$40.95

Yale Forklift A927 (NR040ECR, NDR030ECR,NDR035ECR, NR045ECR) NEW Service Manual - PDF

Yale Forklift A927 (NR040ECR, NDR030ECR,NDR035ECR, NR045ECR) NEW Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift A927 (NR040ECR, NDR030ECR,NDR035ECR, NR045ECR) NEW Service Manual – PDF DOWNLOAD

Language : English

Pages : 998

Downloadable : Yes

File Type : PDF

PART NO. 524150797

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift A927 (NR040ECR, NDR030ECR,NDR035ECR, NR045ECR) NEW Service Manual – PDF DOWNLOAD

524150797-8000YRM0231-(02-2023)-UK-EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524158040-2240YRM0001-(01-2023)-UK-EN 23

General 29

Battery Type 29

Lead-Acid Batteries 29

Lithium-Ion Batteries 30

Specific Gravity 30

Chemical Reaction in a Cell 30

Electrical Terms 32

Battery Selection 33

Battery Voltage 34

Battery as a Counterweight 34

Battery Ratings 34

Kilowatt-Hours 34

Battery Maintenance 35

Safety Procedures 35

Maintenance Records 35

New Battery 35

Cleaning Battery 36

Adding Water to Battery 38

Hydrometer 38

Battery Temperature 39

Charging Battery 40

Types of Battery Charges 41

Methods of Charging 42

Troubleshooting Charger 43

Knowing When Battery Is Fully Charged 43

Where to Charge Batteries 43

Equipment Needed 43

Battery Connectors 44

Battery Care 44

Troubleshooting 46

524223769-2200YRM1128-(01-2023)-UK-EN 51

Series Code / Model Designation Reference Table 59

General 61

Deutsch Crimping Tool 62

How to Strip a Wire for Use With Deutsch Crimping Tool 62

How to Crimp With the Deutsch Crimping Tool 63

Calibration Test for the Deutsch Crimping Tool 65

Deutsch Connectors 67

DT, DTM, and DTP Series Connectors 67

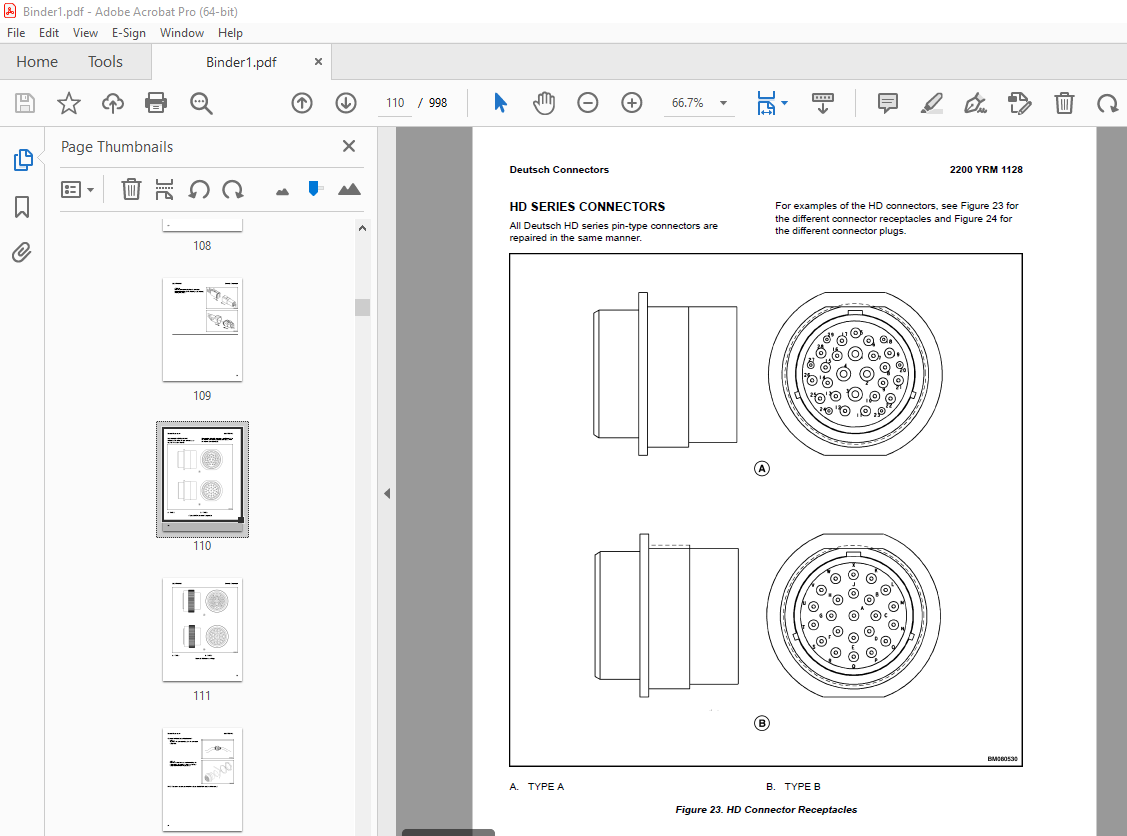

HD Series Connectors 110

Metri-Pack Connectors 132

Remove and Install 132

Micro-Pack Connectors 135

Weather-Pack Connectors 136

AMPSEAL Crimping Tools 138

AMP Hand Crimping Tool With Certi-Crimp 138

Description 138

Stripping Wire for Use with AMP Hand Crimping Tool 139

Insulation Crimp Adjustment 140

Maintenance and Inspection for AMP Hand Crimping Tool 140

AMP Hand Crimping Tool 140

Crimp Height Inspection 140

How to use AMP Hand Crimping Tool 141

AMP Pro-Crimper II Tool 141

Description 141

Remove and Install Die Set and Locator Assembly 142

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 142

Contact Support Adjustment 143

Crimp Height Adjustment 144

Maintenance and Inspection Procedures 144

PRO-CRIMPER II Tool 144

Crimp Height Inspection 144

How to Use AMP PRO-CRIMPER II Tool 145

AMPSEAL Connector Assemblies 146

Description for Plug Connector Assembly 146

Seal Plug 147

Contact Crimping 147

Description for Plug Connector and Header Assembly 152

Voltage Reading 155

Seal Plug 155

Contact Crimping 155

AMP Superseal 1 5 Crimping Tools 162

Mini Mic Receptacle and Tab Contacts 162

Description 162

Crimping Conditions and Measurements 162

Insertion of Rubber Seal on Cable 164

AMP Hand Application Tool 169

Description 169

Maintenance and Inspection 169

Crimp Height Inspection 169

Crimp Height Adjustment 170

How to Use AMP Hand Application Tool 170

AMP Pro-Crimper II Tool 171

Description 171

Remove and Install Die Set and Locator Assembly 171

Adjustments 172

Contact Support 172

Crimp Height 173

Inspections and Maintenance 174

Crimp Height Inspection 174

Visual Inspection 174

Maintenance 175

How to Use Pro-Crimper II Tool 175

AMP Superseal 1 5 Connector Assemblies 176

Description 176

Repair and Maintenance 183

Panel Mount Option 183

AMP Fastin-Faston Hand Tools 184

