$40.95

Yale Forklift A908 (ERC040-65GH) Service Manual – PDF DOWNLOAD

Yale Forklift A908 (ERC040-65GH) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A908 (ERC040-65GH) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1124

Downloadable : Yes

File Type : PDF

PART NO. 524150797

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A908 (ERC040-65GH) Service Manual – PDF DOWNLOAD

524150797-8000YRM0231-(02-2023)-UK-EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524150797-8000YRM0231-(03-2020)-UK-EN 23

General 27

Threaded Fasteners 27

Nomenclature, Threads 27

Strength Identification 28

Cotter (Split) Pins 29

Fastener Torque Tables 34

Conversion Table 36

524158039-0620YRM0294-(09-2016)-UK-EN 43

General 47

Brush and Commutator Inspection 48

Hydraulic Pump Motor and Traction Motor 48

Steering Pump Motor 51

Normal Commutator Surface 51

Commutator Problems 51

Brush Replacement 56

Stoning the Commutator 59

Motors Repair 60

Disassemble 61

Traction Motor and Hydraulic Pump Motor 61

Steering Pump Motor 62

Assemble 66

Traction Motor and Hydraulic Pump Motor 66

Steering Pump Motor 68

Brush Alignment, Traction and Hydraulic Motors 70

Tests for Damaged Field and Armature 71

Test for an Open Circuit in One Armature Winding 71

Test for Short Circuit in One Armature Winding 71

Test for Short Circuit to Armature Shaft 72

Test for Open Circuit in Field Coil 72

Test for Short Circuit in Field Coil 73

Test for Short Circuit Between Field and Motor Case 73

Brush Holder Test 73

Troubleshooting 74

524158040-2240YRM0001-(01-2023)-UK-EN 79

General 85

Battery Type 85

Lead-Acid Batteries 85

Lithium-Ion Batteries 86

Specific Gravity 86

Chemical Reaction in a Cell 86

Electrical Terms 88

Battery Selection 89

Battery Voltage 90

Battery as a Counterweight 90

Battery Ratings 90

Kilowatt-Hours 90

Battery Maintenance 91

Safety Procedures 91

Maintenance Records 91

New Battery 91

Cleaning Battery 92

Adding Water to Battery 94

Hydrometer 94

Battery Temperature 95

Charging Battery 96

Types of Battery Charges 97

Methods of Charging 98

Troubleshooting Charger 99

Knowing When Battery Is Fully Charged 99

Where to Charge Batteries 99

Equipment Needed 99

Battery Connectors 100

Battery Care 100

Troubleshooting 102

524158040-2240YRM0001-(03-2020)-UK-EN 107

General 111

Battery Type 111

Lead-Acid Batteries 111

Lithium-Ion Batteries 112

Specific Gravity 112

Chemical Reaction in a Cell 112

Electrical Terms 114

Battery Selection 114

Battery Voltage 115

Battery as a Counterweight 116

Battery Ratings 116

Kilowatt-Hours 116

Battery Maintenance 116

Safety Procedures 116

Maintenance Records 117

New Battery 117

Cleaning Battery 117

Adding Water to Battery 119

Hydrometer 120

Battery Temperature 121

Charging Battery 122

Types of Battery Charges 122

Methods of Charging 124

Troubleshooting Charger 124

Knowing When Battery Is Fully Charged 125

Where to Charge Batteries 125

Equipment Needed 125

Battery Connectors 126

Battery Care 126

Troubleshooting 128

524158753-1600YRM0720-(11-2006)-UK-EN 133

toc 133

Steering Housing and Control Unit 133

Safety Precautions Maintenance and Repair 134

General 137

Description 137

Operation 138

Steering Wheel and Column Assembly Repair 139

Assembly Components, Remove 139

Steering Control Unit, Disassemble 144

Steering Control Unit, Clean 144

Steering Control Unit, Assemble 144

Assembly Components, Install 146

System Air Removal 148

Troubleshooting 148

524158890-4000YRM0521-(03-2006)-UK-EN 153

toc 153

Mast 153

Safety Precautions Maintenance and Repair 154

General 157

Description and Operation 157

Carriages 157

Mast Mounts 159

