$41.95

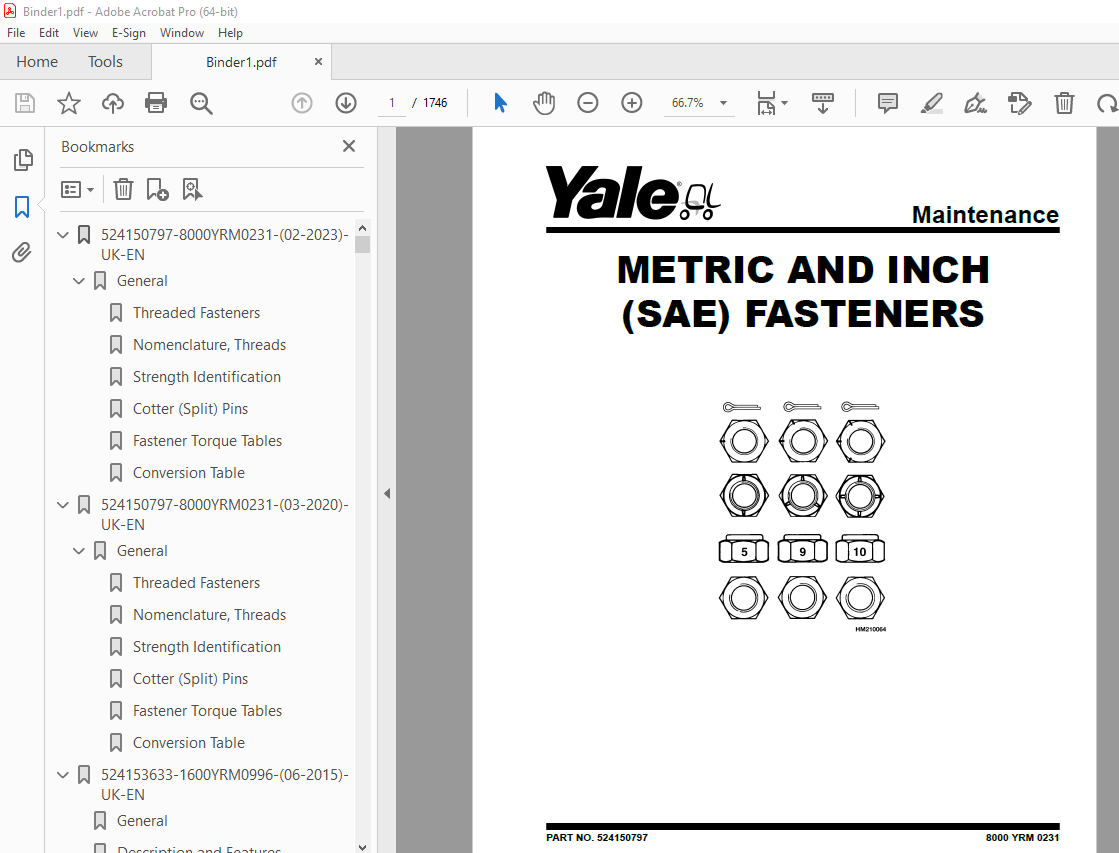

Yale Forklift B883 (ESC030-40AC) Service Manual – PDF DOWNLOAD

Yale Forklift B883 (ESC030-40AC) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift B883 (ESC030-40AC) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1746

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift B883 (ESC030-40AC) Service Manual – PDF DOWNLOAD

524150797-8000YRM0231-(02-2023)-UK-EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524150797-8000YRM0231-(03-2020)-UK-EN 23