Description – AMP Double Action Hand Tool 184

Maintenance and Inspection Procedures 184

Daily Maintenance 184

Periodic Tool Inspection 185

Lubrication 185

Visual Inspection 185

Crimp Height Inspection 185

Certi-Crimp Ratchet Inspection 186

How to Use AMP Double Action Hand Tool 187

Description – AMP Extraction Tool 188

Maintenance and Inspection 189

How to Use AMP Extraction Tool 189

AMP Fastin-Faston Receptacles and Housings 191

Description 191

Wire Repair 199

Wire Splicing Requirements 199

Deutsch Jiffy Splice 200

Twisted/Shielded Cable and Leads Repair 206

Special Tools 208

550191464-0630YRM2084-(09-2022)-UK-EN 217

General 223

General 223

Description 224

Discharging The Capacitors 225

Master Drive Unit Repair 229

Maintenance 229

Draining the Oil 229

Remove 229

Disassemble 231

Clean and Inspect 232

Assemble 232

Install 233

Replace the Wheel Seal on Kordel Drive Units 234

Tools required 234

Truck setup 234

Wheel shaft seal and protection ring removal (method 1) 234

Wheel shaft seal and protection ring removal (method 2) 235

Wheel shaft seal and protection ring installation 236

Troubleshooting 238

550209887-1900YRM2189-(09-2022)-UK-EN 241

General 247

Discharging the Capacitors 250

Description 253

Control Handle 255

Sidestance Control Handle 255

Fore/Aft Stance 256

Maintenance 257

Oil Level and Leaks 257

Operation 257

Oil Change 257

Drain 257

Cylinder Identification 259

Fill 261

Main Lift Cylinders 261

Free-Lift Cylinders 262

Breather Cap 263

Inspect 263

Hydraulic Oil Filter 263

Change 263

Oil Strainer 264

Check 264

Hydraulic System 265

General 265

Cleaning 265

Noise Levels 265

Hoses 265

Fittings 267

Hydraulic Lift Pump and Motor 268

Lift Trucks Equipped With a 25cc or 32cc Hydraulic Pump 268

Remove 268

Disassemble – Lift Trucks Equipped With a 25cc or 32cc Hydraulic Pump 272

Clean 274

Inspect 274

Assemble 274

Install 274

Lift Truck Models Equipped With a 28/9cc Double Hydraulic Pump 276

Remove 276

Disassemble 280

Clean 282

Inspect 282

Assemble 282

Install 282

Manual Lowering Valve 283

Pressure Test Ports 284

Pressure Transducer 285

Relief Valve 286

Lowering Control Valve 287

Auxiliary Hydraulics 288

Reach Carriage Hydraulics 288

Selector Auxiliary Valve 288

Remove 289

Install 289

Auxiliary Manifold 289

Remove 289

Install 289

Auxiliary Direction Control Manifold 289

Remove 291

Install 292

Auxiliary Motor and Pump 292

Remove 293

Disassemble 295

Assemble 296

Install 296

Hydraulic Tank 298

Remove 298

Disassemble 299

Breather Assembly 300

Filter Assembly 300

Tank Fittings 301

Clean and Inspect 302

Assemble 302

Breather Assembly 302

Filter Assembly 302

Tank Fittings 303

Install 303

Specifications 304

Troubleshooting 305

550267564-0630YRM2448-(09-2022)-UK-EN 309

General 315

General 315

Description 315

Discharging The Capacitors 316

Master Drive Unit Repair 320

Maintenance 320

Draining the Oil 320

Remove 320

Disassemble 322

Clean and Inspect 323

Assemble 323

Install 324

Replace the Wheel Seal on Kordel Drive Units 324

Tools required 324

Truck setup 324

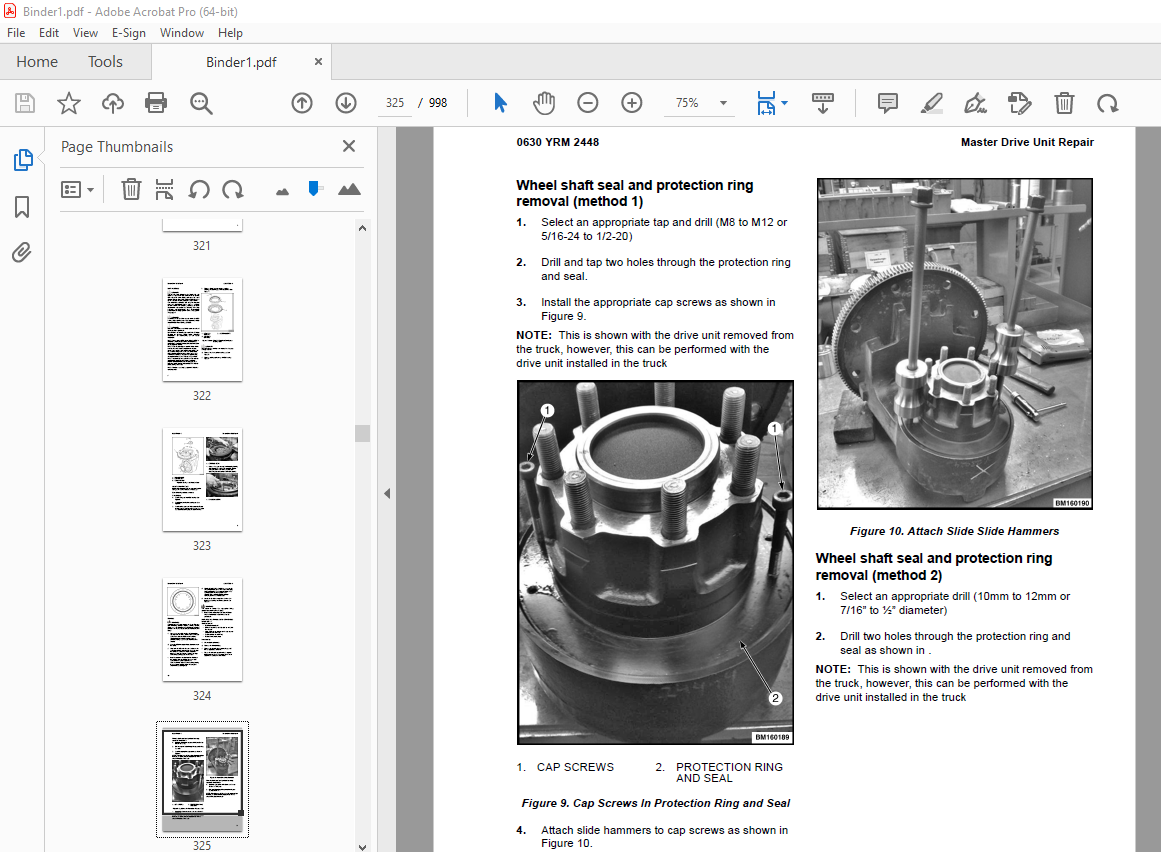

Wheel shaft seal and protection ring removal (method 1) 325

Wheel shaft seal and protection ring removal (method 2) 325

Wheel shaft seal and protection ring installation 327

Troubleshooting 328

550273551-0100YRM2471-(09-2022)-UK-EN 331

General 337

Discharging the Capacitors 337

Description 340

Repairs – General 341

Covers, Panels, and Plates 342

Service Access Panel 342

Removal 342

Inspection and Cleaning 343

Installation 343

