$40.95

Yale Forklift C839 (ERC070HH, ERC080HH, ERC100HH, ERC120HH) Service Manual PDF

Yale Forklift C839 (ERC070HH, ERC080HH, ERC100HH, ERC120HH) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift C839 (ERC070HH, ERC080HH, ERC100HH, ERC120HH) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1298

Downloadable : Yes

File Type : PDF

PART NO. 524150783

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift C839 (ERC070HH, ERC080HH, ERC100HH, ERC120HH) Service Manual – PDF DOWNLOAD

524150783-1600YRM0326-(03-2007)-UK-EN 1

toc 1

Steering Axle 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Steering Axle Assembly Repair 10

Steering Axle GP/GLP/GDP070-110LG/MG (B813), GC/GLC070-120LG/MG 10

Remove 10

Install 10

Steering Axle GDP60-70CA (GP/GLP/GDP135-155CA) (A878, B878), GLP 11

Remove 11

Install 11

Wheels and Hubs Repair (All Units) 12

Remove and Disassemble 12

Clean 12

Inspect 12

Assemble and Install 12

Spindles and Bearings Repair (All Units) 14

Remove 14

Clean 14

Assemble and Install 15

Tie Rods Repair (All Units) 16

Remove 16

Clean 16

Install 16

Steering Cylinder Repair 19

Remove and Disassemble 19

Clean and Inspect 19

Assemble and Install 19

Troubleshooting 20

524150797-8000YRM0231-(02-2023)-UK-EN 25

General 31

Threaded Fasteners 31

Nomenclature, Threads 31

Strength Identification 32

Cotter (Split) Pins 33

Fastener Torque Tables 38

Conversion Table 40

524150797-8000YRM0231-(03-2020)-UK-EN 47

General 51

Threaded Fasteners 51

Nomenclature, Threads 51

Strength Identification 52

Cotter (Split) Pins 53

Fastener Torque Tables 58

Conversion Table 60

524153920-4000YRM0736-(07-2010)-UK-EN 67

toc 67

Masts 67

Safety Precautions Maintenance and Repair 68

General 71

Description and Operation 71

Carriages 71

Two-Stage Mast With Limited Free-Lift 71

Two-Stage Mast With Full Free-Lift 72

Three-Stage Mast With Full Free-Lift 73

Safety Procedures When Working Near Mast 75

Fork Replacement 77

Remove 78

Install 78

Carriage Repair 79

Remove 79

Sideshift Carriage Repair 81

Remove 81

Disassemble 81

Assemble 81

Install 81

Two-Stage Mast With Limited Free-Lift Repair 83

Remove, GLP/GDP3 5-5 5LJ/MJ (GP/GLP/GDP070-120LJ/MJ) Model Lift 83

Remove, GC070-120LJ/MJ, ERC070-120HG (A839), and ERC35-55HG (ERC 85

Disassemble 88

Clean and Inspect 88

Assemble 89

Install, GLP/GDP3 5-5 5LJ/MJ (GP/GLP/GDP070-120LJ/MJ) Lift Truck 90

Install, GC070-120LJ/MJ, ERC070-120HG (A839), and ERC35-55HG (ER 92

Two-Stage Mast With Full Free-Lift Repair 94

Remove 94

Disassemble 94

Clean and Inspect 96

Assemble 96

Install 96

Three-Stage Mast With Full Free-Lift Repair 98

Remove 98

Disassemble 98

Clean and Inspect 102

Assemble 102

Install 103

Mast Operation Check 109

Lift and Tilt System Leak Check 110

Lift System 110

Tilt System 111

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment 112

Lift Chain Adjustments 114

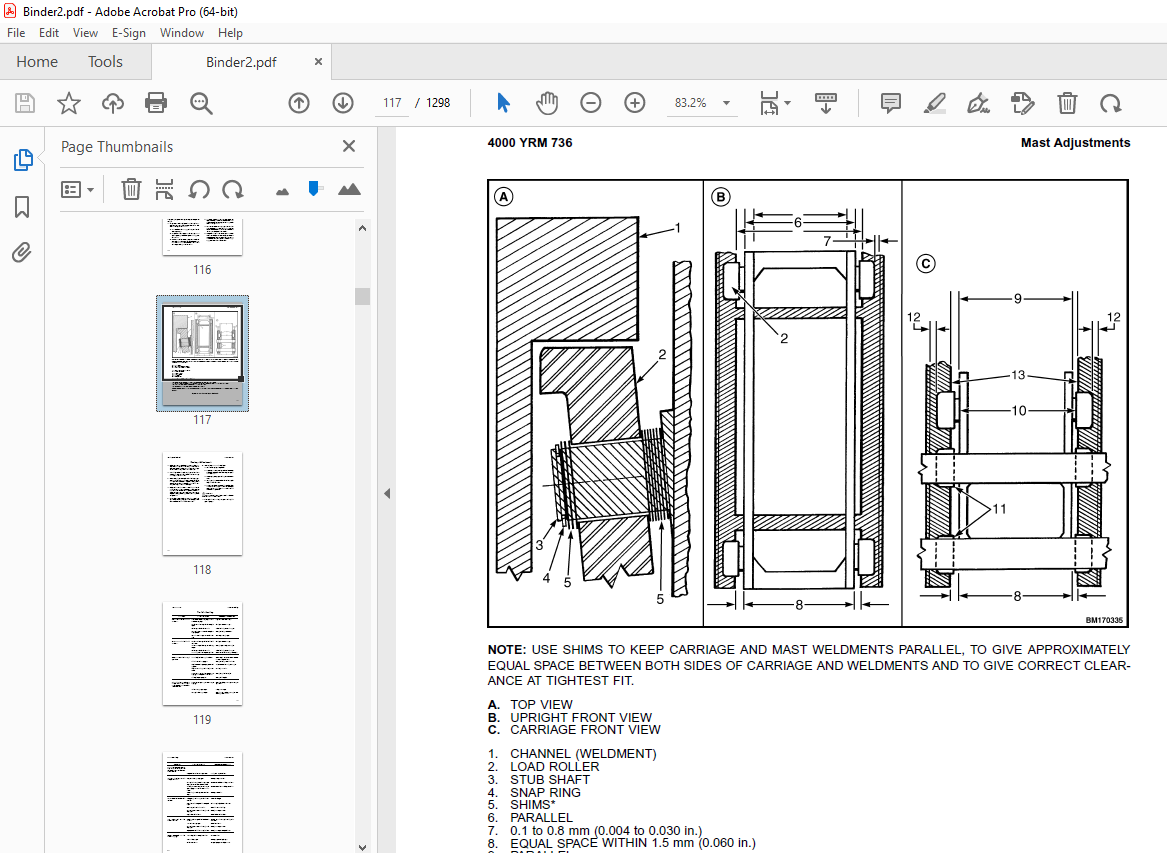

Mast Adjustments 116