General 27

Threaded Fasteners 27

Nomenclature, Threads 27

Strength Identification 28

Cotter (Split) Pins 29

Fastener Torque Tables 34

Conversion Table 36

524153633-1600YRM0996-(06-2015)-UK-EN 43

General 47

Description and Features 47

On-Demand Steering Circuit 47

Description 48

A883 48

B883 / C883

49

Steering Control Handle 50

Remove 50

Install 50

Steering Sensor 50

Test 50

Remove 50

Install 50

Steering Control Unit (SCU) 51

Description 51

Inspect 51

Remove 51

Repair 53

Replace 53

Steering Pump and Motor Assembly 54

Description 54

Inspect 54

Remove 54

Repair 55

Disassemble 55

Assemble 56

Install 57

Power Steering Pump 57

Description 57

Repair 57

Disassemble 57

Assemble 58

Steer Unit Actuator-Kordel™ 59

Description 59

Inspect 59

Steering Actuator 59

Remove 59

Disassemble 61

Clean 61

Inspect 61

Assemble 63

Install 64

Steer Tire and Wheel 64

Remove 64

Install 65

Wheel Hub 65

Remove 65

Clean 65

Inspect 66

Install 66

Checks and Adjustments 66

Air in System 66

Operation Check 67

Steering Pressure 67

Troubleshooting 68

524158040-2240YRM0001-(01-2023)-UK-EN 73

General 79

Battery Type 79

Lead-Acid Batteries 79

Lithium-Ion Batteries 80

Specific Gravity 80

Chemical Reaction in a Cell 80

Electrical Terms 82

Battery Selection 83

Battery Voltage 84

Battery as a Counterweight 84

Battery Ratings 84

Kilowatt-Hours 84

Battery Maintenance 85

Safety Procedures 85

Maintenance Records 85

New Battery 85

Cleaning Battery 86

Adding Water to Battery 88

Hydrometer 88

Battery Temperature 89

Charging Battery 90

Types of Battery Charges 91

Methods of Charging 92

Troubleshooting Charger 93

Knowing When Battery Is Fully Charged 93

Where to Charge Batteries 93

Equipment Needed 93

Battery Connectors 94

Battery Care 94

Troubleshooting 96

524158040-2240YRM0001-(03-2020)-UK-EN 101

General 105

Battery Type 105

Lead-Acid Batteries 105

Lithium-Ion Batteries 106

Specific Gravity 106

Chemical Reaction in a Cell 106

Electrical Terms 108

Battery Selection 108

Battery Voltage 109

Battery as a Counterweight 110

Battery Ratings 110

Kilowatt-Hours 110

Battery Maintenance 110

Safety Procedures 110

Maintenance Records 111

New Battery 111

Cleaning Battery 111

Adding Water to Battery 113

Hydrometer 114

Battery Temperature 115

Charging Battery 116

Types of Battery Charges 116

Methods of Charging 118

Troubleshooting Charger 118

Knowing When Battery Is Fully Charged 119

Where to Charge Batteries 119

Equipment Needed 119

Battery Connectors 120

Battery Care 120

Troubleshooting 122

524183085-2200YRM1058-(04-2011)-UK-EN 127

toc 127

Troubleshooting and Adjustments Using the AC Controls Program (E 127

Safety Precautions Maintenance and Repair 128

General 131

Computer Requirements 131

Software, Install 131

Language Selection 131

Demo Mode 132

Connect PC to Lift Truck 136

Starting AC Controls Program 138

Lift Truck Control Setup 143

Change Lift Truck Serial Number or Hourmeter 143

Setting Factory Default Values or Changing Lift Truck Parameters 144

Create New Custom Lift Truck Configuration 150

Lift Truck Configuration Properties 153

Import New Lift Truck Configuration From Disk 156

Delete Custom Lift Truck Configuration or Password File 158

Dash Display 161

Custom Display Languages 161

Download Display Language 163

Clear Operator Log 163

Password Functions 166

Enable/Disable Password and Lift Truck Inspection Functions 166

Truck Inspection Checklist 166

Password 166

Password Properties 166

Create New Password File 171

Download Passwords 172

Upload Passwords 174

Reports Menu 176

Devices Report 176

Custom Report 176

Password Report 176

Operator Report 183

Current Settings Report 186

Status Code Report 190

Status Codes Log 193

Troubleshooting 195

Diagnostics 195

Help Menu 198

General 198

Contents 198

Technical Support 198

About Electric Truck AC Controls Program 198

524223769-2200YRM1128-(01-2023)-UK-EN 205

Series Code / Model Designation Reference Table 213

General 215

Deutsch Crimping Tool 216

How to Strip a Wire for Use With Deutsch Crimping Tool 216

How to Crimp With the Deutsch Crimping Tool 217

Calibration Test for the Deutsch Crimping Tool 219

Deutsch Connectors 221

DT, DTM, and DTP Series Connectors 221

HD Series Connectors 264

Metri-Pack Connectors 286

Remove and Install 286

Micro-Pack Connectors 289

Weather-Pack Connectors 290

AMPSEAL Crimping Tools 292

AMP Hand Crimping Tool With Certi-Crimp 292

Description 292

Stripping Wire for Use with AMP Hand Crimping Tool 293

Insulation Crimp Adjustment 294

Maintenance and Inspection for AMP Hand Crimping Tool 294

AMP Hand Crimping Tool 294

Crimp Height Inspection 294

How to use AMP Hand Crimping Tool 295

AMP Pro-Crimper II Tool 295

Description 295

Remove and Install Die Set and Locator Assembly 296

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 296

Contact Support Adjustment 297

Crimp Height Adjustment 298

Maintenance and Inspection Procedures 298

PRO-CRIMPER II Tool 298

Crimp Height Inspection 298

How to Use AMP PRO-CRIMPER II Tool 299

AMPSEAL Connector Assemblies 300

Description for Plug Connector Assembly 300

Seal Plug 301

Contact Crimping 301

Description for Plug Connector and Header Assembly 306

Voltage Reading 309

Seal Plug 309

Contact Crimping 309

AMP Superseal 1 5 Crimping Tools 316

Mini Mic Receptacle and Tab Contacts 316

Description 316

Crimping Conditions and Measurements 316

Insertion of Rubber Seal on Cable 318

AMP Hand Application Tool 323

Description 323

Maintenance and Inspection 323

Crimp Height Inspection 323

Crimp Height Adjustment 324

How to Use AMP Hand Application Tool 324

AMP Pro-Crimper II Tool 325

Description 325

Remove and Install Die Set and Locator Assembly 325

Adjustments 326

Contact Support 326

Crimp Height 327

Inspections and Maintenance 328

Crimp Height Inspection 328

Visual Inspection 328

Maintenance 329

How to Use Pro-Crimper II Tool 329

AMP Superseal 1 5 Connector Assemblies 330

Description 330

Repair and Maintenance 337

Panel Mount Option 337

AMP Fastin-Faston Hand Tools 338

Description – AMP Double Action Hand Tool 338

Maintenance and Inspection Procedures 338

Daily Maintenance 338

Periodic Tool Inspection 339

Lubrication 339

Visual Inspection 339

Crimp Height Inspection 339

Certi-Crimp Ratchet Inspection 340

How to Use AMP Double Action Hand Tool 341

Description – AMP Extraction Tool 342

Maintenance and Inspection 343

How to Use AMP Extraction Tool 343

AMP Fastin-Faston Receptacles and Housings 345

Description 345

Wire Repair 353

Wire Splicing Requirements 353

Deutsch Jiffy Splice 354

Twisted/Shielded Cable and Leads Repair 360

Special Tools 362

524223769-2200YRM1128-(07-2020)-UK-EN 371

Series Code / Model Designation Reference Table 377

General 380

Deutsch Crimping Tool 380

How to Strip a Wire for Use With Deutsch Crimping Tool 380

How to Crimp With the Deutsch Crimping Tool 381

Calibration Test for the Deutsch Crimping Tool 383

Deutsch Connectors 385

DT, DTM, and DTP Series Connectors 385

HD Series Connectors 427

Metri-Pack Connectors 450

Remove and Install 450

Micro-Pack Connectors 452

Weather-Pack Connectors 453

AMPSEAL Crimping Tools 455

AMP Hand Crimping Tool With Certi-Crimp 455

Description 455

Stripping Wire for Use with AMP Hand Crimping Tool 455

Insulation Crimp Adjustment 456

Maintenance and Inspection for AMP Hand Crimping Tool 456

AMP Hand Crimping Tool 456

Crimp Height Inspection 456

How to use AMP Hand Crimping Tool 457

AMP Pro-Crimper II Tool 457

Description 457

Remove and Install Die Set and Locator Assembly 458

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 459

Contact Support Adjustment 459

Crimp Height Adjustment 460

