$41.95

Yale Forklift C813 (GDP070-090LJ; GDP100-120MJ) Service Manual PDF

Yale Forklift C813 (GDP070-090LJ; GDP100-120MJ) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift C813 (GDP070-090LJ; GDP100-120MJ) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1140

Downloadable : Yes

File Type : PDF

PART NO. 524150774

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift C813 (GDP070-090LJ; GDP100-120MJ) Service Manual – PDF DOWNLOAD

524150774 0600YRM0705 (03 2006) US EN 1

toc 1

Perkins Diesel Engines 1

Safety Precautions Maintenance and Repair 2

General 9

General Safety Rules 9

Description 10

Engine Serial Number Codes 13

Engine Data 13

Engine Removal and Installation 15

Lift Engine 15

Cylinder Head Assembly Repair 15

Valve Cover 15

Remove 15

Install 16

Rocker Arm Assembly 16

Remove 16

Install 16

Disassemble 16

Inspect 17

Assemble 17

Valve Clearance Adjustments 17

Four-Cylinder Engines 18

Six-Cylinder Engines 18

Valve Springs 18

Cylinder Head Assembly 20

Remove 20

Install 22

Valves and Valve Springs 26

Remove 26

Inspect 26

Install 27

Valve Guides 27

Inspect 27

Remove 28

Install 28

Cylinder Head and Valve Seats 28

Inspect 28

Repair 28

New Valve Seats, Install 28

Piston and Connecting Rod Assemblies Repair 30

Rod Bearings 30

Remove 31

Install 31

Piston and Connecting Rod Assembly 32

Service Note 32

Remove 32

Install 33

Piston Rings 34

Remove 34

Inspect 34

Install 34

Piston and Connecting Rod 35

Disassemble 35

Inspect 36

How to Select Correct Replacements 36

Install 37

Piston Cooling Jets 37

Remove 37

Install 38

Crankshaft Assembly Repair 38

General 38

Crankshaft Pulley 39

Engine AR, Remove 39

Engines YG and YH, Remove 39

Inspect 40

Engine AR, Install 40

Engines YG and YH, Install 40

Rear Oil Seal 41

Replace 41

Main Bearings 42

Remove 42

Inspect 43

Install 43

Thrust Washers 43

Crankshaft Axial Movement, Check 43

Remove 44

Install 44

Crankshaft 45

Remove 45

Inspect 45

Install 45

Flywheel 47

Remove 47

Ring Gear, Replace 47

Install 47

Flywheel Housing 48

Remove 48

Install 48

Timing Case and Timing Gears Repair 49

General 49

Timing Case Cover 49

Remove 49

Install 50

Front Oil Seal 50

Remove 50

Install 50

Crankshaft Pulley Wear Sleeve 51

Install 51

Idler Gear and Hub 51

Remove 51

Install 52

Air Compressor Drive, Bendix 53

Disassemble 53

Assemble 54

Fuel Injection Pump Gear 54

Remove 55

Install 55

Camshaft Gear 56

Remove 56

Install 56

Crankshaft Gear 57

Remove 57

Install 57

Timing Case 57

Remove 57

Install 58

Camshaft and Tappets 59

Remove 59

Install 59

Cylinder Block Assembly Repair 60

Description 60

Cylinder Block 60

Disassemble 60

Inspect 61

Assemble 61

Cylinder Bore (Four-Cylinder Engines) 61

Cylinder Liner (Six-Cylinder Engines) 62

Inspect 62

Cylinder Liner Condition, Check 62

Remove 63

Service Liner, Install 63

Partially Finished Liner, Install 65

Engine Timing 65

Description 65

How to Set Number One Piston to TDC on Compression Stroke 67

How to Set Number One Piston to TDC on Compression Stroke (Alter 67

Valve Timing, Check 68

Fuel Injection Pump Timing, Check 69

Turbocharger – Engine YH Repair 70

General 70

Remove 70

Install 70

Impeller and Compressor Housing, Clean 71

Lubrication System Repair 72

General 72

Oil Filter, Replace 72

Filter Head 72

Remove and Install 72

Oil Sump 73

Remove 73

Install 73

Oil Pump 73

Remove 73

Inspect 74

Install 75

Relief Valve 75

Remove 75

Disassemble 76

Inspect 76

Assemble 76

Install 76

Idler Gear Shaft, Replace 77

Remove 77

Remove (Alternative) 77

Install 78

Install (Alternative) 78

Install (Alternative for Four-Cylinder Engines Only) 79

Fuel System Repair 79

Description 79

Fuel Injection Pump 80

Remove 80

Install 81

Check and Adjust 81

Fuel System Air Removal 82

Fuel Filter, Replace 83

Canister Type 83

Quick Release Canister Type 84

Fuel Injectors 85

Remove 85

Inspect 85

Install 85

Fuel Pump 86

Remove 86

Disassemble 86

Assemble 87

Install 88

Test 88

Cooling System Repair 88

General 88

Thermostat 88

Remove 88

Install 89

Test 89

Coolant Pump 89

Remove 89

Disassemble 90

Assemble 91

Install 94

Fan and Fan Drive 94

Remove 94

Install 95

Oil Cooler (Six-Cylinder Engines) 95

Remove 95

Disassemble and Assemble 95

Install 96

Oil Cooler Bypass Valve 96

Electrical Equipment Repair 96

Drive Belts 96

Adjustment 96

Remove 97

Install 97

Alternator 97

Remove 97

Install 97

Starter Motor 98

Remove 98

Install 98

Cold Start Aid 98

Air Compressor – Engines YG and YH 98

General 98

Repair 98

Remove 98

Install 99

Rotary Exhauster Replacement 100

Remove 100

Clean 100

Install 100

Engine Specifications 101

Cylinder Head Assembly 101

Piston and Connecting Rods 104

Crankshaft Assembly 107

Crankshaft Overhaul 108

Timing Case and Drive Assembly 110

Engine Block Assembly 111

Turbocharger 114

Lubrication System 114

Fuel System 115

Cooling System 117

Flywheel and Housing 117

Electrical Equipment 118

Torque Specifications 118

Cylinder Head Assembly 118

Piston and Connecting Rod Assemblies 118

Crankshaft Assembly 118

Timing Case and Drive Assembly 119

Turbocharger 119

Lubrication System 119

Fuel System 119

Cooling System 119

Flywheel 119

Auxiliary Equipment 119

Special Torque Specifications 120

Flywheel and Housing 120

