$35.95

Yale Forklift A888 (ERP10-15RCF) Service Manual - PDF

Yale Forklift A888 (ERP10-15RCF) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A888 (ERP10-15RCF) Service Manual – PDF DOWNLOAD

Language : English

Pages : 450

Downloadable : Yes

File Type : PDF

PART NO. 524150790

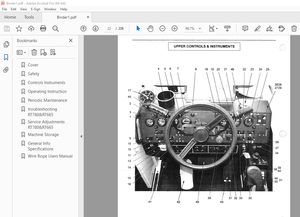

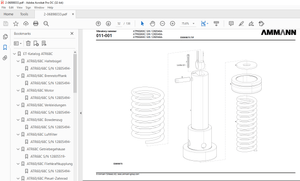

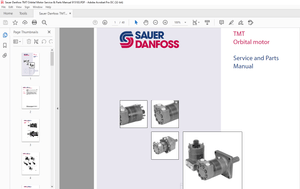

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A888 (ERP10-15RCF) Service Manual – PDF DOWNLOAD

524150790-2100YRM0103-(03-2007)-UK-EN 1

toc 1

Tilt Cylinders 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Tilt Cylinder Repair 5

Remove 5

Disassemble 5

Clean 5

Assemble 6

Tilt Cylinders With O-Ring or Single-Lip Seals 6

Tilt Cylinders 7

Install 8

Tilt Cylinder Leak Check 10

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 11

Torque Specifications 11

Piston Rod Nut 11

Retainer 11

Troubleshooting 12

tables 1

Table 1 Movement Rates (Maximum) for Tilt Cylinders 10

524150797-8000YRM0231-(03-2020)-UK-EN 17

General 21

Threaded Fasteners 21

Nomenclature, Threads 21

Strength Identification 22

Cotter (Split) Pins 23

Fastener Torque Tables 28

Conversion Table 30

524156985-2200YRM1014-(11-2001)-UK-EN 37

toc 37

Sevcon Traction and Pump Controllers 37

Safety Precautions Maintenance and Repair 38

Sevcon PCpak 43

Introduction 43

System Requirements 43

Traction Controller Safety 43

Traction Controller Introduction 44

Traction Controller Installation 44

Mounting 44

Traction Controller Calibration 46

Adjustments 46

Status and Test Information 47

Traction Controller Configuration 48

System Configuration 48

System Voltage 48

System I/O Configuration 48

System/Motor Setup 50

Armature Field Map 50

Armature and Field Current Limit 51

Contactor Chopping 52

Accelerator Full/Zero Setting 52

Performance 52

Acceleration Delay 52

Deceleration Delay 52

Control Mode 53

Plugging 53

Types of Braking 53

Braking Levels 53

Footbraking 53

Footbrake Pot 53

Footbrake Priority 54

Creep Speed 54

Maximum Speed 55

Traction Controller Commissioning 55

Checklist 55

Traction Controller Features 57

Accelerator Characteristics 57

Features 58

Standard Controller Features 58

Power Steer 58

High Speed Switch and Anti-Tie Down 59

Seat Switch 60

Traction Drive Hours Meter 60

Personality Checksum 60

Reverse Buzzer 60

Traction Controller Safety Features 60

Start Up Sequence 60

SRO (Static Return to Off) 60

Belly Switch (not used) 60

Anti-Rollback 61

Anti-Rolloff 61

Fail-Safe 61

Traction Controller Protection 61

Controller Protection Features 61

Temperature Monitoring 61

Maximum Temperature Logging 62

Timed Current Cutback 62

Safe Operating Area (SOA) 63

Under-Voltage and Over-Voltage Protection 63

Traction Controller Diagnostics 64

Fault Codes 64

Fault Code Clearance 66

Software Version and Serial Number Indication 66

Pump Controller Safety 66

Pump Controller Introduction 67

Pump Controller Installation 67

Mounting 67

MillipaK Pump Power Wiring 68

Pump Controller Calibration 69

Adjustments 69

Status and Test Information 70

Pump Controller Configuration 70

System Configuration 70

System Voltage 70

System I/O Configuration 70

Current Limit 72

Accelerator Full/Zero Setting 72

Performance 72

Lift and Power Steer Ramps 73

Creep Speed 73

Maximum Speed 73

Pump Controller Commissioning 74

Under-Voltage Protection 74

Commissioning Checklist 74

Personalities Record 74

Pump Controller Features 76

Features 76

Standard Controller Features 76

Lift Switch Inputs – Priority 76

Lift Switch Inputs – Additive 76

Compensation 76

Power Steer Input 77

Lift Inhibit Input 77

Cooling Fan 77

Pump Hours Meter 77