Maintenance and Inspection Procedures 460

PRO-CRIMPER II Tool 460

Crimp Height Inspection 460

How to Use AMP PRO-CRIMPER II Tool 461

AMPSEAL Connector Assemblies 462

Description for Plug Connector Assembly 462

Seal Plug 463

Contact Crimping 463

Description for Plug Connector and Header Assembly 468

Voltage Reading 470

Seal Plug 470

Contact Crimping 470

AMP Superseal 1 5 Crimping Tools 477

Mini Mic Receptacle and Tab Contacts 477

Description 477

Crimping Conditions and Measurements 477

Insertion of Rubber Seal on Cable 479

AMP Hand Application Tool 484

Description 484

Maintenance and Inspection 484

Crimp Height Inspection 484

Crimp Height Adjustment 485

How to Use AMP Hand Application Tool 485

AMP Pro-Crimper II Tool 486

Description 486

Remove and Install Die Set and Locator Assembly 487

Adjustments 487

Contact Support 487

Crimp Height 488

Inspections and Maintenance 489

Crimp Height Inspection 489

Visual Inspection 489

Maintenance 490

How to Use Pro-Crimper II Tool 490

AMP Superseal 1 5 Connector Assemblies 491

Description 491

Repair and Maintenance 498

Panel Mount Option 498

AMP Fastin-Faston Hand Tools 499

Description – AMP Double Action Hand Tool 499

Maintenance and Inspection Procedures 499

Daily Maintenance 499

Periodic Tool Inspection 500

Lubrication 500

Visual Inspection 500

Crimp Height Inspection 500

Certi-Crimp Ratchet Inspection 501

How to Use AMP Double Action Hand Tool 502

Description – AMP Extraction Tool 503

Maintenance and Inspection 503

How to Use AMP Extraction Tool 504

AMP Fastin-Faston Receptacles and Housings 505

Description 505

Wire Repair 512

Wire Splicing Requirements 512

Deutsch Jiffy Splice 513

Twisted/Shielded Cable and Leads Repair 518

Special Tools 521

524319496-2100YRM1382-(02-2018)-UK-EN 529

Safety Procedures When Working Near Mast 537

General 539

Description 540

Tilt Cylinder Repair for 2 0-5 5T Trucks 540

Remove 540

Disassemble 542

Inspect 543

Clean 543

Assemble 543

Install 545

Tilt Cylinders, Adjust 545

Tilt Cylinder Leak Check 548

Tilt Cylinder Repair

for 1 0-2 0T Trucks 549

Remove 549

Disassemble 551

Inspect 553

Clean 553

Assemble 553

Install 553

Tilt Cylinders, Adjust 554

Tilt Cylinders Leak Check 555

Lift Cylinder Repair

for 2 0-3 5T Trucks 556

Main Lift Cylinders 556

Remove 556

Two-Stage FFL 556

Three-Stage FFL 558

Four-Stage FFL 558

Two-Stage LFL 559

Disassemble 559

Two-Stage FFL 559

Three-Stage FFL 561

Four-Stage FFL 561

Two-Stage LFL 563

Clean 564

Inspect 564

Assemble 564

Two-Stage FFL 564

Three-Stage FFL 564

Four-Stage FFL 565

Two-Stage LFL 565

Install 566

Two-Stage FFL 566

System Air Bleed Procedures 566

Three-Stage FFL 566

Four-Stage FFL 567

Two-Stage LFL 567

Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 568

Main Lift Cylinder 568

Remove 568

Main Lift Cylinders – Two-Stage FFL Mast 568

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 570

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 574

Main Lift Cylinder – Two-Stage LFL Mast 574

Disassemble 577

Main Lift Cylinders – Two-Stage FFL Mast 577

Main Lift Cylinder – Three-Stage FFL Mast 579

Main Lift Cylinder – Two-Stage LFL Mast 579

Clean 580

Inspect 580

Assemble 581

Main Lift Cylinder – Two-Stage FFL Mast 581

Main Lift Cylinder – Three-Stage FFL Mast 581

Main Lift Cylinder – Two-Stage LFL Mast 581

Install 582

Main Lift Cylinder – Two-Stage FFL Mast 582

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 582

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 583

Main Lift Cylinder – Two-Stage LFL Mast 584

System Air Bleed Procedures 585

All Main Lift Cylinders 585

Lift Cylinder Repair for 1 5-2 0T Trucks 585

Main Lift Cylinder 585

Remove 585

Two-Stage FFL 586

Three-Stage FFL 586

Two-Stage LFL 587

Four-Stage FFL 589

Disassemble 590

Two-Stage FFL 590

Three-Stage FFL 592

Two-Stage LFL 592

Four-Stage FFL 593

Clean 596

Inspect 596

Assemble 596

Two-Stage FFL 596

Three-Stage FFL 597

Two-Stage LFL 597

Four-Stage FFL 598

Install 599

Two-Stage FFL 599

System Air Bleed Procedures 599

Three-Stage FFL Mast 599

Two-Stage LFL 600

Four-Stage FFL 600

Mast and Carriage Install for Two-Stage FFL, Three-Stage FFL, and Two-Stage LFL 601

Mast and Carriage Installation for Four-Stage FFL 601

Lift Cylinder Repair

for 4 0-5 5T Trucks 602

Main Lift Cylinders 602

Remove 602

Two-Stage FFL 602

Three-Stage FFL 604

Two-Stage LFL 604

Disassemble 605

Two-Stage FFL 605

Three-Stage FFL 607

Two-Stage LFL 608

Clean 609

Inspect 609

Assemble 609

Two-Stage FFL 609

Three-Stage FFL 610

Two-Stage LFL 610

Install 611

Two-Stage FFL 611

System Air Bleed Procedures 611

Three-Stage FFL 611

Two-Stage LFL 612

Free-Lift Cylinder Repair

for 2 0-3 5T Trucks 613

Free-Lift Cylinder 613

Remove 613

Two and Three-Stage FFL Mast 613

Four-Stage FFL For Lift Truck ERC22-356VG (ERC045-070VG) (A968) 614

Disassemble 616

Two and Three-Stage FFL Mast 616

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 617

Clean 617

Inspect 617

Assemble 618

Two and Three-Stage FFL Mast 618

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 618

Install 619

Two and Three-Stage FFL Mast 619

Four-Stage FFL Mast for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 619

Free Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 620

Free-Lift Cylinder 620

Remove 620

Three-Stage FFL Mast 620

Disassemble 622

Clean 623

Inspect 623

Assemble 623

Install 623

Free Lift Cylinder Repair

for 1 5-2 0T Trucks 624

Free-Lift Cylinder 624

Remove 624

Two and Three-Stage FFL Mast 624

Four-Stage FFL Mast 626

Disassemble 628

Two-Stage and Three-Stage FFL Masts 628

Four Stage FFL Mast 629

Clean 630

Inspect 630

Assemble 630

Two-Stage and Three-Stage FFL Masts 630

Four-Stage FFL Mast 631

Install 631

Two-Stage and Three-Stage FFL Masts 631

Four-Stage FFL Mast 631

All Masts 633

Free-Lift Cylinder Repair

for 4 0-5 5T Trucks 634

Free-Lift Cylinder 634

Remove 634

Two and Three-Stage FFL Mast 634

Disassemble 635

Two and Three-Stage FFL Mast 635

Clean 636

Inspect 636

Assemble 636

Two and Three-Stage FFL Mast 636

Install 637

Two and Three-Stage FFL Mast 637

Sideshift Cylinder Repair

for 1 5-3 5T Trucks Prior to December 2016 637

Remove 637

Disassemble 641

Clean and Inspect 643

Assemble and Install 643

Sideshift Cylinder Repair

for 1 5-3 5T Trucks After December 2016 644

Remove 644

Disassemble 648

Clean and Inspect 650

Assemble and Install 650

Integral Side-Shift Cylinder Gland Leak Checks 652

Sideshift Cylinder Repair

for 4 0-5 5T Trucks 653

Remove 653

Disassemble 653

Clean and Inspect 655

Assemble and Install 655

Fork Positioner Cylinder Repair Prior to December 2016 655

Remove 655

Disassemble 656

Clean 658

Inspect 658

Assemble 659

Install 659

Fork Positioner Cylinder Adjustment 659

Fork Positioner Cylinder Repair After December 2016 660

Remove 660

Disassemble 660

Clean 663

Inspect 663

Assemble 664

Install 664

Fork Positioner Cylinder Adjustment 664

Lift Cylinder Leak Check 665

Seal Kit Installation 665

External Installation (Seal and Back-Up Ring) 666

Internal Installation (Piston Rod Assembly) 666

Torque Specifications for Lift Truck Models ERC22-35VG (ERC045-070VG) (A968) and ERP22-25VL (ERP045-070VL) (A976) 666

Tilt Cylinders 666

Piston Rod Nut 666

Gland 667

Tilt Cylinder Mounting Capscrew 667

Tilt Cylinder Rod End Capscrew 667

Main and Free-Lift Cylinder 667

Sideshift Cylinder 667

Fork Positioner Cylinder 667

Torque Specifications for Lift Truck Model ERP15VT (G807) 667

Tilt Cylinders 667

Main and Free-Lift Cylinders 667

Sideshift Cylinder 668

Torque Specifications for Lift Truck Models ERP16-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), ESC030-40AC (B883),ESC030-40AD (C883) 668

