$41.95

Yale Forklift B674 (GDP360EF36, GDP360EF48) Service Manual – PDF DOWNLOAD

Yale Forklift B674 (GDP360EF36, GDP360EF48) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift B674 (GDP360EF36, GDP360EF48) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1292

Downloadable : Yes

File Type : PDF

PART NO. 524150797

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift B674 (GDP360EF36, GDP360EF48) Service Manual – PDF DOWNLOAD

524150797 8000YRM0231 (02 2023) US EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524150797 8000YRM0231 (03 2020) US EN 23

General 27

Threaded Fasteners 27

Nomenclature, Threads 27

Strength Identification 28

Cotter (Split) Pins 29

Fastener Torque Tables 34

Conversion Table 36

550223081 0100YRM2251 (02 2020) US EN 43

Series Code / Model Designation Reference Table 49

General 49

Precautions 49

Section 1 – Cab Repair 50

Operator’s Cab Assembly 50

Tilting the Cab 50

Raising 50

Lowering 51

Remove 52

Install 54

Cab Tilt System 55

Hand Tilt Pump 55

Remove 55

Install 57

Electric Tilt Pump 57

Remove 57

Install 58

Cab Tilt Cylinder 59

Remove 59

Install 60

Latch 61

Remove 61

Install 62

Cab Windows 62

Window Replacement 62

Front Window 62

Remove 62

Install 62

Rear Window 63

Remove 63

Install 63

Top Window 63

Remove 63

Install 63

Door Window 63

Remove 63

Install 64

Sliding Window and Sliding Tracks 64

Remove 64

Install 65

Weather Strip Replacement 65

Window Stopper Replacement 65

Sliding Window Frame 65

Remove 65

Install 65

Window Wipers 66

Window Wiper Assembly Replacement 66

Remove 66

Install 66

Front Window Wiper Motor Assembly 66

Remove 66

Install 67

Rear Window Wiper Motor Assembly 67

Remove 67

Install 67

Top Window Wiper Motor Assembly 68

Remove 68

Install 68

Window Washer System 68

Window Washer Reservoir and Pumps 68

Remove 68

Install 69

Window Washer Hoses 69

Remove 69

Install 70

Window Washer Spray Nozzles 70

Front Window 70

Remove 70

Install 70

Rear Window 70

Remove 70

Install 70

Top Window 70

Remove 70

Install 70

Cab Door Assembly 71

Cab Door 71

Remove 71

Install 71

Door Hinge 72

Remove/Install 72

Door Latch 73

Remove 73

Install 73

Door Handle 73

Remove 73

Install 74

Door Release 74

Remove 74

Install 74

Door Push Button 75

Remove 75

Install 75

Steering Wheel and Steering Column Assembly 75

Steering Wheel and Horn 75

Remove 75

Install 77

Steering Column Assembly 77

Remove 77

Install 78

Shift Lever 78

Remove 78

Install 78

Gear Selection Lever 79

Remove 79

Install 79

Turn Signal Lever 79

Remove 79

Install 79

Pedals 79

Brake and Inching Pedal 79

Remove 79

Install 80

Accelerator Pedal and Sensor 80

Remove 80

Install 80

Adjust Sensor 81

Power Assist Armrest 81

Remove 81

Install 82

Armrest Components 83

Electrical Mini-Levers 83

Remove 83

Install 83

Armrest Switch Groups 84

Remove 84

Install 84

Ignition Key Switch and Start/Stop Button Switch 85

Remove 85

Install 85

Joystick 86

Remove 86

Install 86

USB Power Socket 87

Remove 87

Install 87

12V Power Socket 87

Remove 87

Install 88

Display Replacement 88

Seat Assembly 89

Remove 89

Install 89

Initialize New Seat 89

Cab Interior 90

Floor Mat 90

Remove 90

Install 90

Radio Console 91

Remove 91

Install 91

Air Duct Replacement 91

Remove 91

Install 92

Accessories 92

Mirror Replacement 92

Sunshade Replacement 93

Top 93

Rear 93

Map Light Replacement 93

Interior Fan Replacement 93

Training Seat 94

Field Installation 94

Remove 94

Checks and Adjustments 94

Label Check and Replacement 94

Cab Tilt System Oil Level Check 94

Door Striker Pin Adjustment 95

Section 2 – Cab Heater and Air Conditioner Repair 96

Heater Assembly 96

Access 96

Remove 97

Install 98

Heater Parts 99

Heater Core 99

Remove 99

Install 100

Water Valve 100

Remove 100

Install 101

Heater/Air Conditioning Assembly 101

Remove 101

Install 103

Filtration 103

Fresh Air Filter 103

Remove 103

Install 104

Air Conditioning Technical Detail 105

Maintenance, Service and Repairs 105

Safety Precautions 105

General Statements for Maintenance and Repairs 106

Residual Pressure 106

Refrigeration Circuit 106

Cooling Water Circuit 106