Operator Compartment Covers 343

Front Covers (Left and Right) 343

Main Cover, Battery Tray Cover (With Tiller Cover), and Service Cover 344

Remove 344

Install 347

Caster Cover 347

Compartment Door Assembly 347

Inspection 348

Door Latch and Stop 348

Remove 348

Inspect 349

Install 349

Adjustment 349

Door Pad 349

Remove 349

Install 350

Operator Back Pad 350

Operator Wall Pad 350

Storage Container 350

Remove 350

Base Arms and Load Wheel Boxes 351

Description 351

Inspection (Bolt-On Wheel Box) 351

Repair 351

Overhead Guard Replacement 352

Remove 354

Inspect 354

Install 354

Light Assemblies 354

Painting and Vinyl Wrap Instructions 355

Painting Instructions 355

Vinyl Wrap 355

Removal 356

Surface Preparation 356

Installation 357

Repair 358

Safety Labels Replacement 359

Frame Fasteners 362

Repair 362

Threaded Insert Removal 362

Inspection 362

Install 362

550273552-0620YRM2472-(09-2022)-UK-EN 365

General 371

Discharging the Internal Capacitors 371

Traction Motor Repair 374

Remove 374

Disassemble 377

Clean/Inspect 382

Assemble 382

Install 383

Hydraulic Motor Repair 385

Auxiliary Motor Repair 393

General 393

Special Tools 394

Tool Chart 394

Troubleshooting 395

550273553-1600YRM2473-(09-2022)-UK-EN 399

General 405

Discharging the Capacitors 406

Raising the Lift Truck 408

How to Raise the Drive Tire End 409

How to Raise the Entire Lift Truck 410

Description 411

Steering Handle Assembly 413

Description 413

Remove (Fixed and Adjustable) 413

Disassemble (Fixed Steering Handle) 414

Assemble (Fixed Steering Handle) 416

Disassemble (Adjustable Steering Handle) 416

Assemble (Adjustable Steering Handle) 419

Install (Fixed and Adjustable) 419

Steering Sensors and Steering Controllers 420

Steering Motor 420

Description 420

Remove 420

Steering Motor 420

Disassemble 422

Assemble 422

Install 422

Steering Motor 423

Caster Assembly – General 424

Caster Adjustment 424

Elastomer Spring Type Adjustment 424

Remove Spring Assembly 426

Replace Spring Pack 427

Install Spring Assembly 427

Proximity Switch Adjustment 428

Caster Wheels 429

Remove 429

Install 429

Caster Wheel Assembly (Non-steered) 431

Description 431

Remove 431

Disassemble 432

Upper and Lower Support Housings 432

Spring Assembly From Lower Support Assembly 433

Caster Spindle From Lower Support 433

Lower Support Housing 434

Upper Support Housing 435

Assemble 435

Upper Support Housing 435

Lower Support Housing 436

Caster Spindle to Lower Support 437

Spring Assembly to Lower Support 437

Upper and Lower Support Housings 437

Install 437

Troubleshooting 439

550273554-1800YRM2474-(09-2022)-UK-EN 441

General 447

Discharging the Capacitors 447

Electric Brake 450

Air Gap 451

Coil Resistance Check 453

Remove 454

Install 454

Troubleshooting 456

550273555-2200YRM2475-(09-2022)-UK-EN 459

General 467

Discharging the Internal Capacitors 468

Static Strap 471

Inspect 471

Replace 471

Safety Procedures When Working Near Mast 472

Automated Battery Charger and Battery Cables 475

Inspect 475

Automated Battery Charger 475

Remove 475

Install 476

Battery Cables 476

Remove 476

Install 477

Manually Charging the Battery 477

Key Switch 478

General 478

Replace 478

Major Electrical System Features 480

General 480

Integrated System 480

CANbus Advantages 480

CANbus Communications 480

Electric Steering 480

Centering Proximity Sensor 480

Traction and Hydraulic Functions 481

Vehicle System Manager 481

Input Devices 481

Output Devices 481

Encoder Integrity 481

Test Encoders 481

Proximity Switches 481