Turbocharger 120

Electrical Equipment 120

Auxiliary Equipment 120

Special Tools* 121

Troubleshooting 126

tables 1

Table 1 Cylinder Head 101

Table 2 Valve Guides 101

Table 3 Inlet Valves 101

Table 4 Exhaust Valves 102

Table 5 Valve Springs 104

Table 6 Tappets 104

Table 7 Rocker Arm Shaft 104

Table 8 Rocker Arms and Bushings 104

Table 9 Pistons (Engine AR) 104

Table 10 Pistons (Engines YG and YH) 104

Table 11 Piston Rings (Engine AR) 105

Table 12 Piston Rings (Engines YG and YH) 105

Table 13 Piston Pins 106

Table 14 Connecting Rods 106

Table 15 Small End Bushings 106

Table 16 Connecting Rod Bearings (Engines AR and YG) 106

Table 17 Connecting Rod Bearings (Engine YH) 106

Table 18 Piston Cooling Jets 107

Table 19 Crankshaft 107

Table 20 Main Bearings 107

Table 21 Crankshaft Thrust Washers 107

Table 22 Crankshaft Heat Treatment 108

Table 23 Crankshaft Overhaul Specifications 108

Table 24 Maximum Variation (Run-out) 110

Table 25 Camshaft 110

Table 26 Camshaft Thrust Washer 110

Table 27 Camshaft Gear 110

Table 28 Gear for Fuel Injection Pump 111

Table 29 Crankshaft Gear 111

Table 30 Idler Gear and Hub 111

Table 31 Cylinder Block (Engine AR) 111

Table 32 Cylinder Bore Specifications 112

Table 33 Cylinder Block (Engines YG and YH) 113

Table 34 Cylinder Liners (Engines YG and YH) 113

Table 35 Cylinder Liner Specifications (Partially Finished) 113

Table 36 Oil Pump (Engine AR) 114

Table 37 Oil Pump (Engines YG and YH) 114

Table 38 Idler Gear for Oil Pump 114

Table 39 Relief Valve 115

Table 40 Oil Filter 115

Table 41 Lucas Fuel Injection Pump 115

Table 42 Fuel Injector Codes 116

Table 43 Fuel Pump (Engine AR) 117

Table 44 Fuel Pump (Engines YG and YH) 117

Table 45 Fuel Filter 117

Table 46 Coolant Pump 117

Table 47 Thermostat 117

Table 48 Fan Drive Housing 117

Table 49 Limits for Flywheel Run Out and Alignment (Total Indic 117

Table 50 Alternator 118

Table 51 Starter Motor 118

Table 52 Cold Start Aid 118

Table 53 List of Possible Causes 126

524150791 2200YRM0002 (01 2016) US EN 131

General 135

Description 136

Alternator Repair 138

Alternator Type A 138

Remove and Disassemble 138

Clean 140

Assemble 140

Install 141

Alternator Type B 144

Remove and Disassemble 144

Clean 144

Assemble 145

Install 146

General Check and Adjustment 146

Low Output Check (Type A or Type B) 147

High Output Check (Type A or Type B) 150

Brushes Circuit Check 151

Delco Alternators 151

Motorola Alternators 151

Diodes Check 152

Diode Bridge Check 152

Delco and Leece-Neville Alternators 152

Motorola Alternators 152

Rotor Field Winding Check 153

Stator Windings Check 154

Voltage Regulator Check 154

Troubleshooting 154

524150797 8000YRM0231 (02 2023) US EN 159

General 165

Threaded Fasteners 165

Nomenclature, Threads 165

Strength Identification 166

Cotter (Split) Pins 167

Fastener Torque Tables 172

Conversion Table 174

524150797 8000YRM0231 (03 2020) US EN 181

General 185

Threaded Fasteners 185

Nomenclature, Threads 185

Strength Identification 186

Cotter (Split) Pins 187

Fastener Torque Tables 192

Conversion Table 194

524153606 1300YRM0801 (08 2001) US EN 201

toc 201

Hydrostatic Transmission 201

Safety Precautions Maintenance and Repair 202

General 205

TransLink—42 User Interface Software 205

Connecting PC to TCM 205

Transmission Fluid 206

Startup and Calibration 208

Startup Procedure Following Service or Repairs 208

Throttle System Calibration 209

Hydrostatic Pump Repair 210

Remove 210

Install 211

Charge Pump Repair 213

Remove 213

Inspect 214

Install 214

Pump Control Valve Repair 214

Remove 214

Inspect 214

Install 214

Replace Pilot Solenoid 215

Replace Directional Solenoid Pair 215

Clean or Replace Pilot Supply Filter Disk 216

Replace Loop Relief Cartridges 216

Replace Filter Cartridge 216

Replace Filter Head 216

Drive Axle Repair 216

Remove and Disassemble 216

Inspect 217

Assemble and Install 217

Axle Valve Repair 219

Remove 219

Inspect 219

Install 220

Replace Pressure Reducing Valve 220

Replace Shuttle Valve 220

Replace Charge Supply Regulator 220

Replace Retard Valve 220

Replace Temperature Sensor 220

Transmission Control Module (TCM) Replacement 221

Throttle Pedal/ Foot Directional Control Pedal Repair 222

Remove Standard Throttle Pedal 222

Install Standard Throttle Pedal 222

Remove and Disassemble Foot Directional Control Pedal 222

Assemble and Install Foot Directional Control Pedal 223

Replace Throttle Pedal Position Sensor 225

Replace Throttle Pedal Switch 225

Throttle-Up Assembly Repair 226

Remove 226

Inspect 226

Install 226

Replace Throttle Motor 227

Replace Engine Throttle Position Sensor 227

Throttle-Up Switch Assembly Repair 227

Remove 227

Install 227

Replace Lift Lever Position Sensor 227

Replace Throttle-Up Switches 228

Hydrostatic Drive Checks and Adjustments 228

Swashplate Positioning Cylinder 228

Truck Travel Speed Limit Adjustment 229

Charge Pressure 229

Pilot Supply Pressure 229

Pilot Pressure 230

POR Pressure 230

Loop Pressure 230

Throttle Pedal/ Foot Directional Control Pedal Checks and Adjust 231

Throttle Cable 231

Pedal Stop 231

Standard Throttle Pedal 231

Foot Directional Control Pedal 231

Foot Directional Control Pedal Operation 231

Throttle Pedal Position Sensor 231

Throttle Pedal Switch 232

