$40.95

Yale Forklift A875 (GDPGLP20-30RFTF Europe) Service Manual – PDF DOWNLOAD

Yale Forklift A875 (GDPGLP20-30RFTF Europe) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A875 (GDPGLP20-30RFTF Europe) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1576

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A875 (GDPGLP20-30RFTF Europe) Service Manual – PDF DOWNLOAD

524150775 0700YRM0626 (03 2003) UK EN 1

toc 1

Cooling System 1

Safety Precautions Maintenance and Repair 2

General 5

Description 6

Radiator 6

Radiator Cap 6

Thermostat 6

Water Pump 7

Fan and Fan Shroud 7

Cooling System Checks 7

Radiator 7

Thermostat 7

Water Pump 8

Exhaust Leaks 8

Fan and Fan Shroud 8

Radiator Cleaning 8

Drain 8

Clean 8

Fill 9

Troubleshooting 10

524150790 2100YRM0103 (03 2007) UK EN 13

toc 13

Tilt Cylinders 13

Safety Precautions Maintenance and Repair 14

General 17

Description 17

Tilt Cylinder Repair 17

Remove 17

Disassemble 17

Clean 17

Assemble 18

Tilt Cylinders With O-Ring or Single-Lip Seals 18

Tilt Cylinders 19

Install 20

Tilt Cylinder Leak Check 22

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 23

Torque Specifications 23

Piston Rod Nut 23

Retainer 23

Troubleshooting 24

tables 13

Table 1 Movement Rates (Maximum) for Tilt Cylinders 22

524150791 2200YRM0002 (01 2016) UK EN 29

General 33

Description 34

Alternator Repair 36

Alternator Type A 36

Remove and Disassemble 36

Clean 38

Assemble 38

Install 39

Alternator Type B 42

Remove and Disassemble 42

Clean 42

Assemble 43

Install 44

General Check and Adjustment 44

Low Output Check (Type A or Type B) 45

High Output Check (Type A or Type B) 48

Brushes Circuit Check 49

Delco Alternators 49

Motorola Alternators 49

Diodes Check 50

Diode Bridge Check 50

Delco and Leece-Neville Alternators 50

Motorola Alternators 50

Rotor Field Winding Check 51

Stator Windings Check 52

Voltage Regulator Check 52

Troubleshooting 52

524150792 2200YRM0106 (01 2016) UK EN 57

General 61

Description and Operation 62

Starter Repair 66

Remove 66

Disassemble 66

Clean 67

Assemble 67

Install 68

General Checks and Adjustments 68

Troubleshooting 70

524150797 8000YRM0231 (02 2023) US EN 77

General 83

Threaded Fasteners 83

Nomenclature, Threads 83

Strength Identification 84

Cotter (Split) Pins 85

Fastener Torque Tables 90

Conversion Table 92

524150797 8000YRM0231 (03 2020) UK EN 99

General 103

Threaded Fasteners 103

Nomenclature, Threads 103

Strength Identification 104

Cotter (Split) Pins 105

Fastener Torque Tables 110

Conversion Table 112

524153914 2200YRM0107 (03 2008) UK EN 119

toc 119

High Energy Ignition (HEI) System 119

Safety Precautions Maintenance and Repair 120

Description 123

Distributor Repair 125

Remove 125

Disassemble 125

Assemble 131

Install, If Crankshaft WAS NOT Rotated when Distributor was Remo 132

Install, If Crankshaft WAS Rotated when Distributor was Removed 132

Ignition Coil Replacement 134

Some Four- and Six-Cylinder Models 134

Remove 134

Install 134

V8, Some Four- and Six-Cylinder Models 135

Remove 135

Install 135

Electronic Module Replacement 136

Remove 136

Install 136

Sensing Coil Replacement 138

Remove 138

Install 138

Spark Plugs Replacement 138

Remove 138

Install 139

Visual Check 139

High Voltage Wires Check 139

Ignition Coil Check 140

Coil in Distributor Cap Design 140

Separate Coil Design 140

Sensing Coil, Check 141

Electronic Module Check 141

Ignition Timing Adjustment 142

GM V8-366 (6-liter) Ignition System Check 143

GM V6-LPG (4 3 liter) GM V6-LPG (4 3 liter) Ignition Timing and 143

Specifications 143

Troubleshooting 144

524153916 2200YRM0765 (03 2003) UK EN 149

toc 149

Microprocessor Spark Timing System (MSTS) 149

Safety Precautions Maintenance and Repair 150

General 153

Description 154

What MSTS Does 154

How MSTS Begins Operation 154

Operation 155

Distributor 155

Ignition Coil 156

Ignition Module 156

When Engine Is Being Started 156

When Engine Is Running 158

Manifold Absolute Pressure (MAP) Sensor 159

Engine Coolant Temperature (ECT) Sensor 159

MSTS Module Corrections 160

Troubleshooting 161

General 161

Tools and Test Equipment 163

MSTS 164

Troubleshooting Procedure 164

Where to Start 164

Visual/Physical Inspection 164

Knowledge/Tools Required 164

Damage From Static Discharge (Static Electricity) 165

Troubleshooting Information 165

Malfunction Indicator Lamp (MIL) 165

Connecting CodeMate Tester 165

Reading Diagnostic Trouble Codes (DTC) 166

Clearing Diagnostic Trouble Codes (DTC’s) 167

On-Board Diagnostic (OBD) System Check 167

Test Description 167

No Malfunction Indicator Lamp 169

Circuit Description 169

Test Description 169

No DTC-12, Malfunction Indicator Lamp ON 171

Circuit Description 171

Test Description 171

Starter Rotates Engine, Engine Does Not Run 172

Test Description 172

DTC-14 Engine Coolant Temperature (ECT) (Low Temperature Indicat 176

Circuit Description 176

Test Description 176

DTC-15 Engine Coolant Temperature Sensor (ECT) (High Temperature 178

Circuit Description 178

Test Description 178

DTC-34 Manifold Absolute Pressure (MAP) Sensor 180

Circuit Description 180

Test Description 180

DTC-41 Electronic Spark Timing (EST) Open Circuit 183

Circuit Description 183

Test Description 183

DTC-42 Electronic Spark Timing (EST) Grounded Circuit 185

Circuit Description 185

Test Description 185

DTC-51 MSTS Failure 187

Circuit Description 187

Distributor Repair 187

Remove 187

Disassemble 188

Inspect 188

Assemble 188

Install 189

Ignition Timing 189

Ignition Module Repair 190

Test For Fault 190

Replace 190

Sensing Coil Repair 191

Test For Fault 191

Replace 191

Ignition Coil Repair 192

Test For Fault 192

Remove 192

Install 192

MSTS Module Repair 193

Remove 193

Install 193

ECT Sensor Replacement 193

MAP Sensor Replacement 194

tables 149

Table 1 MSTS Module Connections 162

Table 2 Pressure Conversion Chart 163

Table 3 MSTS Diagnostic Codes 165

524158636 0100YRM0505 (06 2004) UK EN 197

toc 197

Frame 197

Safety Precautions Maintenance and Repair 198

General 201

Description 201

Operator Module Repair 201

Remove 201

Install 201

Hood and Side Covers Repair 203

Remove 203

Install and Adjust 203

Overhead Guard Repair 205

Remove and Install 205

LED Backup and Brake Lights, Replace 206

Remove 206

Install 206

Counterweight Repair 207

Remove 207

Install 208

Exhaust System Repair 209

Muffler, Replace 210

Radiator and Cooling System Repair 216

Remove 216

Install 216

Operator Restraint System Repair 218

Engine Repair 219

Remove Engine Only 219

Remove Engine and Transmission 219

Install Engine Only 220

Install Engine and Transmission 221

Fuel and Hydraulic Tanks Repair 221

Inspect 221

Small Leaks, Repair 221

Large Leaks, Repair 221

Clean 222

Steam Method of Cleaning 222

Chemical Solution Method of Cleaning 222

Additional Preparations for Repair 222

Safety Labels 223

tables 197

Table 1 Weight of Counterweights 208

524158637 0600YRM1020 (10 2006) UK EN 229

toc 229

GM Engine Repair 229

Safety Precautions Maintenance and Repair 230

General 233

Description 233

Engine Removal and Installation 241

Cylinder Head and Valve Mechanism Repair 241

Cylinder Head, Remove 241

Cylinder Head, Disassemble 243

Clean and Inspect 243

Valves and Valve Seats 246

Studs for Rocker Arms 246

Hydraulic Valve Lifters 247

Replace 247

Clean and Inspect 247

Cylinder Head, Assemble 247

Cylinder Head, Install 248

Valve Clearance, Adjust 249

Rocker Arm Cover, Install 249

Timing Gear Cover Repair 250

Remove 250

Install 250

Timing Wheel Repair 251

Timing Wheel, Removal 251

Timing Wheel, Install 251

Air Gap Adjustment 252

Camshaft Repair 254

Camshaft, Remove 254

Camshaft, Clean and Inspect 254

Camshaft Bearings, Remove 256

Camshaft Bearings, Clean and Inspect 256

Camshaft Bearings, Install 256

Camshaft, Install 257

Distributor Repair 257

Remove 257

Install 258

Lubrication System Repair 259

