$41.95

Yale Forklift B878 (GP GDP GLP135 155CA) Service Manual – PDF DOWNLOAD

Yale Forklift B878 (GP GDP GLP135 155CA) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift B878 (GP GDP GLP135 155CA) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1350

Downloadable : Yes

File Type : PDF

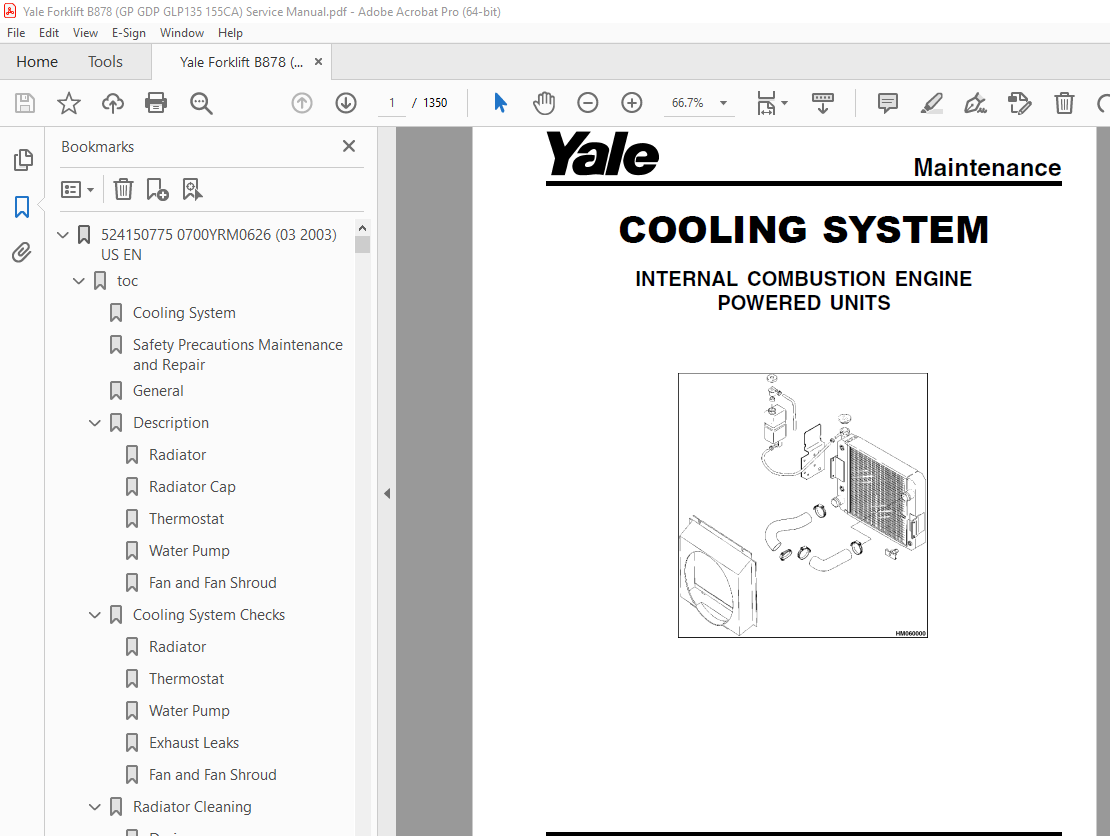

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift B878 (GP GDP GLP135 155CA) Service Manual – PDF DOWNLOAD