Two-Stage Mast, Limited Free-Lift (LFL) 160

Description and Operation 160

Two-Stage Mast, Full Free-Lift (FFL) 162

Description and Operation 162

Three-Stage Mast, Full Free-Lift (FFL) 164

Description and Operation 164

Four-Stage Mast 166

Description and Operation 166

Cylinder Cushion During Lifting Sequence 170

Cylinder Cushion During Lowering Sequence 171

524179934-0100YRM0558-(11-2007)-UK-EN 175

toc 175

Frame 175

Safety Precautions Maintenance and Repair 176

General 179

Description 179

Main Frame 179

Other Frame Weldments 181

Overhead Guard 181

Overhead Guard Replacement 183

Remove 183

Install 183

Battery and Operator Restraint System, Hood and Seat Brake, and 190

Battery Restraint System 190

Hood 191

Hood With E-Hydraulics 192

Seat Brake 193

Operator Restraint System and Seat Assembly 193

Automatic Locking Retractor (ALR) 193

Emergency Locking Retractor (ELR) 194

Counterweight Replacement 195

Remove 195

Install 196

Traction Motor Replacement 197

Remove 197

Install 199

Hydraulic Tank Repair 200

Inspect 200

Clean 201

Steam Method 201

Chemical Solution 201

Additional Preparations for Repair 202

Small Leaks, Repair 202

Large Leaks, Repair 202

Preparations for Usage After Repair 202

Painting Instructions 202

Safety Label Replacement 204

Battery Specifications 206

tables 175

Table 1 Counterweights 195

Table 2 Lift Truck Models ERC20-30AGF (ERC40-065RF/ZF, ERC40-06 206

Table 3 Lift Truck Models ERC20-30AGF (ERC040-065GH) (A908) 207

524179937-1400YRM0285-(06-2010)-UK-EN 211

toc 211

Drive Axle, Speed Reducer, and Differential 211

Safety Precautions Maintenance and Repair 212

General 215

Description 215

Drive Axle, Speed Reducer, and Differential Repair 217

Drive Axle, Remove 217

Drive Axle, Disassemble 218

Speed Reducer and Differential, Disassemble 218

Clean 220

Inspect 220

Assemble 221

Speed Reducer and Differential, Assemble 221

Input Gear Assembly, Install 221

New Pinion Assembly, Install 222

Drive Axle, Assemble 228

Drive Axle Assembly, Install 228

Torque Specifications 229

Troubleshooting 230

tables 211

Table 1 Adjustment of Shims for Pinion Assembly 222

Table 2 Ring and Pinion Tooth Contact Adjustment 226

524179942-1800YRM0574-(04-2008)-UK-EN 233

toc 233

Brake System 233

Safety Precautions Maintenance and Repair 234

General 237

Description and Operation 237

Service Brakes 237

Master Cylinder 238

Parking Brake 239

Service Brakes Repair 239

Remove and Disassemble 239

Clean 243

Inspect 243

Assemble and Install 243

Adjust 246

Parking Brake Repair 248

Remove and Disassemble 248

Assemble and Install 248

Adjust 249

Master Cylinder Repair 253

Remove 253

Disassemble 254

Clean and Inspect 256

Assemble 256

Install 259

Seat Brake Assembly 259

Seat Brake, Adjust – Lift Truck Models ERC20-30AGF (ERC040-065RF 259

Brake Switch, Adjust – Lift Truck Models ERC20-30AGF (ERC040-065 259

Electric Seat Brake, Adjust for Lift Truck Model ERC20-32AGF (ER 260

Electric Seat Brake Adjustment With Handle For Lift truck Models 262

Remove 262

Clean 262

Inspect 262

Install 264

Adjustments 264

Solenoid Adjustment 264

Traction cutoff Switch Adjustment 264

Cable Adjustment 266

Service Brakes Adjustment 268

Brake Pedal Adjustment 268

Master Cylinder Adjustment 268

Brake System Air Removal 268

Parking Brake Not Applied Switch Test 269

Torque Specifications 269

Troubleshooting 269

524179945-1900YRM0559-(04-2009)-UK-EN 275

toc 275

Hydraulic System 275

Safety Precautions Maintenance and Repair 276

General 279

Description 279

Hydraulic System 279

Operation 287

Hydraulic System 287

Hydraulic Gear Pump 293

Steering Pump 293

Hydraulic Tank Repair 301

