$40.95

Yale Forklift A839 (ERC35-40-45-55HG) Service Manual – PDF DOWNLOAD

Yale Forklift A839 (ERC35-40-45-55HG) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A839 (ERC35-40-45-55HG) Service Manual – PDF DOWNLOAD

Language : English

Pages : 932

Downloadable : Yes

File Type : PDF

PART NO. 524150783

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A839 (ERC35-40-45-55HG) Service Manual – PDF DOWNLOAD

524150783-1600YRM0326-(03-2007)-UK-EN 1

toc 1

Steering Axle 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Steering Axle Assembly Repair 10

Steering Axle GP/GLP/GDP070-110LG/MG (B813), GC/GLC070-120LG/MG 10

Remove 10

Install 10

Steering Axle GDP60-70CA (GP/GLP/GDP135-155CA) (A878, B878), GLP 11

Remove 11

Install 11

Wheels and Hubs Repair (All Units) 12

Remove and Disassemble 12

Clean 12

Inspect 12

Assemble and Install 12

Spindles and Bearings Repair (All Units) 14

Remove 14

Clean 14

Assemble and Install 15

Tie Rods Repair (All Units) 16

Remove 16

Clean 16

Install 16

Steering Cylinder Repair 19

Remove and Disassemble 19

Clean and Inspect 19

Assemble and Install 19

Troubleshooting 20

524150790-2100YRM0103-(03-2007)-UK-EN 25

toc 25

Tilt Cylinders 25

Safety Precautions Maintenance and Repair 26

General 29

Description 29

Tilt Cylinder Repair 29

Remove 29

Disassemble 29

Clean 29

Assemble 30

Tilt Cylinders With O-Ring or Single-Lip Seals 30

Tilt Cylinders 31

Install 32

Tilt Cylinder Leak Check 34

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 35

Torque Specifications 35

Piston Rod Nut 35

Retainer 35

Troubleshooting 36

tables 25

Table 1 Movement Rates (Maximum) for Tilt Cylinders 34

524150794-4000YRM0135-(03-2011)-UK-EN 41

toc 41

Lift Cylinders 41

Safety Precautions Maintenance and Repair 42

Safety Procedures When Working Near Mast 45

General 49

Description 49

Lowering Control Valve 49

Cylinders (General) 52

Lift Cylinder Repair 52

Lift Cylinder Removal Without Removing Mast 52

Standard Masts With Main Lift Cylinder Fastened to Crossmember o 52

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to 53

Masts That Have Two Cylinders, Main Lift Cylinder and Free-Lift 54

Disassemble 54

Assemble 54

Lift Cylinder Installation in Mast 56

Standard Masts With Main Lift Cylinder Fastened to Crossmember o 56

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to 56

Chevron-Style Packing 57

Chevron-Style Packing Installation on Piston 57

Chevron-Style Packing Installation in Packing Gland 59

Lift Cylinders for HI VIS® Masts 61

Description 61

Lowering Control Valve 61

Remove 63

Disassemble 64

Assemble 64

Install 66

Main Lift Cylinders 66

Free-Lift Cylinder 66

Lift System Leak Check 66

Specifications 67

Troubleshooting 68

tables 41

Table 1 Cylinder Retainer Torque Specifications and Weight Guid 67

524150797-8000YRM0231-(02-2023)-UK-EN 73

General 79

Threaded Fasteners 79

Nomenclature, Threads 79

Strength Identification 80

Cotter (Split) Pins 81

Fastener Torque Tables 86

Conversion Table 88

524153919-4000YRM0741-(03-2005)-UK-EN 95

toc 95

Lift Cylinders 95

Safety Precautions Maintenance and Repair 96

Safety Procedures When Working Near Mast 99

General 101

Description 101

Lowering Control Valve (Velocity Fuse) 101

Lift Cylinder Repair 104

Remove 104

Disassemble 105

Assemble 105

Install 105

Lift System Leak Check 106

Troubleshooting 107

524153920-4000YRM0736-(07-2010)-UK-EN 111

toc 111

Masts 111

Safety Precautions Maintenance and Repair 112

General 115

Description and Operation 115

Carriages 115

Two-Stage Mast With Limited Free-Lift 115