524150775 0700YRM0626 (03 2003) US EN 1

toc 1

Cooling System 1

Safety Precautions Maintenance and Repair 2

General 5

Description 6

Radiator 6

Radiator Cap 6

Thermostat 6

Water Pump 7

Fan and Fan Shroud 7

Cooling System Checks 7

Radiator 7

Thermostat 7

Water Pump 8

Exhaust Leaks 8

Fan and Fan Shroud 8

Radiator Cleaning 8

Drain 8

Clean 8

Fill 9

Troubleshooting 10

524150779 1400YRM0046 (08 2012) US EN 13

toc 13

Differential 13

Safety Precautions Maintenance and Repair 14

General 17

Description 17

Differential Repair 17

Remove 17

Differential Carrier From Axle Housing, Remove 17

Differential and Ring Gear From Differential Carrier, Remove 21

Drive Pinion and Pinion Carrier From Differential Carrier, Remov 23

Disassemble 24

Differential and Ring Gear Assembly, Disassemble 24

Drive Pinion and Pinion Carrier, Disassemble 25

Clean and Inspect 28

Assemble 29

Pinion, Bearings, and Pinion Carrier, Assemble 29

Pinion Bearings, Adjust Preload 29

Press Method 29

Yoke or Flange Method 30

Triple-Lip Seal, Install 31

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion) 32

Differential and Ring Gear, Assemble 34

Differential Gears Rotating Torque, Check 36

Differential and Ring Gear Assembly, Install 37

Differential Bearings, Preload Adjust 38

Ring Gear, Runout Check 39

Ring Gear Backlash, Adjust 40

Gear Set, Tooth Contact Pattern Check 42

Thrust Screw, Install and Adjust 45

Install 45

Differential Assembly Into Axle Housing, Install 45

Specifications 46

Troubleshooting 50

tables 13

Table 1 Ring Gear Backlash Adjustment Specifications 41

Table 2 Ring and Pinion Tooth Contact Adjustment 42

Table 3 General Specifications 46

Table 4 Rivet Installation Pressure 46

Table 5 Pinion Adjustment 46

Table 6 Pinion Preload Pressure 47

Table 7 Torque Specifications 48

Table 8 Torque Specifications for Metric Hardware 49

Table 9 Torque Specifications for Metric (Fine) Hardware 49

524150783 1600YRM0326 (03 2007) US EN 53

toc 53

Steering Axle 53

Safety Precautions Maintenance and Repair 54

General 57

Description 57

Steering Axle Assembly Repair 62

Steering Axle GP/GLP/GDP070-110LG/MG (B813), GC/GLC070-120LG/MG 62

Remove 62

Install 62

Steering Axle GDP60-70CA (GP/GLP/GDP135-155CA) (A878, B878), GLP 63

Remove 63

Install 63

Wheels and Hubs Repair (All Units) 64

Remove and Disassemble 64

Clean 64

Inspect 64

Assemble and Install 64

Spindles and Bearings Repair (All Units) 66

Remove 66

Clean 66

Assemble and Install 67

Tie Rods Repair (All Units) 68

Remove 68

Clean 68

Install 68

Steering Cylinder Repair 71

Remove and Disassemble 71

Clean and Inspect 71

Assemble and Install 71

Troubleshooting 72

524150790 2100YRM0103 (03 2007) US EN 77

toc 77

Tilt Cylinders 77

Safety Precautions Maintenance and Repair 78

General 81

Description 81

Tilt Cylinder Repair 81

Remove 81

Disassemble 81

Clean 81

Assemble 82

Tilt Cylinders With O-Ring or Single-Lip Seals 82

Tilt Cylinders 83

Install 84

Tilt Cylinder Leak Check 86

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 87

Torque Specifications 87

Piston Rod Nut 87

Retainer 87

Troubleshooting 88

tables 77

Table 1 Movement Rates (Maximum) for Tilt Cylinders 86

524150791 2200YRM0002 (01 2016) US EN 93

General 97

Description 98

Alternator Repair 100

Alternator Type A 100

Remove and Disassemble 100

Clean 102

Assemble 102

Install 103

Alternator Type B 106

Remove and Disassemble 106

Clean 106

Assemble 107

Install 108

General Check and Adjustment 108

Low Output Check (Type A or Type B) 109

High Output Check (Type A or Type B) 112

Brushes Circuit Check 113

Delco Alternators 113

Motorola Alternators 113

Diodes Check 114

Diode Bridge Check 114

Delco and Leece-Neville Alternators 114

Motorola Alternators 114

Rotor Field Winding Check 115

Stator Windings Check 116

Voltage Regulator Check 116

Troubleshooting 116

524150792 2200YRM0106 (01 2016) US EN 121

General 125

Description and Operation 126

Starter Repair 130

Remove 130

Disassemble 130

Clean 131

Assemble 131

Install 132

General Checks and Adjustments 132

Troubleshooting 134

524150794 4000YRM0135 (03 2011) US EN 141

toc 141

Lift Cylinders 141

Safety Precautions Maintenance and Repair 142

Safety Procedures When Working Near Mast 145

General 149

Description 149

Lowering Control Valve 149

Cylinders (General) 152

Lift Cylinder Repair 152

Lift Cylinder Removal Without Removing Mast 152

Standard Masts With Main Lift Cylinder Fastened to Crossmember o 152

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to 153

Masts That Have Two Cylinders, Main Lift Cylinder and Free-Lift 154

Disassemble 154

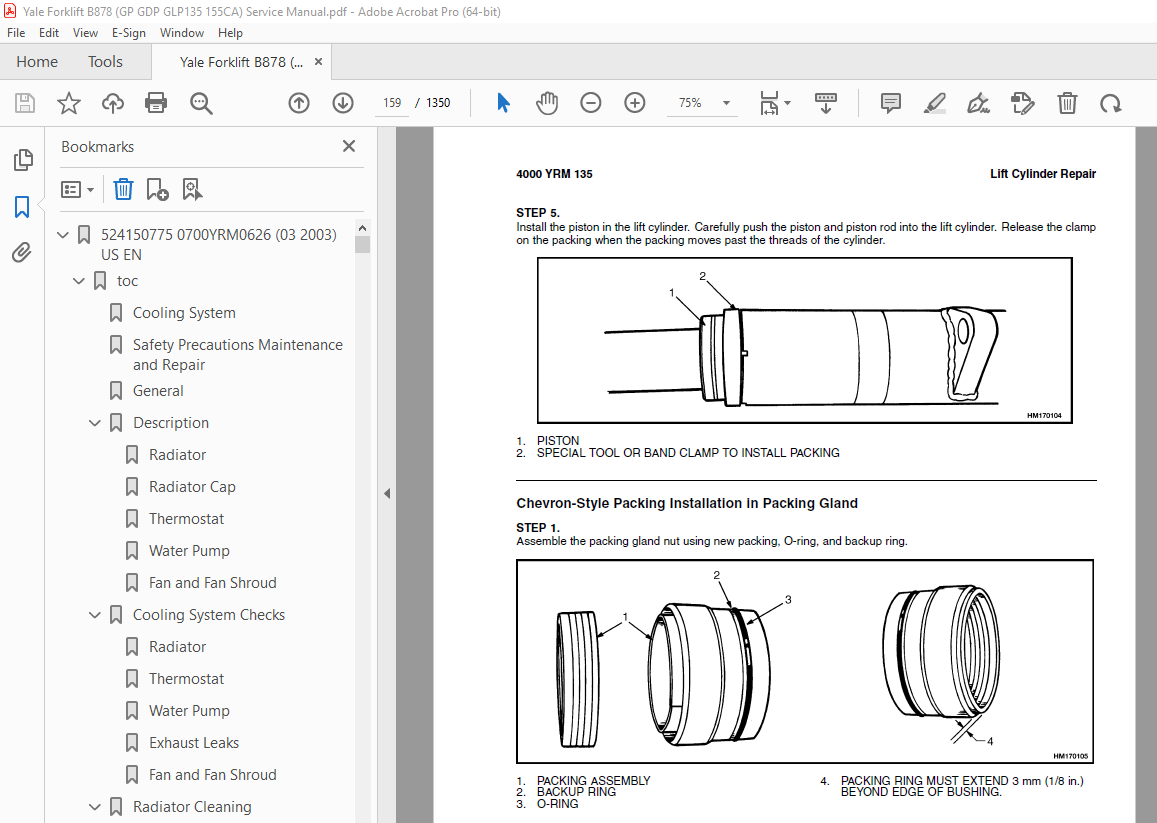

Assemble 154

Lift Cylinder Installation in Mast 156

Standard Masts With Main Lift Cylinder Fastened to Crossmember o 156

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to 156

Chevron-Style Packing 157

Chevron-Style Packing Installation on Piston 157

Chevron-Style Packing Installation in Packing Gland 159

Lift Cylinders for HI VIS® Masts 161

Description 161

Lowering Control Valve 161

Remove 163

Disassemble 164

Assemble 164

Install 166

Main Lift Cylinders 166

Free-Lift Cylinder 166

Lift System Leak Check 166

Specifications 167

Troubleshooting 168

tables 141

Table 1 Cylinder Retainer Torque Specifications and Weight Guid 167

524150797 8000YRM0231 (02 2023) US EN 173

General 179

Threaded Fasteners 179

Nomenclature, Threads 179

Strength Identification 180

Cotter (Split) Pins 181

Fastener Torque Tables 186

Conversion Table 188

524150797 8000YRM0231 (03 2020) US EN 195

General 199

Threaded Fasteners 199

Nomenclature, Threads 199

Strength Identification 200

Cotter (Split) Pins 201

Fastener Torque Tables 206

Conversion Table 208

524153897 0600YRM0590 (04 2014) US EN 215

524153907 1900YRM0097 (05 2012) US EN 267

toc 267

Hydraulic Gear Pumps 267

Safety Precautions Maintenance and Repair 268

Description 271

Operation 272

Flow Control Valve 272

Relief Valve 272

Hydraulic Gear Pump Repair 273

Remove 273

Disassemble 274

Clean 274

Inspect 275

Assemble 278

Install 280

Pump Output Check 280

Method No 1 280

Method No 2 281

Hydraulic System Air Check 282

Troubleshooting 283

524185155 0100YRM0322 (02 2007) US EN 289

toc 289

Frame 289

Safety Precautions Maintenance and Repair 290

General 293

Description 293

Counterweight Repair 294

Remove 294

Install 294

Hood Repair 295

Remove 295

Install 295

Overhead Guard Repair 295

Remove 295

Install 295

Operator Restraint System Repair 296

Automatic Locking Retractor (ALR) 296

Emergency Locking Retractor (ELR) 296

Hydraulic Tank Repair 298

Remove 298

Inspect 298

Small Leaks Repair 298

Large Leaks Repair 298

Clean 298

Steam Method 298

Chemical Solution Method 299

Other Methods of Preparation for Repair 299

Install 299

Fuel Tank Repair 300

Remove 300

Repair 300

Install 300

Radiator Repair 300

Remove 300

Install 300

Engine Repair 301

Remove 301

Install 301

Throttle Pedal Adjustment 303

Perkins 1104C-44(RE) Diesel Engine 303

Safety Labels 304

Cab Repair 306

Cab, Replace 306

Window, Replace 306

Windshield Wipers and Heater 306

tables 289

Table 1 Material Specifications for Cab Windows 306

524185156 1300YRM0324 (10 2003) US EN 311

toc 311

Two-Speed Powershift Transmission 311

Safety Precautions Maintenance and Repair 312

General 315

Mechanical Description 315

Torque Converter 315

Transmission Pump 316

Shaft Assemblies 316

Input Shaft 317

Forward Clutch Shaft 317

Clutch Assemblies 317

Countershaft 324

Output Shaft 324

Hydraulic Operation 325

Torque Converter 325

Seal Rings 326

Control Valve 326

System Pressure Regulator 329

Clutch Pressure Regulator 329

Torque Converter Regulator 330

Inching Spool 330

Direction Spool, Direction Control Lever 330

Direction Spool, Foot Directional Control Pedal 331

