMIT 3 732

Function Number 56 CONTROLLED ACCELERATION 732

Function Number 57 SPEED LIMIT 2 732

Function Number 58 SPEED LIMIT 3 732

Function Number 60 CONTROLLED ACCELERATION 733

Function Number 61 SPEED LIMIT 2 733

Function Number 62 SPEED LIMIT 3 733

Register Parameters 733

Troubleshooting 733

General 733

Status Codes 734

Register Maps 736

Status Code Charts 747

EV-100ZX SCR Motor Controller Repair 788

Fuses 788

SCR, Check 788

SCR Assembly 790

Thermal Protector 790

SCR 1 Assembly, Replace 790

OFF Circuit for SCR 1 791

Reactor Assembly, Check 791

Suppressors for SCR 2 and SCR 5, Check 791

SCR 2 and SCR 5, Check 791

SCR 2 and SCR 5, Replace 792

Capacitor C1, Check 792

Diodes D3 and D4 792

Diodes D3 and D4, Check 792

Diodes D3 and D4, Replace 792

Motor Current Sensor 792

Contactors 793

Contactor, Repair 793

Control Card 795

Control Card Plugs 796

Brush Wear Indicators 796

Theory of Operation 797

Electronic Speed Controls 797

Silicon Controlled Rectifier (SCR) 798

Motor Circuit That Operates With Pulses 799

Traction Circuit 800

Hydraulic Pump Motor 800

SCR 1 OFF Circuit 800

SCR 1 OFF Operation 801

Induction Current from Motor 803

Control Cards 804

Pulse Monitor Trip (PMT) (Traction Circuit Only) 804

SRO Circuit (Traction Circuit Only) 804

Sequence of Operation 805

Control Card Adjustments (Traction Circuit) 805

Accelerator Control 809

SCR Control (Hydraulic Pump Motor) 809

Contactors 809

Circuit Protection 810

Traction Circuit Fuse 810

Current Limit 810

Thermal Protection 810

Suppressors 811

Truck Management Module (TMM1) 811

Display Panels 812

Display Panel 812

Optional Basic Display Panel 812

Features of the Optional Basic Display Panel 812

Description of Features on the Optional Basic Display Panel 813

Standard Display Panel 813

Features of the Standard Display Panel 813

Description of Features on the Standard Display Panel 814

Premium Display Panel 815

Features on the Premium Display Panel 815

Description of Features on the Premium Display Panel 816

Curtis 1215 Display Panel 818

Description and Features 818

Operation 819

tables 697

Table 1 Terminal and Plug Wire Connections for Control Card ZY, 710

Table 2 Terminal and Plug Wire Connections for Control Card ZH, 712

Table 3 Terminal and Plug Wire Connections for Control Card ZH, 714

Table 4 Terminal and Plug Wire Connections for Controller with 716

Table 5 Status Codes List 735

Table 6 Register Map for Control Cards ZH and ZY (Traction) 737

Table 7 Register Map for Control Card ZP (Hydraulic Pump) 742

Table 8 Terminal and Plug Wire Connections for TMM1 Module 812

524179950-2200YRM0624-(07-2003)-UK-EN 823

toc 823

EV-100ZX TM SCR MOTOR CONTROLLER 823

Safety Precautions Maintenance and Repair 824

Register Parameters 827

General 827

Function Numbers 828

Control Card Checks and Adjustments 828

Register Parameter Tables 829

tables 823

Table 1 EV-100ZX Parameters [Heavy Duty Motor ( Yale Part Numbe 829

Table 2 EV-100ZX Parameters [Heavy Duty Motor ( Yale Part Numbe 833

Table 3 EV-100ZX Parameters [Standard Motor ( Yale Part Number 837

Table 4 EV-100ZX Parameters [Standard Motor ( Yale Part Number 841

Table 5 EV-100ZX Parameters [Standard Motor ( Yale Part Number 845

Table 6 EV-100ZX Parameters (Standard System) (Hydraulic Pump C 849

Table 7 EV-100ZX Parameters (Low Energy System) (Hydraulic Pump 852