Foot Directional Control Pedal Switch 233

Throttle-Up Assembly Checks and Adjustments 234

Engine Throttle Position Sensor 234

Throttle-Up Motor 234

Throttle-Up Switch Assembly Checks and Adjustments 235

Throttle-Up Switches 235

Lift Lever Position Sensor 235

Sensor Checks 236

Charge Pressure Sensor 236

Brake Pressure Sensor 236

Oil Temperature Sensor 237

Speed Sensor 237

Event Codes 238

Troubleshooting 244

tables 201

Table 1 Charge and Brake Sensor Outputs 236

Table 2 Oil Temperature Sensor Outputs 237

Table 3 Speed Sensor Outputs 237

524153897 0600YRM0590 (04 2014) US EN 253

524153904 1600YRM0732 (10 2003) US EN 305

toc 305

Steering Control Unit 305

Safety Precautions Maintenance and Repair 306

General 309

Description 309

Operation 309

Steering Wheel and Column Assembly Repair 311

Remove and Disassemble 311

Assemble and Install 311

Steering Control Unit 314

Disassemble 314

Clean 316

Assemble 317

System Air Removal 320

Troubleshooting 320

524153909 1900YRM0743 (06 2005) US EN 325

toc 325

Hydraulic System 325

Safety Precautions Maintenance and Repair 326

General 329

Description 329

Operation 331

Hydraulic Pump GLP/GDP 3 5-5 5LJ/MJ (GP/GLP/GDP70-120LJ/MJ) 331

Hydraulic Pump GC070-120LJ/MJ 331

Main Control Valve 331

Steering Control Unit 332

Specifications 332

Hydraulic System Capacity (Powershift) 332

Hydraulic System Capacity (Hydrostatic) 332

Hydraulic Tank Capacity (Powershift and Hydrostatic) 333

Hydraulic Tank Capacity 333

Relief Pressures @ 2200 RPM, 50 to 80 C ( 120 to 180 F) 333

Hydraulic Pump Flow to Valve 333

Steering Priority Flow 333

Troubleshooting 333

Lift, Lower and Tilt Circuit 334

Steering Circuit 335

524153910 2000YRM0754 (12 2003) US EN 339

toc 339

Main Control Valve 339

Safety Precautions Maintenance and Repair 340

General 343

Description 343

Operation 343

Lift Section 343

Tilt and Auxiliary Sections 347

Reattaching the Clevis End of the Tilt Spool 348

Relief Valve 348

Main Control Valve Repair 348

Remove and Disassemble 348

Clean and Inspect 350

Assemble 352

Install 352

Pressure Relief Valve Check and Adjustment 353

Main Relief Valve (Lift) 353

Steering Relief Valve 353

Secondary Relief Valve (Tilt and Auxiliary) 356

Specifications 357

Troubleshooting 357

524153913 2200YRM0755 (10 2003) US EN 363

toc 363

Starter 363

Safety Precautions Maintenance and Repair 364

General 367

Description 367

Yoke Assembly 368

Armature Assembly 368

Clutch Assembly 368

Magnetic Switch Assembly 368

Operation 368

Starter Repair 369

Remove 369

Disassemble 370

Clean 373

Assemble 374

Install 377

General Checks and Adjustments 377

Armature Tests 378

Armature Short Circuit Test 378

Armature Winding Ground Test 378

Commutator Run-Out Test 378

Yoke Test 379

Brush and Brush Holder Check 379

Brush Holder Insulation Test 379

Clutch Test 379

Magnetic Switch Test 380

Pull-In Test 380

Hold-In Test 380

Return Test 380

Performance Tests 381

No-Load Test 381

Troubleshooting 381

524153914 2200YRM0107 (03 2008) US EN 387

toc 387

High Energy Ignition (HEI) System 387

Safety Precautions Maintenance and Repair 388

Description 391

Distributor Repair 393

Remove 393

Disassemble 393

Assemble 399

Install, If Crankshaft WAS NOT Rotated when Distributor was Remo 400

Install, If Crankshaft WAS Rotated when Distributor was Removed 400

Ignition Coil Replacement 402

Some Four- and Six-Cylinder Models 402

Remove 402

Install 402

V8, Some Four- and Six-Cylinder Models 403

Remove 403

Install 403

Electronic Module Replacement 404

Remove 404

Install 404

Sensing Coil Replacement 406

Remove 406

Install 406

Spark Plugs Replacement 406

Remove 406

Install 407

Visual Check 407

High Voltage Wires Check 407

Ignition Coil Check 408

Coil in Distributor Cap Design 408

Separate Coil Design 408

Sensing Coil, Check 409

Electronic Module Check 409

Ignition Timing Adjustment 410

GM V8-366 (6-liter) Ignition System Check 411

GM V6-LPG (4 3 liter) GM V6-LPG (4 3 liter) Ignition Timing and 411

Specifications 411

Troubleshooting 412

524153915 2200YRM0756 (02 2007) US EN 417

toc 417

Instrument Panel Indicators and Senders 417

Safety Precautions Maintenance and Repair 418

General 421

Description 421

Instruments and Senders 421

Password Function 427

Supervisor Password Function 427

Entering Operator Passwords 427

Deleting Operator Passwords 428

Retrieve the Most Recent Operator Password Used to Enable the Tr 428

Display All Operator Passwords Programmed Into the System 428

Enable and Disable Operator Passwords Function 428

Allow Supervisor Password to Enable the Truck to Start 428

Operator Passwords Function 428

Component Replacement – General Information 429

Sender Replacement 429

Fuel Level Sender 429

Pressure and Temperature Sender 430

Seat Sensor, Operator Presence System (OPS) 431

Remove 431

Install 431

Operator Presence System Module Replacement 431

Remove 431

Install 433

Display Panel Replacement 434

Specifications 436

Troubleshooting 437

Troubleshooting For Operator Presence System GP/GLP/GDP70-120LJ/ 438

Troubleshooting For Operator Presence System GC70-120LJ/MJ (C818 440

tables 417

Table 1 Instrument Panel Description 422

Table 2 Sender Description 426

Table 3 Meter and Sender Specifications 436

Table 4 Troubleshooting Procedure for the Operator Presence Mod 438