Range Spool 332

Drain Spool 332

Accumulator 332

Modulator Spool 332

Operation 333

Lubrication Circuit 333

Foot Directional Control Pedal 334

Oil Flow Diagrams 335

Neutral 335

Forward-Low 335

Forward-Low-Inching 335

Reverse-Low 336

524185157 1300YRM0325 (10 2003) US EN 343

toc 343

Two-Speed Powershift Transmission 343

Safety Precautions Maintenance and Repair 344

General 347

Transmission Repair 347

Transmission and Torque Converter, Remove 347

Transmission, Disassemble 349

Reverse-Low Clutch, Disassemble 352

Reverse-High Clutch, Disassemble 355

Forward-Low Clutch, Disassemble 358

Forward-High Clutch, Disassemble 361

Clean and Inspect 363

Forward Low and High Clutches Assembly 364

Forward Clutches, Assemble 366

Reverse-Low Clutch, Assemble 372

Reverse Clutches, Assemble 374

Transmission, Assemble 381

Torque Converter, Install 387

Control Valve Repair 388

Remove 388

Disassemble 389

Assemble 390

Install 392

Foot Directional Control Pedal 392

Remove and Disassemble 392

Assemble and Install 392

Stall Test 395

Linkage Adjustments 396

Linkage for Inching Pedal GDP60-70CA (GP/GLP/GDP135-155CA) (A878 396

Linkage for Inching Pedal GC/GLC/GDC135-155CA (A879, B879) 399

Linkage for Range Lever – Early Model GDP60-70CA (GP/GLP/GDP135- 401

Linkage for Direction Control Lever – Early Model GDP60-70CA (GP 403

Linkage for Range Lever – Later Model GDP60-70CA (GP\GLP\GDP135- 403

Linkage for Direction Control Lever – Later Model GDP60-70CA (GP 405

Linkage for Range Lever GC/GLC/GDC135-155CA (A879, B879) 407

Linkage for Direction Control Lever GC/GLC/GDC135-155CA (A879, B 407

Oil Pressure Check 409

System Pressure Check Port 410

Torque Converter Check Port 410

Clutch Pressure Check Port 410

Inching Pressure 410

Solenoid Check Ports ( Foot Directional Control Only) 410

Lubrication Pressure Check Ports 410

Specifications 410

Troubleshooting 411

Correct System Pressure: 1300 ±124 kPa ( 189 ±18 psi) 413

Correct Clutch Pressure: 924 ±69 kPa ( 134 ±10 psi) 414

Correct Solenoid Pressure (Foot Directional Control Only): 965 ± 415

Torque Converter Pressure: 834 ±69 kPa ( 121 ±10 psi) 415

Lubrication Pressure: 83 ±21 kPa ( 12 ±3 psi) 416

tables 343

Table 1 Stall Speed Specifications 395

524185159 1400YRM0049 (09 2003) US EN 419

toc 419

Drive Axle 419

Safety Precautions Maintenance and Repair 420

General 423

Description 423

Drive Axle Repair 424

Disassemble 424

Clean 427

Inspect 427

Assemble 428

Torque Specifications 431

Troubleshooting 431

524185160 1600YRM0054 (10 2003) US EN 435

toc 435

Steering Control Unit 435

Safety Precautions Maintenance and Repair 436

General 439

Description 439

Operation 439

Steering Wheel and Column Assembly Repair 441

Steering Column Assembly Repair 441

Type A Steering Column Assembly 441

Remove and Disassemble 441

Assemble and Install 443

Type B Steering Column Assembly 445

Remove and Disassemble 445

Assemble and Install 445

Steering Control Unit 448

Disassemble 448

Clean 451

Assemble 452

System Air Removal 457

Troubleshooting 457

524185161 1800YRM0327 (09 2003) US EN 461

toc 461

Brake System 461

Safety Precautions Maintenance and Repair 462

General 465

Description 465

Operation 466

Brake Booster and Master Cylinder 466

Brake Booster 466

Master Cylinder 467

Service Brake Assembly 468

Parking Brake 469

Brake Shoe Assemblies Repair 470

Remove and Disassemble 470

Clean and Inspect 470

Cleaning Procedures 470

Inspect 470

Assemble and Install 472

Master Cylinder Repair 473

Remove 473

Disassemble 473

Assemble 475

Install 475

Brake Booster Repair 475

Remove 475

Disassemble 475

Clean and Inspect 477

Assemble 477

Install 477

Brake System Air Removal 477

Brake Pedal Adjustment 478

Brake Shoes Adjustment 479

Parking Brake Adjustment 479

Parking Brake Switch Adjustment 479

Brake Booster Relief Valve Check 479

Troubleshooting 480

524185163 1900YRM0328 (09 2003) US EN 485

toc 485

Hydraulic System 485

Safety Precautions Maintenance and Repair 486

General 489

Description and Operation 489

Hydraulic Pumps 490

Main Control Valve 491

Control Valve Lever 491

Steering Control Unit 491

Brake Valve 492

Troubleshooting 492

Lift, Lower, and Tilt Circuit 493

Steering and Brake System 494

524185164 2000YRM0090 (10 2003) US EN 499

toc 499

Main Control Valve 499

Safety Precautions Maintenance and Repair 500

General 503

Description 503

Operation 503

Lift Spool 503

Tilt Spool 503

Tilt Backward 503

Tilt Forward 507

Two-Stage Relief Valve 508

Main Control Valve Repair 509

Remove and Disassemble 509

Clean and Inspect 509

Assemble 509

Install 510

Two-Stage Relief Valve 510

Troubleshooting 511

tables 499

Table 1 Relief Pressures (Oil temperature at 55 to 66 C ( 131 t 510

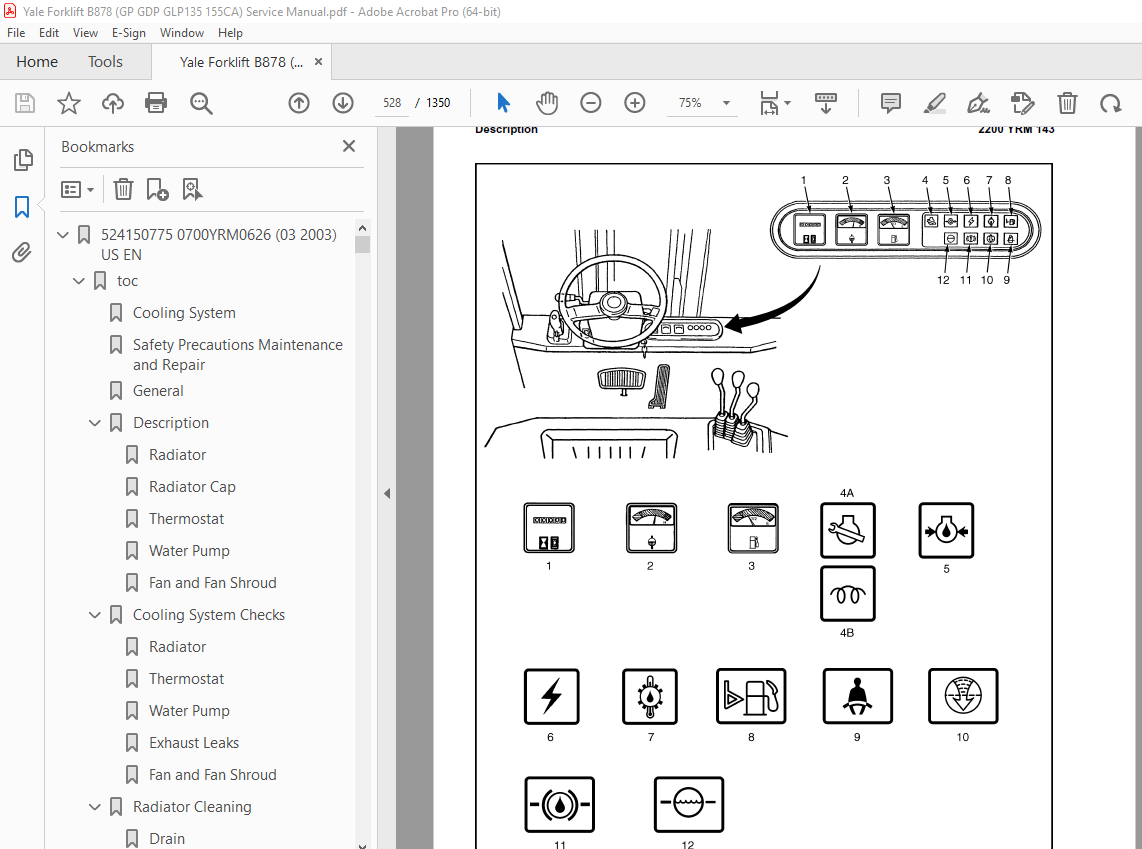

524185165 2200YRM0143 (02 2007) US EN 515

toc 515

Instrument Panel Indicators and Senders 515

Safety Precautions Maintenance and Repair 516

General 519

Description 520

Internal Combustion Engine Trucks 520

Instrument Cluster Panels at Base of Steering Column, Descriptio 525

Trucks With Instrument Cluster Display Panels, Description 526

Electric Lift Trucks 529

Battery Gauge With Lift Interrupt (Curtis 933/1 and 933/4 Models 530

Battery Gauge With Lift Interrupt and Brush Wear Indicator (GE), 530

EV-100LX Motor Controller Display Panel (ITW), Description 531

Adjustments – General 532

Replacement – General Information 532

Internal Combustion Engine Display Panel Replacement 532

Display Panels Mounted at Base of Steering Column 532

Remove 532

Install 534

Instrument Cluster Display Panels Mounted on Cowl 534

Remove and Install 534

Inner Components, Replace 534

Electric Truck Display Panel Replacement 536

GE and Curtis 933/1 and 933/4 Battery Gauges 536

Controller for Battery Indicator, Replace 536

ITW Display Panel, Replace 536

Remove 536

Sender Replacement 540

Fuel Level Sender 540

Pressure and Temperature Sender 540

Seat Sensor, Operator Presence System (OPS) 541

Remove 541

Install 541

Operator Presence System Module Replacement 541

Remove 541

Install 543

Specifications 544

Meter Specifications 544

Sender Specifications 545

Troubleshooting 546

Meter 546

Troubleshooting for Operator Presence System 547

tables 515

Table 1 Troubleshooting Procedure for Operator Presence Module 547

524185167 4000YRM0329 (09 2010) US EN 553

toc 553

Masts 553

Safety Precautions Maintenance and Repair 554

General 557

Description and Operation 557

General 557

Safety Procedures When Working Near Mast 558

Two-Stage Mast 560

Three-Stage Mast 561

Carriage Repair 562

Remove 562

Sideshift Carriage, Disassemble 564

Sideshift Carriage, Assemble 566

Install 566

Two-Stage Mast Repair 567

Remove 567

Disassemble 569

Clean and Inspect 569

Assemble 570

Install 571

Three-Stage Mast Repair 572

Remove 572

Disassemble 572

Clean and Inspect 573

Assemble 573

Install 574

Mast Operation Check 575

Lift and Tilt System Leaks Check 575

Lift System 575

Tilt System 576

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment 576

Lift Chain Adjustments 577

Mast Adjustments 579

Carriage Adjustment 581

Troubleshooting 582

tables 553

Table 1 Mast Parts Weight 567

Table 2 Hook-Type Carriage Chain Adjustment 578

Table 3 Pin-Type Carriage Chain Adjustment 578

524185168 8000YRM0331 (09 2003) US EN 587

toc 587

Capacities and Specifications 587

Safety Precautions Maintenance and Repair 588

Lift Truck Weights 591

Capacities 591

Tire Sizes 592

Tire Pressure 592

Electrical System 592

Wheel Nut Torque 592

Engine Specifications 593

Hydraulic System 593

Mast Speeds 594

Transmission Oil Pressures 594

Torque Specifications 595

Engine – GM 4 3L V-6 595

Engine – Perkins 1004 4 595

Clutch 595

Manual Transmission 595

Powershift Transmission 595

Speed Reducer 596

Drive Axle 596