Tank, Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P1 301

Tank, Remove [ERP20-30ALF (B216) and ERP20-30ALF (ERP040-060DH) 303

Tank, Remove [ERP20-32ALF (ERP040-065DH) (E216)] 304

Hydraulic Tank [ERC35-55HG (ERC70-120HH) (B839/C839)] 304

Inspect 305

Small Leaks, Repair 306

Large Leaks, Repair 306

Clean 306

Steam Method 306

Chemical Solution Method 307

Additional Methods for Tank Repair 307

Tank, Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P 307

Tank, Install [ERP20-30ALF (B216) and ERP20-30ALF (ERP040-060DH) 308

Tank, Install [ERP20-32ALF (ERP040-065DH) (E216)] 308

Filter Replacement 309

All Lift Trucks Except [ERC35-55HG (ERC70-120HH) (B839/C839); ER 309

Remove 309

Install 310

Lift Truck Models [ERC35-55HG (ERC70-120HH) (B839/C839)] 310

Remove 310

Install 310

Lift truck Models [ERC20-32AGF (ERC040-065GH) (A908) and ERC/P16 311

Remove 311

Install 311

Lift Truck Models [ERP20-32ALF (ERP040-065DH) (E216)] 313

Remove 313

Install 313

Hydraulic Pump Repair 316

Hydraulic Pump, Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A81 316

Hydraulic Pump, Disassemble ERC/P16-20AAF (ERC030-040AF, AG/BG) 316

Inspect 318

Clean 318

Pump Seal Replace and Pump Assemble 318

Assemble Pump on Motor 318

Hydraulic Pump and Motor, Install [ERC/P16-20AAF (ERC030-040AF, 320

Hydraulic Pump, Remove [ERP20-30ALF (B216); ERP20-30ALF (ERP040- 321

Hydraulic Pump, Disassemble [ERC35-55HG (ERC70-120HH) (B839/C839 322

Hydraulic Pump, Inspect [ERC35-55HG (ERC70-120HH) (B839/C839) an 324

Hydraulic Pump, Clean [ERC35-55HG (ERC70-120HH) (B839/C839) and 324

Hydraulic Pump, Assemble [ERC35-55HG (ERC70-120HH) (B839/C839) a 324

Hydraulic Pump and Motor, Install [ERP20-30ALF (B216); ERP20-30A 324

Main Control Valve Repair 326

Steering Pump Repair 326

Pump, Remove and Disassemble [ERC/P16-20AAF (ERC030-040AF, ERC03 326

Pump, Remove and Disassemble [ERP20-30ALF (B216); ERP20-30ALF (E 328

Pump, Assemble and Install 330

Steering Control Unit Replacement 331

Remove 331

Install 331

Steering Cylinder Repair 337

Main Control Valve Check and Adjust 337

Steering Relief Valve Check and Adjust 338

Specifications 338

Relief Valve Pressures* 338

Hydraulic Tank Capacity (dipstick full mark) 339

Hydraulic Pump Capacities – All Models Except ERC35-55HG (ERC70- 339

Hydraulic Pump Capacities – Models ERC35-55HG (ERC70-120HH) (B83 339

Troubleshooting 339

Steering 339

Steering Housing and Steering Control Unit 340

Hydraulic System 341

524179946-2000YRM0562-(02-2009)-UK-EN 347

toc 347

Manual hydraulic Control Valve 347

Safety Precautions Maintenance and Repair 348

General 351

Description 351

Operation 354

ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P16-20AAF (ERC03 354

ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D216) and ERP20- 354

Lift Section 356

Tilt Section 356

Tilt Backward 356

Tilt Forward 356

Relief Valve 358

Main Control Valve Repair 359

Main Control Valve Without OPS Solenoid 359

Remove 359

Disassemble 359

Clean and Inspect 363

Assemble 363

Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P16-20A 364

Install [ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D216) a 364

Main Control Valve With OPS Solenoid 365

Remove 365

Disassemble 365

Clean and Inspect 367

Relief Valve Repair 369

Assemble 370

Install 371

Control Lever Linkage Repair 371

Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814),ERC/P16-20AAF 371

Disassemble [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814),ERC/P16- 371

Assemble and Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814) 373

Control Valve Linkage Repair 373

Remove and Disassemble [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A81 373