Maintenance Intervals 106

Repairs 107

Checklist 107

550223082 0700YRM2252 (02 2020) US EN 111

Series Code / Model Designation Reference Table 115

General 115

Precautions 115

Cooling System 116

Cooling Core Assembly 116

Remove 117

Disassemble 122

Assemble 122

Install 123

Cooling System Components 125

Cooling Fan 125

Remove 125

Install 126

Checks and Adjustments 126

Cooling System Checks 126

Basic Checks 127

Coolant Quality Checks 127

Coolant Flow Checks 128

Thermostat 128

Water Pump 128

Cooling Core Efficiency 129

Cooling Core Flow Restrictions 129

Engine Leak Tests 129

External Leak Test 129

Check for Coolant Leak Into The Engine Oil Sump 130

Combustion Leak Test 131

Engine Cooling System Maintenance 131

Draining the Engine Cooling System 131

Filling the Engine Cooling System 132

Flushing the Engine Cooling System 132

Cleaning the Engine Cooling System 133

550223083 0900YRM2253 (03 2020) US EN 135

Series Code / Model Designation Reference Table 143

General 143

Precautions 143

Special Tools 144

Section 1 – Drive Shaft Repair 145

Drive Shaft Assembly 145

Remove 145

Disassemble 147

Clean and Inspect 147

Assemble 147

Install 148

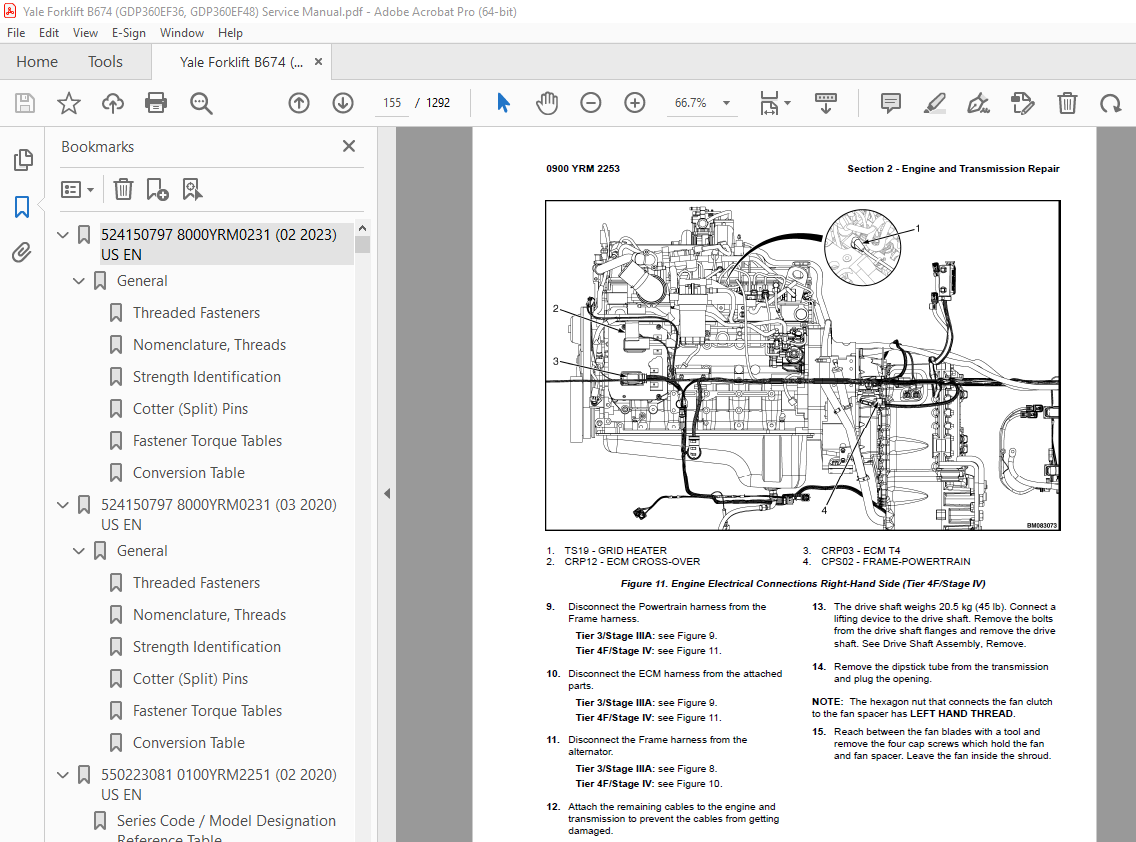

Section 2 – Engine and Transmission Repair 148

Engine and Transmission Assembly 148

Remove 148

Precautions 148

Remove Air Conditioning Compressor 149

Drain the Engine Cooling System 150

Drain Hydraulic Oil 151

Drain Transmission Oil 151

Disconnect Drive Shaft, Fan Clutch, Tubes, Pipes, Cables, Wires and Lines 151

Remove Engine and Transmission 156

Install 159

Install Engine and Transmission 159

Install Air Conditioning Compressor 160

Connect Drive Shaft, Fan, Tubes, Pipes, Cables, Wires and Lines 160

Refill the Systems 160

Starting the Engine 161

Engine Repair 162

Transmission Assembly 163

Remove 163

Install 165

Transmission Components 168

Disassemble 168

Transmission Case, Disassemble 168

Oil Pump, Disassemble 175

Clutch K3, Third Speed, Disassemble 177

Clutch K2, Second Speed, Disassemble 183

Clutch KR, Reverse, Disassemble 190

Clutch KV, Forward, Disassemble 197

Input Shaft, Disassemble 204

Clutch K1, First Speed, Disassemble 205

Clean and Inspect 211

Housings 211

Oil Seals and Gaskets 211

Bearings 212

Gears and Shafts 212

Assemble 213

Clutch K1, First Speed, Assemble 213

Input Shaft, Assemble 221

Clutch KV, Forward, Assemble 222

Clutch KR, Reverse, Assemble 231

Clutch K2, Second Speed, Assemble 240

Clutch K3, Third Speed, Assemble 249

Oil Pump, Assemble 257

Transmission Case, Assemble 259

Transmission Oil Filter Assembly 268

Clean 270

Inspect 270

Transmission Control Valve 271

Clean 276

Inspect 276

Transmission Test and Calibration 283

Precautions 283

Transmission Oil Sampling 283

Preparation 283

Sampling Procedure 283

Stall Test 283

Stall Test Procedure 283

Inch Pedal Calibration 284

Brake and Inch Pedal Adjustment 284

Inch Sensor Adjustment 285

Inch Pedal Calibration 285

Preparation 285

Calibration Procedure 286

Clutch Calibration 286

Control Valve Pressure Checks 286

Speed and Temperature Sensor Checks 289

Electrical Specifications 289

Section 3 – Engine Intake and Exhaust Repair 291

Air Filter Assembly 291

Remove 291

Install 291

Exhaust System (Tier 3/Stage IIIA) 293

Remove 293

Install 294

Exhaust System (Tier 4F/Stage IV) 294

Exhaust Pipes High Mount 294

Remove 294

Install 294

Exhaust Pipes and Diffuser Low Mount 296

Remove 296

Install 296

Engine After Treatment (EAS) System (Tier4F\Stage IV) 296

Engine After Treatment System Assembly 297

Preparation 297

Remove 298

Install 299

Engine After Treatment (EAS) System Components 299

Exhaust Seal Rings 299

Selective Catalytic Reducer (SCR) 300

Remove 300

Install 300

Decomposition Reactor Tube (DRT) 300

Remove 300

Install 301

Diesel Oxidation Catalyst (DOC) 301

Remove 301

Install 301

DEF System 302

DEF System Assembly 302

DEF System Components 302

DEF Tank 302

Remove 302

Install 303

DEF Tank Fill Cap 304

DEF Tank Unit 304

Remove 304

Install 304

DEF Tank Suction Filter 304

Replace 304

DEF Pump Assembly 305

Remove 305

Install 306

DEF Pump Filter 306

Replace 306