Two-Stage Mast With Full Free-Lift 116

Three-Stage Mast With Full Free-Lift 117

Safety Procedures When Working Near Mast 119

Fork Replacement 121

Remove 122

Install 122

Carriage Repair 123

Remove 123

Sideshift Carriage Repair 125

Remove 125

Disassemble 125

Assemble 125

Install 125

Two-Stage Mast With Limited Free-Lift Repair 127

Remove, GLP/GDP3 5-5 5LJ/MJ (GP/GLP/GDP070-120LJ/MJ) Model Lift 127

Remove, GC070-120LJ/MJ, ERC070-120HG (A839), and ERC35-55HG (ERC 129

Disassemble 132

Clean and Inspect 132

Assemble 133

Install, GLP/GDP3 5-5 5LJ/MJ (GP/GLP/GDP070-120LJ/MJ) Lift Truck 134

Install, GC070-120LJ/MJ, ERC070-120HG (A839), and ERC35-55HG (ER 136

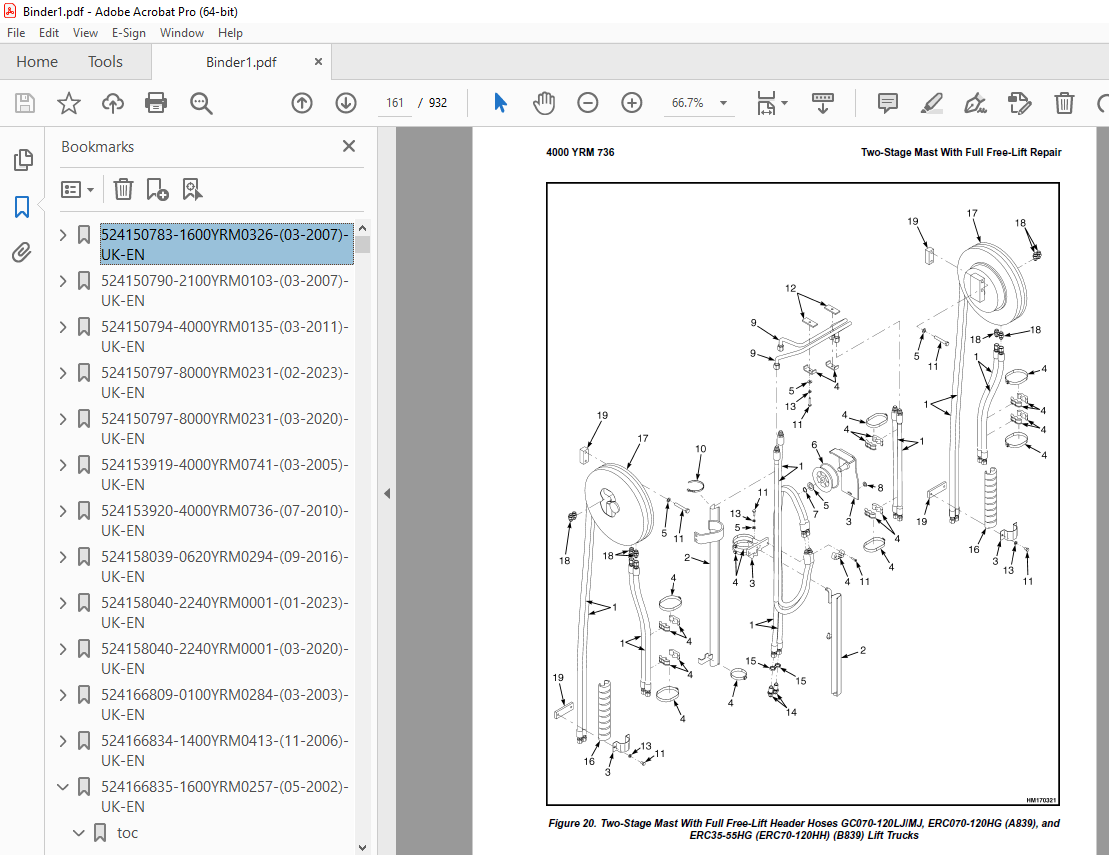

Two-Stage Mast With Full Free-Lift Repair 138

Remove 138

Disassemble 138

Clean and Inspect 140

Assemble 140

Install 140

Three-Stage Mast With Full Free-Lift Repair 142

Remove 142

Disassemble 142

Clean and Inspect 146

Assemble 146

Install 147

Mast Operation Check 153

Lift and Tilt System Leak Check 154

Lift System 154

Tilt System 155

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment 156

Lift Chain Adjustments 158

Mast Adjustments 160

Carriage Adjustment 162

Troubleshooting 163

tables 111

Table 1 Tilt Cylinder Leak Check Specifications, GC070-120LJ/MJ 155

Table 2 Hook-Type Carriage Chain Adjustment 158

Table 3 Pin-Type Carriage Chain Adjustment 159

524158039-0620YRM0294-(09-2016)-UK-EN 169

General 173

Brush and Commutator Inspection 174

Hydraulic Pump Motor and Traction Motor 174

Steering Pump Motor 177

Normal Commutator Surface 177

Commutator Problems 177

Brush Replacement 182

Stoning the Commutator 185

Motors Repair 186

Disassemble 187

Traction Motor and Hydraulic Pump Motor 187

Steering Pump Motor 188

Assemble 192

Traction Motor and Hydraulic Pump Motor 192

Steering Pump Motor 194

Brush Alignment, Traction and Hydraulic Motors 196

Tests for Damaged Field and Armature 197

Test for an Open Circuit in One Armature Winding 197

Test for Short Circuit in One Armature Winding 197

Test for Short Circuit to Armature Shaft 198

Test for Open Circuit in Field Coil 198

Test for Short Circuit in Field Coil 199

Test for Short Circuit Between Field and Motor Case 199

Brush Holder Test 199

Troubleshooting 200

524158040-2240YRM0001-(01-2023)-UK-EN 205

General 211

Battery Type 211

Lead-Acid Batteries 211

Lithium-Ion Batteries 212

Specific Gravity 212

Chemical Reaction in a Cell 212

Electrical Terms 214

Battery Selection 215

Battery Voltage 216

Battery as a Counterweight 216

Battery Ratings 216

Kilowatt-Hours 216

Battery Maintenance 217

Safety Procedures 217

Maintenance Records 217

New Battery 217

Cleaning Battery 218

Adding Water to Battery 220

Hydrometer 220

Battery Temperature 221

Charging Battery 222

Types of Battery Charges 223

Methods of Charging 224

Troubleshooting Charger 225

Knowing When Battery Is Fully Charged 225

Where to Charge Batteries 225

Equipment Needed 225

Battery Connectors 226

Battery Care 226

Troubleshooting 228

524166809-0100YRM0284-(03-2003)-UK-EN 233

toc 233

Frame 233

Safety Precautions Maintenance and Repair 234

General 237

Description 237

Overhead Guard Repair 240

Remove 240

Install 240

Battery Restraint and Seat Assembly Repair 241

Seat Brake Assembly, Adjust 242

Counterweight Repair 244

Remove 244

Install 244

Traction Motor Repair 245

Remove 245

Install 246

Hydraulic Tank Repair 246

Inspect 246

Small Leaks, Repair 246

Large Leaks, Repair 247

Clean 247

Steam Method 247

Chemical Solution Method 248

Additional Preparations For Repair 248