Assemble and Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814) 374

Control Lever Linkage Repair 374

Remove [ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D216) an 374

Disassemble [ERP20-30ALF (B216), ERP20-30ALF (ERP040-060DH) (D21 376

Assemble and Install [ERP20-30ALF (B216), ERP20-30ALF (ERP040-06 376

Pressure Relief Valve Check and Adjustment 377

Primary Relief Valve 377

Secondary Relief Valve 378

Troubleshooting 379

524179953-4000YRM0563-(04-2005)-UK-EN 383

toc 383

Four-Stage Mast 383

Safety Precautions Maintenance and Repair 384

General 387

Description 387

Carriages 387

Mast Mounts 388

Mast 388

Description 388

Operation 389

Forks Repair 392

Remove 392

Install 392

Safety Procedures When Working Near Mast 394

Carriage Repair 396

Remove 396

Standard Carriage 396

Sideshift Carriage 397

Repairs 398

Install 398

Standard Carriage 398

Sideshift Carriage 398

Mast Repair 399

Remove 399

Disassemble 399

Clean and Inspect 400

Assemble 401

Install 403

Lift Cylinders Repair 406

Remove 406

Main Lift Cylinders 406

Free-Lift Cylinders 406

Disassemble 406

Assemble 408

Install 410

Main Lift Cylinder 410

Free-Lift Cylinder 411

Header Hose Arrangements 412

Header Hoses, Install 412

Lift and Tilt System Leaks Check 419

Lift Cylinders Leaks Check 419

Tilt Cylinders Leaks Check 419

Tilt Cylinders Adjustment 420

Lift Chain Adjustments 421

Mast Adjustments 422

Carriage Adjustments 424

Troubleshooting 425

tables 383

Table 1 Standard Four-Stage Hose Dimensions 418

Table 2 Hook type Carriage Chain Adjustment 421

Table 3 Pin-Type Carriage Chain Adjustment 422

524183081-1600YRM1054-(11-2006)-UK-EN 429

toc 429

Steering System for AC Electric Lift Trucks 429

Safety Precautions Maintenance and Repair 430

General 433

Description 434

Steering Wheel and Column Assembly Repair 435

General 435

Assembly Components, Remove 437

Assembly Components, Install 438

Power Steering Motor and Pump 439

Description 439

Remove 439

Disassemble 442

Install 442

Power Steering Pump, Repair 442

Seal, Replace 443

Steering System Air Removal 444

Steering Pressure Check 444

Steering Motor Circuits Check 445

Troubleshooting 446

524183082-2200YRM1055-(10-2009)-UK-EN 451

toc 451

Electrical System (Trucks With AC Controllers) 451

Safety Precautions Maintenance and Repair 452

General 455

Description 456

Features of the Display Panels 456

Other Control Components 457

Display Panel and Key Switch Replacement 458

Display Panel, Replace 458

Key Switch, Replace 460

Controller Replacement 460

Traction and Pump Motor Controller Replacement 460

Master Controller, Replace 466

Master Controller, Remove ERP20-30ALF (ERP040-060DH) (D216), ERP 466

Master Controller, Install ERP20-30ALF (ERP040-060DH) (D216), ER 466

Master Controller, Remove ERC/P16-20AAF (ERC030-040AH) (B814/C81 468

Master Controller, Install ERC/P16-20AAF (ERC030-040AH) (B814/C8 468

Master Controller, Remove ERC35-55HG (ERC070-120HH) (B839/C839) 470

Master Controller, Install ERC35-55HG (ERC070-120HH) (B839/C839) 470

Control Components Replacement 471

General 471

Start Switch, Replace 471

Brake Light Switch, Replace 472

Seat Switch, Replace 472

Parking Brake Switch, Replace 473

Foot Directional Control Pedal Direction Switches, Replace 475

Steering Column Direction Control Switches, Replace 478

Remove 478

Install 478

Brake Fluid Switch, Replace 480

Brush Wear and Over Temperature Sensors (DC Pump Motor Only) 480

Rocker Switches for Lights, Replace 480

Accelerator Position Sensor, Replace 481

On-Demand Steering Sensor, Replace 482

Lights, Converter, Relay, and Reverse Alarm 482

Brake, Tail, and Reverse Light Assembly, Replace 483

Incandescent Assembly 483

LED Assembly – Remove 485

LED Assembly – Install 485

Strobe Light Assembly, Replace 488

Wire Harness Repair 489

Del-City Crimp-Solder-Shrink Splice 489