Carriage Adjustment 118

Troubleshooting 119

tables 67

Table 1 Tilt Cylinder Leak Check Specifications, GC070-120LJ/MJ 111

Table 2 Hook-Type Carriage Chain Adjustment 114

Table 3 Pin-Type Carriage Chain Adjustment 115

524158040-2240YRM0001-(01-2023)-UK-EN 125

General 131

Battery Type 131

Lead-Acid Batteries 131

Lithium-Ion Batteries 132

Specific Gravity 132

Chemical Reaction in a Cell 132

Electrical Terms 134

Battery Selection 135

Battery Voltage 136

Battery as a Counterweight 136

Battery Ratings 136

Kilowatt-Hours 136

Battery Maintenance 137

Safety Procedures 137

Maintenance Records 137

New Battery 137

Cleaning Battery 138

Adding Water to Battery 140

Hydrometer 140

Battery Temperature 141

Charging Battery 142

Types of Battery Charges 143

Methods of Charging 144

Troubleshooting Charger 145

Knowing When Battery Is Fully Charged 145

Where to Charge Batteries 145

Equipment Needed 145

Battery Connectors 146

Battery Care 146

Troubleshooting 148

524158040-2240YRM0001-(03-2020)-UK-EN 153

General 157

Battery Type 157

Lead-Acid Batteries 157

Lithium-Ion Batteries 158

Specific Gravity 158

Chemical Reaction in a Cell 158

Electrical Terms 160

Battery Selection 160

Battery Voltage 161

Battery as a Counterweight 162

Battery Ratings 162

Kilowatt-Hours 162

Battery Maintenance 162

Safety Procedures 162

Maintenance Records 163

New Battery 163

Cleaning Battery 163

Adding Water to Battery 165

Hydrometer 166

Battery Temperature 167

Charging Battery 168

Types of Battery Charges 168

Methods of Charging 170

Troubleshooting Charger 170

Knowing When Battery Is Fully Charged 171

Where to Charge Batteries 171

Equipment Needed 171

Battery Connectors 172

Battery Care 172

Troubleshooting 174

524158753-1600YRM0720-(11-2006)-UK-EN 179

toc 179

Steering Housing and Control Unit 179

Safety Precautions Maintenance and Repair 180

General 183

Description 183

Operation 184

Steering Wheel and Column Assembly Repair 185

Assembly Components, Remove 185

Steering Control Unit, Disassemble 190

Steering Control Unit, Clean 190

Steering Control Unit, Assemble 190

Assembly Components, Install 192

System Air Removal 194

Troubleshooting 194

524166834-1400YRM0413-(11-2006)-UK-EN 199

toc 199

Drive Axle, Speed Reducer, and Differential 199

Safety Precautions Maintenance and Repair 200

General 203

Description 203

Drive Axle, Speed Reducer, and Differential Repair 204

Remove 204

General 204

Traction Motor, Speed Reducer, and Differential 205

Motor, Speed Reducer, and Differential, Remove 205

Disassemble 208

Speed Reducer 208

Differential 209

Clean 210

Inspect 210

Assemble 210

Speed Reducer 210

Input Gear, Install 210

New Pinion, Install 210

Differential 213

Drive Axle Housing 216

Remove 216

Clean 217

Inspect 217

Assemble 217

Troubleshooting 220

tables 199

Table 1 Pinion Assembly Shims Adjustment 212

Table 2 Ring and Pinion Tooth Contact Adjustment 214

524166837-1800YRM0338-(05-2009)-UK-EN 223