Tilt Cylinders 668

Main and Free-Lift Cylinders 668

Sideshift Cylinder 669

Fork Positioner Cylinder 669

Torque Specifications for Lift Truck Model ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 669

Tilt Cylinders 669

Main and Free-Lift Cylinder 669

Sideshift Cylinder 669

Torque Specifications for Lift Truck Model ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 669

Tilt Cylinder 670

Main and Free Lift Cylinder 670

Sideshift Cylinder 670

524319496-2100YRM1382-(07-2023)-UK-EN 673

Safety Procedures When Working Near Mast 683

General 686

Description 686

Tilt Cylinder Repair for 2 0-5 5T Trucks 687

Remove 687

Disassemble 689

Inspect 690

Clean 690

Assemble 690

Install 692

Tilt Cylinders, Adjust 692

Tilt Cylinder Leak Check 695

Tilt Cylinder Repair

for 1 0-2 0T Trucks 696

Remove 696

Disassemble 699

Inspect 701

Clean 701

Assemble 701

Install 701

Tilt Cylinders, Adjust 702

Tilt Cylinders Leak Check 703

Lift Cylinder Repair

for 2 0-3 5T Trucks 705

Main Lift Cylinders 705

Remove 705

Two-Stage FFL 705

Three-Stage FFL 707

Four-Stage FFL 707

Two-Stage LFL 708

Disassemble 708

Two-Stage FFL 708

Three-Stage FFL 710

Four-Stage FFL 712

Two-Stage LFL 713

Clean 714

Inspect 714

Assemble 714

Two-Stage FFL 714

Three-Stage FFL 715

Four-Stage FFL 715

Two-Stage LFL 716

Install 716

Two-Stage FFL 716

System Air Bleed Procedures 716

Three-Stage FFL 717

Four-Stage FFL 717

Two-Stage LFL 718

Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 719

Main Lift Cylinder 719

Remove 719

Main Lift Cylinders – Two-Stage FFL Mast 719

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 721

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 725

Main Lift Cylinder – Two-Stage LFL Mast 725

Disassemble 728

Main Lift Cylinders – Two-Stage FFL Mast 728

Main Lift Cylinder – Three-Stage FFL Mast 730

Main Lift Cylinder – Two-Stage LFL Mast 731

Clean 732

Inspect 732

Assemble 732

Main Lift Cylinder – Two-Stage FFL Mast 732

Main Lift Cylinder – Three-Stage FFL Mast 733

Main Lift Cylinder – Two-Stage LFL Mast 733

Install 733

Main Lift Cylinder – Two-Stage FFL Mast 733

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 734

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 735

Main Lift Cylinder – Two-Stage LFL Mast 736

System Air Bleed Procedures 736

All Main Lift Cylinders 737

Lift Cylinder Repair for 1 5-2 0T Trucks 738

Main Lift Cylinder 738

Remove 738

Two-Stage FFL 738

Three-Stage FFL 738

Two-Stage LFL 739

Four-Stage FFL 741

Disassemble 743

Two-Stage FFL 743

Three-Stage FFL 744

Two-Stage LFL 745

Four-Stage FFL 746

Clean 748

Inspect 749

Assemble 749

Two-Stage FFL 749

Three-Stage FFL 749

Two-Stage LFL 750

Four-Stage FFL 750

Install 751

Two-Stage FFL 751

System Air Bleed Procedures 752

Three-Stage FFL Mast 752

Two-Stage LFL 752

Four-Stage FFL 753

Mast and Carriage Install for Two-Stage FFL, Three-Stage FFL, and Two-Stage LFL 753

Mast and Carriage Installation for Four-Stage FFL 754

Lift Cylinder Repair for 4 0-5 5T Trucks 755

Main Lift Cylinders 755

Remove 755

Two-Stage FFL 755

Three-Stage FFL 757

Two-Stage LFL 757

Disassemble 758

Two-Stage FFL 758

Three-Stage FFL 760

Two-Stage LFL 761

Clean 762

Inspect 762

Assemble 762

Two-Stage FFL 762

Three-Stage FFL 763

Two-Stage LFL 763

Install 764

Two-Stage FFL 764

System Air Bleed Procedures 764

Three-Stage FFL 764

Two-Stage LFL 765

Free-Lift Cylinder Repair for 2 0-3 5T Trucks 766

Free-Lift Cylinder 766

Remove 766

Two and Three-Stage FFL Mast 766

Four-Stage FFL For Lift Truck ERC22-356VG (ERC045-070VG) (A968) 767

Disassemble 769

Two and Three-Stage FFL Mast 769

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 770

Clean 770

Inspect 771

Assemble 771

Two and Three-Stage FFL Mast 771

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 771

Install 772

Two and Three-Stage FFL Mast 772

Four-Stage FFL Mast for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 772

Free Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 774

Free-Lift Cylinder 774

Remove 774

Three-Stage FFL Mast 774

Disassemble 776

Clean 777

Inspect 777

Assemble 777

Install 777

Free Lift Cylinder Repair for 1 5-2 0T Trucks 779

Free-Lift Cylinder 779

Remove 779

Two and Three-Stage FFL Mast 779

Four-Stage FFL Mast 781

Disassemble 784

Two-Stage and Three-Stage FFL Masts 784

Four Stage FFL Mast 784

Clean 785

Inspect 785

Assemble 785

Two-Stage and Three-Stage FFL Masts 785

Four-Stage FFL Mast 786

Install 786

Two-Stage and Three-Stage FFL Masts 786

Four-Stage FFL Mast 787

All Masts 790

Free-Lift Cylinder Repair

for 4 0-5 5T Trucks 791

Free-Lift Cylinder 791

Remove 791

Two and Three-Stage FFL Mast 791

Disassemble 792

Two and Three-Stage FFL Mast 792

Clean 793

Inspect 793

Assemble 793

Two and Three-Stage FFL Mast 793

Install 794

Two and Three-Stage FFL Mast 794

Sideshift Cylinder Repair

for 1 5-3 5T Trucks Prior to December 2016 795

Remove 795

Disassemble 798

Clean and Inspect 800

Assemble and Install 800

Sideshift Cylinder Repair

for 1 5-3 5T Trucks After December 2016 802

Remove 802

Disassemble 805

Clean and Inspect 806

Assemble and Install 807

Integral Side-Shift Cylinder Gland Leak Checks 809

Sideshift Cylinder Repair

for 4 0-5 5T Trucks 810

Remove 810

Disassemble 811

Clean and Inspect 812

Assemble and Install 812

Fork Positioner Cylinder Repair Prior to December 2016 813

Remove 813

Disassemble 813

Clean 816

Inspect 816

Assemble 817

Install 817

Fork Positioner Cylinder Adjustment 817

Fork Positioner Cylinder Repair After December 2016 819

Remove 819

Disassemble 819

Clean 822

Inspect 822

Assemble 823

Install 823

Fork Positioner Cylinder Adjustment 823

Lift Cylinder Leak Check 825

Seal Kit Installation 826

External Installation (Seal and Back-Up Ring) 826

Internal Installation (Piston Rod Assembly) 826

Torque Specifications for Lift Truck Models ERC22-35VG (ERC045-070VG) (A968) and ERP22-25VL (ERP045-070VL) (A976) 827