Front, Rear Driving Light or Spot Light Assemblies, Replace 490

Converter, Replace 490

Remove, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216), ERP 490

Install, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216), ER 492

Remove, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) and 492

Install, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) and 492

Remove, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 494

Install, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 494

Reverse Relay, Replace 495

Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908), ERC/P16-20A 495

Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 495

Backup Alarm, Replace 497

Horn and Horn Button, Replace 497

Horn Replacement for Lift Trucks ERP20-30ALF (ERP040-060DH) (D21 497

Horn Replacement for Lift Trucks ERC35-55HG (ERC70-120HH) (B839/ 499

Horn Switch and Cover, Replace 500

Hydraulic Pump Switches 501

Fan Power Supply, Replace 501

Remove, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 501

Install, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 501

Remove, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216) and 502

Install, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216) and 503

Remove, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) 503

Install, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) 503

Control and Power Fuse Check 504

Fuse Locations 504

Brake Light Switch Adjustment 510

Seat Switch Check 511

Seat Brake Adjustment 511

Parking Brake Switch Adjustment 512

Direction Switches Check 512

Foot Directional Control Pedal 512

Steering Column 513

Foot Directional Control Pedal or Accelerator Pedal Adjustment 513

Accelerator Position Sensor Adjustment and Start Switch Adjustme 514

Acceleration Position Sensor, Adjust 514

Start Switch, Adjust 516

tables 451

Table 1 Wire Splice Size 489

524183083-2200YRM1056-(03-2009)-UK-EN 519

toc 519

AC Motor Controllers/Display Panel 519

Safety Precautions Maintenance and Repair 520

Description 523

General 523

AC Motors 523

Motor Controllers 523

Master Controller 523

Dash Display 523

Controller Area Network Bus (CANbus) 523

Master Controller Checks and Adjustments 524

Function Settings 525

General 525

Function Numbers 525

Function Descriptions 528

General 528

Function Number 1 BATTERY VOLTAGE 528

Function Number 2 EXTENDED SHIFT 528

Function Number 3 ACCELERATION 1 528

Function Number 4 ACCELERATION 2 528

Function Number 5 TOP SPEED LIMIT 528

Function Number 6 REGEN BRAKING 528

Function Number 7 AUTO DECELERATION 529

Function Number 8 BDI ADJUSTMENT 529

Function Number 9 LIFT INTERRUPT 529

Function Number 10 POWER STEERING TIME DELAY 529

Function Number 11 SERVICE REMINDER 529

Function Number 12 CUSTOM 529

Function Number 13 PUMP SPEED 1 529

Function Number 14 PUMP SPEED 2 530

Function Number 15 PUMP SPEED 3 530

Function Number 16 PUMP ACCELERATION 530

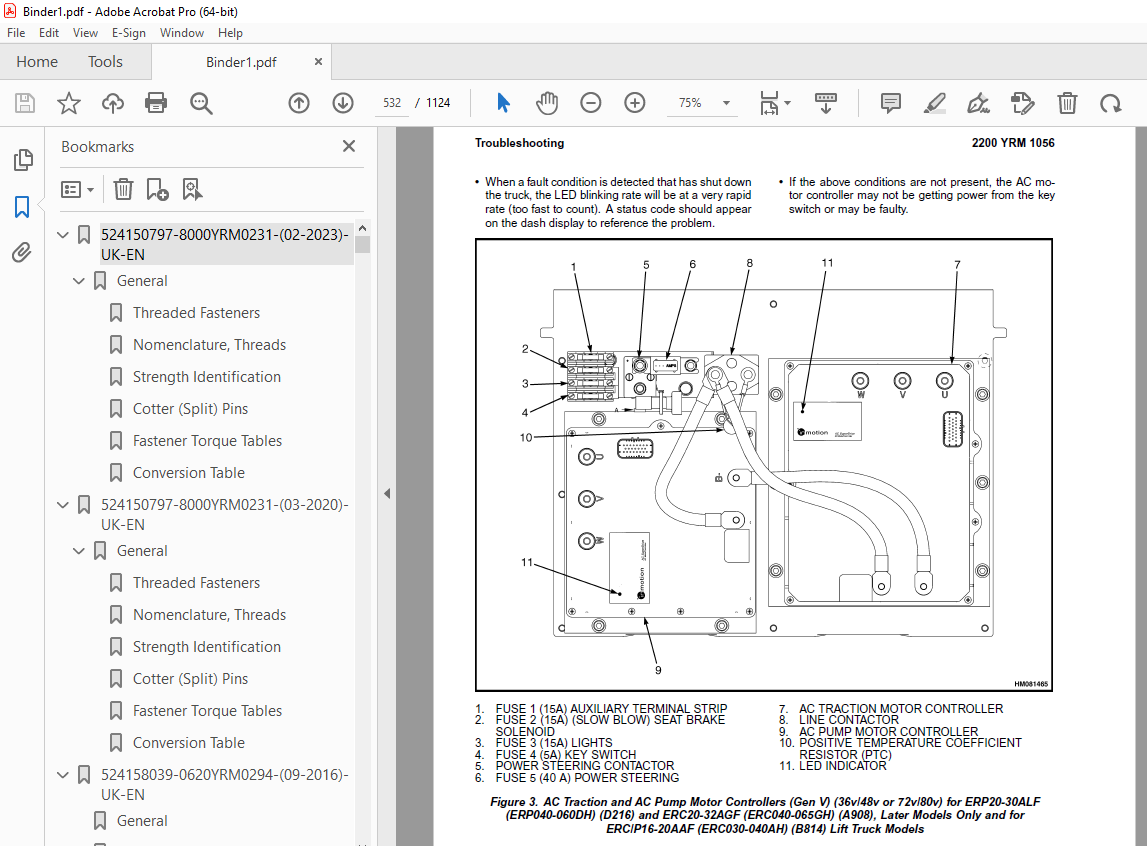

Troubleshooting 530

General 530

Controller Status Light Emitting Diodes (LEDs) 531

Master Controller 531

AC Motor Controllers 531

Status Codes 537

AC Motor Controllers Status Code Charts 539

Troubleshooting When Dash and/or Lift Truck is not Operational 560

Typical Symptoms 560

Truck Runs but Dash Display is not Operational, or Only Displays 560

Truck Does Not Run and Dash is Not Operational or Only Displays 561

Hydraulics Operate Normally, Traction Does Not Operate Correctly 562

Traction Operates Normally, Hydraulics do Not Operate Correctly, 562

AC Transistor Motor Controller Replacement 562

General 562

General Maintenance Instructions 568

Special Precautions 568

Fuses 569

Fan Test 569

Contactors 569

Repair 569

Thermal Sensors 573

Motor Controller, Replace 573

Display Panel 574

General 574

Premium Display Panel 574