Oil Pan 259

Remove 259

Install 259

Oil Pump 259

Remove 259

Disassemble 260

Clean and Inspect 261

Assemble 261

Install 261

Piston and Piston Rod Assemblies Repair 261

Piston Rod Bearings, Replace 261

Piston and Piston Rod Assemblies, Remove 263

Piston and Piston Rod Assemblies, Disassemble 263

Pistons, Clean and Inspect 264

Cylinder Bores, Inspect and Repair 264

Piston Rings, Inspect 265

Piston and Piston Rod Assemblies, Assemble 266

Piston and Piston Rod Assemblies, Install 266

Crankshaft Repair 267

Main Bearings, Replace 267

Oil Seal for Rear Main Bearing, Replace 268

Crankshaft, Remove 268

Inspect and Repair 269

Main Bearing and Journal Clearance, Check 270

Crankshaft, Install 271

Flywheel and Flywheel Housing Repair 271

Flywheel, Remove 272

Ring Gear, Replace 273

Flywheel, Install 273

Cooling System Repair 273

Water Pump 273

Remove 273

Inspect 273

Install 274

Thermostat 274

Remove and Install 274

Alternator Repair 274

Starter Repair 274

Checks and Adjustments 276

Engine Compression Test 276

Test Procedure 276

Test Results 276

Engine Noise Diagnostic Test 276

Description 276

Test Procedure 276

Engine Specifications 278

Engine Data 278

Cylinder Bore 278

Piston 278

Piston Rings 278

Wrist Pin 279

Crankshaft 279

Piston Rod 280

Camshaft 280

Hydraulic Valve System 280

Cylinder Head Warpage 281

Lubrication System 281

Cooling System 281

Torque Specifications 282

Troubleshooting 283

524158742 0600YRM0496 (01 2011) UK EN 289

toc 289

Mazda Engine 289

Safety Precautions Maintenance and Repair 290

General 293

Description 293

Engine Removal and Installation 293

Cylinder Head, Camshaft, and Valve Mechanism Repair 294

Remove 294

Clean 295

Inspect and Repair 296

Cylinder Head 296

Rocker Shaft Assembly 296

Camshaft 296

Valve Guides 297

Valve Seats 298

Valves 298

Valve Springs 299

Install 299

Crankshaft and Main Bearings Repair 302

Remove 302

Inspect and Repair 302

Crankshaft 302

Main Bearings 302

Install 303

Pistons and Connecting Rods Repair 304

Remove and Disassemble 304

Clean 304

Inspect and Repair 304

Pistons 304

Piston Rings 305

Connecting Rods and Bearings 305

Assemble and Install 306

Cylinder Block Repair 307

Oil Pump Repair 307

Remove 307

Disassemble 308

Clean 308

Inspect 308

Assemble 309

Install 310

Cooling System Repair 310

Thermostat 310

Replace 310

Fan Assembly 310

Remove and Disassemble 310

Assemble and Install 311

Water Pump 311

Remove and Disassemble 311

Assemble and Install 312

Distributor Repair 313

Remove 313

Install 313

Flywheel and Ring Gear Repair 314

Remove 314

Ring Gear, Replace 314

Install 314

Flywheel Repair 315

Remove 315

Install 315

Valve Adjustment 316

Compression Pressure Check 316

Engine Timing Adjustment 317

Throttle Linkage Adjustment 317

Gasoline Engines 317

LPG Engines (IMPCO) 317

LPG Engines (AISAN) 318

Engine Specifications 318

Engine Data 318

Thermostat 318

Cylinder Head 318

Valve Mechanism 318

Camshaft 319

Crankshaft 319

Connecting Rods 320

Cylinder Block 320

Pistons 320

Oil Pump 320

Torque Specifications 321

Troubleshooting 322

524158744 0900YRM0498 (12 2003) UK EN 327

toc 327

LPG Fuel System 327

Safety Precautions Maintenance and Repair 328

General 331

Description and Operation 331

Fuel Tank 332

Fuel Filter and Fuel Valve Unit 332

Vaporizer 332

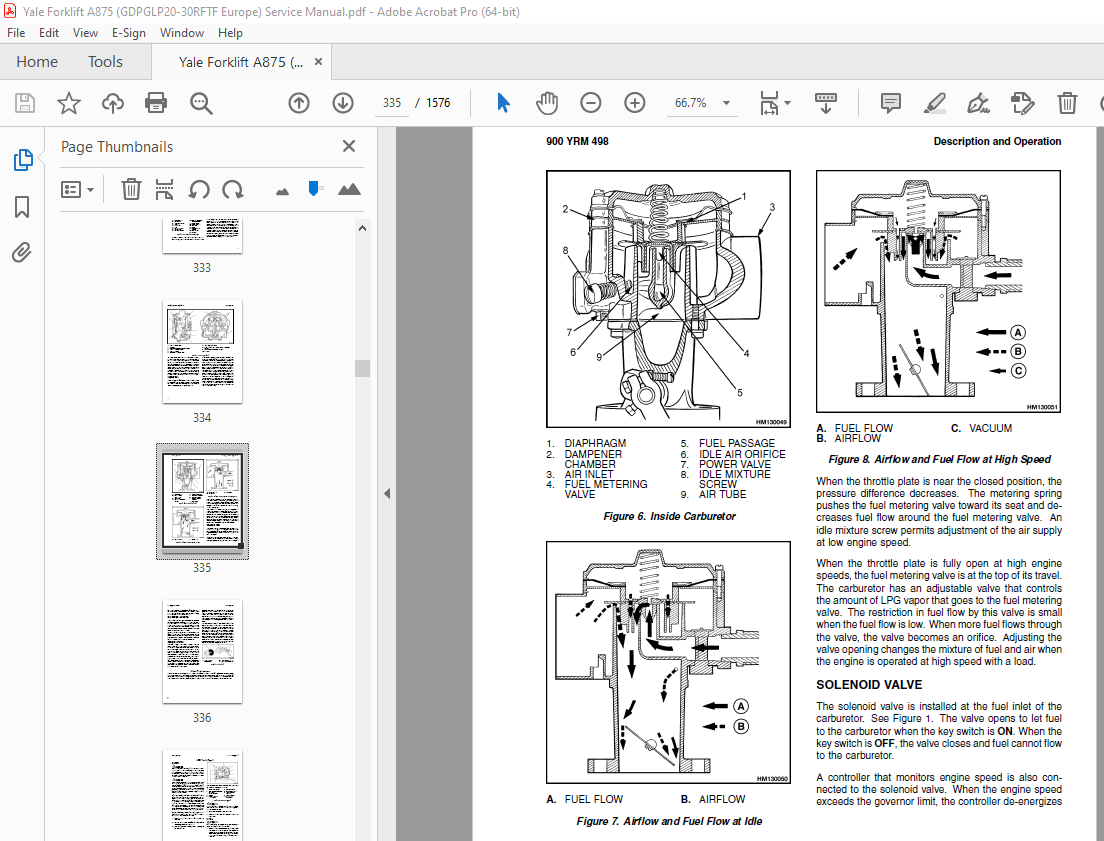

Carburetor 334

Solenoid Valve 335

Idle Control Actuator 336

Governor System 336

Hose Replacement 336

LPG Tank Repair 337

Remove 337

Install 337

Hydrostatic Relief Valve Repair 338

Remove and Install 338

Filter Unit Repair 338

Fuel Filter Element, Replace 338

Diaphragm and Fuel Valve, Replace 340

Vaporizer Repair 340

Remove 340

Disassemble 340

Clean 340

Inspect 340

Assemble 342

Install 346

Carburetor Repair 346

Remove 346

Disassemble 346

Clean 346

Assemble 348

Install 348

Solenoid Valve Repair 348

Governor System Check 349

Filter Unit Check 349

Vaporizer Check 350

Pressure Reducer Valve 350

Vapor Valve 350

Carburetor Adjustment 350

Idle, Adjust 350

Power Mixture 351

Throttle Linkage Adjustment 352

Foot Directional Control Pedal, Check 353

Troubleshooting 354

524158746 0900YRM0523 (12 2003) UK EN 361

toc 361

LPG Fuel System 361

Safety Precautions Maintenance and Repair 362

General 365

Description and Operation 365

Fuel Tank 367

Fuel Filter and Fuel Valve Unit 367

Vaporizer 368

Carburetor 370

Solenoid Valve 372

Idle Control Actuator 372

Governor 372

Hose Replacement 372

LPG Tank Repair 373

Remove 373

Install 373

Hydrostatic Relief Valve Repair 374

Remove and Install 374

Filter Unit Repair 374

Fuel Filter Element, Replace 374

Diaphragm and Fuel Valve, Replace 376

Vaporizer Repair 376

Remove 376

Disassemble 376

Clean 376

Inspect 376

Assemble 378

Install 381

Carburetor Repair 382

Remove 382

Disassemble 382

Clean 382

Assemble 385

Install 385

Solenoid Valve Repair 385

Governor Repair 385

Filter Unit Check 386

Vaporizer Check 386

Pressure Reducer Valve 386

Vapor Valve 386

Carburetor Adjustment 386

Idle Mixture 386

Idle, Adjust 386

Power Mixture, Adjust 387

Governor Check and Adjustment 388

Check 388

Adjust 388

Throttle Linkage Adjustment GC/GLC040-065RG/TG/ZG and GP/GLP/GDP 389

Throttle Linkage Adjustment GP/GLP/GDP16-20AF/BF (GP/GLP/GDP030- 390

Foot Directional Control Pedal Check 391

Troubleshooting 392

524158747 0900YRM0925 (12 2003) UK EN 399

toc 399

LPG Fuel System 399

Safety Precautions Maintenance and Repair 400

General 403

Description and Operation 403

Fuel Tank 404

Regulator 404

Start Mode 406

Idle Mode 406

Run Mode 406

Resonator 406

Carburetor 407

Start Mode 407

Idle Mode 407

Run Mode 407

Governor 408

Hoses Replacement 409

LPG Tank Repair 409

Remove 409

Install 409

Relief Valve Repair 410

Remove and Install 410

Carburetor Repair 410

Remove 410

Disassemble 410

Clean 411

Assemble 411

Install 412

Governor Repair 412

Remove 412

Inspect 412

Install 412

Regulator Repair 413

Remove 413

Disassemble 413

Clean 413

Inspect 413

Assemble 415

Install 416

Regulator Adjustment 416

Regulator Height Adjustment 416

Regulator Assembly Air Tightness Test 417

Carburetor Adjustment 418

Idle Speed and Fuel Mixture 418

Idle Control Adjustment 418

Governor Adjustment 419

Checks 419

Adjustments 419

Throttle Linkage Adjustment 420

Foot Directional Control Pedal Check 421

Throttle Linkage Adjustment 422

Troubleshooting 423

tables 399

Table 1 Power Adjusting Screw 412

Table 2 Air Adjusting Screw 412

Table 3 Idle Mixture Adjusting Screw 415

Table 4 Idle Mixture Adjusting Screw 418

524158748 0900YRM0948 (10 2006) UK EN 431

toc 431

LPG Fuel System 431

Safety Precautions Maintenance and Repair 432

General 435

Description and Operation 435

Fuel Tank 435

Oxygen Sensor 435

Regulator 435

Start Mode 438

Idle Mode 441

Run Mode 441

Resonator 441

Carburetor 441

Start Mode 441

Idle Mode 442

Run Mode 442

Governor 443

Hoses Replacement 443

LPG Tank Repair 444

Remove 444

Install 444

Relief Valve Repair 445

Remove and Install 445

Carburetor Repair 445

Remove 445

Disassemble 445

Clean 446

Assemble 446

Install 447

Fuel Injector Repair 447

Remove 447

Clean and Inspect 447

Install 447

Governor Repair 448

Remove 448

Inspect 448

Install 448

Regulator Repair 448

Remove 448

Install 448

Oxygen Sensor Repair 448

Remove and Install 448

Vacuum Switches Repair 449

Remove and Install 449

Inspect 449

Resistor Repair 449

Remove and Install 449

Inspect 449

Carburetor and New Regulator Adjustment 449

Idle Speed and Fuel Mixture 449

Idle Control Adjustment 450

Governor Checks and Adjustments 451

Checks 451

Adjustments 451

Throttle Linkage Adjustment 451

Foot Directional Control Pedal Check 453

Check Engine Light 453

Inspect Warning Lamp 453

Check Feedback Operation 453

Check VAC1 and VAC2 Signals 453

Check Resistor 453

Check Fuel Injector 453

Check Oxygen Sensor 454