Table 5 Troubleshooting Procedure for the Operator Presence Mod 440

524153919 4000YRM0741 (03 2005) US EN 445

toc 445

Lift Cylinders 445

Safety Precautions Maintenance and Repair 446

Safety Procedures When Working Near Mast 449

General 451

Description 451

Lowering Control Valve (Velocity Fuse) 451

Lift Cylinder Repair 454

Remove 454

Disassemble 455

Assemble 455

Install 455

Lift System Leak Check 456

Troubleshooting 457

524153920 4000YRM0736 (07 2010) US EN 461

toc 461

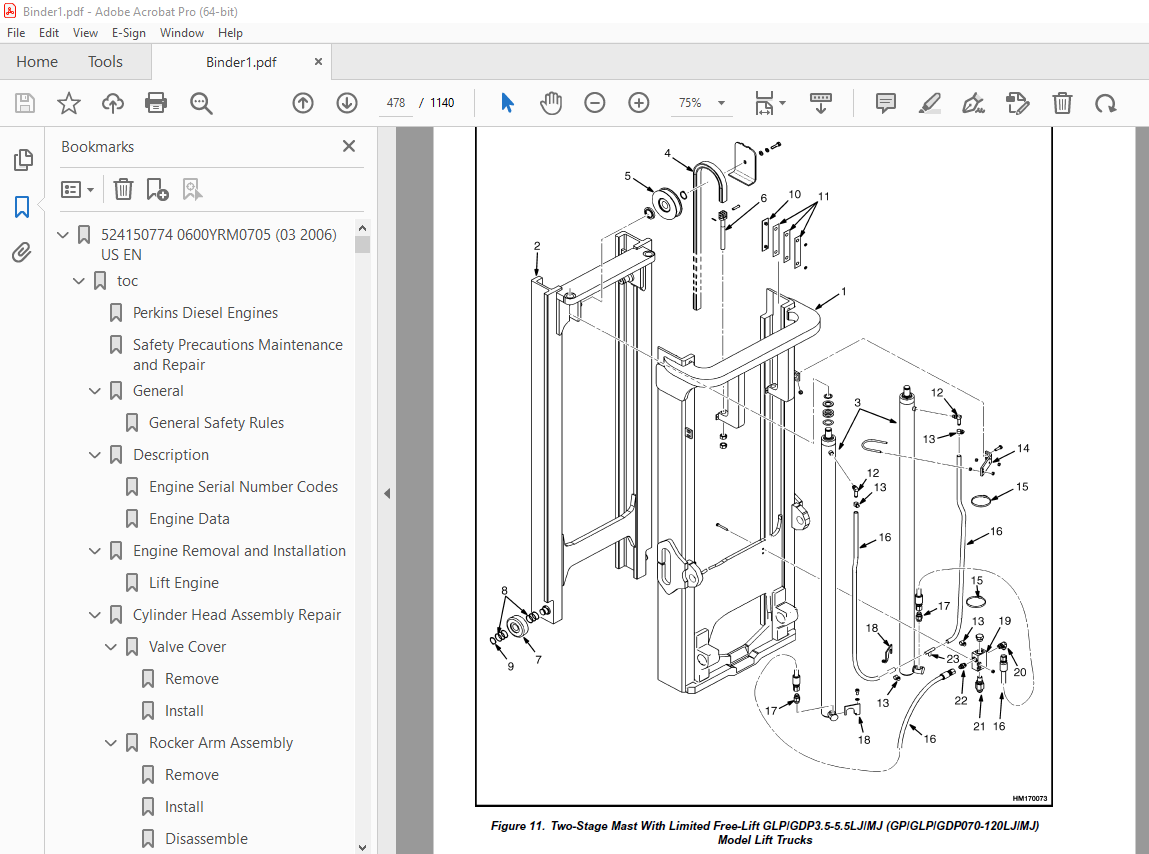

Masts 461

Safety Precautions Maintenance and Repair 462

General 465

Description and Operation 465

Carriages 465

Two-Stage Mast With Limited Free-Lift 465

Two-Stage Mast With Full Free-Lift 466

Three-Stage Mast With Full Free-Lift 467

Safety Procedures When Working Near Mast 469

Fork Replacement 471

Remove 472

Install 472

Carriage Repair 473

Remove 473

Sideshift Carriage Repair 475

Remove 475

Disassemble 475

Assemble 475

Install 475

Two-Stage Mast With Limited Free-Lift Repair 477

Remove, GLP/GDP3 5-5 5LJ/MJ (GP/GLP/GDP070-120LJ/MJ) Model Lift 477

Remove, GC070-120LJ/MJ, ERC070-120HG (A839), and ERC35-55HG (ERC 479

Disassemble 482

Clean and Inspect 482

Assemble 483

Install, GLP/GDP3 5-5 5LJ/MJ (GP/GLP/GDP070-120LJ/MJ) Lift Truck 484

Install, GC070-120LJ/MJ, ERC070-120HG (A839), and ERC35-55HG (ER 486

Two-Stage Mast With Full Free-Lift Repair 488

Remove 488

Disassemble 488

Clean and Inspect 490

Assemble 490

Install 490

Three-Stage Mast With Full Free-Lift Repair 492

Remove 492

Disassemble 492

Clean and Inspect 496

Assemble 496

Install 497

Mast Operation Check 503

Lift and Tilt System Leak Check 504

Lift System 504

Tilt System 505

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment 506

Lift Chain Adjustments 508

Mast Adjustments 510

Carriage Adjustment 512

Troubleshooting 513

tables 461

Table 1 Tilt Cylinder Leak Check Specifications, GC070-120LJ/MJ 505

Table 2 Hook-Type Carriage Chain Adjustment 508

Table 3 Pin-Type Carriage Chain Adjustment 509

524173800 0100YRM0726 (02 2007) US EN 519

toc 519

Frame 519

Safety Precautions Maintenance and Repair 520

General 523

Description 523

Counterweight Repair 523

Remove 523

Install 524

Hood Repair 524

Remove 524

Install 524

Overhead Guard Repair 526

Remove 526

Inspect 526

Install 526

LED Backup and Brake Lights, Replace 526

Remove 526

Install 526

Operator Restraint System Repair 527

Automatic Locking Retractor (ALR) 527

Emergency Locking Retractor (ELR) 528

Radiator Repair 529

Remove 529

Install 529

Exhaust System Repair 531

Muffler 531

Remove 531

Install 531

LPG/Gas Engine Exhaust Pipe – Lift Trucks Without Low Emissions 534

Remove 534

Install 534

EPA Compliant LPG/Gas Engine Exhaust System 534

Remove 534

Install 536

Diesel Engine Exhaust Pipe 536

Remove 536

Install 538

Engine Repair 538

Remove 538

Install 540

Throttle Pedal Adjustment 542

Perkins 1104C-44(RE) Diesel Engine 542

Lift Trucks With an Accelerator Pedal 542

Lift Trucks With a Foot Directional Control Pedal 543

Fuel and Hydraulic Tanks Repair 545

Inspect 545

Small Leaks, Repair 545

Large Leaks, Repair 545

Clean 545

Steam Method 545

Chemical Solution Method 545

Other Preparation Methods for Repair 546

Safety Labels 546

tables 519

Table 1 Weight of Counterweights 523

524173801 0100YRM0778 (06 2004) US EN 551

toc 551

Operators Cab 551

Safety Precautions Maintenance and Repair 552

General 555

Cab Repair 556

Remove 556

Install 557

Switch Panel 557

Window Wipers Replacement 558

Front Wiper Assembly 558

Rear Wiper Assembly 558

Door Handle Assembly 560

Fuse Panel 561

Heater Assembly 561

Remove 561

Install 561

Window Replacement 563

Options 565

Rear Strobe Lights 565

Heavy-Duty Air Cleaner 565

Label Replacement 566

Electrical Schematics 566

tables 551

Table 1 Material Specifications for Cab Windows 563

524173802 0700YRM0740 (02 2004) US EN 571

toc 571

Cooling System 571

Safety Precautions Maintenance and Repair 572

General 575

Description 575

Radiator 575

Radiator Cap 575

Thermostat 575

Water Pump 576

Fan and Fan Shroud 576

Drive Shaft 576

Cooling System Checks 576

Exhaust Leaks into Cooling System 576

Radiator Repair 576

Checks 576

Clean 576

Cooling System 578

Drain 578

Fill 578

Water Pump Repair 578

Checks 578

Thermostat Repair 579

Checks 579

Fan Assembly Repair 579

Remove 579

Inspect 579

Install 579

Fan Belt Repair 582

Remove 582

Install 582

Drive Shaft Repair 582

Remove 582

Install 582

Troubleshooting 582

524173803 0900YRM0745 (09 2003) US EN 587

toc 587

LPG Fuel System 587

Safety Precautions Maintenance and Repair 588

General 591

Description and Operation 591

Fuel Tank 591

Fuel Filter and Fuel Valve Unit 591

LPG Convertor Vaporizer (IMPCO) 591

LPG Controller (Dana EPIC/Teleflex-GFI) 595

Filter Section 595

Lock-Off Section 595

Converter Section – Primary Regulation (Stage 1) 595

Converter Section – Secondary Regulation (Stage 2) 595

Carburetor 596

Governor 599

Two-Way Valves, Open-Loop System 599

Closed-Loop Fuel Control 599

O E Tune Valve, Closed-Loop Fuel System 600

Oxygen Sensor, Closed-Loop Fuel System 600

LPG Tank Repair 600

Remove 600

Install 600

Hydrostatic Relief Valve Repair 601

Remove and Install 601

Filter Unit Repair 602