Painting Instructions 248

Safety Label Replacement 249

tables 233

Table 1 Battery Specifications 238

Table 2 Seat Brake Adjustment 243

Table 3 Counterweights 244

524166834-1400YRM0413-(11-2006)-UK-EN 255

toc 255

Drive Axle, Speed Reducer, and Differential 255

Safety Precautions Maintenance and Repair 256

General 259

Description 259

Drive Axle, Speed Reducer, and Differential Repair 260

Remove 260

General 260

Traction Motor, Speed Reducer, and Differential 261

Motor, Speed Reducer, and Differential, Remove 261

Disassemble 264

Speed Reducer 264

Differential 265

Clean 266

Inspect 266

Assemble 266

Speed Reducer 266

Input Gear, Install 266

New Pinion, Install 266

Differential 269

Drive Axle Housing 272

Remove 272

Clean 273

Inspect 273

Assemble 273

Troubleshooting 276

tables 255

Table 1 Pinion Assembly Shims Adjustment 268

Table 2 Ring and Pinion Tooth Contact Adjustment 270

524166835-1600YRM0257-(05-2002)-UK-EN 279

toc 279

Steering Control Unit 279

Safety Precautions Maintenance and Repair 280

General 283

Description 283

Control Valve Section 283

Metering Section 283

Disassembly and Inspection 284

Disassemble and Inspect 288

Assembly 304

Assemble 304

Troubleshooting 327

524166836-1600YRM0485-(07-2003)-UK-EN 331

toc 331

Steering System for Electric Lift Trucks 331

Safety Precautions Maintenance and Repair 332

General 335

Description 337

Steering Wheel and Column Assembly Repair 338

Assembly Components, Remove 338

Assembly Components, Install 342

Power Steering Motor and Pump 343

Description 343

Remove and Disassemble, Models ERC 20-30AGF (ERC040-065RF/ZF, RG 344

Remove and Disassemble, Models ERC35-55HG (ERC70-120HD, ERC70-12 345

Remove and Disassemble, Models ERP20-30ALF 348

Remove and Disassemble, Models ERC/P16-20AAF (ERC040-065AF, AG/B 348

Assemble and Install, All Models With A Vertical Mount Except ER 349

Assemble and Install, Models ERP20-30ALF 349

Assemble and Install, Models ERC/P16-20AAF (ERC030-040AF, AG/BG) 350

Power Steering Pump, Repair 350

Seal, Replace 351

Hydraulic Steering Motor 352

Steering System Air Removal 352

Steering Pressure Check 352

Optical Encoder and Activator Circuits Check 353

Troubleshooting 355

524166837-1800YRM0338-(05-2009)-UK-EN 359

toc 359

Brake System 359

Safety Precautions Maintenance and Repair 360

General 363

Description and Operation 363

Brake Booster and Master Cylinder 363

Master Cylinder 363

Service Brake Assembly 363

Parking Brake 367

Seat Brake 368

Brake Shoe Assemblies Repair 369

Remove and Disassemble 369

Clean and Inspect 369

Assemble and Install 371

Master Cylinder Repair 375

Master Cylinder For Lift Truck Models GC/GLC70-120LG/MG (B818) a 375

Remove 375

Disassemble 375

Assemble 376

Install 376

Master Cylinder For Lift Truck Models ERC70-120HD, ERC70-120HG ( 377

Remove and Disassemble 377

Clean and Inspect 378

Assemble and Install 378

Brake Booster Repair 378

Remove 378

Disassemble 378

Clean and Inspect 379

Assemble 380

Install 380

Brake System Air Removal 380

Brake Pedal Adjustment 380

Brake Pedal GP/GLP/GDP70-120LG/MG (B813) With Manual Transmissio 380

Brake Shoes Adjustment 382

Parking Brake Adjustment 382

Parking Brake Adjustment, Lift Truck Models GC/GLC70-120LG/MG (B 382

Parking Brake Lever and Switch Adjustment ERC70-120HD and ERC70- 383

Seat Brake Assembly 384

Remove 384

Clean and Inspect 384

Install 384

Adjustments 386

Solenoid Adjustment 386

Traction cutoff Switch Adjustment 386

Cable Adjustment 386

Brake Booster Relief Valve Check 389

Troubleshooting 389