toc 223

Brake System 223

Safety Precautions Maintenance and Repair 224

General 227

Description and Operation 227

Brake Booster and Master Cylinder 227

Master Cylinder 227

Service Brake Assembly 227

Parking Brake 231

Seat Brake 232

Brake Shoe Assemblies Repair 233

Remove and Disassemble 233

Clean and Inspect 233

Assemble and Install 235

Master Cylinder Repair 239

Master Cylinder For Lift Truck Models GC/GLC70-120LG/MG (B818) a 239

Remove 239

Disassemble 239

Assemble 240

Install 240

Master Cylinder For Lift Truck Models ERC70-120HD, ERC70-120HG ( 241

Remove and Disassemble 241

Clean and Inspect 242

Assemble and Install 242

Brake Booster Repair 242

Remove 242

Disassemble 242

Clean and Inspect 243

Assemble 244

Install 244

Brake System Air Removal 244

Brake Pedal Adjustment 244

Brake Pedal GP/GLP/GDP70-120LG/MG (B813) With Manual Transmissio 244

Brake Shoes Adjustment 246

Parking Brake Adjustment 246

Parking Brake Adjustment, Lift Truck Models GC/GLC70-120LG/MG (B 246

Parking Brake Lever and Switch Adjustment ERC70-120HD and ERC70- 247

Seat Brake Assembly 248

Remove 248

Clean and Inspect 248

Install 248

Adjustments 250

Solenoid Adjustment 250

Traction cutoff Switch Adjustment 250

Cable Adjustment 250

Brake Booster Relief Valve Check 253

Troubleshooting 253

524166839-2000YRM0077-(02-2009)-UK-EN 259

toc 259

Manual hydraulic Control Valve 259

Safety Precautions Maintenance and Repair 260

General 263

Description 263

Operation 265

Lift Section 267

Tilt Section 268

Tilt Backward 268

Tilt Forward 268

Relief Valve 270

Solenoid Valve for Auxiliary Function 271

Main Control Valve Repair 272

Remove and Disassemble – Control Valve Without OPS Solenoid 272

Remove and Disassemble – Control Valve With OPS Solenoid 272

Clean and Inspect 274

Assemble – Control Valve Without OPS 274

Assemble – Control Valve With OPS 274

Install 275

Solenoid Valve for Auxiliary Function Repair 275

Remove and Disassemble 275

Assemble and Install 277

Troubleshooting 277

Pressure Relief Valve Check and Adjustment 278

Primary Relief Valve 278

Secondary Relief Valve 278

Control Lever Arrangement and Adjustment 279

Specifications 281

Troubleshooting 281

524179945-1900YRM0559-(04-2009)-UK-EN 287

toc 287

Hydraulic System 287

Safety Precautions Maintenance and Repair 288

General 291

Description 291

Hydraulic System 291

Operation 299

Hydraulic System 299

Hydraulic Gear Pump 305

Steering Pump 305

Hydraulic Tank Repair 313

Tank, Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P1 313

Tank, Remove [ERP20-30ALF (B216) and ERP20-30ALF (ERP040-060DH) 315

Tank, Remove [ERP20-32ALF (ERP040-065DH) (E216)] 316

Hydraulic Tank [ERC35-55HG (ERC70-120HH) (B839/C839)] 316

Inspect 317

Small Leaks, Repair 318

Large Leaks, Repair 318

Clean 318

Steam Method 318

Chemical Solution Method 319

Additional Methods for Tank Repair 319

Tank, Install [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A814); ERC/P 319