Check Vacuum Switch 1 454

Check Vacuum Switch 2 454

After Completing Checks 454

Troubleshooting 454

tables 431

Table 1 Adjusting Screw 447

524158749 1300YRM0500 (08 2003) UK EN 463

toc 463

Single-Speed Powershift Transmission 463

Safety Precautions Maintenance and Repair 464

General 467

Description and Operation 467

General 467

Torque Converter 468

Description 468

Operation 468

Clutch Assemblies 470

Description 470

Operation 471

Hydraulic System 474

General 474

Control Valve 475

General 475

Clutch Pressure Regulator 476

Inching Spool Assembly 477

Direction Spool 477

Modulator Circuit 477

Torque Converter Regulator 477

Foot Directional Control Pedal 477

Foot Directional Control Pedal Start Circuit 478

Direction Control Lever 478

Differential 478

Oil Flow Diagrams 480

Neutral 480

Modulator Operation 480

Forward 484

Forward-Inching 484

524158750 1300YRM0501 (03 2004) UK EN 491

toc 491

Single-Speed Powershift Transmission 491

Safety Precautions Maintenance and Repair 492

General 495

Transmission Removal 499

Torque Converter and Housing Repair 499

Remove 499

Install 499

Transmission Pump Repair 501

Remove 501

Repair 501

Install 501

Front Cover and Pump Drive Repair 501

Remove and Disassemble 501

Assemble and Install 501

Clutch Assemblies Repair 504

Remove and Disassemble 507

Inspect 509

Assemble 510

Install 515

Differential Repair 516

Remove and Disassemble 516

Inspect 517

Assemble and Install 518

Control Valve Repair 525

Remove and Disassemble 525

Inspect 525

Assemble and Install 525

Foot Directional Control Pedal Repair 528

Remove and Disassemble 528

Assemble and Install 528

Direction Control Lever Repair 531

Remove and Disassemble 531

Assemble and Install 531

Stall Test 532

Inching/Brake Pedal Adjustment 533

Neutral Start Switch, Foot Directional Control Pedal Adjustment 537

Neutral Start Switch, Foot Directional Control Pedal Adjustment 538

Neutral Start Switch Test, Foot Directional Control Pedal 539

Oil Pressure Checks 539

Relief Valve for Transmission Pump Check, TEST PORT 1 539

Clutch Pressure Check, TEST PORTS 2 and 3 539

Torque Converter Regulator Check, TEST PORT 4 540

Lubrication Circuit Oil Pressure Check, TEST PORT 5 540

Modulator Pressure Check, TEST PORT 6 540

Troubleshooting 541

Troubleshooting – Pressure Tests 544

tables 491

Table 1 Adjustment of Shims for Pinion Assembly 518

Table 2 Ring and Pinion Tooth Contact Adjustment 519

Table 3 Stall Speeds 533

Table 4 Transmission Oil Pressures Test Ports 540

524158751 1400YRM0499 (10 2004) UK EN 549

toc 549

Drive Axle 549

Safety Precautions Maintenance and Repair 550

General 553

Description 553

Drive Axle Repair 553

Remove and Disassemble 553

Clean and Inspect 555

Assemble and Install 555

Torque Specifications 557

GP2 00-3 00RF/TF (GP040-060RG/TG/ZG) 557

GC040-065TF/RF 557

Troubleshooting 558

524158752 1600YRM0316 (08 2006) UK EN 561

toc 561

Steering Axle 561

Safety Precautions Maintenance and Repair 562

General 565

Description 565

Steering Axle Assembly Repair 566

Remove 566

Install 566

Wheels and Hubs Repair 567

Remove and Disassemble 567

Clean 567

Assemble and Install 567

Spindles, Bearings, and Tie Rods Repair 569

Remove 569

Install 569

Steering Cylinder Repair 570

Remove and Disassemble 570

Clean and Inspect 571

Assemble and Install 571

Torque Specifications 571

Troubleshooting 572

524158753 1600YRM0720 (11 2006) UK EN 577

toc 577

Steering Housing and Control Unit 577

Safety Precautions Maintenance and Repair 578

General 581

Description 581

Operation 582

Steering Wheel and Column Assembly Repair 583

Assembly Components, Remove 583

Steering Control Unit, Disassemble 588

Steering Control Unit, Clean 588

Steering Control Unit, Assemble 588

Assembly Components, Install 590

System Air Removal 592

Troubleshooting 592

524158754 1800YRM0506 (05 2005) UK EN 597

toc 597

Brake System 597

Safety Precautions Maintenance and Repair 598

General 601

Description and Operation 601

Service Brakes 601

Master Cylinder 601

Parking Brake 603

Service Brakes Repair 603

Remove and Disassemble 603

Clean 605

Inspect 605

Assemble and Install 607

Adjust 611

Parking Brake Repair 611

Remove and Disassemble 611

Assemble and Install 611

Adjust 611

Master Cylinder Repair 613

Remove 613

Clean and Inspect 613

Repair 614

Install 616

Service Brakes Adjustment 616

Brake System Air Removal 617

Parking Brake Not Applied Switch Test 617

Parking Brake Switch Test (Foot Directional Control Pedal Only) 617

Inching/Brake Pedal Adjustment 618

Neutral Start Switch Adjustment, Foot Directional Control Pedal 622

Neutral Start Switch Adjustment, Foot Directional Control Pedal 623

Neutral Start Switch Test (Foot Directional Control Pedal) 624

Torque Specifications 624

GP2 00-3 00RF/TF (GP040-060RG/TG/ZG) 624

GC040-065RG/TG/ZG 624

Troubleshooting 624

524158755 1900YRM0513 (06 2004) UK EN 631

toc 631

Hydraulic System 631

Safety Precautions Maintenance and Repair 632

General 635

Description 635

Hydraulic System 635

Gear Pump Assembly 635

Flow Control Valve 635

Relief Valve 635

Operation 642

Hydraulic System 642

Gear Pump 642

Flow Control Valve 642

Relief Valve 642

Gear Pump Assembly Repair 644

Remove and Disassemble 644

Assemble and Install 645

Steering Relief Pressure Check and Adjustment 645

Gear Pump Flow Check 646

Troubleshooting 646

524158756 2000YRM0516 (12 2003) UK EN 651

toc 651

Main Control Valve 651

Safety Precautions Maintenance and Repair 652

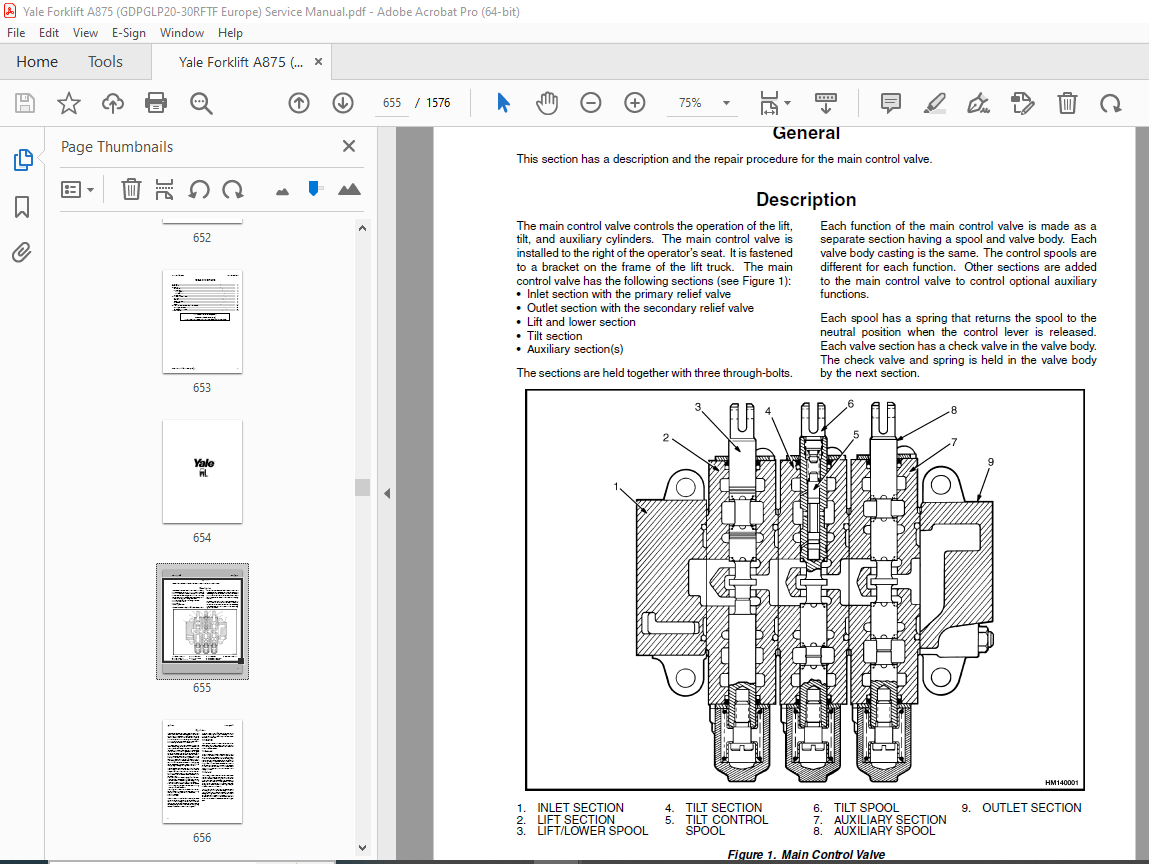

General 655

Description 655

Operation 656

Lift Section 656

Tilt Section 656

Tilt Backward 656

Tilt Forward 656

Relief Valve 660

Main Control Valve Repair 661

Remove 661

Disassemble 661

Clean and Inspect 661

Assemble 661

Install 667

Pressure Relief Valve Check and Adjustment 668

Primary Relief Valve 668

Secondary Relief Valve 668

Troubleshooting 669

524158757 2200YRM0514 (01 2004) UK EN 673

toc 673

Instrument Cluster 673

Safety Precautions Maintenance and Repair 674

General 677

Description 677

Instrument Cluster Display Panel, Internal Combustion Lift Truck 677

Instrument Cluster Display Panel, Electric Lift Truck Models 684

Optional Basic Display Panel 684

Features of the Optional Basic Display Panel 684

Description of Features on the Optional Basic Display Panel 684

Standard Display Panel 685

Features of the Standard Display Panel 685

Description of Features on the Standard Display Panel 685

Premium Display Panel 686

Features on the Premium Display Panel 686

Description of Features on the Premium Display Panel 687

Curtis 1215 Display Panel 689

Description and Features 689

Operation 690

Cluster-Type Display Panel (Internal Combustion) Replacement 691

Remove 691

Install 691

Cluster Display Panel (Electric Lift Truck) Replacement 694

Curtis 1215 Display Panel Replacement 699

Remove 699

Install 699

tables 673

Table 1 Instrument Cluster, Internal Combustion 678

524158758 2200YRM0524 (12 2003) UK EN 703

toc 703

Electrical System 703

Safety Precautions Maintenance and Repair 704

General 707

Description 707

Starting System 707

Ignition System 707

Charging System 708

Starter Repair 709

Remove and Disassemble 709

Assemble and Install 709

Coil Replacement 711

Distributor Repair 712

Remove and Disassemble 712

Assemble and Install 712

Distributor Repair 714

Remove and Disassemble 714

Assemble and Install 716

Alternator Repair 716

Remove and Disassemble 716

Assemble and Install 717

General Checks and Adjustments 718

Starter Checks 718

Operation, Check 718

Brush Holder, Check 719

Armature, Check 719

Field Windings, Check 719

Clutch and Bearing, Check 719

Ignition System Check and Adjustment 720

Engine Timing, Adjust 720

Spark Plugs, Check 720

Charging Circuit Checks 721

Low Output, Check 721

High Output, Check 722

Diodes, Check 722

Rotor Field Winding, Check 723

Stator Windings, Check 723