DEF Dosing Valve 307

Remove 307

Install 307

DEF System Checks and Adjustments 308

DEF Dosing Valve 308

DEF Pump 308

Fuel Tank 308

Remove 308

Clean and Repair 310

Install 310

Section 4 – Drive Axle Repair 311

Drive Axle Assembly 311

Remove 311

Install 313

Drive Axle Components 314

Planetary Gear Assembly 314

Preparations 315

Repairing and Replacing Parts 320

Welding 320

Clean 320

Ground or Polished Parts 320

Parts With Rough Finishes 321

Axle Assemblies 321

Drying Cleaned Parts 321

Preventing Corrosion 321

Inspect 321

Service Brake Assembly 326

Remove Service Brake 328

Clean 332

Ground and Polished Parts 333

Parts With Rough Finish 333

Wet Disc Brake and Axle Assembly 333

Inspect 333

Face Seals 333

Disc 334

Wear Limits 334

Replace Parts 335

Differential Assembly 341

Preparations 343

Remove 343

Differential Carrier From Axle Housing 343

Main Differential and Ring Gear Assembly From Differential Carrier 344

Drive Pinion and Pinion Carrier From Differential Carrier 346

Disassemble 349

Main Differential and Ring Gear Assembly 349

Drive Pinion, Bearings, and Pinion Carrier 350

Clean and Inspect 353

Assemble 353

Drive Pinion, Bearings, and Pinion Carrier 353

Pinion Bearings Preload Adjustment 355

Press Method 355

Flange Method 356

Triple-Lip Oil Seal 357

Pinion Carrier Shim Set Thickness Adjustment (Depth of Pinion) 358

Main Differential and Ring Gear Assembly 360

Differential Gears Rotating Torque 362

Install 363

Differential and Ring Gear Assembly 363

Differential Bearings Preload Adjustment 365

Method 1 365

Method 2 366

Ring Gear Runout Check 367

Ring Gear Backlash Adjustment 367

Tooth Contact Pattern Check 369

Thrust Screw Installation and Adjustment 372

Differential Carrier Into Axle Housing 372

Parking Brake 373

Preparations 374

Parking Brake Caliper 375

Remove 375

Disassemble 375

Clean and Inspect 376

Assemble 376

Install 376

Parking Brake Caliper Pads 377

Remove 377

Install 377

Drive Axle Checks and Adjustments 377

Oil Drain and Refill Procedures 377

Differential 377

Drain 377

(Re)Fill 378

Hub Assembly 378

Drain 378

(Re)Fill 378

Service Brake 379

Drain 379

(Re)Fill and De-aerate 379

Wheel Bearing Preload 379

Adjust 379

Parking Brake Adjustments 379

Parking Brake Bleed 379

Parking Brake Emergency Release 380

Park Brake Selector Valve Check 380

Park Brake Selector Valve Coil Check 380

Accumulator Pre-Charge Check 381

Parking Brake Pads Adjustment 381

Condition Check, Shuttle Valve L in the Main Control Valve 382

Condition Check, Shuttle Valve N in the Main Control Valve 382

Condition Check, Priority Valve on the Main Control Valve 383

Pressure Check, Port MLS1 383

Drive Axle Torque Specifications 384

Section 5 – Steering Axle Repair 386

Steering Axle Assembly 386

Remove 386

Install 387

Steering Axle Components 387

Tie Rod 387

Remove 387

Clean and Inspect 388

Install 388

Steering Cylinder 388

Remove 388

Clean and Inspect 391

Assemble and Install 391

Hubs 392

Remove and Disassemble 392

Clean and Inspect 392

Assemble and Install 393

Spindle 394

Remove 394

Clean and Inspect 394

Assemble and Install 395

Steering Axle Checks and Adjustments 395

Maximum Steering Angle Adjustment 395

Torque Specifications 396

Wheel Nuts 396

Steering Cylinder 396

Torque Specifications 396

Steering Axle 396

Wheel Nuts 396

Steering Cylinder 396

550223084 1900YRM2254 (02 2020) US EN 399

Series Code / Model Designation Reference Table 407

General 407

Precautions 407

Section 1 – Hydraulic System Repair 407

Main Control Valve 407

Remove 407

Clean 410

Inspect 410

Assemble 410

Install 411

Priority Valve (A) 413

Remove 413

Clean 413

Inspect 414

Component Functionality Test 414

Install 414

Check Valve (K) 414

Remove 414

Clean 414

Inspect 414

Component Functionality Test 414

Install 414

Check Valve (I) 414

Remove 414

Clean 414

Inspect 415

Component Functionality Test 415

Install 415

Check Valve (Q) 415

Remove 415

Clean 415

Inspect 415

Component Functionality Test 415

Install 415

Screen Cartridge (O) 415

Disassemble 415

Component Functionality Test 415

Assemble 416

Shuttle Valves (L) and (M) 416