Tank, Install [ERP20-30ALF (B216) and ERP20-30ALF (ERP040-060DH) 320

Tank, Install [ERP20-32ALF (ERP040-065DH) (E216)] 320

Filter Replacement 321

All Lift Trucks Except [ERC35-55HG (ERC70-120HH) (B839/C839); ER 321

Remove 321

Install 322

Lift Truck Models [ERC35-55HG (ERC70-120HH) (B839/C839)] 322

Remove 322

Install 322

Lift truck Models [ERC20-32AGF (ERC040-065GH) (A908) and ERC/P16 323

Remove 323

Install 323

Lift Truck Models [ERP20-32ALF (ERP040-065DH) (E216)] 325

Remove 325

Install 325

Hydraulic Pump Repair 328

Hydraulic Pump, Remove [ERC/P16-20AAF (ERC030-040AF, AG/BG) (A81 328

Hydraulic Pump, Disassemble ERC/P16-20AAF (ERC030-040AF, AG/BG) 328

Inspect 330

Clean 330

Pump Seal Replace and Pump Assemble 330

Assemble Pump on Motor 330

Hydraulic Pump and Motor, Install [ERC/P16-20AAF (ERC030-040AF, 332

Hydraulic Pump, Remove [ERP20-30ALF (B216); ERP20-30ALF (ERP040- 333

Hydraulic Pump, Disassemble [ERC35-55HG (ERC70-120HH) (B839/C839 334

Hydraulic Pump, Inspect [ERC35-55HG (ERC70-120HH) (B839/C839) an 336

Hydraulic Pump, Clean [ERC35-55HG (ERC70-120HH) (B839/C839) and 336

Hydraulic Pump, Assemble [ERC35-55HG (ERC70-120HH) (B839/C839) a 336

Hydraulic Pump and Motor, Install [ERP20-30ALF (B216); ERP20-30A 336

Main Control Valve Repair 338

Steering Pump Repair 338

Pump, Remove and Disassemble [ERC/P16-20AAF (ERC030-040AF, ERC03 338

Pump, Remove and Disassemble [ERP20-30ALF (B216); ERP20-30ALF (E 340

Pump, Assemble and Install 342

Steering Control Unit Replacement 343

Remove 343

Install 343

Steering Cylinder Repair 349

Main Control Valve Check and Adjust 349

Steering Relief Valve Check and Adjust 350

Specifications 350

Relief Valve Pressures* 350

Hydraulic Tank Capacity (dipstick full mark) 351

Hydraulic Pump Capacities – All Models Except ERC35-55HG (ERC70- 351

Hydraulic Pump Capacities – Models ERC35-55HG (ERC70-120HH) (B83 351

Troubleshooting 351

Steering 351

Steering Housing and Steering Control Unit 352

Hydraulic System 353

524183081-1600YRM1054-(11-2006)-UK-EN 359

toc 359

Steering System for AC Electric Lift Trucks 359

Safety Precautions Maintenance and Repair 360

General 363

Description 364

Steering Wheel and Column Assembly Repair 365

General 365

Assembly Components, Remove 367

Assembly Components, Install 368

Power Steering Motor and Pump 369

Description 369

Remove 369

Disassemble 372

Install 372

Power Steering Pump, Repair 372

Seal, Replace 373

Steering System Air Removal 374

Steering Pressure Check 374

Steering Motor Circuits Check 375

Troubleshooting 376

524183082-2200YRM1055-(10-2009)-UK-EN 381

toc 381

Electrical System (Trucks With AC Controllers) 381

Safety Precautions Maintenance and Repair 382

General 385

Description 386

Features of the Display Panels 386

Other Control Components 387

Display Panel and Key Switch Replacement 388

Display Panel, Replace 388

Key Switch, Replace 390

Controller Replacement 390

Traction and Pump Motor Controller Replacement 390

Master Controller, Replace 396

Master Controller, Remove ERP20-30ALF (ERP040-060DH) (D216), ERP 396

Master Controller, Install ERP20-30ALF (ERP040-060DH) (D216), ER 396

Master Controller, Remove ERC/P16-20AAF (ERC030-040AH) (B814/C81 398

Master Controller, Install ERC/P16-20AAF (ERC030-040AH) (B814/C8 398

Master Controller, Remove ERC35-55HG (ERC070-120HH) (B839/C839) 400

Master Controller, Install ERC35-55HG (ERC070-120HH) (B839/C839) 400