Brushes and Bearings, Check 723

Voltage Regulator, Check 723

Troubleshooting 724

524158890 4000YRM0521 (03 2006) UK EN 729

toc 729

Mast 729

Safety Precautions Maintenance and Repair 730

General 733

Description and Operation 733

Carriages 733

Mast Mounts 735

Two-Stage Mast, Limited Free-Lift (LFL) 736

Description and Operation 736

Two-Stage Mast, Full Free-Lift (FFL) 738

Description and Operation 738

Three-Stage Mast, Full Free-Lift (FFL) 740

Description and Operation 740

Four-Stage Mast 742

Description and Operation 742

Cylinder Cushion During Lifting Sequence 746

Cylinder Cushion During Lowering Sequence 747

524158891 4000YRM0522 (07 2010) UK EN 751

toc 751

Mast 751

Safety Precautions Maintenance and Repair 752

General 755

Safety Procedures When Working Near Mast 756

Fork Repair 758

Remove 758

Install 758

Carriages Repair 760

Standard Carriage, Remove 760

Hang-On Sideshift Carriage, Remove 761

Standard Carriage and Hang-On Sideshift Carriage, Repair 762

Standard Carriage, Install 763

Hang-On Sideshift Carriage, Install 764

Integral Sideshift Carriage 764

Remove 764

Clean and Inspect 768

Repair 769

Install 770

Mast Repair 771

Remove 771

Two-Stage LFL and Two-Stage FFL Masts, Disassemble 773

Three-Stage FFL Mast 781

Disassemble 781

Mast and Chains, Clean and Inspect 784

Two-Stage LFL and Two-Stage FFL Mast, Assemble 785

Three-Stage FFL Mast, Assemble 786

Install 787

Lift Cylinders Repair 789

Main Lift Cylinders, Remove 789

Free-Lift Cylinder, Remove 789

Cylinders, Disassemble 790

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 790

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 792

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 792

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 793

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 794

Clean and Inspect 795

Cylinders, Assemble 795

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 795

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 796

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 797

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 797

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 798

Main Lift Cylinders, Install 799

Free-Lift Cylinder, Install 799

Header Hose Arrangements 800

Two-Stage LFL Mast, New Hose Install 800

Two-Stage LFL Mast, Adjust Hoses After Installation 805

Two-Stage FFL Mast, New Hose Install 805

Two-Stage FFL Mast, Adjust Hoses After Installation 813

Three-Stage FFL Mast, New Hose Install 813

Three-Stage FFL Mast, Adjust Hoses After Installation 824

Header Hose Arrangement 825

Two-Stage LFL Mast, New Hose Install 825

Two-Stage LFL Mast, Adjust Hoses After Installation 830

Two-Stage FFL Mast, New Hose Install 830

Two-Stage FFL Mast, Adjust Hoses After Installation 836

Three-Stage FFL Mast, New Hose Install 836

Three-Stage FFL Mast, Adjust Hoses After Install 845

Lift and Tilt System Leak Check 846

Lift Cylinders Leak Check 846

Tilt Cylinders Leak Check 846

Tilt Cylinders Adjustment 847

Lift Chains Adjustment 849

Mast Adjustment 851

Carriage Adjustment 853

Troubleshooting 854

tables 751

Table 1 Hook-Type Carriage Chain Adjustment 849

Table 2 Pin-Type Carriage Chain Adjustment 850

524158901 8000YRM0708 (01 2011) UK EN 857

toc 857

Capacities and Specifications 857

Safety Precautions Maintenance and Repair 858

Lift Truck Weights 861

Tire Pressure 861

Tire Sizes 862

Capacities 862

Electrical System 863

Gasoline/LPG 863

Diesel 863

Transmission Oil Pressures 864

Hydraulic System 864

Stall Speeds 865

Engine Specifications 865

Gasoline/LPG 865

Diesel 867

Mast Speeds 868

Gasoline/LPG Engines (US Models) 868

Diesel Engines (US Models) 872

Gasoline/LPG Engines (US Models) 874

Gasoline/LPG Engines (European Models) 879

Diesel Engines (European Models) 883

Torque Specifications 884

Frame 884

Brake System 885

Mast 885

Steering System 885

Drive Axle 885

Transmission and Differential 885

Engine – Mazda FE and F2 886

Engine – GM 3 0L 887

Engine – Mazda XA and HA Diesel 887

524158902 8000YRM0709 (10 2004) UK EN 891

toc 891

Diagrams 891

Safety Precautions Maintenance and Repair 892

524162461 0600YRM1019 (01 2011) UK EN 957

toc 957

Mazda XA and HA Diesel Engines 957

Safety Precautions Maintenance and Repair 958

General 963

Description 963

Engine Removal and Installation 963

Cylinder Head and Valve Mechanism Repair 965

Remove 965

Clean 965

Inspect and Repair 966

Cylinder Head 966

Rocker Shaft Assembly 966

Valve Guides 967

Valve Seats 967

Valves 968

Valve Springs 968

Push Rods 969

Cylinder Head, Assemble 969

Cylinder Head, Install 970

Timing Gears Repair 971

Remove 971

Clean and Inspect 971

Install 972

Camshaft Repair 973

Remove 973

Inspect and Repair 973

Install 974

Crankshaft and Main Bearings Repair 974

Remove 974

Inspect and Repair 974

Crankshaft 974

Main Bearings 975

Install 975

Piston and Connecting Rods Repair 976

Remove and Disassemble 976

Clean 976

Inspect and Repair 976

Pistons 976

Piston Rings 977

Connecting Rods and Bearings 977

Assemble and Install 978

Cylinder Block and Liners Repair 979

Inspect and Repair 979

Lubrication System Repair 981

Oil Pump 981

Remove 981

Disassemble 981

Clean 981

Inspect 981

Assemble 982

Install 983

Oil Filter Mount 983

Remove 983

Install 983

Oil Cooler 984

Remove 984

Clean and Inspect 984

Install 984

Cooling System Repair 984

Thermostat 984

Remove and Install 984

Water Pump 985

Remove 985

Disassemble 985

Inspect 986

Assemble 986

Install 987

Fuel System Repair 988

Description and Operation 988

Fuel Injection Pump 988

Remove 988

Install 989

Fuel Filter 990

Filter, Replace 990

Water Sensor Check 991

Fuel System Air Removal 991

Fuel Injectors 992

Remove and Disassemble 992

Clean and Inspect 992

Assemble 992

Inspect and Adjust 992

Install 993

Flywheel and Ring Gear Repair 993

Flywheel, Remove 993

Ring Gear, Replace 993

Flywheel, Install 994

Flywheel, Remove 994

Flywheel, Install 994

Alternator Repair 995

Starting System Repair 996

Cold Start Aid 996

Description and Operation 996

Glow Plugs, Replace 996

Glow Plugs, Check 997

Fuse 997

Relay and Controller 997

Checks and Adjustments 998

Valves, Adjust 998

Compression Pressure Check 998

Throttle Linkage, Adjust 999

Fuel Injection Pump Timing Check 1000

Engine Specifications 1001

Engine Data 1001

Cylinder Head 1001

Camshaft 1002

Crankshaft 1003

Connecting Rods 1004

Cylinder Block 1005

Pistons 1005

Oil Pump 1005

Torque Specifications 1006

Special Tools 1007

Troubleshooting 1009

tables 957

Table 1 Camshaft Journal Diameters 973

Table 2 Crankshaft Journal Diameters 975

Table 3 Piston Diameters 977

Table 4 Cylinder Liner Diameters 979

524175194 8000YRM0707 (07 2006) UK EN 1017

toc 1017

Periodic Maintenance 1017

Safety Precautions Maintenance and Repair 1018

General 1023

Serial Number 1023

How to Move Disabled Lift Truck 1023

How to Tow Lift Truck 1023

How to Put Lift Truck on Blocks 1024

How to Raise Drive Tires 1024

How to Raise Steering Tires 1024

Maintenance Schedule 1025

Maintenance Procedures Every 8 Hours or Daily 1033

How to Make Checks With Engine Stopped 1033

Tires and Wheels 1034

Forks 1034

Adjust 1034

Remove 1035

Install 1036

Forks, Mast, and Lift Chains, Inspect 1036

Safety Labels 1037

Operator Restraint System 1037

Steering Column Latch 1037

Fuel, Oil, or Coolant Leaks, Check 1037

Drive Belt 1038

Intake Manifold Rubber Cap 1038

Powershift Transmission Oil Temperature 1038

Powershift Transmission Oil Level 1038

Hydrostatic Transmission Oil Level 1039

Engine Oil 1039

Hydraulic System 1039

Air Filter 1041

How to Make Checks With Engine Running 1041

Gauges, Indicator Lights, Horn, Fuses, and Relays 1041

Engine Oil Pressure 1041

Cooling System 1042

Steering System 1042

Service Brakes 1043

Brake Fluid Level 1043

Operation, Check 1043

Parking Brake 1043

Water Separator, Diesel Engine 1044