524166838-1900YRM0286-(07-2002)-UK-EN 395

toc 395

Hydraulic System 395

Safety Precautions Maintenance and Repair 396

General 399

Description 399

Hydraulic System 399

Operation 400

Hydraulic System 400

Hydraulic Pump 401

Steering Pump 402

Hydraulic Pump Repair 402

Remove 402

Seal, Replace 403

Install 404

Main Control Valve Check and Adjust 404

Linkage and Switches 405

Relief Valve 405

Steering Relief Valve Check and Adjust 407

Specifications 407

Relief Valve Pressures 407

Capacities 407

Hydraulic Pump Capacities 407

Troubleshooting 408

524166839-2000YRM0077-(02-2009)-UK-EN 413

toc 413

Manual hydraulic Control Valve 413

Safety Precautions Maintenance and Repair 414

General 417

Description 417

Operation 419

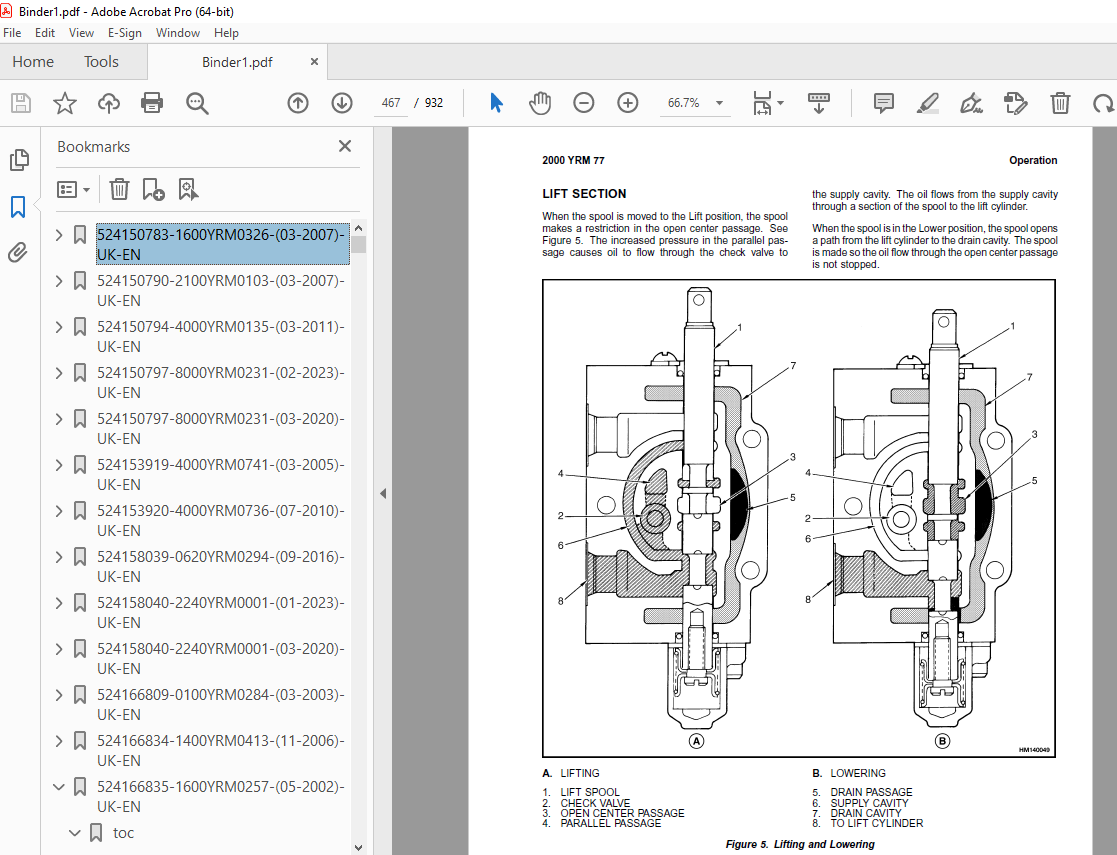

Lift Section 421

Tilt Section 422

Tilt Backward 422

Tilt Forward 422

Relief Valve 424

Solenoid Valve for Auxiliary Function 425

Main Control Valve Repair 426

Remove and Disassemble – Control Valve Without OPS Solenoid 426

Remove and Disassemble – Control Valve With OPS Solenoid 426

Clean and Inspect 428

Assemble – Control Valve Without OPS 428

Assemble – Control Valve With OPS 428

Install 429

Solenoid Valve for Auxiliary Function Repair 429

Remove and Disassemble 429

Assemble and Install 431

Troubleshooting 431

Pressure Relief Valve Check and Adjustment 432

Primary Relief Valve 432

Secondary Relief Valve 432

Control Lever Arrangement and Adjustment 433

Specifications 435

Troubleshooting 435

524166840-2200YRM0560-(07-2005)-UK-EN 441

toc 441

Electrical System 441

Safety Precautions Maintenance and Repair 442

General 447

Description 448

ZX Series Display Panels 448

Optional Basic Display Panel 448

Features of the Optional Basic Display Panel 448

Description of Features on the Optional Basic Display Panel 448

Standard Display Panel 449

Features of the Standard Display Panel 449

Description of Features on the Standard Display Panel 449

Premium Display Panel 450

Features on the Premium Display Panel 450

Description of Features on the Premium Display Panel 451

Curtis 1215 Display Panel 453

Description and Features 453

Operation 453

SEM Display Panels – Features 454

Descriptions of Common Features 455

LED Symbol Indicators – SEM 455

LCD Screen 455

Battery Discharge Indicator (BDI) 455

Service Reminder 456

Status Codes 456

Hourmeter 456

Additional Features of Premium Display Panel 457

Descriptions of Additional Features 457

LCD Screen 457

Operator Passwords 457

Daily Checklist and Service Items 457

Performance Modes 457

Status Code Lists 458

Adjustment of BDI 458

SEM Display Panel Indicators 458

All Indicator Symbols 458

Hourmeter Indicator Symbol 458

Wrench Symbol 458

Battery Symbol 458

Battery Discharge Indicator (BDI) 458

Brake Fluid Too Low Symbol 458

Parking Brake Symbol 458

Fasten Seat Belt Symbol 459

LCD Screen (Standard Display Panel) 459

Additional Components of Premium Display Panel 459

Alpha Numerical Screen 459

STAR Push Button 459

Push Buttons ##1 Through ##5 – SEM 459

Other Control Components 459

Display Panel Components – ZX, and Curtis Replacement 460

ZX Panel Replacement 460

Curtis 1215 Display Panel Replacement 465

Remove 465

Install 465

SEM Display Panel Replacement 466

Motor Controller (SR or SP) Replacement 466

Remove 466

Install 466

Control Components Replacement 468

Start Switch, Replace 468

Brake Light Switch, Replace 469

Seat Switch, Replace 469

External Seat Switch, Adjust 470

Switch for Optional Seat Brake, Replace 471

Parking Brake Switch, Replace 471

Direction Switches Foot Directional Control Replace 472