Remove 416

Clean 416

Inspect 416

Component Functionality Test 416

Install 416

Logic Valve (N) 417

Remove 417

Clean 417

Inspect 417

Component Functionality Test 417

Install 417

Full Flow Relief Valve (C) (Relief Spool) 417

Remove 417

Clean 417

Inspect 418

Assemble 418

Install 418

Pilot Supply Valve (F) 418

Remove 418

Clean 418

Inspect 418

Assemble 418

Component Functionality Test 418

Install 418

Load Sense (LS) Relief Valve (H) and Full Flow Relief Valve (G) 418

Remove 418

Clean 418

Inspect 419

Component Functionality Test 419

Install 419

Load Sense Relief Valve (H) Adjustment 419

Full Flow Relief Valve (G) Adjustment 419

Load Sense Selector Valve (D) 419

Remove 419

Clean 419

Inspect 420

Assemble 420

Install 420

Lift Pressure Selector Valve (B) 420

Remove 420

Clean 420

Inspect 421

Assemble 421

Install 421

Variable Displacement Pump (Primary and Secondary) 421

Remove 421

Clean 423

Inspect 423

Install 423

Electrical Actuation Module 425

Remove 425

Clean 425

Inspect 425

Assemble 425

Install 425

Emergency Lowering Valve (Left Slice Only) 427

Remove 427

Clean 427

Inspect 427

Install 427

Load Sense and Pressure Controller Valve on Pump 427

Remove 427

Clean 428

Inspect 428

Assemble 428

Install 428

Carriage Valve 428

Remove 429

Clean and Inspect 429

Assemble 429

Install 430

Manual End Cap 430

Remove 431

Clean 431

Inspect 431

Assemble 431

Install 431

Tilt Lock Valve 431

Remove 431

Clean 433

Inspect 433

Assemble 433

Install 433

Lowering Control Valve 433

Remove 433

Clean 434

Inspect 434

Install 434

Hydraulic Tank 435

Remove 435

Inspect 437

Clean 437

Steam Cleaning Method 437

Chemical Solution Cleaning Method 438

Repair 438

Small Leaks 438

Large Leaks 438

Inspection after Repair 438

Install 439

Hydraulic Checks and Adjustments 440

Adjustment of Pressure Controller on Pump 440

Adjustment of Load Sense Controller on the Secondary Variable Pump 441

Adjustment of Load Sense Controller on the Primary Variable Pump 442

Hydraulic System Torque Specifications 443

Section 2 – Steering System Hydraulics Repair 444

Steering Control Unit 444

Remove 444

Install 445

Steering Cylinder 445

Remove 445

Clean and Inspect 448

Assemble and Install 448

Steering System Torque Specifications 449

Steering Control Unit 449

Steering Cylinder 449

Section 3 – Brake System Hydraulics Repair 449

Brake Treadle Valve 449

Remove 449

Install 450

Accumulator 451

Remove 451

Disassemble 451

Clean 454

Inspect 454

Repair 454

Assemble 454

Install 455

Pre-Charge Filling 455

Parking Brake 456

Parking Brake Caliper 456

Remove 456

Disassemble 457

Clean and Inspect 457

Assemble 458

Install 458

Parking Brake Caliper Pads 459

Remove 459

Install 459

Parking Brake Bleed 459

Parking Brake Emergency Release 460

Brake Flow Distribution Manifold 460

Remove 460

Disassemble 462

Clean and Inspect 462

Assemble 462

Install 462

Brake Control Manifold 463

Remove 463

Install 464

Orifices (F) and (G) 464

Disassemble 464

Assemble 464

Orifice (H) 464

Disassemble 464

Assemble 465

Unloading Valve (B) 465

Disassemble 465

Assemble 465

Screen 465

Disassemble 465

Assemble 465

Check Valve (E) 465

Disassemble 465

Assemble 465

Pressure Reducer Valve (C) 466

Disassemble 466

Assemble 466

Park Brake Selector Valve (A) 466

Disassemble 466

Assemble 466

Brake System Checks and Adjustments 467

Hydraulic Pressure Checks Preparation 467

Park Brake Selector Valve Check 467

Park Brake Selector Valve Coil Check 467

Accumulator Pre-Charge Check 468

Parking Brake Adjustment 468

Condition Check, Shuttle Valve (L) in the Main Control Valve 469

Condition Check, Shuttle Valve (N) in the Main Control Valve 469

Condition Check, Priority Valve on the Main Control Valve 469

Pressure Check, Port MLS1 470

Hydraulic Brake Torque Specifications 470

Hydraulic Hose Torque Procedure 471

Section 4 – Cylinder Repair 471

Front End Cylinders 471

Side Shift Cylinder 471

Disassemble 471

Clean and Inspect 472

Assemble 472

Fork Positioner Cylinder 472

Disassemble 472

Clean and Inspect 473

Assemble 473

Tilt Cylinders 474

Disassemble 474

Clean and Inspect 474

Assemble 474