Fuel Filter Element, Replace 602

Diaphragm and Fuel Valve, Replace 602

Hoses Replacement 602

LPG Convertor Vaporizer (IMPCO) Repair 604

Remove 604

Disassemble 604

Clean 604

Inspect 604

Assemble 606

Install 610

LPG Controller (Dana EPIC/Teleflex-GFI) Repairs 610

Remove 610

Disassemble 610

Converter Section 610

Filter Section 612

Lock-Off Section 612

Clean 614

Inspect 614

LPG Controller Assembly 614

Filter Section 614

Lock-Off Section 614

Converter Section 614

Carburetor Repair 616

Remove 616

Disassemble 616

Clean 616

Assemble 617

Install 617

Governor Assembly Repair 618

Governor Motor Repair 620

Remove 620

Install 620

Filter Unit Check 620

Vaporizer Check 621

Pressure Reducer Valve 621

Vapor Valve 621

Carburetor Adjustment 621

Idle Mixture 621

Idle Speed 621

Throttle Linkage Adjustment 621

LPG Controller Adjustments (Dana EPIC/Teleflex-GFI) 622

Filter and Lock-Off Sections Leak Check 622

Lock-Off Section Functional Check 623

Controller Pressure Test 623

Adjustment of Secondary Lever 624

Final Adjustment Check 624

Troubleshooting 625

524173804 1300YRM0727 (06 2004) US EN 635

toc 635

Two-Speed Powershift Transmission 635

Safety Precautions Maintenance and Repair 636

General 639

Mechanical Description 639

Torque Converter 640

Transmission Pump 640

Shaft Assemblies 640

Input (Reverse) Shaft 640

Counter (Forward) Clutch Shafts 640

Clutch Assemblies 640

Output Gear and Pinion 641

Electronic Control Unit 641

Hydraulic Operation 642

Torque Converter 642

Seal Rings 643

Control Valve 643

Clutch Pressure Regulator 643

Inching Spool Assembly 643

Direction Spool 645

Modulator Circuit 645

Torque Converter Regulator 645

Foot Directional Control Pedal 646

Foot Directional Control Pedal Start Circuit 646

Direction Control Lever 647

Oil Flow Diagrams 647

Neutral 648

Modulator Operation 649

Forward-Low 651

Forward-Low-Inching 651

Reverse 657

524173805 1300YRM0728 (08 2006) US EN 665

toc 665

Two-Speed Powershift Transmission 665

Safety Precautions Maintenance and Repair 666

General 669

Transmission Repair 669

Remove 669

Install 669

Clutch Packs Repair 672

Remove and Disassemble 672

Clutch Assemblies, Disassemble 675

Inspect 677

Assemble and Install 678

Clutch Assemblies, Assemble and Install 678

Differential Repair 686

Remove and Disassemble 686

Inspect 687

Original Parts, Assemble and Install 687

New Parts, Assemble and Install 687

Adjustments With Original Shim Pack 688

Adjustments Without Original Shim Pack 689

Differential and Ring Gear Assembly, Assemble 691

Control Valve Repair 696

Remove and Disassemble 696

Inspect 698

Assemble and Install 698

Foot Directional Control Pedal Repair 699

Remove and Disassemble 699

Assemble and Install 699

Direction Control Lever 702

Remove and Disassemble 702

Assemble and Install 702

Stall Test 703

Inching/Brake Pedal Adjustment 704

Foot Directional Control Pedal Neutral Start Switch Adjustment 706

Foot Directional Control Pedal Neutral Start Switch Test 707

Test 1 707

Test 2 707

Electronic Control Unit Check 708

Oil Pressure Check 709

Transmission Pump Relief Valve, Test Port 1, Check 710

Input (Reverse) Clutch Pressure, Test Port 2, Check 710

Counter (Forward) Clutch Pressure, Test Ports 3 and 4, Check 710

Torque Converter Regulator, Test Port 5, Check 710

Lubrication Circuit Oil Pressure, Test Port 6, Check 710

Modulator Pressure, Test Port 7, Check 710

2-Speed Transmission Will Not Shift 711

Troubleshooting 712

Troubleshooting – Pressure Tests 715

tables 665

Table 1 Pinion Variation Numbers Examples 688

Table 2 Ring and Pinion Tooth Contact Adjustment 694

Table 3 Stall Speeds (New Engines) 703

Table 4 Electronic Control Unit Connector 708

Table 5 Transmission Pressure Port Check 709

524173806 1400YRM0731 (09 2003) US EN 719

toc 719

Drive Axle 719

Safety Precautions Maintenance and Repair 720

General 723

Description 723

Drive Axle Repair 723

Remove and Disassemble 723

Clean and Inspect 725

Assemble and Install 725

Troubleshooting 727

524173807 1600YRM0733 (09 2003) US EN 731

toc 731

Steering Axle 731

Safety Precautions Maintenance and Repair 732

General 735

Description 735

Steering Axle Assembly Repair 736

Remove 736

Install 736

Wheels and Hub Repair 737

Remove and Disassemble 737

Clean 737

Inspect 737

Assemble and Install 737

Spindles and Bearings Repair 738

Remove 738

Clean 738

Inspect 738

Assemble and Install 738

Tie Rods Repair 739

Remove 739

Clean 739

Inspect 739

Install 739

Steering Cylinder Repair 739

Remove and Disassemble 739

Clean and Inspect 739

Assemble and Install 740

Troubleshooting 741

524173808 1800YRM0734 (05 2005) US EN 745

toc 745

Brake System 745

Safety Precautions Maintenance and Repair 746

General 749

Description and Operation 749

Brake Booster and Master Cylinder 749

Service Brake Assembly 749

Parking Brake 749

Brake Shoe Assemblies Repair 750

Remove and Disassemble 750

Clean 752

Inspect 752

Assemble and Install 753

Brake Booster and Master Cylinder Repair 756

Remove 756

Disassemble 756

Clean and Inspect 756

Assemble 756

Install 756

Brake Booster Filter, Replace 756

Parking Brake Repair 759

Remove and Disassemble 759

Assemble and Install 759

Brake System Air Removal 759

Brake Pedal Adjustment 759

Parking Brake Adjustment 760