Dash Display Panel 482

BDI 483

Speed 483

Steer Angle 483

Truck Hours 483

Performance Mode 483

HMI Control Box 483

Setup 484

Calibrations 484

AC Motor Controllers and Connecting Cables 485

General 485

Controller Removal 485

Install 487

Low-Voltage Protection Function 489

CDF File Installation Procedure 490

Contactor and Electrical Panel Checks 492

Fuse Panel and Relays 492

Contactors Inspection 493

General 493

Test 494

Tips 495

Replacing The Main Contactor 495

Remove 495

Install 497

Replacing The Freezer Contactor 498

Remove 498

Install 499

Instrument Panel and Dash Display 500

Description 500

Remove 501

Display 502

Install 502

Battery Power Disconnect Switches 503

Replace 503

Multifunction Controls 506

Multifunction Control Handle 506

Horn 506

Inspection 507

Remove 507

Install 509

Multifunction Control Handle Disassembly and Repair 510

Handle Grip and Switch Repairs 510

Handle Grip Support Mounting 510

Handle Disassembly 510

Steering Handle 514

Steering Unit Repair 514

Steering Sensors and Steering Controllers 518

Steering Proximity Sensor 518

Remove 518

Adjust/Install 519

Power Steering Controller 520

Remove 520

Disassemble 521

Assemble 521

Install 522

Brake Switch 523

General 523

Repair, Cushioned and Non-Heated Floor Plate Configuration 523

Repair, Suspended, Non-Heated Floor Plate Configuration 525

Repair, Heated Floor Plate Configuration 526

General 526

Heated Floor Plate Assembly 526

Operator Sensing System 529

General 529

Remove 530

Install 531

Audible Alarm and Horn 532

Horn 532

Audible Alarm 532

Light Assemblies 534

General 534

Front Headlights 535

Remove 535

Install 535

Front Blue Spot Light, Rear Work Light, and Rear Blue Spot Light 536

Remove 536

Install 536

Visible Alarm Light (Strobe Light) 537

Remove 537

Install 537

Light Switches 537

Cooling Fans 538

Electrical Compartment Fans 538

Controller Cooling Fan, Replace 538

Rear Cooling Fan, Replace 539

Vehicle Systems Manager, O-Box, and DC/DC Converter 540

General 540

Vehicle Systems Manager (VSM) 540

Remove 540

Install 541

O-Box (Control Module) 542

Remove 542

Install 544

DC-DC Converter 545

Remove 545

Install 546

Lift Truck Automation System 547

General 547

Preperation 547

Microscan3 Sensors 548

Side Sensors 548

Remove 548

Install 548

Front Sensor 548

Remove 548

Install 549

Rear Sensor 549

Remove 549

Install 550

Adjust Microscan3 Sensor 550

Automated Mid-Range Distance Sensor 551

Replace 551

Height Proximity Switch Option 552

Test 553

Remove 553

Install 553

Reach Carriage Proximity Sensor 555

General 555

Remove 555

Install 556

Adjust 556

Automated Carriage Camera Option 557

Wireless Camera 557

Remove 557

Install 557

Wireless Camera Monitor 558

Remove Monitor Assembly 558

Install Monitor Assembly 559

Automated Lookdown Sensor Option 560

Replace 560

Automated LiDAR Navigation Sensor Option 561

Replace 561

Replace the Power and Communication Wire Harness Cables 561

Remove 561

Install 562

550273556-2200YRM2476-(09-2022)-UK-EN 565

General 575

Menu Navigation 577

Navigation Key 577

Arrow Keys and Scroll Bar 578

Startup Sequence 579

Password Entry 581

Adding/Changing Passwords 581

Home Screen 581

Home Screen Layout 582

Meters 582

Driving Meter 582

Dynamic Meter 583

Center Area 583

Meter Frame 583

Companion Icon 583

Unit Indicator 583

Steer Direction 583

Gauges 584

Menu Structure 588

Password Based Menus 591

Service Logging In 592

Log In 592

Enable/disable password (optional) 593

Main Menus 594

Information Menu 596

Faults Menu 597