Control Components Replacement 401

General 401

Start Switch, Replace 401

Brake Light Switch, Replace 402

Seat Switch, Replace 402

Parking Brake Switch, Replace 403

Foot Directional Control Pedal Direction Switches, Replace 405

Steering Column Direction Control Switches, Replace 408

Remove 408

Install 408

Brake Fluid Switch, Replace 410

Brush Wear and Over Temperature Sensors (DC Pump Motor Only) 410

Rocker Switches for Lights, Replace 410

Accelerator Position Sensor, Replace 411

On-Demand Steering Sensor, Replace 412

Lights, Converter, Relay, and Reverse Alarm 412

Brake, Tail, and Reverse Light Assembly, Replace 413

Incandescent Assembly 413

LED Assembly – Remove 415

LED Assembly – Install 415

Strobe Light Assembly, Replace 418

Wire Harness Repair 419

Del-City Crimp-Solder-Shrink Splice 419

Front, Rear Driving Light or Spot Light Assemblies, Replace 420

Converter, Replace 420

Remove, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216), ERP 420

Install, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216), ER 422

Remove, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) and 422

Install, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) and 422

Remove, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 424

Install, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 424

Reverse Relay, Replace 425

Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908), ERC/P16-20A 425

Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 425

Backup Alarm, Replace 427

Horn and Horn Button, Replace 427

Horn Replacement for Lift Trucks ERP20-30ALF (ERP040-060DH) (D21 427

Horn Replacement for Lift Trucks ERC35-55HG (ERC70-120HH) (B839/ 429

Horn Switch and Cover, Replace 430

Hydraulic Pump Switches 431

Fan Power Supply, Replace 431

Remove, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 431

Install, Lift Truck Models ERC35-55HG (ERC70-120HH) (B839/C839) 431

Remove, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216) and 432

Install, Lift Truck Models ERP20-30ALF (ERP040-060DH) (D216) and 433

Remove, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) 433

Install, Lift Truck Models ERC20-32AGF (ERC040-065GH) (A908) 433

Control and Power Fuse Check 434

Fuse Locations 434

Brake Light Switch Adjustment 440

Seat Switch Check 441

Seat Brake Adjustment 441

Parking Brake Switch Adjustment 442

Direction Switches Check 442

Foot Directional Control Pedal 442

Steering Column 443

Foot Directional Control Pedal or Accelerator Pedal Adjustment 443

Accelerator Position Sensor Adjustment and Start Switch Adjustme 444

Acceleration Position Sensor, Adjust 444

Start Switch, Adjust 446

tables 381

Table 1 Wire Splice Size 419

524183083-2200YRM1056-(03-2009)-UK-EN 449

toc 449

AC Motor Controllers/Display Panel 449

Safety Precautions Maintenance and Repair 450

Description 453

General 453

AC Motors 453

Motor Controllers 453

Master Controller 453

Dash Display 453

Controller Area Network Bus (CANbus) 453

Master Controller Checks and Adjustments 454

Function Settings 455

General 455

Function Numbers 455

Function Descriptions 458

General 458

Function Number 1 BATTERY VOLTAGE 458

Function Number 2 EXTENDED SHIFT 458

Function Number 3 ACCELERATION 1 458

Function Number 4 ACCELERATION 2 458

Function Number 5 TOP SPEED LIMIT 458

Function Number 6 REGEN BRAKING 458