Personality Checksum 77

Pump Controller Safety Features 78

Fail-safe 78

Pump Controller Protection 78

Controller Protection Features 78

Temperature Monitoring 78

Maximum Temperature Logging 78

Timed Current Cutback 79

Safe Operating Area (SOA) 79

Pump Controller Diagnostics 80

Diagnostics 80

Fault Clearance 80

Using Status and Test Menus 80

Software Version and Serial Number Indication 81

Pump Controller Specifications 82

Power Configurations 82

EMC Standards 82

Socket B Protection 82

Contactor Drive Ratings 82

Analogue Input Impedance 82

Digital Input Impedance 82

Ordering Information 83

EMC Guidelines 83

Power Cables 83

Signal Cables 83

Controller 83

tables 37

Table 1 Adjustment Menus 46

Table 2 Status and Test Information Menus 47

Table 3 Description of each Digital I/O Configuration 48

Table 4 Digital Functions 49

Table 5 Pin Allocations 50

Table 6 Analogue Functions 50

Table 7 Personality Record 55

Table 8 Internal Power Steer Triggers 58

Table 9 Timed Current Limit Cutback Levels 62

Table 10 Under- and Over-Voltage Cutback Levels 63

Table 11 Flash Fault Descriptions 64

Table 12 Fault Codes and Descriptions 64

Table 13 Software Version Format 66

Table 14 Serial Number Format 66

Table 15 Analogue Function 72

Table 16 Personality Record 74

524158040-2240YRM0001-(03-2020)-UK-EN 87

General 91

Battery Type 91

Lead-Acid Batteries 91

Lithium-Ion Batteries 92

Specific Gravity 92

Chemical Reaction in a Cell 92

Electrical Terms 94

Battery Selection 94

Battery Voltage 95

Battery as a Counterweight 96

Battery Ratings 96

Kilowatt-Hours 96

Battery Maintenance 96

Safety Procedures 96

Maintenance Records 97

New Battery 97

Cleaning Battery 97

Adding Water to Battery 99

Hydrometer 100

Battery Temperature 101

Charging Battery 102

Types of Battery Charges 102

Methods of Charging 104

Troubleshooting Charger 104

Knowing When Battery Is Fully Charged 105

Where to Charge Batteries 105

Equipment Needed 105

Battery Connectors 106

Battery Care 106

Troubleshooting 108

524166836-1600YRM0485-(07-2003)-UK-EN 113

toc 113

Steering System for Electric Lift Trucks 113

Safety Precautions Maintenance and Repair 114

General 117

Description 119

Steering Wheel and Column Assembly Repair 120

Assembly Components, Remove 120

Assembly Components, Install 124

Power Steering Motor and Pump 125

Description 125

Remove and Disassemble, Models ERC 20-30AGF (ERC040-065RF/ZF, RG 126

Remove and Disassemble, Models ERC35-55HG (ERC70-120HD, ERC70-12 127

Remove and Disassemble, Models ERP20-30ALF 130

Remove and Disassemble, Models ERC/P16-20AAF (ERC040-065AF, AG/B 130

Assemble and Install, All Models With A Vertical Mount Except ER 131

Assemble and Install, Models ERP20-30ALF 131

Assemble and Install, Models ERC/P16-20AAF (ERC030-040AF, AG/BG) 132

Power Steering Pump, Repair 132

Seal, Replace 133

Hydraulic Steering Motor 134

Steering System Air Removal 134

Steering Pressure Check 134

Optical Encoder and Activator Circuits Check 135

Troubleshooting 137

524175461-0100YRM0793-(09-2002)-UK-EN 141

toc 141

Frame 141

Safety Precautions Maintenance and Repair 142

General 145

Description 145

Overhead Guard Repair 146

Remove 146

Install 146

Hood and Seat Assembly Repair 146

Remove 148

Install 148

Counterweight Repair 148

Remove 148

Install 149

Hydraulic Tank Repair 150

Inspect 150

Small Leaks, Repair 150

Large Leaks, Repair 150

Clean 150

Steam Method 150

Chemical Solution Method 151

Additional Preparations for Repair 151

Safety Labels 151

Battery Specifications 154

tables 141

Table 1 Weight of Counterweights 149

524175462-0630YRM0794-(09-2002)-UK-EN 157

toc 157

Master Drive Unit (ZF) 157

Safety Precautions Maintenance and Repair 158