Tilt Cylinders 827

Piston Rod Nut 827

Gland 827

Tilt Cylinder Mounting Capscrew 827

Tilt Cylinder Rod End Capscrew 827

Main and Free-Lift Cylinder 827

Sideshift Cylinder 827

Fork Positioner Cylinder 827

Torque Specifications for Lift Truck Model ERP15VT (G807) 828

Tilt Cylinders 828

Main and Free-Lift Cylinders 828

Sideshift Cylinder 828

Torque Specifications for Lift Truck Models ERP16-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), ESC030-40AC (B883),ESC030-40AD (C883) 829

Tilt Cylinders 829

Main and Free-Lift Cylinders 829

Sideshift Cylinder 829

Fork Positioner Cylinder 829

Torque Specifications for Lift Truck Model ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 830

Tilt Cylinders 830

Main and Free-Lift Cylinder 830

Sideshift Cylinder 830

Torque Specifications for Lift Truck Model ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 830

Tilt Cylinder 830

Main and Free Lift Cylinder 830

Sideshift Cylinder 830

524327049-0620YRM1385-(02-2023)-UK-EN 833

General 841

Discharging the Capacitors for Lift Truck Models ESC030-040AC (B883), ESC030-040AD (C883) 847

Discharging the Capacitors (All Other Models) 849

Traction Motor Repair 850

For Lift Truck Models , and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955), ESC030-040AC (B883) 850

Remove 850

Disassemble 851

Electrical Connector Repair or Replacement 853

Clean 853

Inspect 853

Assemble 854

Install 856

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) and ERC16-20VA (ERC030-040VA) (A969) 858

Remove 858

Disassemble 858

Electrical Connector Repair or Replacement 861

Clean 861

Inspect 861

Assemble 862

Install 862

For Lift Truck ERP2 2-3 5VL (ERP045-070VL) (A976) 862

Remove 862

Disassemble 862

Clean 864

Inspect 864

Assemble 865

Install 865

For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080120VM, ERP100VML) (A985) 865

Remove 865

Clean 867

Install 867

For Lift Truck ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 867

Remove 867

Disassemble 867

Electrical Connector Repair or Replacement 869

Clean 869

Inspect 869

Assemble 870

Install 871

Traction Motor Repair for 4-5 5T Lift Trucks 872

For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080120VM, ERP100VML) (A985) 872

Remove 872

Clean 874

Install 874

Hydraulic Motor Repair 875

For Lift Trucks and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955)ESC030-040AC (B883), ESC030-040AD (C883) 875

Remove 875

Disassemble 876

Electrical Connector Repair or Replacement 878

Clean 878

Inspect 878

Assemble 879

Install 881

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) 882

Remove 882

Disassemble 884

Standard Motor 884

Enhanced Motor 886

Electrical Connector Repair or Replacement 887

Clean 888

Inspect 888

Assemble 889

Standard Motor 889

Enhanced Motor 889

Install 890

For Lift Truck Models ERP2 2-3 5VL (ERP045-070VL) (A976) and ERC16-20VA (ERC030-040VA) (A969) 890

Remove 890

Disassemble 890

Electrical Connector Repair or Replacement 896

Clean 897

Inspect 897

Assemble 898

Install 899

For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) and ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 899

Remove 899

Disassemble 899

Electrical Connector Repair or Replacement 902

Clean 902

Inspect 903

Assemble 903

Install 904

Hydraulic Motor Repair For 4 0-5 5T Lift Trucks 904

Remove 904

Disassemble 904

Electrical Connector Repair or Replacement 906

Clean 906

Inspect 907

Assemble 907

Install 908

Torque Specifications 909

Traction Motor for Lift Trucks and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955) 909

Traction Motor for Lift Truck and ERC22-35VG (ERC045-070VG) (A968), ERC16-20VA (ERC030-040VA) (A969),ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 909

Traction Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 909

Hydraulic Motor for Lift Trucks and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955) 909

Hydraulic Motor for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 909

Hydraulic Motor for Lift Truck ERP22-35VG (ERP045-070VG) (A976) 909

Hydraulic Motor for Lift Truck ERC16-20VA (ERC030-040VA) (A969) 909

Hydraulic Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 909

Hydraulic Motor for Lift Truck and ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985)ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 910

524327049-0620YRM1385-(06-2015)-UK-EN 913

General 917

Discharging the Capacitors for Lift Truck Models ESC030-040AC (B883), ESC030-040AD (C883) 924

Discharging the Capacitors (All Other Models) 925

Traction Motor Repair 925

For Lift Truck Models ERP15-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), and ESC030-040AC (B883) 926

Remove 926

Disassemble 927

Electrical Connector Repair or Replacement 930

Clean 930

Inspect 930

Assemble 931

Install 934

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) and ERC16-20VA (ERC030-040VA) (A969) 936

Remove 936

Disassemble 936

Electrical Connector Repair or Replacement 940

Clean 940

Inspect 940

Assemble 941

Install 941

For Lift Truck ERP2 2-3 5VL (ERP045-070VL) (A976) 941

Remove 941

Disassemble 941

Clean 943

Inspect 943

Assemble 944

Install 944

For Lift Truck ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 944

Remove 944

Disassemble 945

Electrical Connector Repair or Replacement 946

Clean 946

Inspect 947

Assemble 947

Install 948

948

Traction Motor Repair For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 948

Remove 948

Clean 950

Install 950

Hydraulic Motor Repair 950

For Lift Trucks ERP15-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), and ESC030-040AC (B883), ESC030-040AD (C883) 950

Remove 950

Disassemble 952

Electrical Connector Repair or Replacement 954

Clean 954

Inspect 954

Assemble 955

Install 957

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) 959

Remove 959

Disassemble 960

Standard Motor 960

Enhanced Motor 961

Electrical Connector Repair or Replacement 963

Clean 964

Inspect 965

Assemble 965

Standard Motor 965

Enhanced Motor 966

Install 967

For Lift Truck Models ERP2 2-3 5VL (ERP045-070VL) (A976) and ERC16-20VA (ERC030-040VA) (A969) 968

Remove 968

Disassemble 968

Electrical Connector Repair or Replacement 974

Clean 975

Inspect 975

Assemble 976

Install 977

977

Hydraulic Motor Repair For 4 0-5 5T Lift Trucks 977

Remove 977

Disassemble 977

Electrical Connector Repair or Replacement 980

Clean 981

Inspect 981

Assemble 982

Install 982

Torque Specifications 983

Traction Motor for Lift Trucks ERP15-20VT (ERP030-040VT) (G807) and ERP16-20VF (ERP30-40VF) (A955) 983

Traction Motor for Lift Truck ERC22-35VG (ERC045-070VG) (A968), ERC16-20VA (ERC030-040VA) (A969), and ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 983

Traction Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 983

Hydraulic Motor for Lift Trucks ERP15-20VT (ERP030-040VT) (G807) and ERP16-20VF (ERP30-40VF) (A955) 983

Hydraulic Motor for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 983

Hydraulic Motor for Lift Truck ERP22-35VG (ERP045-070VG) (A976) 983

Hydraulic Motor for Lift Truck ERC16-20VA (ERC030-040VA) (A969) 983

Hydraulic Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 983

Hydraulic Motor for Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) and ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 984