Steering System 596

Brake System 596

Hydraulic System 596

Tilt Cylinder 596

Mast 596

524185169 8000YRM0341 (06 2009) US EN 599

toc 599

Periodic Maintenance 599

Safety Precautions Maintenance and Repair 600

General 605

Serial Number Data 605

How to Move Disabled Truck 605

How to Tow Lift Truck 605

How to Put Lift Truck on Blocks 606

How to Raise Drive Tires 606

How to Raise Steering Tires 606

Maintenance Schedule 607

Maintenance Procedures Every 8 Hours or Daily 618

How to Make Checks With Engine Stopped 618

Hydraulic System Oil 618

Engine Oil 619

Drive Belts 619

Intake Manifold Rubber Cap 620

Cooling System 620

Air Filter 620

Fuel System 621

Primary Fuel Filter, Diesel Engine 621

Battery 621

Tires and Wheels 622

Forks 622

Adjust 622

Remove and Install 624

Forks, Mast, and Lift Chains, Inspect 625

Operator Restraint System 626

Automatic Locking Retractor (ALR) 626

Emergency Locking Retractor (ELR) 626

Safety Labels 627

How to Make Checks With Engine Running 628

Gauges, Lights, Horn, and Fuses 628

Oil Level, Powershift Transmission 629

Oil Level, Oil Clutch System, GP/GLP/GDP070-110LG/MG 630

Control Levers and Pedals 630

Lift System Operation 630

Inching/Brake Pedal 630

Service Brakes 630

Parking Brake 631

Steering System 631

Maintenance Procedures Every 250 Hours or 6 Weeks 631

Engine Oil and Filter, GM V-6 Engine 631

Lift Chains, Lubrication 631

Drive Shafts 631

Mast Lubrication 632

Crankcase Breather, GM V-6 632

Air Filter, GM V-6 EPA Compliant Engine 632

Maintenance Procedures Every 350 Hours or 2 Months 633

Drive Belts 633

Perkins Diesel Engine 633

GM V-6 Engine (Early Models) 634

GM V-6 Engine (Late Models) 634

Brake Fluid 636

Lift Chains Wear Check 636

Forks Wear and Damage Check 636

Steering Axle Lubrication 636

Fuel System, Checks and Adjustments 637

Diesel Fuel System 637

LPG Carburetor (Early Models) 637

Gasoline Carburetor (Early Models) 638

Fuel Injection (Late Models) 638

Hydraulic Tank Breather 638

Cooling System, Clean Debris from Radiator Core 638

Maintenance Procedures Every 500 Hours or 3 Months 639

Engine Oil and Filter, Perkins Diesel Engine 639

Crankcase Breather, Perkins Diesel Engine 639

PCV Valve, GM V-6 639

Maintenance Procedures Every 1000 Hours or 6 Months 639

Manifold Heat Valve, GM V-6 (Early Models) 639

Ignition System, GM V-6 639

Valve Clearance Adjustment 639

Fuel Filter, Replace (Diesel Engine) 640

Fuel System Air Removal (Perkins 1004-4 Diesel Engine) 640

Fuel Injection Pump With Vent Tube 640

Fuel Injection Pump With Vent Screw 641

Oil Level Check in Transmission 643

Manual Transmission, GP/GLP/GDP070-110LG/MG 643

Speed Reducer for Powershift Transmission, GP/GLP/GDP070-110LG/M 643

Manual Transmission, GDP60-70CA (GP/GLP/GDP135-155CA) 643

Differential and Drive Axle for Powershift Transmission, GDP60-7 643

Differential, Speed Reducer, and Drive Axle for Manual Transmiss 643

Control Levers and Pedals, Lubricate 643

Crankcase Breather, Replace 643

Cooling System, GM V-6 EPA Compliant Engine 643

Spark Plug Replacement 644

Remove 644

Install 644

LPG Fuel Filter GM V-6 EPA Compliant Engine, Replace 644

Inspect Engine Electrical System, Connectors, and FCVS Connectio 645

Maintenance Procedures Every 2000 Hours or Yearly 646

Hydraulic System 646

Hydraulic Oil and Filter, GP/GLP/GDP070-110LG/MG, Replace 646

Hydraulic Oil and Filter, GDP60-70CA (GP/GLP/GDP135-155CA), Repl 646

Oil Change and Oil Filter Replacement, Powershift Transmission, 646

Oil Change, Manual Transmission, GP/GLP/GDP070-110LG/MG 647

Oil Change, Manual Transmission, GDP60-70CA (GP/GLP/GDP135-155CA 647

Oil Change, Speed Reducer, Powershift Transmission, GP/GLP/GDP07 647

Oil and Filter Change, Oil Clutch System, GP/GLP/GDP070-110LG/MG 647

Oil Change, Differential and Drive Axle, Powershift Transmission 647

Oil Change, Differential, Speed Reducer, and Drive Axle, Manual 648

Cooling System 648

PCV Valve, GM V-6 648

Service Brakes 648

LPG Filter, Replace 649

Gasoline Fuel Filter, Replace 649

Hood Latch Check, GP/GLP/GDP070-110LG/MG 649

Air Filter Element, GM V-6 EPA Compliant Engine 650

Oxygen Sensor GM V-6 EPA Compliant Engine 650

Inspect Low Pressure Regulator (LPR) for Oil Buildup and Leaks 650

Check Throttle Shaft for Sticking 651

Inspect Exhaust Manifold and Piping for Leaks 651

Test LPG/GAS Regulator Pressure 651

Safety Procedures When Working Near Mast 651

Lift Chain Adjustments 654

Fuel Injectors Repair 656

Lift and Tilt System Leak Check 656

Lift Cylinders, Leak Check 656

Tilt Cylinders, Leak Check 657

Welding Repairs 657

Overhead Guard Changes 658

Wheel and Tire Replacement 659

Remove Wheels From Lift Truck 659

Remove Wheels From Tire 659

Remove Tire From Two-Piece Wheel 660

Remove Tire From Three- and Four-Piece Wheels 662

Install Wheel in Tire 664

Install Three- or Four-Piece Wheel in Tire 664

Install Two-Piece Wheel in Tire 666

Add Air to Pneumatic Tires 667

Wheels, Install 667

Solid Rubber Tires Repair 668

Wheel, Tire Remove 668

Wheel, Tire Install 670

SIT Tire, Change for GDP60-70CA (A878, and B878), and GP/GLP/GDP 672

Remove SIT Solid Tire From Wheel 672

Install SIT Solid Tire on Wheel 673

Adhesives and Sealants 674

Hydraulic Oil, Lubricant, and Coolant Specifications 674

tables 599

Table 1 Maintenance Schedule 608

Table 2 Hook-Type Carriage Chain Adjustment 654

Table 3 Pin-Type Carriage Chain Adjustment 655

524185171 8000YRM0519 (06 2007) US EN 677

toc 677

Diagrams 677

Safety Precautions Maintenance and Repair 678

524201517 0600YRM1070 (06 2007) US EN 755

toc 755

Perkins Diesel Engines 755

Safety Precautions Maintenance and Repair 756

General 763

General Safety Rules 763

Description 764

Engine Serial Number Codes 766

Engine Data 766

Engine Removal and Installation 767

Cylinder Head Assembly Repair 768

Engine Breather 768

Remove 768

Install 768

Valve Cover 769

Remove 769

Install 769

Rocker Arm Assembly 770

Remove 770

Disassemble 770

Inspect 771

Assemble 771

Install 771

Valve Clearance Adjustments 772

Valve Springs 772

Cylinder Head Assembly 773

Remove 773

Inspect 774

Install 775

Valves and Valve Springs 777

Remove 777

Inspect 778

Install 778

Valve Guides 778

Inspect 778

Remove 779

Install 779

Valve Seats 780

Inspect 780

Repair 780

New Valve Seats, Install 781

Piston and Connecting Rod Assemblies Repair 782

General 782

Rod Bearings 782

Remove 782

Install 783

Piston and Connecting Rod Assembly 784

Service Note 784

Remove 784

Disassemble 784

Inspect 784

How to Select Correct Replacements 786

Assemble 786

Install 787

Piston Cooling Jets 789

Remove 789

Install 789

Crankshaft Assembly Repair 790

General 790

Crankshaft Pulley 790

Remove 790

Inspect 790

Install 790

Rear Oil Seal 791

Remove 791

Install 791

Crankshaft Flange Wear Sleeve 793

Remove 793

Install 793

Main Bearings 794

Remove 794

Inspect 794

Install 794

Thrust Washers 795

Crankshaft Axle Movement, Check 795

Remove 796

Install 796

Crankshaft 797

Remove 797

Inspect 797

Install 797

Crankshaft Timing Ring 799

Remove 799

Install 799

Flywheel 800

Remove 800

Ring Gear, Replace 800

Install 800

Flywheel Housing 801

Remove 801

Install 801

Timing Case and Timing Gears Repair 802

General 802

Timing Case Cover 802

Remove 802

Install 802

Front Oil Seal 803

Remove, With Timing Case Installed 803

Install, With Timing Case Installed 803

Remove, With Timing Case Removed 804

Install, With Timing Case Removed 804

Crankshaft Pulley Wear Sleeve, Install 805

Fuel Pump Gear 805

Remove 805

Install 807

Idler Gear and Hub 808

Remove 808

Disassemble 808

Standard Idler Gear and Hub Assembly 808

Heavy Duty Idler Gear and Hub Assembly 809

Assemble 809

Standard Idler Gear and Hub Assembly 809

Heavy Duty Idler Gear and Hub Assembly 809

Install 810

Camshaft Gear 811

Remove 811