Settings Menu 603

Performance Menu 605

Performance Parameters 606

P1 3 Travel Speed FF 606

P1 5 Travel Speed FT 606

P1 9 Travel Acceleration 606

P1 11 Neutral Braking 606

P1 13 Regen Braking 607

P1 15 Lift Speed 607

P1 19 Lower Speed 607

P1 27 Lift Acceleration 607

P1 29 Lower Acceleration 607

P1 31 Lift Deceleration 607

P1 33 Lower Deceleration 607

P1 35 Reach Mech Spd In 607

P1 37 Reach Mech Spd Out 607

P1 43 Tilt Speed Forward 607

P1 45 Tilt Speed Back 607

P1 53 Sideshift Speed 607

P1 67 Aft Handle Speed FF 608

P1 69 Aft Handle Speed FT 608

P1 71 Aft Handle Regen Braking 608

P1 73 Steer Ratio 608

Hydraulic Menu 608

Hydraulic Parameter Adjustments 608

H1 25 Carry Ht Mode 608

H1 27 Carry Ht Horn Duration 608

H2 3 RTST 608

H2 5 RTST Pause Duration 608

H2 7 RTST Override Mode 608

H2 19 RTST Stop Direction 609

H3 15 Auto Center SS 609

H9 15 Hydraulic Lockout 609

Drive Menu 609

Drive Parameter Adjustments 611

D2 1 Type 611

D2 9 BDI Reset 611

D2 11 Lift INT – Battery 611

D2 21 Ahr Capacity 611

D2 25 BDI Adjust 611

D2 39 Battery Gate Switch (Sw) 611

D4 1 Steer Effort 611

D4 3 Steer Mode 611

D4 51 Steer Speed Red En 612

D4 53 Steer Speed Red 612

D8 2 Mast Up FT Speed Limit 612

D8 3 Carr Ext Spd Red 612

D8 4 FF Spd w/Carr Ext 612

D8 5 FT Spd w/Carr Ext 612

D8 13 Simultaneity Mode 612

D8 55 Mast Up FF Speed Limit 612

Sensors/Presets Menu 612

Sensor/Presets Parameters 613

S1 1 Impact Sensor 613

S1 3 Impact OP (Operator Presence) Filter 613

S1 5 Impact Logging 613

S1 7 Mark Events Crit (Criteria) 613

S1 9 Impact Shutdown 613

S1 11 Shutdown Timeout 613

S1 13 Impact Audible Alarm 613

S1 15 Impact Visual Alarm 613

S1 17 Hard Impacts/Day 613

S1 19 Soft Impacts/Day 613

S1 21 Clear Derate Event 613

S1 23 Soft Count Threshold 613

S1 25 Soft Impact Threshold Horizontal 613

S1 27 Soft Impact Threshold Vertical 613

S1 29 Hard Impact Threshold Horizontal 613

S1 31 Hard Impact Threshold Vertical 614

Shutdown Impact Threshold Horizontal 614

Shutdown Impact Threshold Vertical 614

S3 1 Camera 1 614

S3 5 Fork Laser 614

S4 1 Shelf Height 614

S4 3 Place Offset 614

S4 5 Preset Ht (Height) 614

S4 25 Lift/Low Limit 614

S4 26 Limit Override 614

S4 27 Lift/Low Limit En 614

S4 45 Fork Height Disp 614

S5 7 Connection Type 614

Maintenance Menu 615

Maintenance Parameters 617

M1 1 Reminder Levels 617

M1 3 Level 1 617

M1 5 Level 2 617

M1 7 Level 3 617

M1 9 Level 4 617

M1 11 Level 5 617

M1 13 Level 6 617

M1 15 Derate Speed 617

M1 17 Hours Until Derate 617

M1 19 Reset All 617

M1 21 Disable All 617

M2 1 Checklist 617

M2 3 Checklist Frequency 617

M2 5 Operator Options 617

M2 7 Technical Access 617

M2 9 Shift 1 Start Time 617

M2 11 Shift 2 Start Time 617

M2 13 Shift 3 Start Time 617

M2 15 Shift 4 Start Time 617

M2 17 Question Time Limit 617

M2 19 No Response Shutdown 617

M2 21 Pre Start Overtime 618

M2 23 Post Start Overtime 618

M2 25 Pre Shutdown 618

M2 27 Post Shutdown 618

Truck Setup 618

Setting Time and Date 620

Truck Setup Parameters 621

T1 1 Units 621

T1 3 Languages 621

T1 5 Time 621

T1 7 Time Format 621

T1 15 Service Lockout 621

T1 23 Brightness 621

T1 25 Auto Dim 621

T1 50 Restore Defaults 621

T2 21 Front Blue Lt 621

T2 23 Rear Blue Lt 621

T4 5 Audible Alarm 621

Operators Menu 622

Adding New Operator 622

Adjusting Existing Operator Parameters 623

Operator Parameters 623

O1 5 Access Level 623

O1 7 Delete 623

O1 9 Allowed Performance Modes 624

Calibrations Menu 624

Calibration Parameters 626

H2c Tilt 626

H2c 3 RTST Calibration 626