Parking Brake Not Applied Switch Test 760

Parking Brake Switch Test ( Foot Directional Control Pedal Only) 761

Brake Shoes Adjustment 761

Troubleshooting 762

524173809 1900YRM0753 (09 2003) US EN 767

toc 767

Hydraulic Gear Pump 767

Safety Precautions Maintenance and Repair 768

General 771

Description 771

Operation 771

Hydraulic Gear Pump Repair 772

Remove 772

Disassemble 772

Clean 774

Inspect 774

Assemble 775

Install 775

Pump Output Check 776

Method No 1 776

Method No 2 777

Hydraulic System Air Check 778

Troubleshooting 778

524173810 2100YRM0735 (11 2004) US EN 783

toc 783

Tilt Cylinders 783

Safety Precautions Maintenance and Repair 784

General 787

Description 787

Tilt Cylinder Repair 787

Remove 787

Disassemble 788

Clean 789

Inspect 789

Assemble 789

Install 789

Tilt Cylinder Leak Check 790

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 790

Troubleshooting 790

524173811 2200YRM0744 (09 2003) US EN 795

toc 795

Carbureted Engine Management System (CEMS) 795

Safety Precautions Maintenance and Repair 796

Description 799

Ignition Control System 800

Setting Timing Reference 800

Idle Speed Control System 800

Curb Idle Setting Procedure 800

Governor Control System 801

Closed-Loop Fuel System 802

Closed-Loop Fuel Control 802

Entering Closed-Loop Control 802

Normal Closed-Loop Operation 802

Closed-Loop Diagnostics 802

O E Tune Valve Action at Engine Shutdown 802

Diagnostic System 803

Closed-Loop Diagnostic Troubleshooting 804

Diagnostic Troubleshooting 804

tables 795

Table 1 Diagnostic Codes 803

Table 2 Diagnostic Troubleshooting 804

524173812 2200YRM0766 (08 2002) US EN 811

toc 811

Electronic Engine Control 811

Safety Precautions Maintenance and Repair 812

General 815

Description and Operation 815

General 815

ECM (Electronic Control Module) 815

Diagnostic Connector 815

How ECM Begins Operation 817

Electronic Engine Control 817

What ECM Does 817

Pulse Generator, EST Distributor 819

EST Module 819

When Engine is Being Started 820

When Engine is Running 820

Electronic Control Module (ECM) With EST Distributor, Correction 821

Fuel Control 822

Injection Throttle Body (ITB) 823

Fuel Injectors 824

Fuel Pressure Regulator 824

Governor Throttle Body Assembly 824

Throttle Position Sensor (TPS) 825

Idle Air Control 825

Vacuum Ports 825

Fuel Pump 825

ECM Sensors and Controllers 826

Manifold Absolute Pressure (MAP) 826

Coolant Temperature Sensor (CTS) 827

524173813 2200YRM0767 (04 2005) US EN 831

toc 831

Electronic Engine Control 831

Safety Precautions Maintenance and Repair 832

General 837

Engine Data 837

Light Bulb Check 837

System Check 838

Troubleshooting With Fault Monitor System in ECM 840

How to Clear a Code 842

Fault In the ECM 842

Fuel Control 842

Idle Air Control (IAC) 843

Fuel Pump Circuit 843

Coolant Temperature Sensor (CTS) 843

Manifold Absolute Pressure Sensor (MAP) 843

Throttle Position Sensor (TPS) 843

Throttle Position Sensor Output Check 844

Electronic Spark Timing (EST) 844

Distributor Reference Signal 844

A-1 – No Service Engine Soon Light 845

Circuit Description 845

Test Description 845

Other Troubleshooting Checks: 845

A-2 – No Diagnostic Data or Code 12 847

Circuit Description 847

Test Description 847

A-3 – Starter Cranks Engine, But Does Not Run 849

Circuit Description 849

Test Description 849

Other Troubleshooting Checks: 849

A-4 – Fuel Injector Circuit 851

Circuit Description 851

Test Description 851

A-5 – Fuel Pump Relay Circuit 853

Circuit Description 853

Test Description 853

A-6 – Fuel System Pressure Test 855

Circuit Description 855

Test Description 855

A-7 – MAP Output Check 857

Circuit Description 857

Test Description 857

A-8 – Ignition System Troubleshooting 859

Circuit Description 859

Test Description 859

A-9 – Idle Air Control (IAC) System 863

Circuit Description 863

IAC Valve Reset Procedures 863

Test Description 863

Fault Code 14 – Coolant Temperature Sensor Circuit (Indicates Lo 865

Circuit Description 865

Test Description 865

Fault Code 15 – Coolant Temperature Sensor Circuit (Indicates Hi 867

Circuit Description 867

Test Description 867

Fault Code 21 – Throttle Position Sensor Circuit (Signal Voltage 870

Circuit Description 870

Test Description 870

Fault Code 22 – Throttle Position Sensor Circuit (Signal Voltage 872

Circuit Description 872

Test Description 872

Fault Code 31 – Engine Governor Circuit 874

Circuit Description 874

Test Description 874

Other Troubleshooting Checks 874

Fault Code 33 – MAP Sensor Circuit, Signal Voltage High (Low Vac 876

Circuit Description 876

Test Description 876

Other Troubleshooting Checks 876

Fault Code 34 – MAP Sensor Circuit, Signal Voltage Low (High Vac 878

Circuit Description 878

Test Description 878

Other Troubleshooting Checks 878

Fault Code 41 – Electronic Spark Timing (EST), Open Circuit 880

Circuit Description 880

Test Description 880

Fault Code 42 – EST, Grounded IC Circuit, Open or Grounded Bypas 882

Circuit Description 882

Test Description 883

Other Troubleshooting Checks 883

Fault Code 51 – ECM Failure 885

Circuit Description 885

Other Troubleshooting Checks 885

Troubleshooting, Poor Operation 885

General 885

Make a Careful Visual Check 885

FAULT: Fuel Usage Too High 885

Definition 885

Check 885

FAULT: Codes Or Performance That Is Not Regular 885