524179951-2200YRM0724-(04-2005)-UK-EN 857

toc 857

SR/SP Transistor Motor Controllers 857

Safety Precautions Maintenance and Repair 858

Description 863

General 863

Model Number Data for SR/SP Transistor Motor Controllers 864

Motor Controller Checks and Adjustments 867

Checks and Adjustments Using Handset 867

General 867

Connect Handset 868

Start Sequence 868

Check or Delete Stored Status Codes 869

Returning Lift Truck to Normal Operation 871

Workbench Checks and Adjustments 871

How to Check and Adjust Registers 873

Function Parameters Adjustments 873

General 873

Function Numbers 874

When Handset is Connected to Motor Controller in Lift Truck 874

Function Numbers 1 through 15 874

Function Numbers 16 through 30 874

Function Numbers 48 through 63 875

Function Number Descriptions 876

Traction Motor Controller (Label Letter – SR) 876

Function Number 01 AUTO REGEN ENABLE SPEED 876

Function Number 02 CREEP SPEED 876

Function Number 03 CONTROLLED ACCELERATION 876

Function Number 04 ARMATURE CURRENT LIMIT 876

Function Number 05 REGEN RAMP RATE 877

Function Number 06 FIELD WEAKENING (FW) RATIO 877

Function Number 07 MINIMUM FIELD CURRENT 877

Function Number 08 MAXIMUM FIELD CURRENT 877

Function Number 09 REGENERATIVE BRAKING CURRENT LIMIT (C/L) 877

Function Number 10 FIELD CURRENT FOR REGENERATIVE BRAKING 877

Function Number 12 MAXIMUM ARMATURE % ON TIME (Travel Speed Limi 877

Function Number 13 SPEED LIMIT 3 878

Function Number 14 INTERNAL RESISTANCE COMPENSATION 878

Function Number 15 BATTERY VOLTAGE SELECTION 878

Function Number 16 STALL TRIP POINT % ON TIME 879

Function Number 17 CONTROL TYPE SELECTION 879

Function Number 18 STEERING PUMP TIME DELAY 879

Function Number 19 MAINTENANCE CODE TENS AND UNITS 880

Function Number 20 MAINTENANCE CODE THOUSANDS AND HUNDREDS 880

Function Number 21 AUTO REGEN BRAKING CURRENT LIMIT 880

Function Number 23 FOR SPECIAL FUNCTIONS 880

Function Number 24 FIELD WEAKENING START 880

Function Number 25 MONITOR 880

Function Number 26 BASE RATIO 880

Function Number 28 STORED STATUS CODE COUNT POINTER 880

Functions with Premium Display Panel Only 881

Function Number 48 MODE 1 – CONTROLLED ACCELERATION 881

Function Number 49 MODE 1 FIELD WEAKENING (FW) START 881

Function Number 50 MODE 1 – FIELD WEAKENING (FW) RATIO 881

Function 51 MODE 1 – MAXIMUM ARMATURE % ON TIME (MODE 1 – TRAVEL 882

Function 52 MODE 2 – CONTROLLED ACCELERATION 882

Function Number 53 MODE 2 – FIELD WEAKENING (FW) START 882

Function Number 54 MODE 2 – FIELD WEAKENING (FW) RATIO 882

Function Number 55 MODE 2 – MAXIMUM ARMATURE % ON TIME (MODE 2 – 882

Function Number 56 MODE 3 – CONTROLLED ACCELERATION 882

Function Number 57 MODE 3 – FIELD WEAKENING (FW) START 882

Function Number 58 MODE 3 – FIELD WEAKENING (FW) RATIO 882

Function Number 59 MODE 3 – MAXIMUM ARMATURE % ON TIME (MODE 3 – 883

Function Number 60 MODE 4 – CONTROLLED ACCELERATION 883

Function Number 61 MODE 4 – FIELD WEAKENING (FW) START 883

Function Number 62 MODE 4 – FIELD WEAKENING (FW) RATIO 883

Function Number 63 MODE 4 – MAXIMUM ARMATURE % ON TIME (MODE 4 – 883

Pump Motor Controller (Label Letter – SP) 883

Function Number 01 STORED STATUS CODE 883

Function Number 02 INTERNAL RESISTANCE COMPENSATION START 884

Function Number 03 CONTROLLED ACCELERATION 884