H2c 11 Tilt Calibration 626

D5c Steer Axle 626

D5c 5 Steer Motor Calibration 626

D12c Throttle 626

D12c 3 Aft Throttle Range 626

S8c Height Sensor 626

S8c 1 Mast Height Calibration 626

S8c 5 Lift Enc Zero Pos 626

S12c Load Weight 627

S12c 1 Weight Scale Calibration 627

Diagnostics Menu 627

Diagnostic Parameters 630

C1d VSM/Contactor 630

C1d 1 Electronic Out 1 630

C1d 3 Electronic Out 2 630

C1d 5 Main Contactor 630

C5d Switches/Buttons 630

C5d 1 Horn Switch 630

C5d 11 Audible Alarm 630

C5d 14 Left Batt Gate SW 630

C5d 15 Right Batt Gate SW 630

C6d Occupancy 630

C6d 3 Egress Curtain 630

C6d 5 OP Left Leg Sensor 630

C6d 7 OP Right Leg Sensor 631

Current/Voltage 631

C7d 3 Power Voltage 631

C7d 4 Power Current 631

C7d 5 Sensor Voltage 631

C7d 7 Out 1 Voltage 631

C7d 8 Out 1 Current 631

C7d 9 Out 2 Voltage 631

C7d 10 Out 2 Current 631

C7d 11 Out 3 Voltage 631

C7d 12 Out 3 Current 631

C7d 13 Out 4 Voltage 631

C7d 14 Out 4 Current 631

C7d 15 Out 5 Voltage 631

C7d 17 Out 6 Voltage 631

C7d 18 Out 5 and 6 Current 631

C7d 19 Out 7 Voltage 631

C7d 21 Out 8 Voltage 631

C7d 22 Out 7 and 8 Current 631

C7d 23 Out 9 Voltage 631

C7d 25 Out 10 Voltage 631

C7d 26 Out 9 and 10 Current 631

C7d 27 In 1 Voltage 631

C7d 29 In 2 Voltage 631

C7d 31 In 3 Voltage 631

D2d Battery 631

D2d 1 Battery Voltage 631

D2d 3 State of Charge (SOC) 631

D4d Steer 632

D4d 3 Steer Angle 632

D4d 7 Steer Status 632

D4d 11 Controller Temp 632

D4d 12 Motor Temp 632

D4d 13 Motor Current 632

D4d 14 Cap Voltage 632

D4d 15 Cap Max Voltage 632

D4d 16 Cap Min Voltage 632

D4d 17 Key Voltage 632

D4d 18 Key Max Voltage 632

D4d 19 Key Min Voltage 632

D4d 20 Center Proximity Switch 632

D6d Steer (Caster) 632

D6d 3 Steer Angle 632

D6d 7 Steer Status 632

D6d 11 Controller Temperature 632

D6d 12 Motor Temperature 632

D6d 13 Motor Current 632

D6d 14 Cap Voltage 632

D6d 15 Max Cap Voltage 632

D6d 16 Min Cap Voltage 632

D6d 17 Key Voltage 632

D6d 18 Max Key Voltage 632

D6d 19 Min Key Voltage 632

D6d 20 Center Prox Switch 632

D8d Traction 632

D8d 2 Travel Speed 632

D8d 7 Motor 1 Target Speed 632

D8d 9 Motor 1 Speed 632

D8d 13 Controller 1 Temperature 633

D8d 15 Motor 1 Temperature 633

D8d 17 Motor 1 Current 633

D8d 19 Controller 1 Cap Volts 633

D8d 21 Controller 1 Cap Max Volts 633

D8d 23 Controller 1 Cap Min Volts 633

D8d 25 Controller 1 Key Volts 633

D8d 27 Controller 1 Key Max Volts 633

D8d 29 Controller 1 Key Min Volts 633

D8d 35 Brake Switch 633

D8d 41 Aft Throttle 633

D8d 43 Aft Enable Switch 633

D8d 45 Aft Horn Switch 633

H1d Lift/Lower 633

H1d 7 Lift Pressure 633

H1d 9 Lift Command 633

H1d 13 Function Switch 633

H1d 29 Prop Coil Current 633

H1d 41 Mast Prox Switch 633

H1d 43 Lift Height Sensor 633

H1d 45 Hoist Select Coil Status 633

H1d 47 Lift Coil Status 633

H1d 49 Load Hold Coil Status 633

H2d Tilt 633

H2d 4 Command 633

H2d 17 Tilt Coil Status 633

H3d 3rd Hydraulic Function 633

H3d 4 3rd Command 633

H3d 15 Return Position Proximity Sensor 633

H3d 17 3rd Hydraulic Coil Status 633

H4d 4th Hydraulic Function 634

H4d 4 4th Command 634

H4d 15 4th Hydraulic Coil Status 634

H8d Pump 634

H8d 1 Controller Temp 634

H8d 3 Motor Temp 634

H8d 5 RMS Motor Current 634

H8d 11 Target Motor Speed 634

H8d 13 Motor Speed 634

H8d 31 Mast Prox Switch 634

H8d 33 Aux Motor Target Speed 634

H8d 35 Aux Motor Speed 634

H8d 37 Aux Motor Temperature 634

H8d 39 Aux Motor Current 634

Hour Meters 635

View Hour Meters 635

Hardware and Software Versions 636

View Hardware and Software Versions 636

Interlocks 637