Definition 885

Check 885

FAULT: Dieseling 886

Definition 886

Check 886

FAULT: Backfire 886

Definition 886

Check 886

FAULT: Rough Idle or Engine Stalls During Idle 886

Definition 886

Check 886

FAULT: Smoke In The Exhaust Gases 886

Definition 886

Check 886

FAULT: Engine Is Difficult To Start 887

Definition 887

Check 887

FAULT: Variation In Engine Power When The Throttle Is Held Stead 887

Definition 887

Check 887

FAULT: Decreased Engine Power 888

Definition 888

Check 888

FAULT: Detonation 888

Definition 888

Check 888

FAULT: Engine Momentarily Does Not Increase Power When Throttle 888

Definition 888

Check 889

FAULT: One Cylinder In The Engine Does Not Operate Correctly Th 889

Definition 889

Check 889

Fuel System Components Repair 889

General 889

Fuel Control 889

Injection Throttle Body (ITB) Assembly 890

Remove 890

Clean and Inspect 890

Install 890

Fuel Injectors 892

Remove 892

Install 893

Pressure Regulator 893

Remove 893

Inspect 893

Install 893

Governor Throttle Body (GTB) Assembly 894

Vacuum Ports 894

Remove 894

Inspect 895

Install 895

Throttle Position Sensor (TPS) 895

Remove 895

Inspect 895

Install 895

Idle Air Control (IAC) Valve 896

Remove 896

Clean and Inspect 896

Install 896

Governor Motor 896

Remove 896

Inspect 897

Install 897

Fuel Pump 897

Remove and Disassemble 897

Inspect 897

Electrical Components Repair 898

General 898

Ignition Coil Test 898

Ignition Module Test 898

Distributor 898

Remove 898

Disassemble 899

Assemble 901

Install 901

Firing Order 902

Ignition Timing 902

Ignition Coil 903

Remove 903

Install 903

Procedures for Spark Plugs, Spark Plug Wires, and Boots 903

Troubleshooting of Spark Plugs 904

Coolant Temperature Sensor (CTS) Replacement 905

Manifold Absolute Pressure (MAP) Sensor Replacement 905

Oil Pressure Sender Replacement 905

Low Coolant Sender Replacement 906

Wire Harness 906

Connectors and Terminals 907

Electronic Control Module (ECM) 910

Special Tools 915

tables 831

Table 1 ECM Diagnostic Codes 841

Table 2 Wire Harness Repair 906

Table 3 Weather-Pack Terminal Repair 909

Table 4 ECM Connector J1 Identification 913

Table 5 ECM Connector J2 Identification 914

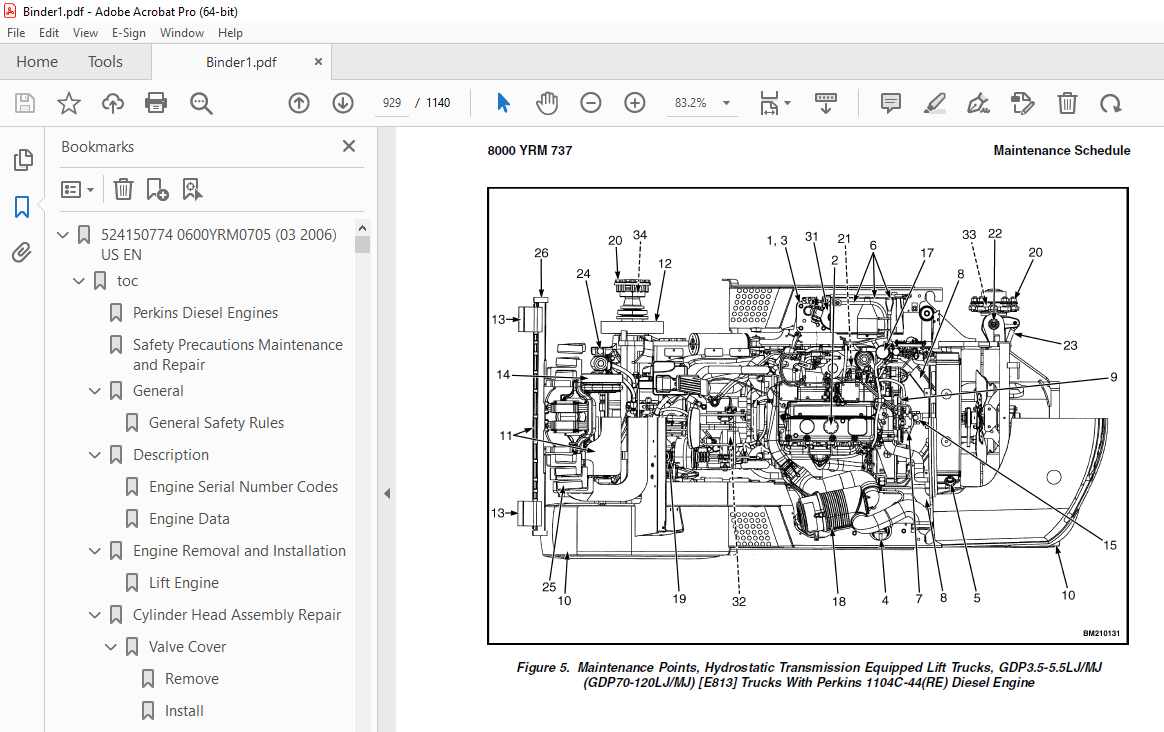

524173814 8000YRM0737 (03 2011) US EN 919

toc 919

Periodic Maintenance 919

Safety Precautions Maintenance and Repair 920

General 925

Serial Number Data 925

How to Move Disabled Lift Truck 925

How to Tow Lift Truck 925

How to Put Lift Truck on Blocks 926

How to Raise Drive Tires 926

How to Raise Steering Tires 926

Maintenance Schedule 927

Maintenance Procedures Every 8 Hours or Daily 939

How to Make Checks With Engine Stopped 939

Engine Oil 940

Hydraulic System Oil 940

Cooling System 941

Heavy Duty Precleaner 941

Fuel System 941

Battery 942

Tires and Wheels 942

Forks 943

Adjust 943

Hook Fork, Remove 944

Hook Fork, Install 944

Forks, Mast, and Lift Chains, Inspect 945

Operator Restraint System 945

Automatic Locking Retractor (ALR) 945

Emergency Locking Retractor (ELR) 945

Safety Labels 947

How to Make Checks With Engine Running 947

Gauges, Lights, Horn, and Fuses 947

Engine Oil Pressure 948

Cooling System 950

Powershift Transmission Oil Level Check 950

Hydrostatic Transmission Oil Level Check 951

Control Levers and Pedals 951

Lift System Operation 951

Inching/Brake Pedal 951

Service Brakes 952

Parking Brake 952

Steering System 952

Maintenance Procedures Every 250 Hours or 6 Weeks 953

Engine Oil and Filter, GM V-6 EPA Compliant Engine (Americas Onl 953

Air Filter, GM V-6 EPA Compliant Engine 953

Maintenance Procedures Every 500 Hours or 2 Months 954

Lift Chains Lubrication 954

Air Filter 954

Hydraulic Pump Drive Shaft 954

Engine Oil and Filter, Diesel and GM V-6 (European Only) 954

Drive Belts 955

Fan Drive Belts 955

Perkins Diesel Engine 955

Alternator Drive Belt 955

GM 4 3L Engine 956

Serpentine Drive Belt 956

Hydraulic Tank Breather, Clean and Check 957

Hydrostatic Transmission Filter 957

Filter Cartridge, Replace 957

Filter Head, Replace 957

Brake Fluid 958

Lift Chains Wear Check 958

Forks, Wear and Damage Check 959

Mast, Lubrication 959

Control Levers and Pedals, Lubrication 960

Steering Axle, Lubrication 960

Fuel System, Checks and Adjustments 960

LPG Carburetor 960

Fuel Injection (Perkins Engine) 960

GM V-6 Engine 960

Cooling System, Clean Debris from Radiator Core 960

Maintenance Procedures Every 1000 Hours or 6 Months 960

PCV Valve, GM V-6 960

Crankcase Breather, GM-V6 960

Spark Plug Replacement 960

Remove 960

Install 961

Valve Clearance, Check and Adjust 961

Water Separator, Diesel Engine 961

Fuel Filter, Replace (Diesel Engine) 962

Fuel System Air Removal, Perkins (1004 42 Diesel Engine) 962

Differential and Drive Axle 964

Cooling System, GM V-6 EPA Compliant Engine 964

LPG Fuel Filter GM V-6 EPA Compliant Engine, Replace 964

Inspect Engine Electrical System, Connectors, and FCVS Connectio 965

Maintenance Procedures Every 2000 Hours or Yearly 965

Differential Thrust Screw 965

Hydraulic System 966

Hydraulic Oil and Filter, Replace 966

Powershift Transmission Oil and Filter, Replace 966

Hydrostatic Transmission Oil and Filter, Replace 967

Cooling System 967

Wheel Bearings 967

Steering Wheels, Lubrication 967

Drive Wheels, Lubrication 968