524333799-4000YRM1405-(06-2019)-UK-EN 987

General 991

Safety Procedures When Working Near Mast 992

Fork Replacement 997

Remove 997

Install 999

Checks 999

Carriages Repair 1000

Standard Carriage 1000

Remove 1000

Clean and Inspect 1004

Install 1004

Integral Sideshift Carriage, Lift Trucks Manufactured Prior To December, 2016 1005

Remove 1005

Disassemble 1008

Clean and Inspect 1008

Assemble 1009

Install 1010

Integral Sideshift Carriage, Lift Trucks Manufactured December, 2016 Through Late June, 2018 1010

Remove 1010

Disassemble 1013

Clean and Inspect 1013

Assemble 1014

Install 1015

Integral Sideshift Carriage, Lift Trucks Manufactured Late June, 2018 1015

Remove 1015

Disassemble 1018

Clean and Inspect 1018

Assemble 1019

Install 1020

Fork Positioner, Lift Trucks Manufactured Prior To December, 2016 1020

Remove 1020

Clean and Inspect 1024

Disassemble and Assemble 1024

Install 1024

Fork Positioner Hydraulic Hose Adjustment 1025

Fork Positioner Carriage, Lift Trucks Manufactured December, 2016 Through Late June, 2018 1027

Remove 1027

Clean and Inspect 1030

Disassemble and Assemble 1030

Install 1030

Fork Positioner Hydraulic Hose Adjustment 1031

Fork Positioner Carriage, Lift Trucks Manufactured June, 2018 and After 1032

Remove 1033

Clean and Inspect 1036

Disassemble and Assemble 1036

Install 1036

Fork Positioner Hydraulic Hose Adjustment 1037

Two-Stage Mast With Limited Free-Lift Repair 1038

Remove 1038

Disassemble 1050

Clean and Inspect 1052

Assemble 1055

Install 1056

Header Hose Installation and Adjustment 1058

Install 1058

Adjust 1066

Two-Stage Mast With Full Free-Lift Repair 1066

Remove 1067

Disassemble 1077

Clean and Inspect 1082

Assemble 1085

Install 1086

Header Hose Installation and Adjustment 1087

Install 1087

Adjust 1096

Three-Stage Mast With Full Free-Lift Repair 1097

Remove 1097

Disassemble 1108

Clean and Inspect 1115

Assemble 1117

Install 1119

Header Hose Installation and Adjustment 1120

Install 1120

Adjust 1129

Four-Stage Mast With Full Free-Lift Repair 1129

Remove 1129

Disassemble 1134

Clean and Inspect 1139

Assemble 1140

Install 1141

Header Hose Installation and Adjustment 1143

Lift Chains Adjustment 1148

Carriage Adjustments 1149

Tilt Cylinders Adjustment 1150

Mast Adjustments 1150

Load Roller, Adjust 1150

Mast Side Kicking, Adjust 1152

550002982-0100YRM1410-(03-2017)-UK-EN 1155

Introduction 1159

General 1159

Description 1159

Discharging the Capacitors 1160

Covers and Pads 1161

Covers 1161

Remove 1161

Install 1164

Pads 1164

Remove 1164

Install 1164

Floor Suspension 1164

Cylinder Replacement 1164

Bearing Replacement 1167

Brake Switch Replacement 1167

Overhead Guard 1168

Description 1168

Remove 1168

Repair 1168

Install 1168

Painting Instructions 1170

Labels and Decals 1171

Safety Labels 1171

Battery 1171

Battery Sizes 1171

Battery Gate Interlock (Option) 1171

Description 1171

Removal 1172

Installation 1172

Adjustment 1172

550002985-1300YRM1411-(12-2016)-UK-EN 1175

General 1179

Discharging the Capacitors 1180

Special Tools 1181

Transaxle Assembly 1182

Remove Transaxle From Frame 1182

Remove the Parking Brake and Traction Motor 1182

Install Parking Brake and Traction Motor 1183

Install Transaxle to Frame 1184

Maintenance and Repair 1185

Speed Sensor Repair 1185

Trunnion Cap Repair 1186

Fluid Level Check 1186

Fluid Change 1187

Breather Repair 1188

Stud Repair 1189

Input Seal Repair 1190

Cover to Housing Seal 1191

During the Transaxle Warranty Period 1191

After the Transaxle Warranty Period 1192

Removing the Cover 1192

Installing the Cover 1192

550002990-1800YRM1412-(07-2015)-UK-EN 1197

Introduction 1201

Description 1201

Discharging the Capacitors 1202

Parking Brake 1203

Override Mode (S/N B883N02459K) 1204

Override Mode (S/N B883N02460K) 1204

Remove 1205

Install 1205

550002993-1900YRM1413-(01-2017)-UK-EN 1209

General 1213

Hoses 1213

Fittings 1213

Discharging the Capacitors 1214

Multifunction Control Handle 1215

Description 1215

Standard (Right/Left) Configuration (B883) 1215

Optional (Push/Pull) Configuration (B883) 1216

Multifunction Control Handle (C883) 1216

Manual Lowering 1217

How to Lower Mast Manually (B883) 1217

How to Lower Mast Manually (C883) 1218

Main Hydraulic Control Valve 1218

Description 1218

Check and Adjust 1218

Check Manifold Pressures 1218

Check Internal Counterbalance Valve 1219

Remove (Control Valve) 1219

Repair (Control Valve) 1222

Disassemble 1222

Clean 1222

Assemble 1223

Install (Control Valve) 1223

Counterbalance Valve 1224

Install 1224

Bleed Procedure 1225

Lift Pump and Motor 1225

Remove 1226

Install 1226

Lift Pump 1227

Disassemble 1227

Assemble 1229

Hydraulic Tank 1229

Inspect 1229

Remove 1231

Clean 1231

Steam Method 1232

Trisodium Phosphate Method 1232

Install 1232

Troubleshooting 1233

550002996-2200YRM1414-(07-2010)-UK-EN 1237

toc 1237

Electrical System 1237

Safety Precautions Maintenance and Repair 1238

General 1241

Discharging the Capacitors 1242

Major Electrical System Features 1244

Integrated System 1244

CANbus Advantages 1244

CANbus Communications 1244

Steering 1244

Traction 1244

Master Control Unit 1244

Multifunction Control Handle 1244

Standard (Right/Left) Configuration 1244

Optional (Push/Pull) Configuration 1245

Remove 1245

Disassemble 1245

Assemble 1247

Install 1248

Multifunction Displays 1248

BDI 1248

Speed 1248

Steer Angle 1248

Truck Hours 1248