General 161

Description 161

Top Section Housing 161

Transmission Housing 161

Repair 162

Remove 162

Disassemble 163

Top Section Housing 163

Transmission Housing 163

Assemble 167

Installing Spiral Bevel Pinion Shaft 167

Measuring Bearing Movement in Bevel Pinion Shaft 169

Assembly of Helical Gear 170

Assembling Crown Gear and Wheel Shaft 170

Assembling Transmission Housing Cover 172

Assembling Input Motor Pinion Gear 172

Inspecting Top Section Housing 172

Measuring Pivoting Bearing Movement 173

Installing Top Section Housing 173

Install 173

Tooth Contact Pattern Adjustment 174

Changing Transmission Oil 175

Troubleshooting 176

tables 157

Table 1 Tooth Contact Pattern 174

524175463-0630YRM0795-(09-2002)-UK-EN 181

toc 181

Master Drive Unit (Kordel) 181

Safety Precautions Maintenance and Repair 182

General 185

Description 185

Upper Section 185

Lower Section 187

Drive Unit Repair 187

Remove 187

Disassemble 188

Assemble 189

General 189

Assemble Component Subassemblies 189

Assemble Components Into Lower Section 191

Assemble Upper and Lower Sections 192

Install 192

Check and Change Transmission Oil 193

Tooth Contact Pattern Adjustment 194

Troubleshooting 195

tables 181

Table 1 Tooth Contact Pattern 194

524175464-1600YRM0796-(09-2002)-UK-EN 199

toc 199

Steering System 199

Safety Precautions Maintenance and Repair 200

General 203

Description 203

Steering Wheel and Column Assembly 204

Steering Control Unit Repair 208

Remove 208

Install 208

Hydraulic Steering Motor Repair 209

Description 209

Remove 209

Disassemble 209

Clean and Inspect 211

Assemble 211

Install 211

Direction Control Lever Repair 212

Remove 212

Assemble 212

Install 213

Power Steering Adjustments 213

Air in Steering System 213

Steering Pressure 213

Steering Chain, Adjust 214

Troubleshooting 214

524175465-1600YRM0797-(09-2002)-UK-EN 219

toc 219

Steering Control Unit 219

Safety Precautions Maintenance and Repair 220

General 223

Description 223

Operation 223

Steering Wheel and Column Assembly Repair 225

Steering Column Assembly Repair 226

Remove and Disassemble 226

Assemble and Install 226

Steering Control Unit, Disassemble 227

Steering Control Unit, Clean 229

Steering Control Unit, Assemble 230

System Air Removal 233

Troubleshooting 234

524175466-1800YRM0803-(09-2002)-UK-EN 239

toc 239

Brake System 239

Safety Precautions Maintenance and Repair 240

General 243

Description and Operation 243

Master Cylinder Repair 245

Remove and Disassemble 245

Clean and Inspect 246

Assemble and Install 246

Service and Parking Brakes Repair 246

Remove and Disassemble 246

Clean 247

Inspect 248

Assemble and Install 248

Brake System Air Removal 249

Service Brakes Adjustment 250

Brake Pedal Adjustment 250

Parking Brake Adjustment 250

Troubleshooting 251

524175467-1900YRM0802-(02-2009)-UK-EN 257

toc 257

Hydraulic System 257

Safety Precautions Maintenance and Repair 258

General 261

Description 261

Control Valve Repair 264

Description 264

Operation 264

Lift 264

Tilt and Auxiliary 264

Relief Valve 264

Check Valves 270

Description 270

Clean and Inspect 270

Repairs 270

Remove 270

Disassemble – Control Valve Without OPS Solenoids 270

Disassemble – Control Valve With OPS Solenoids 271

Inlet Section 272

Lift Section 272

Tilt Section 272

Auxiliary Section 273

Relief Valve Repair – Control Valve Without OPS Solenoids 273

Relief Valve Repair – Control Valve With OPS Solenoids 274

Clean and Inspect 274

Assemble – Control Valve Without OPS Solenoids 275

Assemble – Control Valve With OPS Solenoids 276

Inlet Section 276

Lift/Lower Section 276

Tilt Section 276

Auxiliary Section 276

Control Valve 276

Install 276

Checks 277