PCV Valve, GM V-6 968

Service Brakes 968

Brake Booster Filter, Replace 968

LPG Filter, Replace (Pre-2004) 969

Gasoline Fuel Filter, Replace 969

Operator Restraint System 969

Oxygen Sensor (Pre 2004) 970

Oxygen Sensor GM V-6 EPA Compliant Engine 970

Air Filter Element, GM V-6 EPA Compliant Engine 970

Inspect Low Pressure Regulator (LPR) for Oil Buildup and Leaks 970

Check Throttle Shaft for Sticking 971

Inspect Exhaust Manifold and Piping for Leaks 971

Test LPG/GAS Regulator Pressure 971

Safety Procedures When Working Near Mast 972

Lift Chain Adjustments 974

Fuel Injectors Repair 975

Lift and Tilt System Leak Check 976

Lift Cylinders, Leak Check 976

Tilt Cylinders, Leak Check 976

Welding Repairs 977

Overhead Guard Changes 977

Wheel and Tire Replacement 978

Remove Wheels From Lift Truck 978

Remove Wheel From Tire 979

Remove Tire From Two-Piece Wheel 980

Remove Tire From Three- and Four-Piece Wheel 982

Install Wheel in Tire 983

Install Tire on Three- or Four-Piece Wheel 984

Install Tire in Two-Piece Wheel 985

Add Air to Tires 986

Wheels, Install 986

Dual Drive Wheels Installation 987

Solid Rubber Tire Repair 987

Wheel, Tire Remove 988

Wheel, Tire Install 989

SIT Tire, Change for H3 50-5 50XM (European Trucks Only) 991

Remove SIT Solid Tire From Wheel 992

Install SIT Solid Tire on Wheel 993

Adhesives and Sealants 994

Hydraulic Oil, Lubricant, and Coolant Specifications 994

tables 919

Table 1 Maintenance Schedule 930

Table 2 Hook-Type Carriage Chain Adjustment 974

Table 3 Pin-Type Carriage Chain Adjustment 975

524173815 8000YRM0738 (05 2004) US EN 997

toc 997

Capacities and Specifications 997

Safety Precautions Maintenance and Repair 998

Lift Truck Weights 1001

Electrical System 1001

Stall Speeds 1001

Capacities 1002

Tire Pressure 1002

Engine Specifications 1003

Transmission Oil Pressures 1004

Hydraulic System 1005

Mast Speeds 1006

Torque Specifications 1006

Brake System 1006

Differential 1006

Drive Axle 1007

Engine, GM V-6 4 3 Liter 1007

Engine, Perkins 1004-42 1008

Frame 1008

Lift Cylinders 1008

Main Control Valve 1008

Masts 1008

Powershift Transmission 1009

Steering System 1009

Tilt Cylinders 1009

Hydrostatic Components 1009

tables 997

Table 1 Single-Speed 1004

Table 2 Two-Speed 1004

Table 3 Hydrostatic Transmission 1005

524173816 8000YRM0757 (11 2008) US EN 1013

toc 1013

Diagrams 1013

Safety Precautions Maintenance and Repair 1014

524174200 0900YRM0768 (08 2002) US EN 1055

toc 1055

Dual Fuel System 1055

Safety Precautions Maintenance and Repair 1056

General 1059

Description 1060

Operation 1060

LPG Solenoid Valve Repair 1060

Fuel Selector Switch Repair 1060

Adjustments 1061

Troubleshooting 1061

524174201 1300YRM0751 (06 2004) US EN 1065

toc 1065

Single-Speed Powershift Transmission 1065

Safety Precautions Maintenance and Repair 1066

General 1069

Mechanical Description 1069

Torque Converter 1069

Transmission Pump 1070

Shaft Assemblies 1070

Input (Reverse) Shaft 1070

Counter (Forward) Clutch Shaft 1070

Clutch Assemblies 1070

Output Gear and Pinion 1070

Hydraulic Operation 1071

Torque Converter 1071

Seal Rings 1072

Control Valve 1073

Clutch Pressure Regulator 1074

Inching Spool Assembly 1074

Direction Spool 1074

Modulator Circuit 1074

Torque Converter Regulator 1074

Foot Directional Control Pedal 1075

Foot Directional Control Pedal Start Circuit 1075

Creep Speed Switch (Optional) 1075

Direction Control Lever 1076

Oil Flow Diagrams 1076

Neutral 1076

Modulator Operation 1079

Forward 1079

Forward-Inching 1083

Reverse 1083

524174202 1300YRM0752 (06 2004) US EN 1091

toc 1091

Single-Speed Powershift Transmission 1091

Safety Precautions Maintenance and Repair 1092

General 1095

Transmission Repair 1095

Remove 1095

Install 1095

Clutch Assemblies Repair 1098

Remove and Disassemble 1098

Clutch Assemblies, Disassemble 1101

Inspect 1103

Assemble and Install 1104

Clutch Assemblies, Assemble and Install 1104

Differential Repair 1111

Remove and Disassemble 1111

Inspect 1112

Original Parts, Assemble and Install 1112

New Parts, Assemble and Install 1112

Adjustments With Original Shim Pack 1113

Adjustments Without Original Shim Pack 1114

Assemble Differential and Ring Gear Assembly 1116

Control Valve Repair 1121

Remove and Disassemble 1121

Inspect 1123

Assemble and Install 1123

Foot Directional Control Pedal Repair 1124

Remove and Disassemble 1124

Assemble and Install 1124

Direction Control Lever Repair 1127

Remove and Disassemble 1127

Assemble and Install 1127

Stall Test 1127

Inching/Brake Pedal Adjustment 1128

Neutral Start Switch Adjustment, Foot Directional Control pEDAL 1130

Neutral Start Switch Test, Foot Directional Control Pedal 1131

Oil Pressures Check 1132

Check Relief Valve for Transmission Pump, TEST PORT 1 1132

Check Input (Reverse) Clutch Pressure, TEST PORT 2 1133

Check Counter (Forward) Clutch Pressure, TEST PORT 3 1133

Check Torque Converter Regulator, TEST PORT 4 1133

Check Lubrication Circuit Oil Pressure, TEST PORT 5 1133

Check Modulator Pressure, TEST PORT 6 1133

Troubleshooting 1134

Troubleshooting – Pressure Tests 1137

tables 1091

Table 1 Pinion Variation Numbers Examples 1113

Table 2 Ring and Pinion Tooth Contact Adjustment 1119

Table 3 Stall Speeds 1128

Table 4 Check Ports for Transmission Pressure 1132