De-Aeration of the Tilt Cylinders before Start-up 476

Lift Cylinders 476

Disassemble 476

Clean and Inspect 477

Assemble 477

550223085 2200YRM2255 (02 2023) US EN 479

Series Code / Model Designation Reference Table 485

General 485

Section 1 – Electrical 485

General Fault Finding 485

Preparation 485

Define the Problem Area 485

Identify Possible Causes of Malfunction 485

Determine the Most Probable Cause 485

Fuse Check 485

Wiring Check 486

Component Check 486

Repair and Test 486

Harnesses and Connectors 486

Harnesses Overview 486

Harness Connectors and Terminals 488

Frame Harness Connectors 489

Cab Rear Wall Harness Connectors 493

Mast Harness Connectors 496

Mast Work Lights and Lights Extension Harness Connectors 496

Closed Cab Harness Connectors 497

Steering Column Harness Connectors 501

Cab Tilt Harness Connectors 502

Cab Lights Harness Connectors (LH harness shown) 504

ECM Harness Connectors (Tier 3/Stage IIIA Engine) 506

EAS/ECM Harness Connectors (Tier 4F/Stage IV Engine) 507

DEF Tank Harness Connectors (Only Tier 4F/Stage IV Engine) 509

Powertrain Harness Connectors 510

Hoodspine Harness Tier 3/Stage IIIA Connectors 512

Hoodspine Harness Tier 4F/Stage IV Connectors 512

Carriage Harness Connectors 513

Rear Harness Connectors 514

Wire Harness Identification and Connector Location 517

Fuses and Relays 517

Fuse Relay Board 522

CANbus Circuit 524

Greasing System Electrical 525

Section 2 – Controls 527

Information Display 527

General 527

Information Display Overview 528

Information Display Diagram and Connectors 529

Fault Codes 531

Transmission Calibration 531

Section 3 – User Interface Display 532

Navigation Key 532

Startup Sequence 533

Home Screen 534

Screen Brightness Menu 535

HVAC Controls Menu 536

Logging in 537

Log In/Out 537

View the fault log 538

Fault Log 538

View the hardware and software versions 539

Calibrations 540

Calibrate the clutch pack 540

Calibrate the brake pedal 541

Calibrate the accelerator pedal 541

Calibrate the load weight sensor 541

Diagnostics Menu 542

Hydraulics 542

H1d 1st Hyd Function 543

H2d 2nd Hyd Function 543

Aux Hyd Functions 543

Drive 543

D1 Engine 544

D9 Transmission 544

Controllers 544

C1d VSM 544

C10d Hydraulic Controller 1 544

C11d Armrest Module 544

C12d High Current Module 545

C99d Light module 545

Overview 545

Settings 545

Hydraulics 545

Operators 546

Truck Setup 546

T1 Display 547

T2 Lights 547

T5 Switches 547

Display Flow Chart 547

550223085 2200YRM2255 (03 2020) US EN 557

Series Code / Model Designation Reference Table 561

General 561

Section 1 – Electrical 561

General Fault Finding 561

Preparation 561

Define the Problem Area 561

Identify Possible Causes of Malfunction 561

Determine the Most Probable Cause 561

Fuse Check 561

Wiring Check 562

Component Check 562

Repair and Test 562

Harnesses and Connectors 563

Harnesses Overview 563

Harness Connectors and Terminals 563

Frame Harness Connectors 564

Cab Rear Wall Harness Connectors 567

Mast Harness Connectors 570

Mast Work Lights and Lights Extension Harness Connectors 570

Closed Cab Harness Connectors 571

Steering Column Harness Connectors 575

Cab Tilt Harness Connectors 576

Cab Lights Harness Connectors (LH harness shown) 578

ECM Harness Connectors (Tier 3/Stage IIIA Engine) 580

EAS/ECM Harness Connectors (Tier 4F/Stage IV Engine) 581

DEF Tank Harness Connectors (Only Tier 4F/Stage IV Engine) 583

Powertrain Harness Connectors 584

Hoodspine Harness Tier 3/Stage IIIA Connectors 586

Hoodspine Harness Tier 4F/Stage IV Connectors 586

Carriage Harness Connectors 587

Rear Harness Connectors 589

Wire Harness Identification and Connector Location 591

Fuses and Relays 591

Fuse Relay Board 596

CANbus Circuit 598

Greasing System Electrical 599

Section 2 – Controls 601

Information Display 601

General 601

Information Display Overview 602

Information Display Diagram and Connectors 603

Fault Codes 605

Transmission Calibration 605

Section 3 – User Interface Display 606

Navigation Key 606

Startup Sequence 607

Home Screen 608

Screen Brightness Menu 609

HVAC Controls Menu 610

Logging in 612

Log In/Out 612

View the fault log 613