Drain Water from Water Separator 1044

Fuel Filter, Diesel Engine 1044

Diesel Fuel System, Remove Air 1044

Control Levers and Pedals 1044

Lift System, Operate 1045

Cooling System 1045

Maintenance Procedures Every 250 Hours or 6 Weeks 1046

Drive Belt 1046

GM 3 0L 1046

Engine Oil and Filter, GM 3 0L 1047

Fuel System, GM 3 0L 1047

Engine Speed, LPG Carburetor, GM (Aisan Open-Loop) 1047

Engine Speed, LPG Carburetor, GM 3 0L (Impco) 1047

Cooling System, Clean Debris From Radiator Core 1048

Air Filter 1048

GM 3 0L EPA Compliant Engine 1048

Maintenance Procedures Every 500 Hours or 3 Months 1048

Air Filter 1048

Drive Belt 1048

Mazda FE and F2 Engines 1048

Fan and Alternator Drive Belt 1048

Timing Belt 1049

Mazda XA and HA Diesel Engines 1049

Engine Oil and Filter 1049

Brake Fluid 1050

Hydraulic Tank Breather 1050

Battery 1050

Forks 1050

Lift Chains 1050

Lubrication 1050

Wear, Check 1050

Mast 1051

Steering Axle 1051

Fuel System 1051

Engine Speed, Diesel, Mazda XA and HA Engines 1051

Engine Speed, LPG Carburetor, Mazda (Aisan Open-Loop) 1052

Engine Speed, LPG Carburetor, Mazda (Impco) 1052

Hydraulic System 1053

Drain Tar From Aisan LPG Regulator 1054

Maintenance Procedures Every 1000 Hours or 6 Months 1054

Diesel Fuel System 1054

Fuel Filter, Replace 1054

Check Water Sensor 1055

Diesel Fuel System Air Removal 1055

Differential and Drive Axle, Powershift Transmission 1056

Drive Axle, Hydrostatic Transmission 1056

Valve Clearance, Check and Adjust 1056

Ignition System 1056

GM 3 0L LPG (IMPCO) 1056

GM 3 0L LPG (Aisan) 1056

Mazda FE and F2 1056

Mazda XA and HA Diesel Engines 1057

Aisan Regulator Pressure/Diaphragm and O-Ring Checks 1057

PCV Valve 1057

Integral Sideshift Carriage, Check Bearings 1057

Control Levers and Pedals 1058

Cooling System, GM 3 0L EPA Compliant Engine 1058

LPG Fuel Filter (IMPCO), GM 3 0L EPA Compliant Engine, Replace 1058

Inspect Engine Electrical System, Connectors, and FCVS Connectio 1059

Maintenance Procedures Every 2000 Hours or Yearly 1059

Hydraulic System 1059

Hydraulic Oil and Filter, Replace 1059

Powershift Transmission Oil and Filter 1060

Replace 1060

Hydrostatic Transmission Oil and Filter 1061

Replace 1061

Cooling System 1062

Service Brakes 1062

Differential 1062

Transmission Axle Shaft Oil (Hydrostatic Transmission) 1062

LPG Fuel Filter, Replace (Pre-2004) 1063

PCV Valve 1063

Fuel Filter, Replace (Aisan LPG System) 1063

Integral Sideshift Carriage, Replace Bearings 1063

Oxygen Sensor, GM 3 0L EPA Compliant Engine 1063

Air Filter Element, GM 3 0L EPA Compliant Engine 1064

Inspect Low Pressure Regulator (LPR) for Oil Buildup and Leaks 1064

Check Throttle Shaft for Sticking 1065

Inspect Exhaust Manifold and Piping for Leaks 1065

Test LPG Regulator Pressure 1065

Safety Procedures When Working Near Mast 1065

Hood Latch Check 1068

Lift Chain Adjustments 1069

Lift and Tilt System Leak Check 1071

Lift Cylinder, Leak Check 1071

Tilt Cylinder, Leak Check 1072

Charging Battery 1072

Diesel Engine Fuel Injector Check 1073

Welding Repairs 1073

Overhead Guard Changes 1074

Wheel and Tire Replacement 1074

Pneumatic Tire, Repair GLP/GDP20-30RF/TF Models 1074

Remove Wheels From Lift Truck 1074

Remove Wheel From Tire 1074

Remove Tire From Two-Piece Wheel 1075

Remove Tire From Three- and Four-Piece Wheels 1076

Install Wheel on Tire 1077

Install Tire on Three- or Four-Piece Wheels 1077

Install Three-Piece or Four-Piece Wheel in Tire 1078

Install Tire on Two-Piece Wheel 1079

Install Two-Piece Wheel in Tire 1079

Add Air to Pneumatic Tires 1080

Wheels, Install 1080

Dual Drive Wheels, Install 1080

Solid Rubber Tire, Change GLP/GDP20-30RF/TF Models 1081

Remove Wheel From Tire 1081

Install Wheel in Tire 1083

SIT Tire, Change 1084

Remove SIT Solid Tire From Wheel 1085

Install SIT Solid Tire on Wheel 1086

tables 1017

Table 1 Maintenance Schedule 1026

Table 2 Hook-Type Carriage Chain Adjustment 1070

Table 3 Pin-Type Carriage Chain Adjustment 1070

524199506 1300YRM0717 (07 2003) UK EN 1089

toc 1089

Hydrostatic Transmission 1089

Safety Precautions Maintenance and Repair 1090

General 1093

Hydrostatic Components 1093

Location 1093

Description 1093

Theory of Operation 1093

Features of the Hydrostatic Transmission 1098

Travel Control 1098

Dynamic Braking 1098

Inching 1098

Throttle-Up (Option) 1098

Hydraulic Circuit 1099

Loop 1099

Charge 1099

Control 1099

Cooling 1101

Repairs – General Information 1103

Hydrostatic Transmission Fluid 1103

Transmission Fluid Change Intervals 1103

Operation Following Service or Repairs (Commissioning) 1104

Towing the Lift Truck 1104

Hydrostatic Transmission Repair 1105

Remove 1105

Clean and Inspect 1107

Repairs 1107

Install 1110

Drive Axle Repair 1111

Remove 1111

Inspect 1112

Install 1113

Foot Directional Control Pedal Repair 1114

Remove and Disassemble 1114

Assemble and Install 1114

Direction Control Lever Repair 1117

Remove and Disassemble 1117

Assemble and Install 1117

Throttle-Up System Repair 1118

Remove and Install 1118

Switches 1119

Module, Relays, and Fuse 1120

Throttle Motor 1120

Inching/Brake Pedal Adjustment 1121

Variable Relief Valve Adjustment 1121

Hydrostatic Pump Oil Pressure Check 1122

Loop and Pilot Pressure Checks 1123

Charge Pressure Check 1123

Case Pressure Check 1123

Axle Leakage 1123

Inching Adjustment 1124

Swashplate Positioning Cylinder Check and Adjustment 1124

Throttle-Up System Checks 1124

Check Switches 1124

Check Throttle Motor 1124

Check Control Module 1125

Troubleshooting 1126

Torque Specifications 1134

tables 1089

Table 1 Hydrostatic Transmission Oil 1103

Table 2 Hydrostatic Transmission Pressure Tests 1123

Table 3 Control Module Pin Voltages 1125

524208004 0900YRM1088 (05 2006) UK EN 1137

toc 1137

Electronic Controlled LPG/Gasoline Fuel System 1137

Safety Precautions Maintenance and Repair 1138

General 1143

Fuel System Warnings and Cautions 1143

Glossary 1144

Description and Operation of LPG Fuel System 1148

Propane Fuel System 1148

LPG Fuel Tank 1150

Service Line 1150

Fuel Filter 1150

Low Pressure Lock-Off (LPL) 1150

Low Pressure Regulator (LPR) 1151

Air Fuel Mixer 1151

Throttle Control Device 1152

Drive By Cable 1152

Three-Way Catalytic (TWC) Muffler 1153

Electronic Control Module (ECM) 1153

Heated Exhaust Gas Oxygen (HEGO) Sensor 1154

Description and Operation of Gasoline Fuel System 1156

Gasoline Fuel System Throttle Body Injection (TBI), 3 0L Engine 1156

Gasoline Multi-Point Fuel Injection (MPFI) System, 4 3L Only 1156

Gasoline Fuel Storage Tank 1156

Gasoline Fuel Pump 1156

Fuel Filter 1156

Fuel Pressure Regulator, 3 0L Only 1159

Fuel Rail and Pressure Regulator, 4 3L Only 1160

Fuel Injector 1160

Throttle Control Device 1160

Drive By Cable 1160

Three-Way Catalytic Muffler 1161

Electronic Control Module (ECM) 1161

Heated Exhaust Gas Oxygen (HEGO) Sensor 1163

LPG Fuel System Repair 1163

Propane Fuel System Pressure Relief 1163

Propane Fuel System Leak Test 1163

Propane Fuel Filter Replacement 1164

Remove 1164

Install 1164

Low Pressure Lock-Off (LPL) Replacement 1164

Remove 1164

Install 1164

Pressure Trim Valve (PTV) Replacement 1166

Remove 1166

Install 1166

Low Pressure Regulator 1166

Remove 1166

Install 1166

Fuel Trim Valve (FTV) Solenoid Replacement 1167

Remove 1167

Install 1167

Temperature Manifold Absolute Pressure (TMAP) 1167

Remove 1167

Install 1167

Throttle Body Replacement 1169

Remove 1169

Install 1169

Mixer Replacement 1171

Remove 1171

Install 1171

Coolant Hose Replacement 1171

Remove 1171

Install 1172

Vapor Hose Replacement 1172

Remove 1172

Install 1172

Balance Line Hose Replacement 1172

Remove 1172

Install 1172

PTV Hose Replacement 1172

Remove 1172

Install 1172

FTV Hose Replacement 1173

Remove 1173

Install 1173

Throttle Position Sensor (TPS) Replacement 1173

Foot Pedal Position (FPP) Sensor Replacement 1175

Electronic Control Module (ECM) Replacement 1178