Direction Control Switches (Steering Column), Replace 473

Direction Control Switches, ERC070-120HG (Steering Column), Repl 474

Brake Fluid Switch, Replace 474

Brush Wear and Overtemperature Sensors 474

Rocker Switches for Lights 475

Accelerator Position Sensor, Replace 475

On-Demand Steering Components 477

Lights, Converter, Relay, and Reverse Alarm 479

Incandescent Brake, Tail, and Reverse Light Assembly, Replace 479

LED Brake, Tail, and Reverse Light Assembly, Replace 481

Remove 481

Install 481

Flashing Light Assembly, Replace 481

Front, Rear Driving Light, or Spot Light Assemblies, Replace 483

Operator Compartment Light Assembly, Replace 483

Converter, Replace 484

Relay, Replace 484

Reverse Alarm, Replace 484

Horn and Horn Button 484

Horn Switch and Cover 485

Hydraulic Pump Switches 485

Control and Power Fuses Check 486

ZX Motor Controllers 486

SEM Motor Controllers 486

SEM Controller Field Diagnostic Procedure 491

Armature FET Test 491

Field FET Test 491

Brush Wear and Overtemperature Sensors Check – ZX Motor Controll 495

Thermal Sensors – SEM Motor Controllers Check 496

Start Switch Adjustment 497

Accelerator Potentiometer and Start Switch, ERC070-120HG Lift Tr 498

ERC070-120HG 498

Direction Switches Foot Directional Control Pedal 499

Brake Light Switch Adjustment 500

Seat Switch Check 501

Optional Seat Brake Switch Adjustment 501

Parking Brake Switch Adjustment 502

Direction Switches Check 502

Foot Directional Control Pedal 502

Steering Column 503

Hydraulic Pump Switch Adjustment 503

Foot Directional Control or Accelerator Pedal Adjustment 503

Accelerator Position Sensor Adjustment 504

524166842-2200YRM0725-(07-2002)-UK-EN 509

toc 509

SEM Display Panel 509

Safety Precautions Maintenance and Repair 510

General 513

SEM Display Panel Features 513

Common Features Descriptions 513

LED Symbol Indicators 513

LCD Screen 513

Battery Discharge Indicator (BDI) 513

Service Reminder 514

Status Codes 514

Hourmeter 514

Premium Display Panel Additional Features 515

Additional Features Descriptions (Available With Premium Display 515

LCD Screen 515

Operator Passwords 516

Daily Check List and Service Items 516

Performance Modes 516

Status Code Lists 516

BDI, Adjust 516

SEM Display Panel Indicators 517

All Indicator Symbols 517

Hourmeter Indicator Symbol 517

Wrench Indicator Symbol 517

Battery Indicator Symbol 517

Battery State-of-Charge (BDI) 517

Brake Fluid Low Symbol 517

Parking Brake Symbol 517

Fasten Seat Belt Symbol 517

LCD Screen (Standard Display Panel) 517

Premium Display Panel Additional Components 518

Alpha Numerical Screen 518

STAR Push Button 518

Push Buttons ##1 Through ##5 518

Computer Adjustments 518

Computer System 518

Connect PC to SEM Display Panel 519

ITW Switches Software Program (for SEM Display Panel) 519

Description 519

Where to Get Help 520

Hardware and Software Requirements 520

How to Start ITW Switches Program 520

Menus 521

Create a Setup File 526

SEM Display Panel Replacement 543

General 543

Remove and Replace 543

tables 509

Table 1 Adapter Pins (DB25F to DB9) 518

524166843-2200YRM0808-(06-2005)-UK-EN 549

toc 549

Transistor Motor Controllers (SR and SP) 549

Safety Precautions Maintenance and Repair 550

Description 553

Model Number Data for Transistor Motor Controllers (SR and SP) 554

Motor Controller Checks and Adjustments 557

Checks and Adjustments Using a Handset 557

General 557

Connect Handset 558

Start Sequence 558

Check or Delete Stored Status Codes 559

Returning Lift Truck to Normal Operation 560