Operational Mode 1248

Setup 1249

Setup Instructions 1249

ZAPI ACE0 Traction Control Unit 1249

Normal Operation 1249

Display 1249

Password Access 1249

Startup Checklist 1249

Truck Operation Mode 1250

Diagnostics 1250

Power-On Self-Test 1250

Setup Menu Diagnostics 1250

Checking Transistor Controller 1251

Component Repair and Testing 1251

AC Traction Motor Controller 1252

Controller Removal 1252

Install 1252

Low-Voltage Protection Function 1252

Contactor and Electrical Panel Checks 1253

Fuses 1253

Contactor 1253

General 1253

Test 1253

Contactor Tips 1254

Disassemble and Assemble 1254

Steer Position Sensor 1256

General 1256

Checking the Steer Position Sensor 1256

Installing the Potentiometer 1256

Position Steer Tire for Straight Travel 1256

Potentiometer Position Adjustment 1257

Dash Display Method 1257

Voltmeter Method 1257

Ohmmeter Method 1258

Steer Calibration 1259

Test 1259

Steer Motor 1260

Remove 1260

Install 1260

Traction and Lift Pump Motors 1262

Periodic Maintenance Checks 1262

DC to DC Converter 1262

tables 1237

Table 1 Potentiometer Specifications 1259

550002999-2200YRM1415-(08-2016)-UK-EN 1265

General 1269

Introduction 1269

Discharging the Capacitors 1269

Parameters 1270

Parameter Descriptions 1275

Top Speed Forward 1276

Top Speed Reverse 1276

Accel Mode (1 − 4) 1276

Auto Deceler 1276

Plug Decel 1276

Steer Calibration 1276

Lift Accel 1276

Max Lift Speed 1276

Max Lower Speed 1276

Tilt Speed Free 1276

Tilt Speed Main 1276

Tilt Valv Acc 1276

Tilt Valv Dec 1276

Hyd Mtr Dec 1276

Side Shift Speed 1277

Side Sh Valv Acc 1277

Side Sh Valv Dec 1277

4th Aux In Speed 1277

4th Aux Out Speed 1277

4th Aux Type 1277

Serial Number 1277

BDI Adjustment 1277

BDI Max Adj 1277

BDI Min Adj 1277

BDI Adj Startup 1277

BDI Delta Reset 1277

Battery Type 1278

Lift Interrupt 1278

Visible/Audible Motion Alarm 1278

Trac En Light 1278

Travel Speed Reduction 1278

Lift Limit Override 1278

Service Reminder 1278

Truck Inspection 1279

Simultaneity 1279

Restore Defaults 1279

Speed Unit 1279

Temp Unit 1279

Troubleshooting 1279

General 1279

Non-Status Code Errors 1280

Status Codes 1280

550003002-2200YRM1416-(09-2013)-UK-EN 1399

toc 1399

User Interface 1399

Safety Precautions Maintenance and Repair 1400

General 1403

Description 1403

Button Keypad 1403

LED Indicator Lights 1403

LCD Screen 1403

Dash Display Menu Access 1403

Menu Navigation 1404

Supervisor Menu 1405

View Hourmeters 1405

Truck Hours 1406

Pump Hours 1406

Tract Hours 1406

View Operat Log 1406

Password 1407

Add Password 1408

Delete Password 1408

Edit Password 1409

Operator Passw 1409

Clear Oper Log 1409

tables 1399

Table 1 Supervisor Menu 1405

Table 2 View Hourmeters Menu 1405

Table 3 Password Menu 1407

550003005-2200YRM1417-(09-2013)-UK-EN 1413

toc 1413

User Interface 1413

Safety Precautions Maintenance and Repair 1414

General 1417

Description 1417

Button Keypad 1417

LED Indicator Lights 1417

LCD Screen 1417

Dash Display Menu Access 1418

Menu Navigation 1418

Service-Level Menu 1421

View Hour Meters 1421

Truck Hours 1422

Pump Hours 1422

Tract Hours 1422

Software Version 1423

Master 1423

Slave 1423

Display 1424

Pump 1424

Password 1424

Add Password 1425

Delete Password 1425

Edit Password 1426

Operator Passw 1426

Clear Oper Log 1426

Diagnostic 1426

Error Log 1427

Run Diagnostics 1427

Left Traction Motor Speed 1428

Left Traction Motor Current 1428

Left Traction Motor Temp 1428

Left Traction Controller Temp 1428

Right Traction Motor Speed 1428

Right Traction Motor Current 1429

Right Traction Motor Temp 1429

Right Traction Controller Temp 1429

Steer Position 1429

Pump Motor Speed 1429

Pump Motor Current 1429

Pump Motor Temp 1430

Pump Controller Temp 1430

No Run Diagnostics 1430

Brake Switch 1431

Mast Proximity Switch 1431

Horn Switch – Joystick 1431

Tilt Up Switch – Joystick 1431

Tilt Down Switch – Joystick 1431

Shift Right Switch – Joystick 1432

Shift Left Switch – Joystick 1432

4th-Aux In Switch – Joystick 1432

4th-Aux Out Switch – Joystick 1432

Traction – Joystick 1432

Lift / Lower – Joystick 1432

Setup 1433

Traction Settings 1433

Top Speed Forward 1434

Top Speed Reverse 1434

Acceleration (Modes 1 through 4) 1434

Auto Deceleration 1434

Plugging Deceleration 1435

Steering Calibration 1435

Hydraulic Settings 1435

Lift Acceleration 1437

Max Lift Speed 1437

Max Lower Speed 1437

Tilt Speed Free 1437

Tilt Speed Main 1438

Tilt Valve Acceleration 1438

Tilt Valve Deceleration 1438

Hydraulic Motor Deceleration 1438

Side Shift Speed 1439

4th Aux Speed In 1439

4th Aux Speed Out 1439

4th Aux Type 1439

Truck Settings 1440

Serial Number 1442

Battery Type 1442

BDI Max Adjust 1442

BDI Min Adjust 1442

BDI Adjust Startup 1443

BDI Delta Reset 1443

Lift Interrupt 1443

Motion Alarms (Audible or Visible) 1444

Travel Speed Reduction 1444

Lift Limit Override 1444

Service Reminder 1445

Truck Inspection 1445

Simultaneity 1445

Restore Defaults 1445

Speed Unit 1446

Temp Unit 1446

tables 1413

Table 1 Service-Level Menu 1421

Table 2 View Hour Meters Menu 1421

Table 3 Software Version Menu 1423

Table 4 Password Menu 1424

Table 5 Diagnostic Menu 1426

Table 6 Run Diagnostics Menu 1427

Table 7 No Run Diagnostics Menu 1430

Table 8 Setup Menu 1433

Table 9 Traction Settings Menu 1433

Table 10 Hydraulic Settings Menu (Display Software v3 0) 1435

Table 11 Hydraulic Settings Menu (Display Software v3 02) 1436