Remove 1178

Install 1178

Heated Exhaust Gas Oxygen (HEGO) Sensor Replacement 1178

Remove 1178

Install 1179

Three-Way Catalytic Muffler (TWC) Replacement 1179

Remove 1179

Install 1179

Restricted Exhaust System Diagnosis 1179

Exhaust System Description 1179

Tools Required 1179

Diagnostic Tool 1179

Check at Heated Exhaust Gas Oxygen Sensor (HEGO) 1179

Gasoline Fuel System Repair 1180

Gasoline MPFI and TBI Fuel System Pressure Relief 1180

Gasoline Fuel System Leak Test 1181

Throttle Body Injector (TBI) Assembly Replacement, 3 0L Only 1181

Remove 1181

Install 1181

Throttle Body Assembly Replacement, 3 0L Only 1183

Remove 1183

Install 1183

Throttle Body Assembly Replacement, 4 3L Only 1184

Remove 1184

Install 1184

Fuel Rail Replacement, Gasoline 4 3L Only 1185

Remove 1185

Install 1185

Injector Replacement, Gasoline 4 3L Only 1185

Remove 1185

Install 1185

Injector Replacement, Gasoline 3 0L Only 1187

Remove 1187

Install 1187

Temperature Manifold Absolute Pressure (TMAP) Replacement 1187

Remove 1187

Install 1187

Throttle Position Sensor (TPS) Replacement 1187

Foot Pedal Position (FPP) Sensor Replacement 1190

Electronic Control Module (ECM) Replacement 1193

Remove 1193

Install 1193

Heated Exhaust Gas Oxygen (HEGO) Sensor Replacement 1194

Remove 1194

Install 1194

Three-Way Catalytic Muffler (TWC) Replacement 1194

Remove 1194

Install 1194

Restricted Exhaust System Diagnosis 1194

Exhaust System Description 1194

Tools Required 1194

Diagnostic Tool 1194

Check at Heated Exhaust Gas Oxygen Sensor (HEGO) 1195

LPG System Diagnosis 1195

Fuel System Description 1195

Diagnostic Aids 1196

Tools Required 1196

Duty Cycle Monitoring Tool 1196

Diagnostic Tool 1196

Pressure Gauges 1196

Test Description 1196

Gasoline System Diagnosis 1204

Fuel System Description, 3 0L Only 1204

Fuel System Description, 4 3L Only 1204

Diagnostic Aids 1205

Tools Required 1205

Diagnostic Tool 1205

Test Description 1205

LPG Symptom Diagnosis 1212

Gasoline Symptom Diagnosis 1226

Wire Harness Repair 1237

On Vehicle Service Wiring Harness Repair 1237

Connectors and Terminals 1237

Twisted/Shielded Cable Repair 1238

Twisted Leads Repair 1239

Micro-Pack 1240

Metri-Pack 1240

Remove 1240

Weather-Pack 1242

Weather-Pack Terminal Repair 1243

tables 1137

Table 1 TPS Replacement Procedure 1173

Table 2 FPP Replacement Procedure 1176

Table 3 TPS Replacement Procedure 1188

Table 4 FPP Replacement Procedure 1191

Table 5 LPG Fuel System Diagnosis 1196

Table 6 Fuel Control Diagnosis 1200

Table 7 Gasoline Fuel System Diagnosis, 3 0L Only 1206

Table 8 Gasoline Fuel System Diagnosis, 4 3L Only 1209

Table 9 Preliminary Checks 1212

Table 10 Intermittent 1213

Table 11 No Start 1214

Table 12 Hard Start 1216

Table 13 Cuts Out or Misses 1217

Table 14 Hesitation, Sag, or Stumble 1218

Table 15 Backfire 1219

Table 16 Lack of Power, Sluggishness, or Sponginess 1220

Table 17 Poor Fuel Economy 1221

Table 18 Rough, Unstable, Incorrect Idle, or Stalling 1223

Table 19 Surges or Chuggles 1225

Table 20 Preliminary Checks 1226

Table 21 Intermittent 1227

Table 22 No Start 1228

Table 23 Hard Start 1229

Table 24 Cuts Out or Misses 1230

Table 25 Hesitation, Sag, or Stumble 1231

Table 26 Backfire 1232

Table 27 Lack of Power, Sluggishness, or Sponginess 1233

Table 28 Poor Fuel Economy 1234

Table 29 Rough, Unstable, Incorrect Idle, or Stalling 1235

Table 30 Surges or Chuggles 1236

524208009 2200YRM1090 (04 2005) UK EN 1247

toc 1247

Electronic Control Module (ECM) Diagnostic Troubleshooting 1247

Safety Precautions Maintenance and Repair 1248

General 1257

Description of ECM Based Diagnostics 1257

Definition of Terms 1257

Diagnostics Overview of the Spectrum Fuel System 1257

Malfunction Indicator Lamp (MIL) 1257

Spectrum Diagnostic Trouble Codes (DTC) 1258

Using a Laptop Computer to Diagnose the Spectrum System 1258

Installing the Spectrum Diagnostic Software 1258

Connecting a Laptop Computer to the Spectrum System 1258

Diagnostic Communication Error 1259

Diagnostic Trouble Codes 1259

Checking Diagnostic Trouble Codes 1260

Clearing Diagnostic Trouble Codes 1260

DATA Stream 1260

Reading Sensor and Actuator Values 1260

Graphing and Data Logging 1261

Ignition System Test 1262

Disabling Ignition Outputs 1262

Injector Test 1263

Disabling Injectors 1263

Throttle Test 1264

Using a Diagnostic Jumper to Diagnose the ECI System 1265

On-Board Diagnostics System Check/Malfunction Indicator Lamp 1266

Circuit Description 1266

Preliminary and Intermittent Checks 1269

GM 3 0L Wiring Schematics and Connectors 1271

GM 3 0L Diagnostic Trouble Codes 1285

DTC 111 – IAT High Voltage Motorola® TMAP 1285

Circuit Description 1285

Conditions for Setting the DTC 1285

DTC 112 – IAT Low Voltage Motorola® TMAP 1288

Circuit Description 1288

Conditions for Setting the DTC 1288

DTC 113 – IAT Higher Than Expected 1 Motorola® TMAP 1291

Circuit Description 1291

Conditions for Setting the DTC 1291

Diagnostic Aids 1291

DTC 114 – IAT Higher Than Expected 2 Motorola® TMAP 1292

Circuit Description 1292

Conditions for Setting the DTC 1292

Diagnostic Aids 1292

DTC 115 – Oil Pressure Low 1293

Circuit Description 1293

Conditions for Setting the DTC 1293

DTC 121 – ECT Voltage High 1296

Circuit Description 1296

Conditions for Setting the DTC 1297

DTC 122 – ECT Voltage Low 1300

Circuit Description 1300

Conditions for Setting the DTC 1300

DTC 123 – ECT Higher Than Expected 1 1302

Circuit Description 1302

Conditions for Setting the DTC 1302

DTC 124 – ECT Higher Than Expected 2 1304

Circuit Description 1304

Conditions for Setting the DTC 1304

DTC 131 – MAP High Pressure Motorola® TMAP 1306

Circuit Description 1306

Conditions for Setting the DTC 1306

Diagnostic Aids 1306

DTC 132 – MAP Low Voltage Motorola® TMAP 1308

Circuit Description 1308

Conditions for Setting the DTC 1308

DTC 134 – BP High Pressure Motorola® TMAP 1312

Circuit Description 1312

Conditions for Setting the DTC 1312

DTC 135 – BP Low Pressure Motorola® TMAP 1314

Circuit Description 1314

Conditions for Setting the DTC 1314

DTC 142 – Crank Sync Noise 1318

Circuit Description 1318

Conditions for setting the DTC 1318

DTC 143 – Never Crank Synced At Start 1321

Circuit Description 1321

Conditions for Setting the DTC 1321

DTC 144 – Camshaft Sensor Loss 1324

Circuit Description 1324

Conditions for Setting the DTC 1324

DTC 145 – Camshaft Sensor Noise 1327

Circuit Description 1327

Conditions for Setting the DTC 1327

DTC 211 – Closed Loop Multiplier High (LPG) 1330

Circuit Description 1330

Conditions for Setting the DTC 1330

Diagnostic Aids 1330

DTC 212 – HO 2 S Open/Inactive 1332

Circuit Description 1332

Conditions for Setting the DTC 1332

DTC 221 – Closed Loop Multiplier High (Gasoline) 1336

Circuit Description 1336

Conditions for Setting the DTC 1336

Diagnostic Aids 1337

DTC 222 – Closed Loop Multiplier Low (Gasoline) 1338

Circuit Description 1338

Conditions for Setting the DTC 1338

Diagnostic Aids 1338

DTC 224 – Closed Loop Multiplier Low (LPG) 1340

Circuit Description 1340

Conditions for Setting the DTC 1340

Diagnostic Aids 1341

DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1342

Circuit Description 1342

Conditions for Setting the DTC 1342

Diagnostic Aids 1343

DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1346

Circuit Description 1346

Conditions for Setting the DTC 1346

Diagnostic Aids 1346

DTC 243 – Adaptive Learn High (LPG) 1348

Circuit Description 1348

Conditions for Setting the DTC 1348

Diagnostic Aids 1348

DTC 244 – Adaptive Learn Low (LPG) 1352

Circuit Description 1352

Conditions for Setting the DTC 1352

Diagnostic Aids 1352

DTC 261 – System Voltage High 1354

Circuit Description 1354

Conditions for Setting the DTC 1354

DTC 262 – System Voltage Low 1356

Circuit Description 1356

Conditions for Setting the DTC 1356

DTC 411 – Injector Driver 1 Open 1359

Circuit Description 1359

Conditions for Setting the DTC 1359