Standard Display Panel 574

Display Functions and Features 575

Key-On Initialization 575

Standard Display 576

Premium Display 576

Lift Truck Inspection Function 577

Access to Service Functions 577

Service Functions 577

Service Functions 578

Performance Modes 580

Battery Discharge Indicator (BDI) 580

Hourmeter 581

Dash Display Service Menu Navigation 587

General 587

Moving Through Menu Selections 587

Editing and Adding Information 587

tables 519

Table 1 Factory Parameters for ERP20-30ALF (ERP040-060DH) (D216 525

Table 2 Factory Setting for ERC020-032AGF (ERC40-65GH) (A908) 526

Table 3 Factory Setting for ERC/P16-20AAF (ERC030-040AH) (B814/ 526

Table 4 Factory Parameters for ERC35-55HG (ERC70-120HH) (B839/C 527

Table 5 List of Status Codes 537

Table 6 42-Pin Connections/Descriptions for Master Controller 570

Table 7 Pin Connections/Descriptions for 72/80 (Gen IV) Volt Mo 572

Table 8 Pin Connections/Descriptions for 36/48 and 72v/80v (Gen 572

524183085-2200YRM1058-(04-2011)-UK-EN 591

toc 591

Troubleshooting and Adjustments Using the AC Controls Program (E 591

Safety Precautions Maintenance and Repair 592

General 595

Computer Requirements 595

Software, Install 595

Language Selection 595

Demo Mode 596

Connect PC to Lift Truck 600

Starting AC Controls Program 602

Lift Truck Control Setup 607

Change Lift Truck Serial Number or Hourmeter 607

Setting Factory Default Values or Changing Lift Truck Parameters 608

Create New Custom Lift Truck Configuration 614

Lift Truck Configuration Properties 617

Import New Lift Truck Configuration From Disk 620

Delete Custom Lift Truck Configuration or Password File 622

Dash Display 625

Custom Display Languages 625

Download Display Language 627

Clear Operator Log 627

Password Functions 630

Enable/Disable Password and Lift Truck Inspection Functions 630

Truck Inspection Checklist 630

Password 630

Password Properties 630

Create New Password File 635

Download Passwords 636

Upload Passwords 638

Reports Menu 640

Devices Report 640

Custom Report 640

Password Report 640

Operator Report 647

Current Settings Report 650

Status Code Report 654

Status Codes Log 657

Troubleshooting 659

Diagnostics 659

Help Menu 662

General 662

Contents 662

Technical Support 662

About Electric Truck AC Controls Program 662

524183086-8000YRM1059-(08-2012)-UK-EN 669

toc 669

Electrical Diagrams 669

Safety Precautions Maintenance and Repair 670

524183087-8000YRM1060-(02-2010)-UK-EN 745

toc 745

Periodic Maintenance 745

Safety Precautions Maintenance and Repair 746

General 751

Serial Number Data 751

How to Move Disabled Lift Truck 751

How to Tow Lift Truck 751

How to Put Lift Truck on Blocks 752

How to Raise Drive Tires 752

How to Raise Steering Tires 752

How to Clean a Lift Truck 752

Maintenance Schedule 754

Maintenance Procedures Every 8 Hours or Daily 761

How to Make Checks With Key OFF 761

Tires and Wheels 761

Forks 762

Inspect 762

Mast and Lift Chains, Inspect 763

Safety Labels 763

Steering Column Latch 763

Operator Restraint System 764

Automatic Locking Retractor (ALR) 764

Emergency Locking Retractor (ELR) 764

Battery Restraint System ERC20-32AGF (ERC040-065GH) (A908) and E 765

Battery Restraint System ERP20-30ALF (ERP040-060DH) (D216) Lift 766

Battery 766

Attachment 767

Hydraulic System 767

How to Make Checks With Key ON 768

Horn, Lights, and Alarm 768

Steering System 768

Service Brakes 768

Parking Brake 768

Control Levers and Pedals 769

Direction and Speed Control Pedals 769

Lift System Operation 769

Oil Leaks 769

First Service After First 100 Hours of Operation 769

Change Filter for Hydraulic Oil 769

Maintenance Procedures Every 250 Hours or 6 Weeks 771

Steering King Pins ERC/P16-20AAF (B814/C814) Trucks Only 771

Steering Tie Rods and Spindles 771

Maintenance Procedures Every 500 Hours or 3 Months 771