Function Number 04 CURRENT LIMIT 884

Function Number 07 INTERNAL RESISTANCE COMPENSATION RATE 884

Function Number 11 SPEED LIMIT 1 (SL1) (Slow Speed) – Tilt and S 884

Function Number 12 SPEED LIMIT 2 (SL2) (Medium Speed) – Slow Lif 884

Function Number 13 SPEED LIMIT 3 (SL3) Fast Lift 884

Function Number 16 SPEED/TORQUE COMPENSATION 885

Function Number 17 CONTROL TYPE SELECTION 885

Function Numbers 18 through 27 TEMPORARY DATA REGISTERS 885

Function Number 28 STORED STATUS CODE COUNT POINTER 885

Functions with Premium Display Panel Only 885

Function Number 48 MODE 1 – CONTROLLED ACCELERATION 886

Function Number 49 MODE 1 – SPEED LIMIT 2 886

Function Number 50 MODE 1 – SPEED LIMIT 3 886

Function Number 52 MODE 2 – CONTROLLED ACCELERATION 886

Function Number 53 MODE 2 – SPEED LIMIT 2 886

Function Number 54 MODE 2 – SPEED LIMIT 3 886

Function Number 56 MODE 3 – CONTROLLED ACCELERATION 886

Function Number 57 MODE 3 – SPEED LIMIT 2 886

Function Number 58 MODE 3 – SPEED LIMIT 3 887

Function Number 60 MODE 4 – CONTROLLED ACCELERATION 887

Function Number 61 MODE 4 – SPEED LIMIT 2 887

Function Number 62 MODE 4 – SPEED LIMIT 3 887

Troubleshooting 891

General 891

Status Codes 892

SR (SEM) and SP Status Code Charts 894

SR/SP Transistor Motor Controller Repair 928

General 928

General Maintenance Instructions 928

Special Precautions 931

Fuses 931

Contactors 932

Repair 932

Contactor Driver Module 934

Contactor Driver, Replace 934

Motor Controller Plug 934

Brush Wear Indicators 939

Thermal Sensors 939

Motor Controller, Replace 939

Theory of Operation 940

General 940

SEM System Description 940

SEM System Operation (SR Motor Controller) 940

Reverse Circuit 940

Performance and Efficiency 942

Field Weakening 942

Regenerative Braking 942

SEM System Operation (SP Motor Controller) 943

Creep Speed 943

Controlled Acceleration 943

Current Limit (CL) 943

Braking 943

Regenerative Braking to Zero Speed 943

Pedal Position Braking 944

Auto Braking 944

Auxiliary Speed Control 944

Field Weakening 944

Speed Limits 944

Ramp Operation 944

Ramp Start 944

Anti-rollback 944

Steer Pump Contactor Time Delay 944

Coil Drivers and Internal Coil Suppression 944

System Protective Override 944

Static Return to Off (SRO) 944

Accelerator Volts Hold Off 945

Pulse Monitor Trip (PMT) 945

Thermal Protector (TP) 945

Low Voltage 945

SP Pump Motor Controllers 945

Contactor Driver Module 946

Diagnostics 946

Systems Diagnostics 946

Standard Status Codes 946

Stored Status Codes 946

Hourmeter Readings 946

Maintenance Management Capability 946

tables 857

Table 1 List of Status Codes 870

Table 2 Speed/Torque Compensation 884

Table 3 Function Map for Motor Controllers SR (Traction) 887

Table 4 Function Map for Motor Controller SP (Lift Pump Motor) 890

Table 5 List of Status Codes 892

Table 6 Large (P) Plug (23-Pin) Connections/Descriptions for Mo 935

Table 7 Small Plug (12-Pin) Connections/Descriptions for Motor 936

524179952-2200YRM0739-(04-2005)-UK-EN 949

toc 949

Transistor Motor Controllers 949

Safety Precautions Maintenance and Repair 950

General 953

Function Numbers 953

Motor Controller Checks and Adjustments 954

Parameter Tables 954

tables 949

Table 1 SR (SEM) Register Parameters for Traction Motor Control 954

Table 2 SR (SEM) Register Parameters for Traction Motor Control 958