DTC 412 – Injector Driver 1 Shorted 1362

Circuit Description 1362

Conditions for Setting the DTC 1362

DTC 511 – COP Failure 1365

Circuit Description 1365

Conditions for Setting the DTC 1365

DTC 512 – Invalid Interrupt 1367

Circuit Description 1367

Conditions for Setting the DTC 1367

DTC 513 – A/D Loss 1369

Circuit Description 1369

Conditions for Setting the DTC 1369

DTC 514 – RTI 1 Loss 1371

Circuit Description 1371

Conditions for Setting the DTC 1371

DTC 515 – Flash Checksum Invalid 1373

Circuit Description 1373

Conditions for Setting the DTC 1373

DTC 516 – Ram Failure 1375

Circuit Description 1375

Conditions for Setting the DTC 1375

DTC 531 – External 5V Ref Lower Than Expected 1377

Circuit Description 1377

Conditions for Setting the DTC 1377

DTC 532 – External 5V Ref Higher Than Expected 1380

Circuit Description 1380

Conditions for Setting the DTC 1380

DTC 555 – RTI 2 Loss 1382

Circuit Description 1382

Conditions for Setting the DTC 1382

DTC 556 – RTI 3 Loss 1384

Circuit Description 1384

Conditions for Setting the DTC 1384

DTC 611 – FPP High Voltage 1386

Circuit Description 1386

Conditions for Setting the DTC 1386

DTC 612 – FPP Low Voltage 1389

Circuit Description 1389

Conditions for Setting the DTC 1389

DTC 631 – TPS1 Signal Voltage High 1393

Circuit Description 1393

Conditions for Setting the DTC 1393

DTC 632 – TPS1 Signal Voltage Low 1396

Circuit Description 1396

Conditions for Setting the DTC 1396

DTC 638 – Throttle Unable To Close 1398

Circuit Description 1398

Conditions for Setting the DTC 1398

Diagnostic Aids 1398

DTC 651 – Maximum Govern Speed Override 1402

Circuit Description 1402

Conditions for Setting the DTC 1402

Diagnostic Aids 1402

DTC 652 – Fuel Rev Limit 1404

Circuit Description 1404

Conditions for Setting the DTC 1404

Diagnostic Aids 1404

DTC 653 – Spark Rev Limit 1407

Circuit Description 1407

Conditions for Setting the DTC 1407

Diagnostic Aids 1407

GM 4 3L Wiring Schematics and Connectors 1410

GM 4 3L Diagnostic Trouble Codes 1427

DTC 111 – IAT High Voltage Bosch® TMAP 1427

Circuit Description 1427

Conditions for Setting the DTC 1427

DTC 111 – IAT High Voltage Motorola® TMAP 1430

Circuit Description 1430

Conditions for Setting the DTC 1430

DTC 112 – IAT Low Voltage Bosch® TMap 1432

Circuit Description 1432

Conditions for Setting the DTC 1432

DTC 112 – IAT Low Voltage Motorola® TMAP 1435

Circuit Description 1435

Conditions for Setting the DTC 1435

DTC 113 – IAT Higher Than Expected 1 Bosch® TMAP 1438

Circuit Description 1438

Conditions for Setting the DTC 1438

Diagnostic Aids 1438

DTC 113 – IAT Higher Than Expected 1 Motorola® TMAP 1439

Circuit Description 1439

Conditions for Setting the DTC 1439

Diagnostic Aids 1439

DTC 114 – IAT Higher Than Expected 2 Bosch® TMAP€ 1440

Circuit Description 1440

Conditions for Setting the DTC 1440

Diagnostic Aids 1440

DTC 114 – IAT Higher Than Expected 2 Motorola® TMAP 1441

Circuit Description 1441

Conditions for Setting the DTC 1441

Diagnostic Aids 1441

DTC 115 – Oil Pressure Low 1442

Circuit Description 1442

Conditions for Setting the DTC 1442

DTC 121 – ECT Voltage High 1445

Circuit Description 1445

Conditions for Setting the DTC 1446

DTC 122 – ECT Voltage Low 1448

Circuit Description 1448

Conditions for Setting the DTC 1448

DTC 123 – ECT Higher Than Expected 1 1451

Circuit Description 1451

Conditions for Setting the DTC 1451

DTC 124 – ECT Higher Than Expected 2 1453

Circuit Description 1453

Conditions for Setting the DTC 1453

DTC 131 – MAP High Pressure Bosch® TMAP 1454

Circuit Description 1454

Conditions for Setting the DTC 1454

Diagnostic Aids 1454

DTC 131 – MAP High Pressure Motorola® TMAP 1458

Circuit Description 1458

Conditions for Setting the DTC 1458

Diagnostic Aids 1458

DTC 132 – MAP Low Voltage Bosch® TMAP 1461

Circuit Description 1461

Conditions for Setting the DTC 1461

DTC 132 – MAP Low Voltage Motorola® TMAP 1464

Circuit Description 1464

Conditions for Setting the DTC 1464

DTC 134 – BP High Pressure Bosch® TMAP 1468

Circuit Description 1468

Conditions for Setting the DTC 1468

DTC 134 – BP High Pressure Motorola® TMAP 1470

Circuit Description 1470

Conditions for Setting the DTC 1470

DTC 135 – BP Low Pressure Bosch® TMAP 1472

Circuit Description 1472

Conditions for Setting the DTC 1472

DTC 135 – BP Low Pressure Motorola® TMAP 1476

Circuit Description 1476

Conditions for Setting the DTC 1476

DTC 142 – Crank Sync Noise 1480

Circuit Description 1480

Conditions for setting the DTC 1480

DTC 143 – Never Crank Synced At Start 1483

Circuit Description 1483

Conditions for Setting the DTC 1483

DTC 144 – Camshaft Sensor Loss 1486

Circuit Description 1486

Conditions for Setting the DTC 1486

DTC 145 – Camshaft Sensor Noise 1489

Circuit Description 1489

Conditions for Setting the DTC 1489

DTC 211 – Closed Loop Multiplier High (LPG) 1492

Circuit Description 1492

Conditions for Setting the DTC 1492

Diagnostic Aids 1492

DTC 212 – HO 2 S Open/Inactive 1494

Circuit Description 1494

Conditions for Setting the DTC 1494

DTC 221 – Closed Loop Multiplier High (Gasoline) 1498

Circuit Description 1498

Conditions for Setting the DTC 1498

Diagnostic Aids 1498

DTC 222 – Closed Loop Multiplier Low (Gasoline) 1500

Circuit Description 1500

Conditions for Setting the DTC 1500

Diagnostic Aids 1501

DTC 224 – Closed Loop Multiplier Low (LPG) 1502

Circuit Description 1502

Conditions for Setting the DTC 1502

Diagnostic Aids 1503

DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1504

Circuit Description 1504

Conditions for Setting the DTC 1504

Diagnostic Aids 1505

DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1508

Circuit Description 1508

Conditions for Setting the DTC 1508

Diagnostic Aids 1509

DTC 243 – Adaptive Learn High (LPG) 1511

Circuit Description 1511

Conditions for Setting the DTC 1511

Diagnostic Aids 1512

DTC 244 – Adaptive Learn Low (LPG) 1514

Circuit Description 1514

Conditions for Setting the DTC 1514

Diagnostic Aids 1515

DTC 261 – System Voltage High 1516

Circuit Description 1516

Conditions for Setting the DTC 1516

DTC 262 – System Voltage Low 1518

Circuit Description 1518

Conditions for Setting the DTC 1518

DTC 511 – COP Failure 1521

Circuit Description 1521

Conditions for Setting the DTC 1521

DTC 512 – Invalid Interrupt 1523

Circuit Description 1523

Conditions for Setting the DTC 1523

DTC 513 – A/D Loss 1525

Circuit Description 1525

Conditions for Setting the DTC 1525

DTC 514 – RTI 1 Loss 1527

Circuit Description 1527

Conditions for Setting the DTC 1527

DTC 515 – Flash Checksum Invalid 1529

Circuit Description 1529

Conditions for Setting the DTC 1529

DTC 516 – Ram Failure 1531

Circuit Description 1531

Conditions for Setting the DTC 1531

DTC 531 – External 5V Ref Lower Than Expected 1533

Circuit Description 1533

Conditions for Setting the DTC 1533

DTC 532 – External 5V Ref Higher Than Expected 1536

Circuit Description 1536

Conditions for Setting the DTC 1536

DTC 555 – RTI 2 Loss 1538

Circuit Description 1538

Conditions for Setting the DTC 1538

DTC 556 – RTI 3 Loss 1540

Circuit Description 1540

Conditions for Setting the DTC 1540

DTC 611 – FPP High Voltage 1542

Circuit Description 1542

Conditions for Setting the DTC 1542

DTC 612 – FPP Low Voltage 1546

Circuit Description 1546

Conditions for Setting the DTC 1546

DTC 631 – TPS1 Signal Voltage High 1550

Circuit Description 1550

Conditions for Setting the DTC 1550

DTC 632 – TPS1 Signal Voltage Low 1553

Circuit Description 1553

Conditions for Setting the DTC 1553

DTC 638 – Throttle Unable To Close 1556

Circuit Description 1556

Conditions for Setting the DTC 1556

Diagnostic Aids 1557

DTC 651 – Maximum Govern Speed Override 1559

Circuit Description 1559

Conditions for Setting the DTC 1559

Diagnostic Aids 1559

DTC 652 – Fuel Rev Limit 1562

Circuit Description 1562

Conditions for Setting the DTC 1562

Diagnostic Aids 1562