Install 811

Crankshaft Gear 811

Remove 811

Install 811

Timing Case 812

Remove 812

Install 813

Power Take-Off (PTO) Adaptor 814

Remove 814

Disassemble 814

Assemble 815

Install 815

Camshaft and Tappets 815

Remove 815

Install 816

Cylinder Block Assembly Repair 816

General 816

Cylinder Block 816

Disassemble 816

Inspect 817

Assemble 817

Cylinder Bore 817

Inspect 817

Cylinder Liner Condition Check 817

Engine Timing 818

General 818

How to Set Number One Piston to TDC on Compression Stroke 818

Fuel Injection Pump Timing, Check 819

Fuel Injection Pump Timing, Adjust 820

Lubrication System Repair 822

General 822

Oil Filter, Replace 822

Oil Filter Head 823

Remove 823

Install 823

Oil Sump 823

Remove 823

Install 824

Oil Pump 825

Remove 825

Inspect 825

Install 826

Oil Strainer and Suction Pipe 826

Remove 826

Install 826

Relief Valve 827

Remove 827

Install 827

Dipstick Tube 827

Remove and Install 827

Fuel System Repair 828

General 828

Cold Start Advance Unit (KSB) 828

Typical Fuel System 830

Fuel Filter 831

Remove 831

Install 831

Fuel Injectors 832

Remove 832

Install 833

Fuel System Air Removal 834

Bosch EVPE Fuel Injection Pump 834

General 834

Remove 835

Install 836

Cooling System Repair 836

General 836

Thermostat 838

Remove 838

Install 838

Test 838

Coolant Pump 838

Remove 838

Disassemble 839

Assemble 840

Install 841

Fan 842

Remove and Install 842

Fan Drive 842

Remove 842

Install 842

Oil Cooler 842

Remove 842

Disassemble and Assemble 843

Install 843

Coolant Bypass Hose 843

Removal 843

Install 843

Electrical Equipment Repair 844

Drive Belt 844

Check 844

Adjust 844

Remove 844

Install 844

Alternator 845

Remove 845

Install 845

Fault Diagnosis 845

Normal Operation: 845

If the Warning Lamp is Not Illuminated When the Ignition Switch 846

If the Warning Light Continues to be Illuminated When the Altern 846

Starter Motor 847

Remove 847

Install 847

Test 847

Starting Aid 847

Remove 847

Install 848

Check 848

Power Supply Continuity 848

Operation 848

Pressure Sensor 849

Remove 849

Install 850

Temperature Sensor 850

Remove 850

Install 851

Engine Specifications 851

Cylinder Head Assembly 851

Piston and Connecting Rods 854

Crankshaft Assembly 856

Crankshaft Overhaul 856

Timing Case and Drive Assembly 858

Engine Block Assembly 859

Lubrication System 860

Fuel System 860

Cooling System 861

Flywheel and Housing 862

Electrical Equipment 862

Torque Specifications 862

Special Torque Specifications 863

Cylinder Head Assembly 863

Piston and Connecting Rod Assemblies 863

Crankshaft Assembly 863

Timing Case and Drive Assembly 863

Cylinder block 863

Fuel System 863

Lubrication System 863

Cooling System 864

Flywheel and Housing 864

Electrical Equipment 864

Special Tools 864

Troubleshooting 868

tables 755

Table 1 Cylinder Head 851

Table 2 Valve Guides 852

Table 3 Inlet Valves 852

Table 4 Exhaust Valves 853

Table 5 Valve Springs 854

Table 6 Tappets 854

Table 7 Rocker Arm Shaft 854

Table 8 Rocker Arms and Bushings 854

Table 9 Pistons 854

Table 10 Piston Rings 854

Table 11 Piston Pins 855

Table 12 Connecting Rods 855

Table 13 Small End Bushings 855

Table 14 Connecting Rod Bearings 856

Table 15 Piston Cooling Jets 856

Table 16 Crankshaft Overhaul Specifications 857

Table 17 Maximum Variation (Run-out) 858

Table 18 Camshaft 858

Table 19 Camshaft Thrust Washer 858

Table 20 Camshaft Gear 858

Table 21 Gear for Fuel Pump 858

Table 22 Crankshaft Gear 858

Table 23 Idler Gear and Hub 859

Table 24 Timing Gear Backlash Values 859

Table 25 Cylinder Block 859

Table 26 Oil Pump 860

Table 27 Idler Gear for Oil Pump 860

Table 28 Relief Valve 860

Table 29 Oil Filter 860

Table 30 Bosch Fuel Injection Pump 860

Table 31 Fuel Injector Settings 860

Table 32 Fuel Pump 861

Table 33 Fuel Filter 861

Table 34 Coolant Pump 861

Table 35 Thermostat 861

Table 36 Fan Drive Housing 861

Table 37 Limits for Flywheel Run Out and Alignment (Total Indic 862

Table 38 Alternator 862

Table 39 Starter Motor 862

Table 40 Starting Aids 862

Table 41 List of Possible Causes 869

524208004 0900YRM1088 (05 2006) US EN 873

toc 873

Electronic Controlled LPG/Gasoline Fuel System 873

Safety Precautions Maintenance and Repair 874

General 879

Fuel System Warnings and Cautions 879

Glossary 880

Description and Operation of LPG Fuel System 884

Propane Fuel System 884

LPG Fuel Tank 886

Service Line 886

Fuel Filter 886

Low Pressure Lock-Off (LPL) 886

Low Pressure Regulator (LPR) 887

Air Fuel Mixer 887

Throttle Control Device 888

Drive By Cable 888

Three-Way Catalytic (TWC) Muffler 889

Electronic Control Module (ECM) 889

Heated Exhaust Gas Oxygen (HEGO) Sensor 890

Description and Operation of Gasoline Fuel System 892

Gasoline Fuel System Throttle Body Injection (TBI), 3 0L Engine 892

Gasoline Multi-Point Fuel Injection (MPFI) System, 4 3L Only 892

Gasoline Fuel Storage Tank 892

Gasoline Fuel Pump 892

Fuel Filter 892

Fuel Pressure Regulator, 3 0L Only 895

Fuel Rail and Pressure Regulator, 4 3L Only 896

Fuel Injector 896

Throttle Control Device 896

Drive By Cable 896

Three-Way Catalytic Muffler 897

Electronic Control Module (ECM) 897

Heated Exhaust Gas Oxygen (HEGO) Sensor 899

LPG Fuel System Repair 899

Propane Fuel System Pressure Relief 899

Propane Fuel System Leak Test 899

Propane Fuel Filter Replacement 900

Remove 900

Install 900

Low Pressure Lock-Off (LPL) Replacement 900

Remove 900

Install 900

Pressure Trim Valve (PTV) Replacement 902

Remove 902

Install 902

Low Pressure Regulator 902

Remove 902

Install 902

Fuel Trim Valve (FTV) Solenoid Replacement 903

Remove 903

Install 903

Temperature Manifold Absolute Pressure (TMAP) 903

Remove 903

Install 903

Throttle Body Replacement 905

Remove 905

Install 905

Mixer Replacement 907

Remove 907

Install 907

Coolant Hose Replacement 907

Remove 907

Install 908

Vapor Hose Replacement 908

Remove 908

Install 908

Balance Line Hose Replacement 908

Remove 908

Install 908

PTV Hose Replacement 908

Remove 908

Install 908

FTV Hose Replacement 909

Remove 909

Install 909

Throttle Position Sensor (TPS) Replacement 909

Foot Pedal Position (FPP) Sensor Replacement 911

Electronic Control Module (ECM) Replacement 914

Remove 914

Install 914

Heated Exhaust Gas Oxygen (HEGO) Sensor Replacement 914

Remove 914

Install 915

Three-Way Catalytic Muffler (TWC) Replacement 915

Remove 915

Install 915

Restricted Exhaust System Diagnosis 915

Exhaust System Description 915

Tools Required 915

Diagnostic Tool 915

Check at Heated Exhaust Gas Oxygen Sensor (HEGO) 915

Gasoline Fuel System Repair 916

Gasoline MPFI and TBI Fuel System Pressure Relief 916

Gasoline Fuel System Leak Test 917

Throttle Body Injector (TBI) Assembly Replacement, 3 0L Only 917

Remove 917

Install 917

Throttle Body Assembly Replacement, 3 0L Only 919

Remove 919

Install 919

Throttle Body Assembly Replacement, 4 3L Only 920

Remove 920

Install 920

Fuel Rail Replacement, Gasoline 4 3L Only 921

Remove 921

Install 921

Injector Replacement, Gasoline 4 3L Only 921

Remove 921

Install 921

Injector Replacement, Gasoline 3 0L Only 923

Remove 923

Install 923

Temperature Manifold Absolute Pressure (TMAP) Replacement 923

Remove 923

Install 923

Throttle Position Sensor (TPS) Replacement 923

Foot Pedal Position (FPP) Sensor Replacement 926

Electronic Control Module (ECM) Replacement 929

Remove 929

Install 929

Heated Exhaust Gas Oxygen (HEGO) Sensor Replacement 930

Remove 930

Install 930

Three-Way Catalytic Muffler (TWC) Replacement 930

Remove 930

Install 930

Restricted Exhaust System Diagnosis 930

Exhaust System Description 930

Tools Required 930

Diagnostic Tool 930

Check at Heated Exhaust Gas Oxygen Sensor (HEGO) 931

LPG System Diagnosis 931

Fuel System Description 931

Diagnostic Aids 932

Tools Required 932