Relief Valve Check 277

Adjust 277

Relief Valve 277

Control Levers, Linkage, and Switches 277

Hydraulic Pump Repair 279

Description 279

Repairs 279

Remove 279

Seal, Replace 280

Install 281

Specifications 283

Relief Valves Pressures 283

Hydraulic System Capacity 283

Troubleshooting 283

Hydraulic Pump 283

Control Valve 284

524175469-2200YRM0144-(09-2002)-UK-EN 289

toc 289

Electrical Warning Devices 289

Safety Precautions Maintenance and Repair 290

General 293

Description 293

Operator-Controlled Horns 293

System Warning Lights, Buzzers, and Bells 293

Reverse Warning Horns 293

Warning Lights 294

Replacement 295

General 295

Horns or Bells, Replace 295

Horn Relay or Buzzer, Replace 295

Warning Lights/Bulbs, Replace 296

Light Assemblies, Replace 296

Flashing Units, Replace 296

524175470-2200YRM0806-(09-2002)-UK-EN 299

toc 299

Sevcon® SC2126 Motor Controller 299

Safety Precautions Maintenance and Repair 300

General 303

Lift Truck Control 303

Plugging 304

Contactors 304

Circuit Protection 305

Current Limit 305

Fuses 305

Controller Operation 306

General Operation 306

Operating Frequency 306

Temperature Monitoring 306

Safe Operating Area (SOA) 306

Undervoltage and Overvoltage Protection 306

Diagnostic LED 307

Fault Clearance 307

Software Version and Revision Indication 307

Setup Menu 307

Multi Languages 307

Power Circuit Descriptions 307

Traction Operation 308

Startup Sequence 308

Static Return to Off (SRO) 308

Seat Switch 308

Acceleration Delay 308

Deceleration Delay 308

Creep 308

Regenerative Braking 308

Plug Braking 309

Brake Constant Factor 309

Antirollback 309

Analog Inputs 309

Traction Accelerator 309

Digital Switch Inputs 310

Contactors 310

Contactor Chopping 310

Fail-Safe 310

Pump Operation 310

Pump Speeds and Priorities 311

Additive Speeds 311

Power Steer Speed 311

Pump Inhibit Input 311

Pump Speed Compensation 311

Calibration and Adjustments 312

Traction Personalities (Controller Adjustments) 312

Traction Status Information 314

Traction Test Information 314

BDI Adjustments 315

Fault Log 315

Setup Menu (Enables/Disables Features) 315

Pump Personalities (Controller Adjustments) 315

Pump Status Information 316

Pump Test Information 317

Pump Setup Menu 317

Traction and Pump Adjustment Descriptions 317

Setup Menu Descriptions 319

Controller Connections 320

Power Connections 320

Controller Connections 320

Contactor Connections 320

Contactor Types 320

Fuse Ratings 320

Back Panel Connectors 321

Connector A – 24 Pin 321

Connector B – 12 Pin 321

Connector C – 6 Pin 322

Controller Area Network (CAN) Overview 322

Diagnostics 322

Service and Fault Logs 324

Service Log 324

Fault Log 324

Technical Specifications 325

Environmental 325

Mechanical 325

Electrical 325

Voltage Specifications: 325

Current Specifications: 325

Miscellaneous Controller Specifications: 326

Contactor Repair 327

General 327

Remove Contactor Assembly 327

Contactor Contacts 327

Coil 329

Control Switches 330

Key Switch 330

Seat Switch 330

Start Switch 330

Brake Pedal Adjustment 330

Accelerator Pedal Adjustment 330

tables 299

Table 1 Over- and Undervoltage Protection 306

524175471-4000YRM0222-(09-2002)-UK-EN 335

toc 335

Vista® Masts 335

Safety Precautions Maintenance and Repair 336

General 339

Mast Weldments 339

Carriage 339

Mast Mounts 341

Vista® Two-Stage Mast 342

Description and Operation 342

Vista® Free-Lift Mast 344

Description 344

Operation 344

Vista® Three-Stage Mast 347

Description 347

Operation 347

524175472-4000YRM0374-(09-2002)-UK-EN 351

toc 351

Vista® Masts 351

Safety Precautions Maintenance and Repair 352

Safety Procedures When Working Near Mast 355

General 357

Forks 357