General 637

Switched Inputs and Preset Heights 639

General 639

Setting Preset Heights 640

550273558-4000YRM2478-(09-2022)-UK-EN 645

General 651

Description 653

Lowering Control Valve 654

Safety Procedures When Working Near Mast 656

Main Lift Cylinder Repair 658

Remove 658

Disassemble 659

Clean and Inspect 661

Clean 661

Inspect 661

Assemble 661

Install 663

Main Lift Cylinder Leak Check 663

Free-Lift Cylinder Repair 664

Remove 664

Disassemble 666

Clean 668

Inspect 668

Assemble 668

Install 669

Sideshift Cylinder Repair 670

General 670

Remove 670

Disassemble 671

Clean and Inspect 672

Assemble 672

Install 672

Reach Cylinder Repair 673

Remove 673

Disassemble 674

Clean and Inspect 676

Assemble 676

Install 676

Reach Cylinder Adjustments 678

Tilt Cylinder 679

Lift Chains 679

Clean and Inspect 679

Troubleshooting 681

550273559-4000YRM2479-(09-2022)-UK-EN 683

General 689

Safety Procedures When Working Near Mast 692

Mast Weldments 695

Reach Carriage Assembly 697

550273560-4000YRM2480-(09-2022)-UK-EN 701

General 707

Safety Procedures When Working Near Mast 710

Load Backrest 713

Remove 713

Install 713

Forks 714

Remove 714

Install 715

Flapper Assembly 715

Remove 715

Disassemble 716

Assemble 717

Install 717

Checks 717

Hose And Chain Sheaves 719

General 719

Hose Sheaves 722

Remove 722

Lift Trucks Equipped With E570 Short Mast 722

Lift Trucks Equipped With D585 Tall Mast 727

Clean and Inspect 729

Install 729

Lift Trucks Equipped With E570 Short Mast 729

Lift Trucks Equipped With D585 Tall Mast 730

Main Lift Chain Sheaves 731

Remove 731

Lift Trucks Equipped With E570 Short Mast 731

Lift Trucks Equipped With D585 Tall Mast 731

Clean and Inspect 733

Install 733

Lift Trucks Equipped With E570 Short Mast 733

Lift Trucks Equipped With D585 Tall Mast 733

Free-Lift Chain Sheaves 734

Remove 734

Left Chain Sheave 734

Right Chain Sheave 735

Install 736

Left Chain Sheave 736

Right Chain Sheave 736

Load Rollers 737

Mast Load Rollers 737

Remove 739

Clean and Inspect 741

Install 741

Reach Carriage Assembly 742

Reach Carriage Assembly Remove and Install 743

Description 743

Remove 744

Inspect 748

Install 748

Mast Repair 750

Remove 750

Disassemble 757

Wear Strips and Shims 758

Clean and Inspect 759

Assemble 760

Install 761

Mast Lubrication 763

Header Hose Installation and Adjustment 763

Remove 763

Installation 764

Lift Chains 770

Clean and Inspect 770

Mast Adjustments 771

General 771

Mast Back Angle Adjustment 771

Adjust Main-Lift Chains 772

Adjust Free-Lift Chain 773

Adjust Wear Strips 775

Mast Side Kicking (Racking) 775

Wear Pad Adjustments 776

Proximity Switches 777

Mast Operation Check 778

550273561-4500YRM2481-(09-2022)-UK-EN 781

General 787

Safety Procedures When Working Near Mast 788

Description 791

Load Backrest 793

Remove 793

Install 793

Forks 794

Remove 794

Install 795

Flapper Assembly 795

Remove 795

Disassemble 796

Assemble 797

Install 797

Checks 797

Load Rollers 799

Remove 799

Clean and Inspect 801

Install 801

Reach Carriage Assembly Repair 802

General 802

Reach Carriage Front Frame 802

Remove 802

Disassemble 809

Clean and Inspect 813

Assemble 813

Install 814

Single-Reach Scissor Arms 814

Remove 814

Disassemble 814

Wear Strip – Inspect and Replacement 816

Remove 816

Install 818

Clean and Inspect 818

Assemble 818

Double-Reach Scissor Arms 818

General 818

Disassemble 819

Clean and Inspect 822

Assemble 822

Install 823

Reach Carriage Rear Frame 823

Remove 823

Disassemble 823

Clean and Inspect 824

Assemble 825