Duty Cycle Monitoring Tool 932

Diagnostic Tool 932

Pressure Gauges 932

Test Description 932

Gasoline System Diagnosis 940

Fuel System Description, 3 0L Only 940

Fuel System Description, 4 3L Only 940

Diagnostic Aids 941

Tools Required 941

Diagnostic Tool 941

Test Description 941

LPG Symptom Diagnosis 948

Gasoline Symptom Diagnosis 962

Wire Harness Repair 973

On Vehicle Service Wiring Harness Repair 973

Connectors and Terminals 973

Twisted/Shielded Cable Repair 974

Twisted Leads Repair 975

Micro-Pack 976

Metri-Pack 976

Remove 976

Weather-Pack 978

Weather-Pack Terminal Repair 979

tables 873

Table 1 TPS Replacement Procedure 909

Table 2 FPP Replacement Procedure 912

Table 3 TPS Replacement Procedure 924

Table 4 FPP Replacement Procedure 927

Table 5 LPG Fuel System Diagnosis 932

Table 6 Fuel Control Diagnosis 936

Table 7 Gasoline Fuel System Diagnosis, 3 0L Only 942

Table 8 Gasoline Fuel System Diagnosis, 4 3L Only 945

Table 9 Preliminary Checks 948

Table 10 Intermittent 949

Table 11 No Start 950

Table 12 Hard Start 952

Table 13 Cuts Out or Misses 953

Table 14 Hesitation, Sag, or Stumble 954

Table 15 Backfire 955

Table 16 Lack of Power, Sluggishness, or Sponginess 956

Table 17 Poor Fuel Economy 957

Table 18 Rough, Unstable, Incorrect Idle, or Stalling 959

Table 19 Surges or Chuggles 961

Table 20 Preliminary Checks 962

Table 21 Intermittent 963

Table 22 No Start 964

Table 23 Hard Start 965

Table 24 Cuts Out or Misses 966

Table 25 Hesitation, Sag, or Stumble 967

Table 26 Backfire 968

Table 27 Lack of Power, Sluggishness, or Sponginess 969

Table 28 Poor Fuel Economy 970

Table 29 Rough, Unstable, Incorrect Idle, or Stalling 971

Table 30 Surges or Chuggles 972

524208009 2200YRM1090 (04 2005) US EN 983

toc 983

Electronic Control Module (ECM) Diagnostic Troubleshooting 983

Safety Precautions Maintenance and Repair 984

General 993

Description of ECM Based Diagnostics 993

Definition of Terms 993

Diagnostics Overview of the Spectrum Fuel System 993

Malfunction Indicator Lamp (MIL) 993

Spectrum Diagnostic Trouble Codes (DTC) 994

Using a Laptop Computer to Diagnose the Spectrum System 994

Installing the Spectrum Diagnostic Software 994

Connecting a Laptop Computer to the Spectrum System 994

Diagnostic Communication Error 995

Diagnostic Trouble Codes 995

Checking Diagnostic Trouble Codes 996

Clearing Diagnostic Trouble Codes 996

DATA Stream 996

Reading Sensor and Actuator Values 996

Graphing and Data Logging 997

Ignition System Test 998

Disabling Ignition Outputs 998

Injector Test 999

Disabling Injectors 999

Throttle Test 1000

Using a Diagnostic Jumper to Diagnose the ECI System 1001

On-Board Diagnostics System Check/Malfunction Indicator Lamp 1002

Circuit Description 1002

Preliminary and Intermittent Checks 1005

GM 3 0L Wiring Schematics and Connectors 1007

GM 3 0L Diagnostic Trouble Codes 1021

DTC 111 – IAT High Voltage Motorola® TMAP 1021

Circuit Description 1021

Conditions for Setting the DTC 1021

DTC 112 – IAT Low Voltage Motorola® TMAP 1024

Circuit Description 1024

Conditions for Setting the DTC 1024

DTC 113 – IAT Higher Than Expected 1 Motorola® TMAP 1027

Circuit Description 1027

Conditions for Setting the DTC 1027

Diagnostic Aids 1027

DTC 114 – IAT Higher Than Expected 2 Motorola® TMAP 1028

Circuit Description 1028

Conditions for Setting the DTC 1028

Diagnostic Aids 1028

DTC 115 – Oil Pressure Low 1029

Circuit Description 1029

Conditions for Setting the DTC 1029

DTC 121 – ECT Voltage High 1032

Circuit Description 1032

Conditions for Setting the DTC 1033

DTC 122 – ECT Voltage Low 1036

Circuit Description 1036

Conditions for Setting the DTC 1036

DTC 123 – ECT Higher Than Expected 1 1038

Circuit Description 1038

Conditions for Setting the DTC 1038

DTC 124 – ECT Higher Than Expected 2 1040

Circuit Description 1040

Conditions for Setting the DTC 1040

DTC 131 – MAP High Pressure Motorola® TMAP 1042

Circuit Description 1042

Conditions for Setting the DTC 1042

Diagnostic Aids 1042

DTC 132 – MAP Low Voltage Motorola® TMAP 1044

Circuit Description 1044

Conditions for Setting the DTC 1044

DTC 134 – BP High Pressure Motorola® TMAP 1048

Circuit Description 1048

Conditions for Setting the DTC 1048

DTC 135 – BP Low Pressure Motorola® TMAP 1050

Circuit Description 1050

Conditions for Setting the DTC 1050

DTC 142 – Crank Sync Noise 1054

Circuit Description 1054

Conditions for setting the DTC 1054

DTC 143 – Never Crank Synced At Start 1057

Circuit Description 1057

Conditions for Setting the DTC 1057

DTC 144 – Camshaft Sensor Loss 1060

Circuit Description 1060

Conditions for Setting the DTC 1060

DTC 145 – Camshaft Sensor Noise 1063

Circuit Description 1063

Conditions for Setting the DTC 1063

DTC 211 – Closed Loop Multiplier High (LPG) 1066

Circuit Description 1066

Conditions for Setting the DTC 1066

Diagnostic Aids 1066

DTC 212 – HO 2 S Open/Inactive 1068

Circuit Description 1068

Conditions for Setting the DTC 1068

DTC 221 – Closed Loop Multiplier High (Gasoline) 1072

Circuit Description 1072

Conditions for Setting the DTC 1072

Diagnostic Aids 1073

DTC 222 – Closed Loop Multiplier Low (Gasoline) 1074

Circuit Description 1074

Conditions for Setting the DTC 1074

Diagnostic Aids 1074

DTC 224 – Closed Loop Multiplier Low (LPG) 1076

Circuit Description 1076

Conditions for Setting the DTC 1076

Diagnostic Aids 1077

DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1078

Circuit Description 1078

Conditions for Setting the DTC 1078

Diagnostic Aids 1079

DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1082

Circuit Description 1082

Conditions for Setting the DTC 1082

Diagnostic Aids 1082

DTC 243 – Adaptive Learn High (LPG) 1084

Circuit Description 1084

Conditions for Setting the DTC 1084

Diagnostic Aids 1084

DTC 244 – Adaptive Learn Low (LPG) 1088

Circuit Description 1088

Conditions for Setting the DTC 1088

Diagnostic Aids 1088

DTC 261 – System Voltage High 1090

Circuit Description 1090

Conditions for Setting the DTC 1090

DTC 262 – System Voltage Low 1092

Circuit Description 1092

Conditions for Setting the DTC 1092

DTC 411 – Injector Driver 1 Open 1095

Circuit Description 1095

Conditions for Setting the DTC 1095

DTC 412 – Injector Driver 1 Shorted 1098

Circuit Description 1098

Conditions for Setting the DTC 1098

DTC 511 – COP Failure 1101

Circuit Description 1101

Conditions for Setting the DTC 1101

DTC 512 – Invalid Interrupt 1103

Circuit Description 1103

Conditions for Setting the DTC 1103

DTC 513 – A/D Loss 1105

Circuit Description 1105

Conditions for Setting the DTC 1105

DTC 514 – RTI 1 Loss 1107

Circuit Description 1107

Conditions for Setting the DTC 1107

DTC 515 – Flash Checksum Invalid 1109

Circuit Description 1109

Conditions for Setting the DTC 1109

DTC 516 – Ram Failure 1111

Circuit Description 1111

Conditions for Setting the DTC 1111

DTC 531 – External 5V Ref Lower Than Expected 1113

Circuit Description 1113

Conditions for Setting the DTC 1113

DTC 532 – External 5V Ref Higher Than Expected 1116

Circuit Description 1116

Conditions for Setting the DTC 1116

DTC 555 – RTI 2 Loss 1118

Circuit Description 1118

Conditions for Setting the DTC 1118

DTC 556 – RTI 3 Loss 1120

Circuit Description 1120

Conditions for Setting the DTC 1120

DTC 611 – FPP High Voltage 1122

Circuit Description 1122

Conditions for Setting the DTC 1122

DTC 612 – FPP Low Voltage 1125

Circuit Description 1125

Conditions for Setting the DTC 1125

DTC 631 – TPS1 Signal Voltage High 1129

Circuit Description 1129

Conditions for Setting the DTC 1129

DTC 632 – TPS1 Signal Voltage Low 1132

Circuit Description 1132

Conditions for Setting the DTC 1132

DTC 638 – Throttle Unable To Close 1134

Circuit Description 1134

Conditions for Setting the DTC 1134

Diagnostic Aids 1134

DTC 651 – Maximum Govern Speed Override 1138