Carriage 358

Remove 358

Install 358

Mast 358

Remove 358

Disassemble 360

Two-Stage and Free-Lift Masts 360

Three-Stage Mast 361

Clean and Inspect 362

Assemble 364

Two-Stage and Free-Lift Mast 364

Two-Stage Mast 364

Free-Lift Mast 364

Three-Stage Mast 364

Install 365

Lift Cylinders 365

Lowering Control Valve 369

Lift Cylinder Removal Without Removing Mast 370

Disassemble 370

Main Lift Cylinders 370

Free-Lift Cylinder 370

Assemble 370

Main Lift Cylinders 370

Free-Lift Cylinders 371

Lift Cylinders Installation Into Masts 371

Main Lift Cylinders 371

Free-Lift Cylinder 371

Tilt Cylinder 372

Description 372

Remove 372

Disassemble 372

Clean 372

Assemble 372

Install 373

Sideshift Carriage 374

Remove (Early Models) 375

Remove (Late Models) 375

Repairs (Early Models) 375

Repairs (Late Models) 375

Install (Early Models) 375

Install (Late Models) 377

Lift and Tilt System Leaks Check 377

Lift Cylinders Leaks Check 377

Tilt Cylinder Leaks Check 378

Adjustment of Tilt Cylinder Stroke and Backward Tilt Angle 378

Lift Chain Adjustments 379

Mast Adjustments 380

Carriage Adjustment 382

Sideshift Cylinder Adjustment 382

Troubleshooting 382

524175473-8000YRM0798-(03-2010)-UK-EN 387

toc 387

Periodic Maintenance 387

Safety Precautions Maintenance and Repair 388

General 391

How to Move Disabled Lift Truck 391

How to Tow Lift Truck 391

How to Put Lift Truck on Blocks 392

How to Raise Load Wheels 392

How to Raise Steer Wheels 392

How to Clean a Lift Truck 393

Safety Procedures When Working Near Mast 394

Maintenance Schedule 396

Maintenance Procedures Every 8 Hours or Daily 398

Checks Before Operation 398

Hydraulic System 398

Battery 399

Battery Restraint System 399

Operator Restraint System 400

Mast, Forks, and Lift Chains 400

Lift Chain Adjustments 402

Tires and Wheels 403

Check Operation 403

Gauges and Horn 403

Control Levers and Pedals 403

Lift System Operation 403

Service Brakes 404

Parking Brake 404

Steering System 404

Maintenance Procedures Every 500 Hours or 3 Months 404

Hydraulic Tank Breather 404

Wheel Nut Torques 404

Master Drive Unit (MDU) 404

Mast 405

Lift Chains 405

Forks 406

Safety Labels 406

Brake Fluid 406

Other Lubrication 406

Electrical Inspection 407

Contactors 407

Motor Brushes 407

Maintenance Procedures Every 2000 Hours or Yearly 408

Hydraulic System 408

Change Hydraulic Oil Filter 408

Change Hydraulic Oil 408

Brake Shoes 408

Steering System 408

Master Drive Unit 408

Adjust Service Brakes 409

Adjust Parking Brake 409

Lift and Tilt System Leak Check 410

Lift System 410

Tilt System 411

Battery Maintenance 411

How to Charge Battery 411

How to Change Battery 412

Battery Size Specifications 413

Wheel and Tire Maintenance 413

General 413

How to Change Tires 413

Solid Rubber Tires on Pneumatic Wheels 413

Remove Wheels From Lift Truck 414

Remove Solid Rubber Tire From Pneumatic Wheel 414

Install Solid Rubber Tire on Pneumatic Wheel 415

Wheels, Install 416

tables 387

Table 1 Maintenance Schedule 396

Table 2 Battery Size Specifications – Type: Lead-Acid Battery 413

524175474-8000YRM0804-(09-2002)-UK-EN 419

toc 419

Capacities and Specifications 419

Safety Precautions Maintenance and Repair 420

Wheels and Tires 423

Hydraulic System 423

Motors (24 Volt) 423

Mast Creep Speeds 423

Mast Speeds 424

Battery Size Specifications 425

Torque Specifications 425

Frame 425

Master Drive Unit (MDU) (ZF Gotha) 425

Master Drive Unit (MDU) (Kordel) 425

Steering System 425

Brake System 425

Hydraulic System 426

Mast 426

Wheels 426

Sevcon SC2126 Motor Controller Adjustments 426

524175475-8000YRM0805-(02-2009)-UK-EN 429

toc 429

Diagrams 429

Safety Precautions Maintenance and Repair 430