Fault Log 613

View the hardware and software versions 614

Calibrations 614

Calibrate the clutch pack 615

Calibrate the brake pedal 615

Calibrate the accelerator pedal 616

Calibrate the load weight sensor 616

Diagnostics Menu 616

Hydraulics 617

H1d 1st Hyd Function 617

H2d 2nd Hyd Function 618

Aux Hyd Functions 618

Drive 618

D1 Engine 618

D9 Transmission 618

Controllers 619

C1d VSM 619

C10d Hydraulic Controller 1 619

C11d Armrest Module 619

C12d High Current Module 619

C99d Light module 619

Overview 619

Settings 620

Hydraulics 620

Operators 621

Maintenance 621

Truck Setup 621

T1 Display 621

T2 Lights 622

T5 Switches 622

Display Flow Chart 622

550223086 2400YRM2256 (02 2020) US EN 633

Series Code / Model Designation Reference Table 637

General 637

Greasing System 638

Grease Pump Assembly 638

Remove 639

Install 639

Greasing System Components 639

Grease Line Identification 639

Grease Reservoir 643

Disassemble 643

Assemble 644

Refilling the Grease Reservoir 644

Test Cycles Using the Button on the Pump 645

Bleeding the Pump 645

Bleeding the System 646

Checks and Adjustments 661

Test Procedures 661

Check pressure switch (valve) and cable 661

Check pump and 5/2-way valve 661

Check for Internal System Leaks 662

Technical Data 663

Pump Unit 663

Grease Recommendations 663

Electrical 663

Torque Specifications 665

550223087 4000YRM2257 (02 2020) US EN 667

Series Code / Model Designation Reference Table 673

General 673

Safety Procedures 673

When Working Near The Mast Always 673

When Working on the Hydraulic System 673

Section 1 – Forks and Carriage Repair 674

Forks 674

Pin-Type Forks 675

Remove 675

Install 677

Quick Disconnect DFSSFP Forks 677

Remove 677

Install 678

Integrated DFSSFP Forks 678

Remove 678

Clean and Inspect 679

Install 680

Fork Hanger for Quick Disconnect Forks 680

Remove 680

Clean and Inspect 680

Install 680

Carriage Assembly 681

Carriage Types 681

Remove 684

Install 685

Carriage Components 686

Carriage Bearing Blocks 686

Remove 686

Install 686

Carriage Load Rollers 687

Remove 687

Install 688

Apron Wear Pads (DFSSFP Carriage) 688

Replace 688

Fork Position Cylinder 689

Remove 689

Install 691

Side Shift Cylinder 691

Remove 691

Install 692

Carriage Valve 692

Remove 692

Install 693

Section 2- Mast Repair 694

Mast Assembly 694

Remove 694

Disassemble 696

Assemble 698

Install 698

Inner Mast Load Rollers 700

Remove and Disassemble 700

Assemble and Install 701

Mast Bearing Blocks 701

Remove 701

Install 701

Lift Cylinders 702

Remove 702

Install 703

Mast Components 704

Lift Chains 704

Remove 704

Install 705

Chain Anchor On Carriage 705

Remove 705

Install 706

Top Chain Anchor 706

Remove 706

Install 706

Chain Sheave 706

Remove 706

Install 707

Header Hoses 708

Remove 708

Install 709

Electric Mast Cable 709

Remove 709

Install 710

Hose Sheave 710

Remove and Disassemble 710

Assemble and Install 711

Tilt Cylinder 711

Remove 711

Install 712

Mast Checks and Adjustments 713

General Checks 713

Mast Condition Check 713

Mast Operation Check 713

Fork Inspection 713

Lift Chains 714

Lift Chains Cleaning 714

Lift Chain Inspection 715

Lift Chain Lubricant Requirements 716

Lift Chain Lubrication Procedure 716

Leak Checks 716

Mast Vertical Creep 716

Mast Tilt Drift 717

Adjustments 717

Lift Cylinder Shimming 717

Lift Chain and Fork Height Adjustment 719

Dual Function Fork Guide Shimming 720

Header Hose Tension Adjustment 721

Electric Mast Cable Tension Adjustment 721

Tilt Cylinder Backward Tilt Adjustment 721

Mast Support Pad Adjustment 722

Torque Specifications 723

Torque Values for Mast and Carriage 723

Tightening Torques 724

550223088 8000YRM2258 (01 2020) US EN 729

Series Code / Model Designation Reference Table 733

Counterweight Weights 733

Lift Truck Weights 733

Capacities 733

Electrical System 734

Engine Specifications 734

Mast Speeds 735

Tire Sizes 735

Hydraulic System 736

Torque Specifications, General 736

Transmission ZF 736

Counterweight 736

Steering 736

Wheel Nuts 737

Hydraulic System 737

Mast 737

Carriage 737

Tilt Cylinders 737

Torque Specifications, Cummins Diesel 738