Circuit Description 1138

Conditions for Setting the DTC 1138

Diagnostic Aids 1138

DTC 652 – Fuel Rev Limit 1140

Circuit Description 1140

Conditions for Setting the DTC 1140

Diagnostic Aids 1140

DTC 653 – Spark Rev Limit 1143

Circuit Description 1143

Conditions for Setting the DTC 1143

Diagnostic Aids 1143

GM 4 3L Wiring Schematics and Connectors 1146

GM 4 3L Diagnostic Trouble Codes 1163

DTC 111 – IAT High Voltage Bosch® TMAP 1163

Circuit Description 1163

Conditions for Setting the DTC 1163

DTC 111 – IAT High Voltage Motorola® TMAP 1166

Circuit Description 1166

Conditions for Setting the DTC 1166

DTC 112 – IAT Low Voltage Bosch® TMap 1168

Circuit Description 1168

Conditions for Setting the DTC 1168

DTC 112 – IAT Low Voltage Motorola® TMAP 1171

Circuit Description 1171

Conditions for Setting the DTC 1171

DTC 113 – IAT Higher Than Expected 1 Bosch® TMAP 1174

Circuit Description 1174

Conditions for Setting the DTC 1174

Diagnostic Aids 1174

DTC 113 – IAT Higher Than Expected 1 Motorola® TMAP 1175

Circuit Description 1175

Conditions for Setting the DTC 1175

Diagnostic Aids 1175

DTC 114 – IAT Higher Than Expected 2 Bosch® TMAP€ 1176

Circuit Description 1176

Conditions for Setting the DTC 1176

Diagnostic Aids 1176

DTC 114 – IAT Higher Than Expected 2 Motorola® TMAP 1177

Circuit Description 1177

Conditions for Setting the DTC 1177

Diagnostic Aids 1177

DTC 115 – Oil Pressure Low 1178

Circuit Description 1178

Conditions for Setting the DTC 1178

DTC 121 – ECT Voltage High 1181

Circuit Description 1181

Conditions for Setting the DTC 1182

DTC 122 – ECT Voltage Low 1184

Circuit Description 1184

Conditions for Setting the DTC 1184

DTC 123 – ECT Higher Than Expected 1 1187

Circuit Description 1187

Conditions for Setting the DTC 1187

DTC 124 – ECT Higher Than Expected 2 1189

Circuit Description 1189

Conditions for Setting the DTC 1189

DTC 131 – MAP High Pressure Bosch® TMAP 1190

Circuit Description 1190

Conditions for Setting the DTC 1190

Diagnostic Aids 1190

DTC 131 – MAP High Pressure Motorola® TMAP 1194

Circuit Description 1194

Conditions for Setting the DTC 1194

Diagnostic Aids 1194

DTC 132 – MAP Low Voltage Bosch® TMAP 1197

Circuit Description 1197

Conditions for Setting the DTC 1197

DTC 132 – MAP Low Voltage Motorola® TMAP 1200

Circuit Description 1200

Conditions for Setting the DTC 1200

DTC 134 – BP High Pressure Bosch® TMAP 1204

Circuit Description 1204

Conditions for Setting the DTC 1204

DTC 134 – BP High Pressure Motorola® TMAP 1206

Circuit Description 1206

Conditions for Setting the DTC 1206

DTC 135 – BP Low Pressure Bosch® TMAP 1208

Circuit Description 1208

Conditions for Setting the DTC 1208

DTC 135 – BP Low Pressure Motorola® TMAP 1212

Circuit Description 1212

Conditions for Setting the DTC 1212

DTC 142 – Crank Sync Noise 1216

Circuit Description 1216

Conditions for setting the DTC 1216

DTC 143 – Never Crank Synced At Start 1219

Circuit Description 1219

Conditions for Setting the DTC 1219

DTC 144 – Camshaft Sensor Loss 1222

Circuit Description 1222

Conditions for Setting the DTC 1222

DTC 145 – Camshaft Sensor Noise 1225

Circuit Description 1225

Conditions for Setting the DTC 1225

DTC 211 – Closed Loop Multiplier High (LPG) 1228

Circuit Description 1228

Conditions for Setting the DTC 1228

Diagnostic Aids 1228

DTC 212 – HO 2 S Open/Inactive 1230

Circuit Description 1230

Conditions for Setting the DTC 1230

DTC 221 – Closed Loop Multiplier High (Gasoline) 1234

Circuit Description 1234

Conditions for Setting the DTC 1234

Diagnostic Aids 1234

DTC 222 – Closed Loop Multiplier Low (Gasoline) 1236

Circuit Description 1236

Conditions for Setting the DTC 1236

Diagnostic Aids 1237

DTC 224 – Closed Loop Multiplier Low (LPG) 1238

Circuit Description 1238

Conditions for Setting the DTC 1238

Diagnostic Aids 1239

DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1240

Circuit Description 1240

Conditions for Setting the DTC 1240

Diagnostic Aids 1241

DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1244

Circuit Description 1244

Conditions for Setting the DTC 1244

Diagnostic Aids 1245

DTC 243 – Adaptive Learn High (LPG) 1247

Circuit Description 1247

Conditions for Setting the DTC 1247

Diagnostic Aids 1248

DTC 244 – Adaptive Learn Low (LPG) 1250

Circuit Description 1250

Conditions for Setting the DTC 1250

Diagnostic Aids 1251

DTC 261 – System Voltage High 1252

Circuit Description 1252

Conditions for Setting the DTC 1252

DTC 262 – System Voltage Low 1254

Circuit Description 1254

Conditions for Setting the DTC 1254

DTC 511 – COP Failure 1257

Circuit Description 1257

Conditions for Setting the DTC 1257

DTC 512 – Invalid Interrupt 1259

Circuit Description 1259

Conditions for Setting the DTC 1259

DTC 513 – A/D Loss 1261

Circuit Description 1261

Conditions for Setting the DTC 1261

DTC 514 – RTI 1 Loss 1263

Circuit Description 1263

Conditions for Setting the DTC 1263

DTC 515 – Flash Checksum Invalid 1265

Circuit Description 1265

Conditions for Setting the DTC 1265

DTC 516 – Ram Failure 1267

Circuit Description 1267

Conditions for Setting the DTC 1267

DTC 531 – External 5V Ref Lower Than Expected 1269

Circuit Description 1269

Conditions for Setting the DTC 1269

DTC 532 – External 5V Ref Higher Than Expected 1272

Circuit Description 1272

Conditions for Setting the DTC 1272

DTC 555 – RTI 2 Loss 1274

Circuit Description 1274

Conditions for Setting the DTC 1274

DTC 556 – RTI 3 Loss 1276

Circuit Description 1276

Conditions for Setting the DTC 1276

DTC 611 – FPP High Voltage 1278

Circuit Description 1278

Conditions for Setting the DTC 1278

DTC 612 – FPP Low Voltage 1282

Circuit Description 1282

Conditions for Setting the DTC 1282

DTC 631 – TPS1 Signal Voltage High 1286

Circuit Description 1286

Conditions for Setting the DTC 1286

DTC 632 – TPS1 Signal Voltage Low 1289

Circuit Description 1289

Conditions for Setting the DTC 1289

DTC 638 – Throttle Unable To Close 1292

Circuit Description 1292

Conditions for Setting the DTC 1292

Diagnostic Aids 1293

DTC 651 – Maximum Govern Speed Override 1295

Circuit Description 1295

Conditions for Setting the DTC 1295

Diagnostic Aids 1295

DTC 652 – Fuel Rev Limit 1298

Circuit Description 1298

Conditions for Setting the DTC 1298

Diagnostic Aids 1298

DTC 653 – Spark Rev Limit 1300

Circuit Description 1300

Conditions for Setting the DTC 1300

Diagnostic Aids 1300

Wire Harness Repair 1303

On Vehicle Service Wiring Harness Repair 1303

Connectors and Terminals 1303

Twisted/Shielded Cable Repair 1304

Twisted Leads Repair 1305

Micro-Pack 1306

Metri-Pack 1306

Remove 1306

Weather-Pack 1308

Weather-Pack Terminal Repair 1308

tables 983

Table 1 OBD System Check 1003

Table 2 Preliminary Checks 1005

Table 3 Intermittent Checks 1006

Table 4 Communication Port C002 1007

Table 5 Coil Connector C003 1007

Table 6 Fuel System Interface C004 1007

Table 7 Oil Pressure Connector C005 1008

Table 8 Distributor Connector C006 1008

Table 9 Magnetic Pickup Connector C007 1008

Table 10 Heated Oxygen Sensor C008 1008

Table 11 Throttle Position Sensor Connector C009 1009

Table 12 Foot Pedal Position Connector C010 1009

Table 13 Governor Motor Connector C011 1009

Table 14 TMAP Connector C012 1009

Table 15 Starter Solenoid C013 1010

Table 16 Engine Coolant Temperature C014 1010

Table 17 Battery Connector C015 1010

Table 18 Alternator Connection C016 1010

Table 19 Battery Connector C017 1010

Table 20 Alternator Connector C018 1011

Table 21 Instrument Panel Connector C019 1011

Table 22 Instrument Panel Connector C020 1011

Table 23 Instrument Panel Connector C021 1012

Table 24 Fuel Trim Valve Connector C022 1012

Table 25 Fuel Lockoff Connector C023 1012

Table 26 Pressure Trim Valve Connector C024 1013

Table 27 Throttle Body Injector Connector C025 1013