Table 3 SP Register Parameters for Pump Motor Controller – ERC/ 961

Table 4 SR (SEM) Register Parameters for Traction Motor Control 964

Table 5 SR (SEM) Register Parameters for Traction Motor Control 968

Table 6 SR (SEM) Register Parameters for Traction Motor Control 971

Table 7 SR (SEM) Register Parameters for Traction Motor Control 975

Table 8 SP Register Parameters for Pump Motor Controller – ERC0 978

Table 9 SP Register Parameters for Pump Motor Controller – ERC2 981

Table 10 SR (SEM) Register Parameters for Traction Motor Contro 985

Table 11 SR (SEM) Register Parameters for Traction Motor Contro 988

Table 12 SR (SEM) Register Parameters for Traction Motor Contro 991

Table 13 SP Register Parameters for Pump Motor Controller – ERP 994

Table 14 SP Register Parameters for Pump Motor Controller – ERP 997

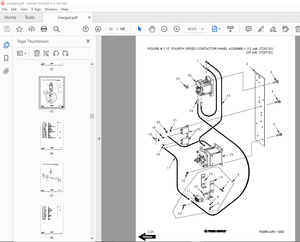

524179953-4000YRM0563-(04-2005)-UK-EN 1003

toc 1003

Four-Stage Mast 1003

Safety Precautions Maintenance and Repair 1004

General 1007

Description 1007

Carriages 1007

Mast Mounts 1008

Mast 1008

Description 1008

Operation 1009

Forks Repair 1012

Remove 1012

Install 1012

Safety Procedures When Working Near Mast 1014

Carriage Repair 1016

Remove 1016

Standard Carriage 1016

Sideshift Carriage 1017

Repairs 1018

Install 1018

Standard Carriage 1018

Sideshift Carriage 1018

Mast Repair 1019

Remove 1019

Disassemble 1019

Clean and Inspect 1020

Assemble 1021

Install 1023

Lift Cylinders Repair 1026

Remove 1026

Main Lift Cylinders 1026

Free-Lift Cylinders 1026

Disassemble 1026

Assemble 1028

Install 1030

Main Lift Cylinder 1030

Free-Lift Cylinder 1031

Header Hose Arrangements 1032

Header Hoses, Install 1032

Lift and Tilt System Leaks Check 1039

Lift Cylinders Leaks Check 1039

Tilt Cylinders Leaks Check 1039

Tilt Cylinders Adjustment 1040

Lift Chain Adjustments 1041

Mast Adjustments 1042

Carriage Adjustments 1044

Troubleshooting 1045

tables 1003

Table 1 Standard Four-Stage Hose Dimensions 1038

Table 2 Hook type Carriage Chain Adjustment 1041

Table 3 Pin-Type Carriage Chain Adjustment 1042

524179955-8000YRM0622-(07-2003)-UK-EN 1049

toc 1049

Electrical Diagrams 1049

Safety Precautions Maintenance and Repair 1050

524179956-8000YRM0742-(06-2004)-UK-EN 1099

toc 1099

Electrical Diagrams 1099

Safety Precautions Maintenance and Repair 1100

524179957-8000YRM0552-(07-2003)-UK-EN 1163

toc 1163

Periodic Maintenance 1163

Safety Precautions Maintenance and Repair 1164

General 1169

Serial Number Data 1169

How to Move Disabled Lift Truck 1169

How to Tow Lift Truck 1169

How to Put Lift Truck on Blocks 1170

How to Raise Drive Tires 1170

How to Raise Steering Tires 1170

Maintenance Schedule 1171

Maintenance Procedures Every 8 Hours or Daily 1178

How to Make Checks With Key OFF 1178

Tires and Wheels 1178

Forks 1179

Adjust 1179

Remove 1180

Install 1180

Forks, Mast, and Lift Chains, Inspect 1180

Safety Labels 1181

Steering Column Latch 1181

Operator Restraint System 1181

Battery Restraint System ERC/P16-20AAF (ERC030-040AF – AG/BG), E 1182

Battery Restraint System ERP20-30ALF 1183

Battery 1184

Hydraulic System 1185

How to Make Checks With Key ON 1185

Gauges, Horn, and Fuses 1185

Steering System 1186

Service Brakes 1186

Parking Brake 1186

Control Levers and Pedals 1186