DTC 653 – Spark Rev Limit 1564

Circuit Description 1564

Conditions for Setting the DTC 1564

Diagnostic Aids 1564

Wire Harness Repair 1567

On Vehicle Service Wiring Harness Repair 1567

Connectors and Terminals 1567

Twisted/Shielded Cable Repair 1568

Twisted Leads Repair 1569

Micro-Pack 1570

Metri-Pack 1570

Remove 1570

Weather-Pack 1572

Weather-Pack Terminal Repair 1572

tables 1247

Table 1 OBD System Check 1267

Table 2 Preliminary Checks 1269

Table 3 Intermittent Checks 1270

Table 4 Communication Port C002 1271

Table 5 Coil Connector C003 1271

Table 6 Fuel System Interface C004 1271

Table 7 Oil Pressure Connector C005 1272

Table 8 Distributor Connector C006 1272

Table 9 Magnetic Pickup Connector C007 1272

Table 10 Heated Oxygen Sensor C008 1272

Table 11 Throttle Position Sensor Connector C009 1273

Table 12 Foot Pedal Position Connector C010 1273

Table 13 Governor Motor Connector C011 1273

Table 14 TMAP Connector C012 1273

Table 15 Starter Solenoid C013 1274

Table 16 Engine Coolant Temperature C014 1274

Table 17 Battery Connector C015 1274

Table 18 Alternator Connection C016 1274

Table 19 Battery Connector C017 1274

Table 20 Alternator Connector C018 1275

Table 21 Instrument Panel Connector C019 1275

Table 22 Instrument Panel Connector C020 1275

Table 23 Instrument Panel Connector C021 1276

Table 24 Fuel Trim Valve Connector C022 1276

Table 25 Fuel Lockoff Connector C023 1276

Table 26 Pressure Trim Valve Connector C024 1277

Table 27 Throttle Body Injector Connector C025 1277

Table 28 Relay and Fuse Center 1277

Table 29 DTC 111 – IAT Voltage High (Motorola® TMAP) 1286

Table 30 DTC 112 – IAT Low Voltage (Motorola® TMAP) 1289

Table 31 DTC 115 – Oil Pressure Low 1294

Table 32 Temperature Resistance 1296

Table 33 DTC 121 – ECT VOLTAGE HIGH 1297

Table 34 DTC 122 – ECT Voltage Low 1301

Table 35 DTC 123 – ECT Higher Than Expected 1 1303

Table 36 DTC 124 – ECT Higher Than Expected 2 1305

Table 37 DTC 131 – MAP HIGH PRESSURE (Motorola® TMAP) 1307

Table 38 DTC 132 – MAP Low Voltage (Motorola® TMAP) 1309

Table 39 DTC 134 – BP High Pressure (Motorola® TMAP) 1313

Table 40 DTC 135 – BP Low Pressure (Motorola® TMAP) 1314

Table 41 DTC 142 – Crank Sync Noise 1318

Table 42 DTC 143 – Never Crank Synced At Start 1321

Table 43 DTC 144 – Camshaft Sensor Loss 1324

Table 44 DTC 145 – Camshaft Sensor Noise 1327

Table 45 DTC 211 – Closed Loop Multiplier High (LPG) 1331

Table 46 DTC 212 – HO 2 S Open/Inactive 1333

Table 47 DTC 221 – Closed Loop Multiplier High (Gasoline) 1337

Table 48 DTC 222 – Closed Loop Multiplier Low (Gasoline) 1340

Table 49 DTC 224 – Closed Loop Multiplier Low (LPG) 1342

Table 50 DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1344

Table 51 DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1347

Table 52 DTC 243 – Adaptive Learn High (LPG) 1350

Table 53 DTC 244 – Adaptive Learn Low (LPG) 1353

Table 54 DTC 261 – System Voltage High 1355

Table 55 DTC 262 – System Voltage Low 1357

Table 56 DTC 411 – Injector Driver 1 Open 1360

Table 57 DTC 412 – Injector Driver 1 Shorted 1363

Table 58 DTC 511 – COP Failure 1366

Table 59 DTC 512 – Invalid Interrupt 1368

Table 60 DTC 513 – A/D Loss 1370

Table 61 DTC 514 – RTI 1 Loss 1372

Table 62 DTC 515 – Flash Checksum Invalid 1374

Table 63 DTC 516 – Ram Failure 1376

Table 64 DTC 531 – External 5V Ref Lower Than Expected 1378

Table 65 DTC 532 – External 5 V Ref Higher Than Expected 1380

Table 66 DTC 555 – RTI 2 Loss 1383

Table 67 DTC 556 – RTI 3 Loss 1385

Table 68 DTC 611 – FPP High Voltage 1386

Table 69 DTC 612 – FPP Low Voltage 1390

Table 70 DTC 631 – TPS1 Signal Voltage High 1394

Table 71 DTC 632 – TPS1 Signal Voltage Low 1397

Table 72 DTC 638 – Throttle Unable To Close 1399

Table 73 DTC 651 – Maximum Govern Speed Override 1403

Table 74 DTC 652 – Fuel Rev Limit 1405

Table 75 DTC 653 – Spark Rev Limit 1408

Table 76 Communication Port C002 1410

Table 77 Injector Connector C003 1410

Table 78 Injector Connector C004 1410

Table 79 Oil Pressure Connector C005 1411

Table 80 Throttle Position Sensor 1 Connector C006 1411

Table 81 Foot Pedal Position Connector C006A 1411

Table 82 Coil Connector C007 1411

Table 83 Module Connector C008 1412

Table 84 Crank Sensor Connector C009 1412

Table 85 EGO Sensor Connector C010 1412

Table 86 Cam Connector C011 1412

Table 87 Throttle Connector C012 1413

Table 88 Bosch TMAP Connector C013 (Gasoline Fuel System Only) 1413

Table 89 Motorola TMAP Connector C013 (LPG Fuel System Only) 1413

Table 90 Starter Solenoid Connector C014 1413

Table 91 ECT Connector C015 1414

Table 92 Starter Relay C016 1414

Table 93 Power Relay C017 1414

Table 94 Fuel Pump Relay C018 1414

Table 95 Battery Connector C019 1414

Table 96 Alternator Connector C020 1414

Table 97 Alternator Connector C021 1415

Table 98 Instrument Panel Connector C022 1415

Table 99 Instrument Panel Connector C023 1415

Table 100 Instrument Panel Connector C024 1416

Table 101 Fuel Trim Valve Connector C025 1416

Table 102 Fuel Lockoff Connector C026 1416

Table 103 Pressure Trim Valve Connector C027 1417

Table 104 Injector 1 Connector C028 1417

Table 105 Injector 2 Connector C029 1417

Table 106 Injector 3 Connector C030 1417

Table 107 Injector 4 Connector C031 1418

Table 108 Injector 5 Connector C032 1418

Table 109 Injector 6 Connector C033 1418

Table 110 Relay and Fuse Center 1419

Table 111 DTC 111 – IAT Voltage High (Bosch® TMAP) 1428

Table 112 DTC 111 – IAT Voltage High (Motorola® TMAP) 1431

Table 113 DTC 112 – IAT Low Voltage (Bosch® TMAP) 1433

Table 114 DTC 112 – IAT Low Voltage (Motorola® TMAP) 1436

Table 115 DTC 115 – Oil Pressure Low 1443

Table 116 Temperature Resistance 1445

Table 117 DTC 121 – ECT VOLTAGE HIGH 1446

Table 118 DTC 122 – ECT Voltage Low 1449

Table 119 DTC 123 – ECT Higher Than Expected 1 1452

Table 120 DTC 124 – ECT Higher Than Expected 2 1454

Table 121 DTC 131 – MAP High Pressure (Bosch® TMAP) 1455

Table 122 DTC 131 – MAP HIGH PRESSURE (Motorola® TMAP) 1459

Table 123 DTC 132 – MAP Low Voltage (Bosch® TMAP) 1462

Table 124 DTC 132 – MAP Low Voltage (Motorola® TMAP) 1465

Table 125 DTC 134 – BP High Pressure (Bosch® TMAP) 1469

Table 126 DTC 134 – BP High Pressure (Motorola® TMAP) 1471

Table 127 DTC 135 – BP Low Pressure (Bosch® TMAP) 1472

Table 128 DTC 135 – BP Low Pressure (Motorola® TMAP) 1476

Table 129 DTC 142 – Crank Sync Noise 1480

Table 130 DTC 143 – Never Crank Synced At Start 1483

Table 131 DTC 144 – Camshaft Sensor Loss 1486

Table 132 DTC 145 – Camshaft Sensor Noise 1489

Table 133 DTC 211 – Closed Loop Multiplier High (LPG) 1493

Table 134 DTC 212 – HO 2 S Open/Inactive 1495

Table 135 DTC 221 – Closed Loop Multiplier High (Gasoline) 1499

Table 136 DTC 222 – Closed Loop Multiplier Low (Gasoline) 1502

Table 137 DTC 224 – Closed Loop Multiplier Low (LPG) 1504

Table 138 DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1506

Table 139 DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1509

Table 140 DTC 243 – Adaptive Learn High (LPG) 1512

Table 141 DTC 244 – Adaptive Learn Low (LPG) 1515

Table 142 DTC 261 – System Voltage High 1517

Table 143 DTC 262 – System Voltage Low 1519

Table 144 DTC 511 – COP Failure 1522

Table 145 DTC 512 – Invalid Interrupt 1524

Table 146 DTC 513 – A/D Loss 1526

Table 147 DTC 514 – RTI 1 Loss 1528

Table 148 DTC 515 – Flash Checksum Invalid 1530

Table 149 DTC 516 – Ram Failure 1532

Table 150 DTC 531 – External 5V Ref Lower Than Expected 1534

Table 151 DTC 532 – External 5 V Ref Higher Than Expected 1536

Table 152 DTC 555 – RTI 2 Loss 1539

Table 153 DTC 556 – RTI 3 Loss 1541

Table 154 DTC 611 – FPP High Voltage 1543

Table 155 DTC 612 – FPP Low Voltage 1547

Table 156 DTC 631 – TPS1 Signal Voltage High 1551

Table 157 DTC 632 – TPS1 Signal Voltage Low 1554

Table 158 DTC 638 – Throttle Unable To Close 1557

Table 159 DTC 651 – Maximum Govern Speed Override 1560

Table 160 DTC 652 – Fuel Rev Limit 1563

Table 161 DTC 653 – Spark Rev Limit 1565