Checks and Adjustments on Workbench 560

How to Check and Adjust Registers 560

Function Parameters Adjustments 562

General 562

Function Numbers 563

When Handset is Connected to Motor Controller in Lift Truck 563

Function Numbers 1 through 15 563

Function Numbers 16 through 30 563

Function Numbers 48 through 63 564

Function Number Descriptions 564

Traction Motor Controller (Label Letter – SR) 564

Functions with Premium Display Panel Only 569

Pump Motor Controller (Label Letter – SP) 571

Functions With Premium Display Panel Only 573

Troubleshooting 579

General 579

Status Codes 579

Status Code Charts 582

Transistor Motor Controllers Repairs 614

General 614

General Maintenance Instructions 617

Special Precautions 617

Fuses 617

Contactors 618

Repair 618

Contactor Driver Module 618

Contactor Driver, Replace 618

Motor Controller Plug 621

Brush Wear Indicators 622

Thermal Sensors 623

Motor Controller, Replace 623

Parameter Tables 626

General 626

Function Numbers 626

Motor Controller Checks and Adjustments 626

Parameter Tables 627

Theory of Operation 634

General 634

SEM System Description 635

SEM System Operation (SR Motor Controller) 635

Reverse Circuit 635

Performance and Efficiency 636

Field Weakening 636

Regenerative Braking 636

Creep Speed 637

Controlled Acceleration 637

Current Limit 637

Braking 637

Regenerative Braking to Zero Speed 637

Pedal Position Braking 637

Auto Braking 637

Auxiliary Speed Control 638

Field Weakening 638

Speed Limits 638

Ramp Operation 638

Ramp Start 638

Anti-Rollback 638

Steer Pump Contactor Time Delay 638

Coil Drivers and Internal Coil Suppression 638

System Protective Override 638

SRO (Static Return to Off) 638

Accelerator Volts Hold Off 638

Pulse Monitor Trip (PMT) 638

Thermal Protector (TP) 639

Low Voltage 639

SP Pump Motor Controllers 639

Contactor Driver Module 639

Diagnostics 639

Systems Diagnostics 639

Standard Status Codes 640

Stored Status Codes 640

Hourmeter Readings 640

Maintenance Management Capability 640

tables 549

Table 1 Speed/Torque Compensation 573

Table 2 Function Map for Motor Controllers SR (Traction) 575

Table 3 Function Map for Motor Controllers SP (Lift Pump Motor) 577

Table 4 List of Status Codes 580

Table 5 Large (P) Plug (23-Pin) Connections/Descriptions for Mo 621

Table 6 Small Plug (12-Pin) Connections/Descriptions for Motor 622

Table 7 Traction Control – SR Transistor Control Settings, 11-I 627

Table 8 Traction Control – SR Transistor Control Settings, 13-I 629

Table 9 Traction Control – SR Transistor Control Settings, 13-I 631

Table 10 Hydraulic Pump – SR Transistor Control Settings (36/48 632

524166844-2200YRM0942-(08-2007)-UK-EN 643

toc 643

Display Panel for SEM Controls 643

Safety Precautions Maintenance and Repair 644

General 647

SEM Display Panel Features 647

Descriptions of Common Features 647

LED Symbol Indicators 647

LCD Screen 647

Battery Discharge Indicator (BDI) 648

Service Reminder 648

Status Codes 648

Hourmeter 648

Additional Features of Premium Display Panel 648

Descriptions of Additional Features (Available With Premium Disp 648

LCD Screen 648

Operator Passwords 649

Daily Check List and Service Items 649

Performance Modes 649

Status Code Lists 649

Adjustment of BDI 649

SEM Display Panel Indicators 650

All Indicator Symbols 650

Hourmeter Indicator Symbol 650

Wrench Indicator Symbol 650

Battery Indicator Symbol 650

Battery State-of-Charge (BDI) 650

Brake Fluid Too Low Symbol 651

Parking Brake Symbol 651

Fasten Seat Belt Symbol 651

LCD Screen (Standard Display Panel) 652