Direction and Speed Control Pedals 1186

Lift System Operation 1187

Maintenance Procedures Every 250 Hours or 6 Weeks 1187

Steering Tie Rods 1187

Maintenance Procedures Every 500 Hours or 3 Months 1188

Hydraulic Tank Breather 1188

Differential and Speed Reducer 1188

Wheel Nut Torques 1189

Steering Axle Spindles 1189

Steering Tie Rods 1189

Mast 1189

Lift Chains 1190

Wear Check 1190

Forks 1191

Brake Fluid 1191

Other Lubrication 1191

Seat Brake, ERC/P16-20AAF (ERC030-040AF – AG/BG), ERC20-30AGF (E 1192

Electrical Inspection 1192

Contactors 1192

Motor Brushes 1197

Motor Brushes, General 1197

Maintenance Procedures Every 1000 Hours or 6 Months 1205

Lift Chains 1205

Forks 1205

Check Upper and Lower Bearings, Integral Sideshift Carriage 1205

Maintenance Procedures Every 2000 Hours or Yearly 1206

Hydraulic System 1206

Change Filter for Hydraulic Oil 1206

Change Hydraulic Oil 1207

Differential and Speed Reducer 1207

Service Brakes 1207

Contactors 1208

Wheel Bearings 1208

Steer Wheels, Lubrication 1208

Drive Wheels, Lubrication 1208

Lift Chains 1208

Replace Upper and Lower Bearings, Integral Sideshift Carriage 1208

Steering Axle 1209

King Pins and Rod Ends (Steering Cylinders) 1209

Other Lubrication 1209

Battery Maintenance 1209

How to Charge Battery 1209

How to Change Battery 1210

General 1210

Change Battery, ERC/P16-20AAF (ERC030-040AF – AG/BG) and ERC20-3 1211

Change ERP20-30ALF Battery 1214

Lift and Tilt System Leak Check 1216

Lift Cylinders Leak Check 1216

Tilt Cylinders Leak Check 1216

Safety Procedures When Working Near Mast 1217

Lift Chain Adjustments 1219

PMT Circuit Check 1221

Welding Repairs 1222

Overhead Guard Changes 1222

Wheels and Tire Maintenance 1222

Tires and Wheels, ERC/P16-20AAF (ERC030-040AF – AG/BG), ERC20-30 1222

Remove Wheels From Lift Truck 1223

Remove and Install Tire on Wheel 1223

Pneumatic Tires and Wheels ERP20-30ALF 1223

Remove Wheels From Lift Truck 1223

Remove Wheel From Pneumatic Tire 1224

Install Wheel in Pneumatic Tire 1225

Install Three- or Four-Piece Wheel in Pneumatic Tire 1226

Add Air to Tires 1227

Wheels, Install 1228

Solid Rubber Tires on Pneumatic Wheels 1228

Remove Wheels From Lift Truck 1228

Remove Solid Rubber Tire From Pneumatic Wheel 1228

Install Solid Rubber Tire on Pneumatic Wheel 1230

Wheels, Install 1231

SIT Tire, Change 1231

Remove SIT Solid Tire From Wheel 1232

Install SIT Solid Tire on Wheel 1233

Adhesives and Sealants 1234

tables 1163

Table 1 Maintenance Schedule 1173

Table 2 Hook-Type Carriage Chain Adjustment 1220

Table 3 Pin-Type Carriage Chain Adjustment 1220

524179959-8000YRM0621-(01-2005)-UK-EN 1237

toc 1237

Capacities and Specifications 1237

Safety Precautions Maintenance and Repair 1238

Wheels and Tires 1241

Counterweights 1241

Hydraulic System 1241

Capacities 1242

Battery Specifications 1242

Battery Height Specifications (Hoods and Battery Types) 1243

Maximum Carriage and Tilt Creep Rates 1244

Mast Speeds 1245

ERC030AF, AG/BG-ERC040AF, AG/BG Mast Speeds (36 and 48 Volt) Ame 1245

ERC/P16-20AAF Mast Speeds (48 Volt) Europe 1249

ERC030AF, AG/BG-ERC040AF, AG/BG Mast Speeds Americas 1253

ERC/P16-20AAF Mast Speeds Europe 1255

Torque Specifications 1256

Frame 1256

Mast 1256

Drive Axle, Speed Reducer, and Differential 1257

Steering Axle 1257

Brake 1257

Adhesives and Sealants 1258