Differential and Speed Reducer ERC20-32AGF (ERC040-065GH) (A908) 771

Wheel Nut Torques 772

Header Hose Checks 772

Mast Lubrication 772

Forks 776

Remove 776

Inspect 776

Install 776

Adjust 777

Brake Fluid ERC/P16-20AAF (ERC030-040AH) (B814/C814) and ERC20-3 777

Parking Brake Adjustment 777

Seat Brake Operations Check 778

Maintenance Procedures Every 1000 Hours or 6 Months 778

Lift Chains 778

Wear Check 778

Lift Chain Lubrication 779

Forks 779

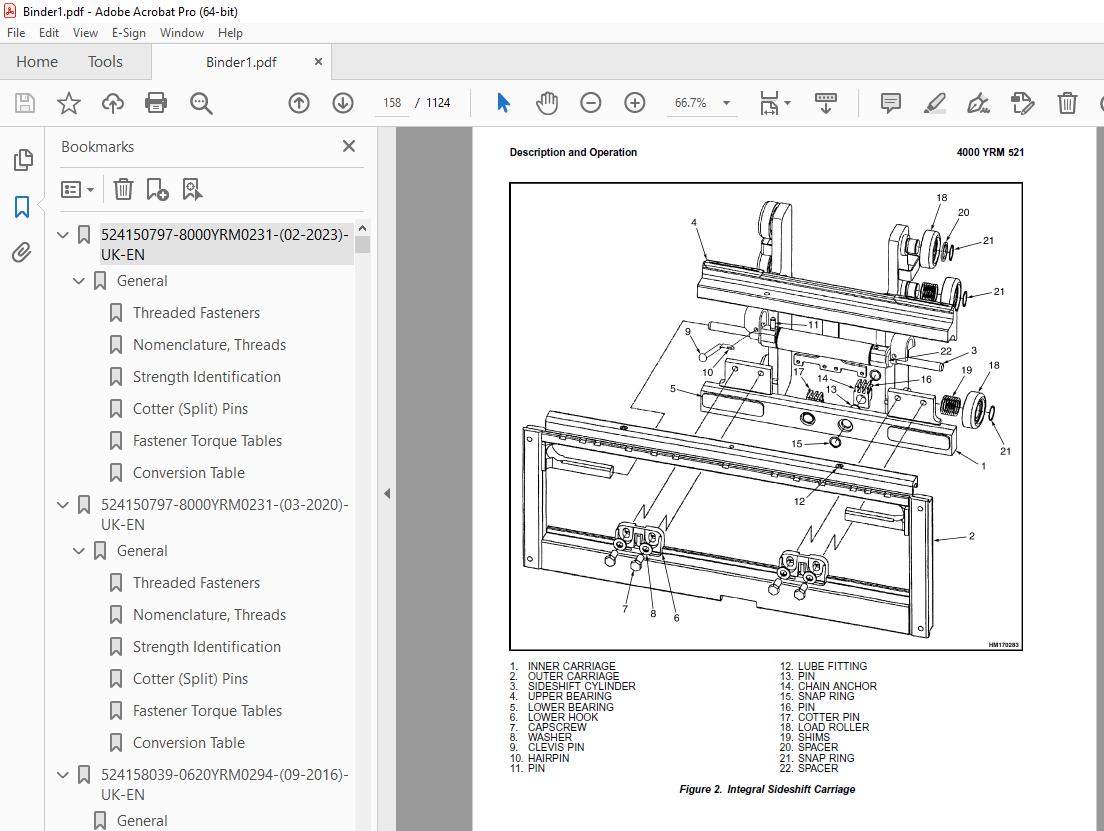

Check Upper and Lower Bearings, Integral Sideshift Carriage 779

Steering King Pins ERC20-32AGF (ERC040-065GH) (A908) Lift Truck 780

Steering Tie Rods ERP20-30ALF (ERP040-060DH) (D216) Lift Truck M 780

Steering Axle Spindles 780

King Pins ERP20-30ALF (ERP040-060DH) (D216) 780

Hydraulic Tank Breather 780

ERP20-30ALF (ERP040-060DH) (D216) 780

ERC20-32AGF (ERC040-065GH) (A908) 781

ERC/P16-20AAF (ERC030-040AH) (B814/C814) 781

Differential and Speed Reducer ERP20-30ALF (ERP040-060DH) (D216) 781

Brake Fluid ERP20-30ALF (ERP040-060DH) (D216) Lift Truck Models 782

Other Lubrication 782

Electrical Inspection 782

Contactors 782

Motor Brushes (DC Pump) 782

Motor Brushes, General 782

Maintenance Procedures Every 2000 Hours or Yearly 786

Hydraulic System 786

Change Filter for Hydraulic Oil 786

Change Hydraulic Oil 787

Differential and Speed Reducer 787

Brake Fluid Replacement 788

Service Brakes 788

Steering Tie Rods and Spindle Lift Truck Models ERC030-040AH (B8 788

Wheel Bearings 789

Steer Wheels, Lubrication 789

Drive Wheels, Lubrication 789

Lift Chains 789

Forks 789

Replace Upper and Lower Bearings, Integral Sideshift Carriage 789

Other Lubrication 789

Battery Maintenance 790

How to Charge Battery 790

How to Change Battery for ERP20-30ALF (ERP040-060DH) (D216) and 791

General 791

How to Change Battery for ERC20-32AGF (ERC040-065GH) (A908) and 793

General 793

Lift and Tilt System Leak Check 796

Lift Cylinders Leak Check 796

Tilt Cylinders Leak Check 797

Safety Procedures When Working Near Mast 797

WHEN WORKING NEAR THE MAST ALWAYS: 797

Lift Chain Adjustments 800

Welding Repairs 801

Overhead Guard Changes 801

Wheels and Tire Maintenance 802

Solid Rubber Tires ERC20-32AGF (ERC040-065GH) (A908) and ERC/P16 802

Remove Wheels From Lift Truck 802

Remove and Install Tire on Wheel 802

Pneumatic Tires and Wheels ERP20-30ALF (ERP040-060DH) (D216) 803

Remove Wheels From Lift Truck 803

Remove Wheel From Pneumatic Tire 804

Install Three- or Four-Piece Wheel in Pneumatic Tire 805

Add Air to Tires 806

Wheels, Install 806

Solid Rubber Tires on Pneumatic Wheels 807

Remove Wheels From Lift Truck 807

Remove Solid Rubber Tire From Pneumatic Wheel 807

Install Solid Rubber Tire on Pneumatic Wheel 809

Wheels, Install 810

Snap-On Tire, Change 810

Remove Snap-On Solid Tire From Wheel 811

Install Snap-On Solid Tire on Wheel 812

Adhesives and Sealants 813

tables 745

Table 1 Maintenance Schedule 756

524204007-8000YRM1083-(01-2006)-UK-EN 817

toc 817

Capacities and Specifications 817

Safety Precautions Maintenance and Repair 818

Counterweights 821

Hydraulic System 821

Steering System 822

Specifications 822

Turning Radius 822

Wheels and Tires 823

Battery Specifications 824

ERC20-30AGF (ERC050-065GH) 824

Capacities 825

Drift Rates (Maximum) for Tilt Cylinders 825

Mast Speeds 826

ERC20-30AGF (ERC040-065GH) Mast Speeds (36 or 48 Volt) Americas 826

ERC20-30AGF Mast Speeds (72 or 80 Volt) Europe 828

ERC20-30AGF Mast Speeds (72 or 80 Volt) Europe 829

Torque Specifications 830

Frame 830

Drive Axle, Speed Reducer, and Differential ERC20-30AGF 830

Steering Axle ERC20-30AGF 831

Masts 831

Seat Brake 831

Hydraulic Pump and Fittings 831

Adhesives and Sealants 832

tables 817

Table 1 Manual Hydraulic Control Valve 821

Table 2 E-Hydraulic Control Valve 821

524205680-0620YRM1098-(03-2010)-UK-EN 835