Additional Components of Premium Display Panel 652

Alphanumeric Screen 652

STAR Push Button 652

Push Buttons 1 Through 5 652

Adjustments With a Computer 652

Computer System 652

Connect PC to SEM Display Panel 653

ITW Switches Windows Software Program (for SEM Display Panel) 654

Description 654

Getting Help 654

Hardware and Software Requirements 654

Install 654

How to Start ITW Switches Program 654

Menus 658

Sample Sessions 667

Replacement 689

SEM Display Panel 689

Remove and Replace 689

tables 643

Table 1 Adapter Pins (DB25F to DB9) 653

524166845-4000YRM0340-(09-2002)-UK-EN 695

toc 695

Masts 695

Safety Precautions Maintenance and Repair 696

General 699

Description and Operation 699

Carriages 699

Two-Stage Mast With Limited Free-Lift 699

Two-Stage Mast With Full Free-Lift Mast 700

Three-Stage Mast With Full Free-Lift 701

Safety Procedures When Working Near Mast 703

Forks Replacement 705

Remove and Install 705

Hook Fork 705

Remove 705

Install 705

Pin Fork 706

Remove 706

Install 706

Carriage Repair 706

Remove 706

Sideshift Carriage Repair 708

Sideshift Carriage (Earlier Designs) 708

Disassemble 708

Assemble 709

Install 712

Sideshift Carriage (1993 and Later Design) 712

Remove 712

Repairs 712

Install 712

Weight of Mast Parts 715

Two-Stage Mast With Limited Free-Lift Repair 715

Remove 715

Disassemble 717

Clean and Inspect 717

Assemble 717

Install 719

Two-Stage Mast With Full Free-Lift Repair 719

Remove 719

Disassemble 719

Clean and Inspect 721

Assemble 721

Install 721

Three-Stage Mast With Full Free-Lift 722

Remove 722

Disassemble 722

Clean and Inspect 722

Assemble 722

Install 724

Mast Operation Check 726

Lift and Tilt System Leak Check 727

Lift System 727

Tilt System 727

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment 728

Lift Chain Adjustments 728

Mast Adjustments 729

Carriage Adjustment 731

Troubleshooting 732

524166846-8000YRM0915-(07-2002)-UK-EN 737

toc 737

Periodic Maintenance 737

Safety Precautions Maintenance and Repair 738

General 741

Serial Number Data 741

How to Move Disabled Lift Truck 741

How to Tow Lift Truck 741

How to Put Lift Truck on Blocks 742

How to Raise Drive Tires 742

How to Raise Steering Tires 743

Maintenance Schedule 743

Maintenance Procedures Every 8 Hours or Daily 746

How to Make Checks with Key Switch OFF 746

Tires and Wheels 746

Forks 746

Adjust 746

Remove 746

Install 748

Inspect Mast, Forks, and Lift Chains 748

Safety Labels 749

Steering Column Latch 749

Operator Restraint System 749

Battery Restraint System 750

Battery 751

Hydraulic System 751

How to Make Checks with Key Switch ON 752

Gauges, Horn, and Fuses 752

Steering System 752

Service Brakes 752

Parking Brake 752

Control Levers and Pedals 752

Lift System Operation 753

Maintenance Procedures Every 500 Hours or 3 Months 753

Differential and Speed Reducer 753

Wheel Nuts 753

Steering Axle Spindles 753

Mast 754

Brake Fluid 754

Other Lubrication 755

Seat Brake 755

Electrical Inspection 755

Contactors 755

Motor Brushes 755

Maintenance Procedures Every 1000 Hours or 6 Months 757

Lift Chains 757

Wear Check 757

Lubrication 757

Forks 757

Maintenance Procedures Every 2000 Hours or Yearly 758

Hydraulic System 758

Hydraulic Tank Breather 758

Change Filter for Hydraulic Oil 758

Change Hydraulic Oil 758

Differential and Speed Reducer 758

Service Brakes 759

Contactors 759

Wheel Bearings 759

Steer Wheels, Lubrication 759

Drive Wheels, Lubrication 759

Lift Chains 759

Battery Maintenance 760

How to Charge Battery 760

How to Change Battery 761