Lubrication System 738

550223089 8000YRM2259 (03 2020) US EN 741

Series Code / Model Designation Reference Table 745

Electrical Schematic T3/T4 Final 746

Hydraulic Schematic 774

550223090 8000YRM2260 (03 2020) US EN 781

Series Code / Model Designation Reference Table 785

General 785

Precautions 785

Main Components 786

Hood Assembly 786

Remove 786

Install 787

Running Boards, Steps and Mud Flaps 788

Counterweight 789

Remove 789

Install 791

Label Replacement 792

550223092 8000YRM2262 (07 2020) US EN 795

Series Code / Model Designation Reference Table 801

General 801

Serial Number Data 801

Truck Handling Procedures 802

Moving and Towing a Lift Truck 802

Precautions 802

Towing the Truck 803

Putting a Lift Truck on Blocks 803

Raising the Drive Tires 803

Raising the Steering Tires 804

Cleaning a Lift Truck 805

Safety Procedures Before Starting Maintenance 806

Making Checks From the Driver Seat with Engine Running 806

Fire Hazard 806

Wait 100 Seconds Before Disconnecting Battery 806

Periodic Maintenance Schedule 807

Daily Inspection 808

Daily Condition Checks 808

Daily Fluid Level Checks 808

Daily Checks from the Driver Seat with Engine Running 809

Initial Inspection 810

First Inspection after First 20 and First 40 Hours of Operation 810

First Inspection after First 100 Hours of Operation 810

First Inspection after First 250 Hours of Operation 811

Periodic Maintenance 811

Inspect and Adjust 811

Annual Inspection 813

Lubricate 815

Change 816

Periodic Maintenance Procedures 818

Air Conditioning System 818

Automatic Greasing System (Optional) 818

Greasing System 818

Greasing System Filter 818

Brake Cooling Filter 819

Brake System Accumulator 819

Cab Air Filter 820

Control Levers, Switches, and Pedals 820

Cooling System 820

Coolant Hoses 820

Coolant Level 821

Coolant Quality 821

Cooling Fan 821

Crankcase Breather Element (Tier 4F/Stage IV Only) 821

Diesel Exhaust Fluid (DEF) System 822

DEF Pump Filter 822

DEF Tank Fill Cap 823

DEF Tank Suction Filter 823

Drive Axle, Differential and Axle Hub Assembly 824

Check Oil level 824

Change Oil 824

Drive Wheel Hub Bearing Preload 824

Drive Shaft 824

Engine Air Filter 825

Engine Air Intake Piping and Charge Air Piping 825

Engine and Transmission Mounts 826

Engine Compartment 826

Engine Drive Belt 827

Engine Drive Belt Tensioner and Pulleys 827

Bearing Condition 827

Pulley Alignment 827

Tensioner Condition 827

Engine Oil 829

Engine Oil Level 829

Engine Oil and Engine Oil Filter 829

Engine Valve Adjustment 830

Fault Codes 832

Forks 832

Fork Guide Bearing Blocks 833

Fork Guide Wear Pads 834

Fork Pins, Carriage Pins, and Carriage Sliding Surfaces 834

Frame, Mast and Carriage 834

Fuel, Oil, DEF, or Coolant Leaks 835

Fuel/Water Separator and Final Fuel Filter 835

Fuel Tank Breather 836

Header Hose Assembly 836

Horn, Gauges, Lights, Alarms and Control System 836

Hydraulic System Oil 836

Hydraulic Oil Testing Procedures 837

Hydraulic Oil Replacement 837

Hydraulic Tank Breather 839

Hydraulic Tank Return Filter 839

Inching Pedal Sensor Calibration 839

Lift Chains 839

Check and Lubricate Lift Chains 839

Adjust Lift Chains 840

Inspect Lift Chains 841

Chain Elongation 841

Lift Chain Wear and Damage 842

Lift System Accumulator (Optional) 842

Load Rollers 842

Carriage Load Rollers 842

(Inner) Mast Load Rollers 843

Mast and Carriage 843

Mast Pivot Pins 843

Operator Presence System 844

Operator Restraint System 844

Seat Belt and Seat Rails 844

Steering Column Pedal 845

Parking and Service Brakes 845

Radiator Assembly 845

Steering Axle Grease Fittings 845

King Pins 845

Tie Rod Pins 845

Pivot Pin 845

Steering System 846

Steering Wheel Hub Bearings 846

Remove and Disassemble 846

Clean and Inspect 847

Assemble and Install 847

Tilt Cylinder Pivot Pins 848

Transmission 849

Transmission Clutch Calibration 849

Transmission Oil Level 849

Transmission Oil and Oil Filter 849

Turbo Charger 850

Vibration Damper (Viscous) 850

Warning and Safety Labels 851

Windows and Mirrors 851

Windshield Washer Fluid Level 851

Wheels and Tires 851

Wheels, Tires, and Tire Pressure 851

Remove Wheels from Lift Truck 852