Install 825

Reach Carriage Adjustments 826

General 826

Check Adjustment 826

Wear Pads Adjustment 826

Free-Lift Chain Adjustment 826

Cylinders Adjustments 826

Reach Carriage Bumper Adjustment 827

Inner Arm Lateral Adjustment 828

Proximity Sensor Lateral Adjustment 829

Lower Hook Adjustment 830

Carriage Stroke Adjustment 831

Lift Chains 833

Specifications 833

Troubleshooting 834

550273562-8000YRM2482-(09-2022)-UK-EN 837

General 843

Preparation for Use 844

Discharging the Internal Capacitors 845

Covers and Doors 848

Remove 848

Install 851

Manual Lowering Valve 852

How to Move Disabled Truck 853

How to Put Lift Truck on Blocks 855

How to Raise Load Wheels 855

How to Raise the Drive Tire End 856

How to Raise the Entire Lift Truck 857

Transporting 858

Loading 858

Unloading 858

Safety Procedures When Working Near Mast 859

Maintenance Schedule 862

Maintenance Procedures Every 8 Hours or Daily 872

Checks With Key Switch Turned OFF 872

Hydraulic System 872

Forks 873

Forks, Remove 873

Forks, Check 873

Forks, Install 875

Forks, Adjust 875

Inspection of Mast and Lift Chains 875

Reach, Tilt, and Sideshift 876

Caster Adjustment 876

Safety Labels 876

Battery 877

Tires and Wheels 877

Frame and Load Wheels 878

Overhead Guard 878

Static Strap 878

Checks With Key Switch Turned ON 879

Horn and Battery Indicator 879

Fuses and Relays 879

Operation 880

Control Levers and Pedals 881

Lift System Operation 881

Multifunction Control Handle 882

Brake 882

Steering System 883

Maintenance Procedures Every 500 Hours or 3 Months 884

Hydraulic System 884

Hydraulic Filter Change 885

Master Drive Unit 887

Adding Oil To Master Drive Unit (MDU) 887

Changing Oil In Master Drive Unit (MDU) 887

Caster Adjustment 890

Elastomer Spring Type Adjustment 890

Spring Pack Replacement 893

Remove Spring Assembly 893

Replace Spring Pack 893

Install Spring Assembly 894

Load Wheels 894

Drive Tire Check 896

Lift System Operation 896

Forks 896

Mast 897

Lift Chains 897

Electrical System 898

Power Cables and Electrical Connections 898

Other Lubrication 898

Maintenance Procedures Every 2000 Hours or Yearly 899

Electric System 899

Main Contactor 899

Inspect 899

Freezer Contactor 900

Remove 900

Install 901

Hydraulic System 902

Drain 902

Cylinder Identification 903

Fill 904

Main Lift Cylinders 904

Free-Lift Cylinders 905

Hydraulic Filter Change 906

Check Hydraulic Strainer 907

Battery Maintenance 908

How to Charge Battery 908

How to Change Battery 909

Lift and Tilt System Leaks Check 912

Lift System 912

Tilt System 912

Tires and Wheels 913

Drive Tire 913

How to Change Drive Tire 913

Load Wheels, Bolt-On Wheel Box 914

Caster Wheels 916

Remove 916

Install 917

Preparation for Storage 918

Short-Term Storage (1 to 6 months) 918

Long-Term Storage (6 months or longer) 918

550273563-8000YRM2483-(09-2022)-UK-EN 921

Lubrication Specifications 927

Oil Capacities 927

Hydraulic System 927

Mast Speeds 928

Carriage Speeds 930

Carriage Operating Times 932

Forks 933

Steering System 933

Brake System 934

Traction Motor Speeds 935

Tire Sizes 936

Torque Specifications 937

Master Drive Unit 937

Reach Carriage 937

Mast 937

Hydraulic System 937

Steering System 937

Load Wheels 937

Fuses 938

Coil Resistance Values 939

Battery Specifications 940

550273564-8000YRM2485-(09-2022)-UK-EN 943

Schematic/Diagram 949

Electrical Schematics 949

Hydraulic Schematics 965

550276785-9000YRM2486-(09-2022)-UK-EN 971

Error code reference charts 975

Vehicle System Manager (VSM) Error Code Reference Chart 975