Table 12 Truck Settings Menu (Display Software v3 0) 1440

Table 13 Truck Settings Menu (Display Software v3 02) 1441

550003008-8000YRM1418-(05-2014)-UK-EN 1449

550003011-8000YRM1419-(05-2014)-UK-EN 1499

550003014-8000YRM1420-(07-2014)-UK-EN 1517

550089226-2200YRM1652-(09-2013)-UK-EN 1543

550089229-2200YRM1653-(04-2020)-UK-EN 1565

General 1573

Introduction 1573

Description 1573

Button Keypad 1573

LED Indicator Lights 1573

LCD Screen 1573

Dash Display Menu Access 1573

Menu Navigation 1574

Dash Display Menu Operation 1574

Nodes 1574

Menu Structure 1575

Service-Level Menu 1576

Hour Meters 1577

H1 Truck Hours 1577

H2 Traction Hours 1577

H3 Pump Hours 1578

H5 Odometer Hours 1578

H10 Display Hours 1578

H30 Traction Node Hours 1578

H31 Traction Slave Node Hours 1578

H50 Pump Node Hours 1578

Performance 1579

Performance Level 1 1579

P1 1 Forward 1580

P1 2 Reverse 1580

P1 3 Acceleration 1580

P1 4 Plug 1580

P1 5 Coast 1581

P1 6 Lift Speed 1581

P1 7 Lower Speed 1581

P1 8 Lift Accel 1581

P1 9 Lift Decel 1581

P1 10 Lower Accel 1581

P1 11 Lower Decel 1581

P1 12 Tilt Speed 1581

P1 13 Tilt Speed Free 1581

P1 14 Tilt Accel 1581

P1 15 Tilt Decel 1581

P1 16 Sideshift Speed 1582

P1 17 4th Function In Speed 1582

P1 18 4th Function Out Speed 1582

Operator Passwords 1582

Add Password 1583

Delete Password 1583

Edit Password 1583

Operator Password 1583

Clear Log 1583

Operator Logs 1583

Operator 1-150 1583

Information 1584

I1 Model 1584

I3 Serial Number 1584

I5 Truck Voltage 1584

Settings 1585

S1 Metric 1586

S2 User Performance 1587

S3 Timeout 1587

S4 Battery Type 1587

S5 BDI Startup Full 1587

S6 BDI Full 1587

S7 BDI Empty 1587

S8 BDI Reset 1587

S9 Lift Interrupt 1587

S10 Audible Warning 1587

S11 Visual Warning 1588

S12 Checklist 1588

S13 Maint Reminder 1588

S14 Restore Default 1588

S15 Truck Lockout 1588

S16 Travel Speed Red (SPED OPTION) 1588

S17 4th Auxiliary Type 1588

S18 Lift Lim Overrid 1588

S43 Simultaneity 1588

S61 Extended Shift 1588

S63 Reduced Speed Tilt 1588

S63 Walk Speed Accel 1589

S64 Walk Speed Decel 1589

S65 Pick Accel 1589

S66 SWS Source 1589

S66 Pick Decel 1589

S67 Min Steer Assist F 1589

S68 Min Steer Assist R 1589

Software Versions 1590

Error Log 1590

(E1) Error Log 1 1591

Error 1 1 (E1 1) 1591

Error 1 2 (E1 2) 1591

Error 1 3 (E1 3) 1591

Error 1 4 (E1 4) 1591

Diagnostics 1592

Diagnostics 1592

D1 Status 1592

D2 Input 1592

D3 Output 1592

D1 Status 1592

D1 1 CAN 1593

D1 2 Contactor 1593

D1 3 Full Traction 1593

D1 4 Limp Traction 1593

D1 5 Steering 1593

D1 6 Lift 1593

D1 7 Lower 1594

D1 8 Tilt 1594

D1 9 Side Shift 1594

D1 13 4th Function 1594

D2 Inputs 1594

D2 10 Display 1594

D2 10 1 Bus Error 1595

D2 10 2 Bus Max Error 1595

D2 10 30 Traction 1595

D2 10 31 Slave Traction 1595

D2 10 50 Pump 1595

D2 10 60 CTRL Hand 1595

D2 30 Traction 1595

D2 30 1 Target Speed 1597

D2 30 2 Motor Speed 1597

D2 30 3 Motor ENC 1597

D2 30 5 Cont Temp 1597

D2 30 6 Motor Temp 1597

D2 30 7 Motor Curr 1597

D2 30 8 Cap V 1597

D2 30 9 Cap Max V 1597

D2 30 10 Cap Min V 1597

D2 30 11 Key V 1598

D2 30 12 Key Max V 1598

D2 30 13 Key Min V 1598

D2 30 14 Brake Connect 1598

D2 30 16 MC Connect 1598

D2 30 18 Steer Position Sensor 1598

D2 30 19 Brake SW 1598

D2 30 32 SOC 1598

D2 31 Slave Traction 1598

D2 31 1 Target Speed 1599

D2 31 2 Motor Speed 1599

D2 31 3 Motor ENC 1600

D2 31 4 Cont Temp 1600

D2 31 6 Motor Temp 1600

D2 31 7 Motor Curr 1600

D2 31 8 Cap V 1600

D2 31 9 Cap Max V 1600

D2 31 10 Cap Min V 1600

D2 31 11 Key V 1600

D2 31 12 Key Max V 1600

D2 31 13 Key Min V 1600

D2 31 14 Brake Connect 1600

D2 50 Pump 1600

D2 50 1 Target Speed 1602

D2 50 2 Motor Speed 1602

D2 50 3 Motor ENC 1602

D2 50 5 Cont Temp 1602

D2 50 6 Motor Temp 1602

D2 50 7 Motor Curr 1602

D2 50 8 Cap V 1602

D2 50 9 Cap Max V 1602

D2 50 10 Cap Min V 1602

D2 50 11 Key V 1602

D2 50 12 Key Max V 1602

D2 50 13 Key Min V 1602

D2 50 14 Mast Prox SW 1602

D2 60 Control Handle 1603

D2 60 1 Horn SW 1604

D2 60 10 Tilt Up SW 1604

D2 60 11 Tilt Down SW 1604

D2 60 12 Shift Right SW 1604

D2 60 13 Shift Left SW 1604

D2 50 14 4th Aux IN SW 1604

D2 50 15 4th Aux OUT SW 1604

D2 60 19 Trac Input 1604

D2 60 20 Lift/Lower Input 1604

D3 Output 1605

D3 10 Display 1605

D3 10 10 Display Com 1605

D3 10 30 Trac Com 1605

D3 10 31 Trac Slave Com 1605

D3 10 50 Pump Com 1605

D3 10 60 Control Handle Com 1605

D3 30 Traction 1606

D3 30 1 U-V Line DC Curr 1607

D3 30 2 U-W Line DC Curr 1607

D3 30 3 V-W Line DC Curr 1607

D3 30 4 Motor Open 1607

D3 30 5 Motor Current 1607

D3 30 6 Brake 1607

D3 30 7 MC 1607

D3 30 8 Lower 1607

D3 30 9 Lift 1607

D3 30 11 Load Hold 1607

D3 30 13 Side Shift Right 1608

D3 30 14 Side Shift Left 1608

D3 30 15 Horn 1608

D3 30 16 Strobe 1608

D3 30 Traction Slave 1608

D3 31 1 U-V Line DC Curr 1609

D3 31 2 U-W Line DC Curr 1609

D3 31 3 V-W Line DC Curr 1609

D3 31 4 Motor Open 1609

D3 31 5 Motor Current 1609

D3 31 6 Brake 1609

D3 31 7 Backup Alarm 1609

D3 31 8 Tilt Back 1609

D3 31 9 Tilt Forward 1609

D3 31 10 Auxiliary Prop Valve 1609

D3 31 11 4th Function In 1609

D3 31 12 4th Function Out 1609

D3 50 Pump 1610

D3 50 1 U-V Line DC Curr 1610

D3 50 2 U-W Line DC Curr 1610

D3 50 3 V-W Line DC Curr 1610

Calibration 1611

550089232-9000YRM1649-(04-2017)-UK-EN 1613

SECTION 9030 ELECTRICAL SYSTEM 1617

Group 03 – General Maintenance and Diagnostic Data 1621

Group 20 – Diagnostic Trouble Codes 1635