Adding Air Pressure to Pneumatic Tires 858

Install Wheels on Lift Truck 862

Capacities and Specifications 864

Approved Fuel and Engine Oils 864

Approved Oils, Fluids, and Grease 864

Engine Oil Viscosity 865

Lift Chain Lubricant Requirements 866

Electrical Components 866

Cab Electric Group 866

Check the Fuses 866

Power Distribution Group 869

550223093 8000YRM2263 (04 2020) US EN 875

Series Code / Model Designation Reference Table 879

General 879

Weight and Dimensions 880

Loading Procedures 884

Loading A Truck on a Transport 884

Loading Disassembled Components 884

Unloading Procedures 885

Unloading A Truck From Transport 885

Lifting a Truck 885

Driving a Truck Off a Trailer 885

Unloading Disassembled Components 885

Moving and Towing 886

Moving a Disabled Lift Truck 886

Precautions 886

Towing A Lift Truck 886

Safety Procedures When Working Near The Mast 887

When Working Near The Mast Always 887

Before Starting Repairs To The Hydraulic System Always 888

Truck Assembly 889

Mast Installation 889

Preparations 889

Installing the Mast 889

Installing the Tilt Cylinders 890

Adjusting the Tilt Cylinders 891

Connecting the Lift Cylinders 892

Connecting the Mast Supply Hoses 892

Carriage and Forks 893

Installing the Carriage 893

Connecting the Header Hoses to the Carriage 893

Install the Forks 894

Installing Pin-Type Forks 894

Installing Quick Disconnect DFSSFP Forks 896

Installing Integrated DFSSFP Forks 897

Adjusting the Carriage 897

Adjusting Header Hose Tension 898

Adjusting the Electrical Cable Tension 899

Installing the Cab Lights 899

Lubrication Points 900

General Checks After Assembly 900

Plumbing Check 900

Lubrication Check 900

Fluid Level Check 900

Functionality Check 900

Literature Package Check 900

Cleaning 900

Labels 900

Wheels and Tires 901

Remove Wheels From Lift Truck 901

Remove Tire From Wheel 902

Install Tire on Wheel 903

Adding Air Pressure to Tires 904

Install Wheels on Lift Truck 905

Capacities and Specifications 906

Torque Values 906

Pre-Delivery 906

Perform Pre-Delivery Inspection 906

Delivery 906

Instructions Operating Manual 906

Instructions Daily Maintenance 906

Handing Over Truck 906

550223094 8000YRM2264 (02 2020) US EN 909

Model Designation / Series Code 913

General 913

Section 1 – Troubleshooting 913

Cab Heater and Air Conditioning 913

Preliminary Checks 913

Checking System Air Output 913

Check The Sight Glass for Bubbles 913

Troubleshooting Procedures 913

General System 914

Climate Control Display Diagnostics Menu Errors 916

Mast 917

Section 2 – Error Codes 920

Cummins Engine 920

General 920

Fault Code Descriptions 920

Finding Fault Code Information 920

Electronic Throttle Calibration 920

Stationary Regeneration Procedure 921

ZF Transmission Codes 974

Hydraulic Control System Fault Codes 1017

VSM 1021

Automatic Greasing System 1033

General Instructions and Safety Information 1033

Test Procedures 1038

Procedure to check pressure switch (valve) and its cable 1038

Procedure to check pump and 5/2-way valve 1039

Procedure when an internal system leak is suspected 1039

550223094 8000YRM2264 (08 2022) US EN 1043

Model Designation / Series Code 1049

General 1049

Section 1 – Troubleshooting 1049

Cab Heater and Air Conditioning 1049

Preliminary Checks 1049

Checking System Air Output 1049

Check The Sight Glass for Bubbles 1049

Troubleshooting Procedures 1050

General System 1050

Climate Control Display Diagnostics Menu Errors 1052

Mast 1053

Section 2 – Error Codes 1056

Armrest 1056

Cabin Tip 1064

Communications 1065

Engine (Cummins) 1067

Cummins Engine 1067

General 1067

Fault Code Descriptions 1068

Finding Fault Code Information 1068

Electronic Throttle Calibration 1068

Stationary Regeneration Procedure 1068

Engine (Mercedes-Benz) 1112

General 1112

Finding Fault Code Information 1112

ACM Faults 1112

CPC4 Faults 1135

MCM Faults 1162

Greasing (Frame) 1203

Greasing (Spreader) 1204

Heating Ventilation and Air Conditioning (HVAC) 1205

Hydraulic Controller 1207

Hydraulic Controller 1 1207

Hydraulic Controller 2 1208

Spreader 1208

Telemetry 1219

TPMS 1219

Transmission (ZF) 1220

VSM 1262

Other 1290