Safety Procedures When Working Near Mast 764

Lift and Tilt System Leaks Check 766

Check Lift Cylinders for Leaks 766

Check Tilt Cylinders for Leaks 766

Lift Chain Adjustments 767

How to Check PMT Circuit 769

Welding Repairs 770

Overhead Guard Changes 770

Tires and Wheels 770

General 770

Remove Wheels from Lift Truck 771

Remove Tire from Wheel and Install Tire on Wheel 771

Install Wheels 771

Battery Specifications 772

tables 737

Table 1 Maintenance Schedule 744

Table 2 Hook-Type Carriage Chain Adjustment 767

Table 3 Pin-Type Carriage Chain Adjustment 768

524166847-8000YRM0916-(07-2002)-UK-EN 775

toc 775

Capacities and Specifications 775

Safety Precautions Maintenance and Repair 776

Lift Truck Weights 779

Tire Sizes 779

Capacities 779

Hydraulic System 779

Mast Speeds 780

Mast Creep Speeds 781

Battery Specifications 781

Traction Speed and Traction Motor Current 782

Hoist Motor Current 783

Torque Specifications 783

Brake System 783

Differential 783

Drive Axle 783

Frame 783

Mast 783

Main Control Valve 783

Steering System 784

Tilt Cylinders 784

524166848-8000YRM0917-(01-2004)-UK-EN 787

toc 787

Diagrams 787

Safety Precautions Maintenance and Repair 788

524167640-2200YRM0947-(08-2007)-UK-EN 813

toc 813

Troubleshooting and Adjustments With a Computer 813

Safety Precautions Maintenance and Repair 814

Computer System 817

Connect a PC to a Control Card 818

Installation 819

SMARTSET™ Windows Software Program 819

How to Start the Program 819

DEMO Mode 820

Selecting the Communications Port 822

Verification of Controller and Lift Truck 823

Select Lift Truck Series 825

Controller Card Register Parameter List 826

How to Change a Parameter 827

How to Save a Changed Parameter File 828

How to Load a Saved Parameter File 830

How to Show and Remove Saved Parameter Files 830

How to Return to Factory Default Settings 831

How to Save Changes to Control Card 832

How to View Status Codes 833

Saving Status Codes 834

How to Show and Remove Saved Status Code Files 835

Closing and Clearing Status Code List 836

How to View Saved Register Data and Saved Status Data 837

How to Save Register Data and Status Code Data In RTF and TXT 839

GE Sentry™ Software Program 840

Installation 840

Description 840

How to Start GE SENTRY Program 840

How to Reset MIN and MAX Display 845

Graphing Mode 846

How to Exit GE SENTRY Program 847

tables 813

Table 1 Cable Connections – Computer to Control 817

Table 2 Adapter Pins (DB25F to DB9) 818

Table 3 Plug-Z Connection 819

524179949-2200YRM0595-(07-2003)-UK-EN 851

toc 851

EV-100ZX™ SCR Motor Controller 851

Safety Precautions Maintenance and Repair 852

Register Parameters 855

General 855

Function Numbers 855

Control Card Checks and Adjustments 856

Register Parameter Tables 856

tables 851

Table 1 EV-100ZX Parameters – ERC040-065RF/ZF, and ERP20-30ALF 857

Table 2 EV-100ZX Parameters – ERC040-065RF/ZF (36 to 48V) (Trac 861

Table 3 EV-100ZX Parameters – ERC20-30AGF, and ERP20-30ALF (72 865

Table 4 EV-100ZX Parameters – ERC20-30AGF (72 to 80V) (Traction 869

Table 5 EV-100ZX Parameters – ERC20-30AGF (72 to 80V) (Low Ener 873

Table 6 EV-100ZX Parameters – ERC70-120HD, ERC040-065RF/ZF, and 877

Table 7 EV-100ZX Parameters – ERC35-55HG, ERC20-30AGF, and ERP2 881

Attachments and Hose Take-Up 887

Brake System 905

Drive Unit Assembly 921

Electrical System 949

Field Conversion Kits 1001

General Information 1005

General Truck 1017

Hydraulic System 1071

Lifting Mechanism 1125

New Text Document 1183

Numerical Index 1184

Options 1206

Steering System 1220

User Support Information 1246