Table 28 Relay and Fuse Center 1013

Table 29 DTC 111 – IAT Voltage High (Motorola® TMAP) 1022

Table 30 DTC 112 – IAT Low Voltage (Motorola® TMAP) 1025

Table 31 DTC 115 – Oil Pressure Low 1030

Table 32 Temperature Resistance 1032

Table 33 DTC 121 – ECT VOLTAGE HIGH 1033

Table 34 DTC 122 – ECT Voltage Low 1037

Table 35 DTC 123 – ECT Higher Than Expected 1 1039

Table 36 DTC 124 – ECT Higher Than Expected 2 1041

Table 37 DTC 131 – MAP HIGH PRESSURE (Motorola® TMAP) 1043

Table 38 DTC 132 – MAP Low Voltage (Motorola® TMAP) 1045

Table 39 DTC 134 – BP High Pressure (Motorola® TMAP) 1049

Table 40 DTC 135 – BP Low Pressure (Motorola® TMAP) 1050

Table 41 DTC 142 – Crank Sync Noise 1054

Table 42 DTC 143 – Never Crank Synced At Start 1057

Table 43 DTC 144 – Camshaft Sensor Loss 1060

Table 44 DTC 145 – Camshaft Sensor Noise 1063

Table 45 DTC 211 – Closed Loop Multiplier High (LPG) 1067

Table 46 DTC 212 – HO 2 S Open/Inactive 1069

Table 47 DTC 221 – Closed Loop Multiplier High (Gasoline) 1073

Table 48 DTC 222 – Closed Loop Multiplier Low (Gasoline) 1076

Table 49 DTC 224 – Closed Loop Multiplier Low (LPG) 1078

Table 50 DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1080

Table 51 DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1083

Table 52 DTC 243 – Adaptive Learn High (LPG) 1086

Table 53 DTC 244 – Adaptive Learn Low (LPG) 1089

Table 54 DTC 261 – System Voltage High 1091

Table 55 DTC 262 – System Voltage Low 1093

Table 56 DTC 411 – Injector Driver 1 Open 1096

Table 57 DTC 412 – Injector Driver 1 Shorted 1099

Table 58 DTC 511 – COP Failure 1102

Table 59 DTC 512 – Invalid Interrupt 1104

Table 60 DTC 513 – A/D Loss 1106

Table 61 DTC 514 – RTI 1 Loss 1108

Table 62 DTC 515 – Flash Checksum Invalid 1110

Table 63 DTC 516 – Ram Failure 1112

Table 64 DTC 531 – External 5V Ref Lower Than Expected 1114

Table 65 DTC 532 – External 5 V Ref Higher Than Expected 1116

Table 66 DTC 555 – RTI 2 Loss 1119

Table 67 DTC 556 – RTI 3 Loss 1121

Table 68 DTC 611 – FPP High Voltage 1122

Table 69 DTC 612 – FPP Low Voltage 1126

Table 70 DTC 631 – TPS1 Signal Voltage High 1130

Table 71 DTC 632 – TPS1 Signal Voltage Low 1133

Table 72 DTC 638 – Throttle Unable To Close 1135

Table 73 DTC 651 – Maximum Govern Speed Override 1139

Table 74 DTC 652 – Fuel Rev Limit 1141

Table 75 DTC 653 – Spark Rev Limit 1144

Table 76 Communication Port C002 1146

Table 77 Injector Connector C003 1146

Table 78 Injector Connector C004 1146

Table 79 Oil Pressure Connector C005 1147

Table 80 Throttle Position Sensor 1 Connector C006 1147

Table 81 Foot Pedal Position Connector C006A 1147

Table 82 Coil Connector C007 1147

Table 83 Module Connector C008 1148

Table 84 Crank Sensor Connector C009 1148

Table 85 EGO Sensor Connector C010 1148

Table 86 Cam Connector C011 1148

Table 87 Throttle Connector C012 1149

Table 88 Bosch TMAP Connector C013 (Gasoline Fuel System Only) 1149

Table 89 Motorola TMAP Connector C013 (LPG Fuel System Only) 1149

Table 90 Starter Solenoid Connector C014 1149

Table 91 ECT Connector C015 1150

Table 92 Starter Relay C016 1150

Table 93 Power Relay C017 1150

Table 94 Fuel Pump Relay C018 1150

Table 95 Battery Connector C019 1150

Table 96 Alternator Connector C020 1150

Table 97 Alternator Connector C021 1151

Table 98 Instrument Panel Connector C022 1151

Table 99 Instrument Panel Connector C023 1151

Table 100 Instrument Panel Connector C024 1152

Table 101 Fuel Trim Valve Connector C025 1152

Table 102 Fuel Lockoff Connector C026 1152

Table 103 Pressure Trim Valve Connector C027 1153

Table 104 Injector 1 Connector C028 1153

Table 105 Injector 2 Connector C029 1153

Table 106 Injector 3 Connector C030 1153

Table 107 Injector 4 Connector C031 1154

Table 108 Injector 5 Connector C032 1154

Table 109 Injector 6 Connector C033 1154

Table 110 Relay and Fuse Center 1155

Table 111 DTC 111 – IAT Voltage High (Bosch® TMAP) 1164

Table 112 DTC 111 – IAT Voltage High (Motorola® TMAP) 1167

Table 113 DTC 112 – IAT Low Voltage (Bosch® TMAP) 1169

Table 114 DTC 112 – IAT Low Voltage (Motorola® TMAP) 1172

Table 115 DTC 115 – Oil Pressure Low 1179

Table 116 Temperature Resistance 1181

Table 117 DTC 121 – ECT VOLTAGE HIGH 1182

Table 118 DTC 122 – ECT Voltage Low 1185

Table 119 DTC 123 – ECT Higher Than Expected 1 1188

Table 120 DTC 124 – ECT Higher Than Expected 2 1190

Table 121 DTC 131 – MAP High Pressure (Bosch® TMAP) 1191

Table 122 DTC 131 – MAP HIGH PRESSURE (Motorola® TMAP) 1195

Table 123 DTC 132 – MAP Low Voltage (Bosch® TMAP) 1198

Table 124 DTC 132 – MAP Low Voltage (Motorola® TMAP) 1201

Table 125 DTC 134 – BP High Pressure (Bosch® TMAP) 1205

Table 126 DTC 134 – BP High Pressure (Motorola® TMAP) 1207

Table 127 DTC 135 – BP Low Pressure (Bosch® TMAP) 1208

Table 128 DTC 135 – BP Low Pressure (Motorola® TMAP) 1212

Table 129 DTC 142 – Crank Sync Noise 1216

Table 130 DTC 143 – Never Crank Synced At Start 1219

Table 131 DTC 144 – Camshaft Sensor Loss 1222

Table 132 DTC 145 – Camshaft Sensor Noise 1225

Table 133 DTC 211 – Closed Loop Multiplier High (LPG) 1229

Table 134 DTC 212 – HO 2 S Open/Inactive 1231

Table 135 DTC 221 – Closed Loop Multiplier High (Gasoline) 1235

Table 136 DTC 222 – Closed Loop Multiplier Low (Gasoline) 1238

Table 137 DTC 224 – Closed Loop Multiplier Low (LPG) 1240

Table 138 DTC 241 – Adaptive Lean Fault (High Limit-Gasoline) 1242

Table 139 DTC 242 – Adaptive Rich Fault (Low Limit-Gasoline) 1245

Table 140 DTC 243 – Adaptive Learn High (LPG) 1248

Table 141 DTC 244 – Adaptive Learn Low (LPG) 1251

Table 142 DTC 261 – System Voltage High 1253

Table 143 DTC 262 – System Voltage Low 1255

Table 144 DTC 511 – COP Failure 1258

Table 145 DTC 512 – Invalid Interrupt 1260

Table 146 DTC 513 – A/D Loss 1262

Table 147 DTC 514 – RTI 1 Loss 1264

Table 148 DTC 515 – Flash Checksum Invalid 1266

Table 149 DTC 516 – Ram Failure 1268

Table 150 DTC 531 – External 5V Ref Lower Than Expected 1270

Table 151 DTC 532 – External 5 V Ref Higher Than Expected 1272

Table 152 DTC 555 – RTI 2 Loss 1275

Table 153 DTC 556 – RTI 3 Loss 1277

Table 154 DTC 611 – FPP High Voltage 1279

Table 155 DTC 612 – FPP Low Voltage 1283

Table 156 DTC 631 – TPS1 Signal Voltage High 1287

Table 157 DTC 632 – TPS1 Signal Voltage Low 1290

Table 158 DTC 638 – Throttle Unable To Close 1293

Table 159 DTC 651 – Maximum Govern Speed Override 1296

Table 160 DTC 652 – Fuel Rev Limit 1299

Table 161 DTC 653 – Spark Rev Limit 1301

524208014 2200YRM1097 (03 2020) US EN 1313

Series Code / Model Designation Reference Table 1317

Description 1318

Distributor Ignition (DI) System 1318

Crankshaft Position (CKP) Sensor 1318

Camshaft Position (CMP) Sensor 1318

Ignition Coil and Ignition Control Module (ICM) 1318

Secondary Ignition Components 1318

Spark Plugs and Wires 1319

Spark Plug Wire Inspection 1319

Spark Plug Wire Replacement 1319

Remove 1319

Install 1320

Spark Plug Inspection 1320

Usage 1320

Inspection 1320

Visual Inspection 1322

Spark Plug Replacement 1322

Remove 1322

Install 1322

Distributor Repair 1323

Inspect 1323

Overhaul 1323

Disassemble 1323

Assemble 1326

Replace 1327

Remove 1327

Install Procedure 1 1329

Install Procedure 2 1330

Ignition Coil Replacement 1331

Remove 1331

Install 1331

Ignition Control Module Replacement 1332

Remove 1332

Install 1332

Starter Replacement 1333

Remove 1333

Install 1336

Sensors and Switches 1337

Gas and LPG Trucks 1337

Crankshaft Position (CKP) Sensor 1337

Remove 1337

Install 1337

Camshaft Position (CMP) Sensor 1338

Remove 1338

Install 1340

Oil Pressure Sensor 1340

Remove 1340

Install 1341

Manifold Absolute Pressure (MAP)/Manifold Air Temperature (MAT) Sensor 1342

Remove 1342

Install 1342

Engine Coolant Temperature (ECT) Sensor 1343

Remove 1343

Install 1344

Air Flow Restriction Switch 1344

Remove 1344

Install 1345

Specifications and Special Tools 1346