toc 835

AC Motor Repair 835

Safety Precautions Maintenance and Repair 836

General 839

AC Motor Repair 839

Disassemble 839

Assemble 843

Troubleshooting 845

524223768-2100YRM1139-(02-2014)-UK-EN 849

524223776-4000YRM1148-(09-2015)-UK-EN 897

General 901

Safety Procedures When Working Near Mast 902

Fork Replacement 904

Remove, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 904

Remove, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 906

Install, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 907

Install, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 907

Checks, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 908

Checks, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 909

Carriages Repair 910

Standard Carriage 910

Remove 910

Repair 911

Install 911

Standard Carriage, Remove 912

Hang-On Sideshift Carriage, Remove 913

Standard Carriage and Hang-On Sideshift Carriage, Repair 914

Standard Carriage, Install 915

Hang-On Sideshift Carriage, Install 915

Integral Sideshift Carriage 916

Remove 916

Clean and Inspect 919

Repair 920

Install 920

Fork Positioner 921

Remove 921

Clean and Inspect 926

Disassemble and Assemble 926

Install 926

Fork Positioner Hydraulic Hose Adjustment 927

Disconnecting Attachment Hydraulic Quick Disconnect Hoses 929

Connecting Attachment Hydraulic Quick Disconnect Hoses 929

Mast Repair 930

Mast, Remove 930

Two-Stage LFL and Two-Stage FFL Masts 933

Disassemble 933

Clean and Inspect 943

Three-Stage FFL Mast 944

Disassemble 944

Clean and Inspect 952

Two-Stage LFL and Two-Stage FFL Mast 954

Assemble 954

Three-Stage FFL Mast 957

Assemble 957

Four-Stage FFL Mast – Manufactured Before July, 2009 959

Disassemble 959

Clean and Inspect 964

Assemble 966

Four-Stage FFL Mast – Manufactured After July, 2009 967

Disassemble 967

Clean and Inspect 974

Assemble 977

Mast, Install 978

Header Hose Arrangement 981

Two-Stage LFL 981

Two-Stage FFL 989

Three-Stage FFL 1004

Standard 1004

Optional Equipment Lift Truck GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) 1021

Four-Stage FFL Mast – Manufactured Before July, 2009 1029

Four-Stage FFL Mast – Manufactured After July, 2009 1038

Adjustment 1045

Lift Chains Adjustment 1045

Carriage Adjustments 1048

Mast Adjustments 1048

Load Roller Adjustment 1048

Mast Side Kicking Adjustment 1051

524256687-2000YRM1224-(04-2008)-UK-EN 1055

toc 1055

Electro-hydraulic Control Valve 1055

Safety Precautions Maintenance and Repair 1056

General 1059

Description 1059

Electro-Hydraulic Control System 1059

Electro-Hydraulic Control Valve 1062

Electro-Hydraulic Valve Driver Module 1078

Mini-Lever Module (MLM) 1078

Joystick 1079

Electro-Hydraulic Control Valve Repair 1080

Remove 1080

Disassemble 1089

Solenoid Coil Replacement 1091

Cartridge Replacement 1093

Electro-Hydraulic Pressure Reducing Valve (EHPR) Replacement 1094

Lift Circuit Check Valve Replacement 1095

Compensator Cartridge Replacement 1095

Primary and Secondary Relief Valves Replacement 1095

Tilt Counterbalance Valve Replacement 1096

Flow Regulator Valve Replacement 1096

Assemble 1096

Install 1096

E-Hydraulics Calibration 1105

Mini-Lever Module 1107

Mini-Lever Module (MLM) 1107

Remove 1107

Install 1107

Mini-Lever Replacement 1107

Remove 1107

Clean and Inspect 1108

Install 1108

Push Button Switch Replacement 1109

Remove 1109

Install 1110

Test 1111

Mini-levers 1111

Full Stroke Test 1111

Function Returns to Neutral Test 1111

Push Button Switch 1112

Joystick 1112

Remove and Disassemble 1112

Inspect 1112

Assemble and Install 1112

Troubleshooting 1113

tables 1055

Table 1 Primary and Secondary Relief Valve Values 1065

Table 2 Solenoid Resistance Values 1091

Table 3 Cartridge and Solenoid Coil Nut Torque for Lift truck M 1094

Table 4 Cartridge and Solenoid Coil Nut Torque for Lift truck M 1094