Function Number 7 AUTO DECELERATION 459

Function Number 8 BDI ADJUSTMENT 459

Function Number 9 LIFT INTERRUPT 459

Function Number 10 POWER STEERING TIME DELAY 459

Function Number 11 SERVICE REMINDER 459

Function Number 12 CUSTOM 459

Function Number 13 PUMP SPEED 1 459

Function Number 14 PUMP SPEED 2 460

Function Number 15 PUMP SPEED 3 460

Function Number 16 PUMP ACCELERATION 460

Troubleshooting 460

General 460

Controller Status Light Emitting Diodes (LEDs) 461

Master Controller 461

AC Motor Controllers 461

Status Codes 467

AC Motor Controllers Status Code Charts 469

Troubleshooting When Dash and/or Lift Truck is not Operational 490

Typical Symptoms 490

Truck Runs but Dash Display is not Operational, or Only Displays 490

Truck Does Not Run and Dash is Not Operational or Only Displays 491

Hydraulics Operate Normally, Traction Does Not Operate Correctly 492

Traction Operates Normally, Hydraulics do Not Operate Correctly, 492

AC Transistor Motor Controller Replacement 492

General 492

General Maintenance Instructions 498

Special Precautions 498

Fuses 499

Fan Test 499

Contactors 499

Repair 499

Thermal Sensors 503

Motor Controller, Replace 503

Display Panel 504

General 504

Premium Display Panel 504

Standard Display Panel 504

Display Functions and Features 505

Key-On Initialization 505

Standard Display 506

Premium Display 506

Lift Truck Inspection Function 507

Access to Service Functions 507

Service Functions 507

Service Functions 508

Performance Modes 510

Battery Discharge Indicator (BDI) 510

Hourmeter 511

Dash Display Service Menu Navigation 517

General 517

Moving Through Menu Selections 517

Editing and Adding Information 517

tables 449

Table 1 Factory Parameters for ERP20-30ALF (ERP040-060DH) (D216 455

Table 2 Factory Setting for ERC020-032AGF (ERC40-65GH) (A908) 456

Table 3 Factory Setting for ERC/P16-20AAF (ERC030-040AH) (B814/ 456

Table 4 Factory Parameters for ERC35-55HG (ERC70-120HH) (B839/C 457

Table 5 List of Status Codes 467

Table 6 42-Pin Connections/Descriptions for Master Controller 500

Table 7 Pin Connections/Descriptions for 72/80 (Gen IV) Volt Mo 502

Table 8 Pin Connections/Descriptions for 36/48 and 72v/80v (Gen 502

524183085-2200YRM1058-(04-2011)-UK-EN 521

toc 521

Troubleshooting and Adjustments Using the AC Controls Program (E 521

Safety Precautions Maintenance and Repair 522

General 525

Computer Requirements 525

Software, Install 525

Language Selection 525

Demo Mode 526

Connect PC to Lift Truck 530

Starting AC Controls Program 532

Lift Truck Control Setup 537

Change Lift Truck Serial Number or Hourmeter 537

Setting Factory Default Values or Changing Lift Truck Parameters 538

Create New Custom Lift Truck Configuration 544

Lift Truck Configuration Properties 547

Import New Lift Truck Configuration From Disk 550

Delete Custom Lift Truck Configuration or Password File 552

Dash Display 555

Custom Display Languages 555

Download Display Language 557

Clear Operator Log 557

Password Functions 560

Enable/Disable Password and Lift Truck Inspection Functions 560

Truck Inspection Checklist 560

Password 560

Password Properties 560

Create New Password File 565

Download Passwords 566

Upload Passwords 568

Reports Menu 570

Devices Report 570

Custom Report 570

Password Report 570

Operator Report 577

Current Settings Report 580

Status Code Report 584

Status Codes Log 587

Troubleshooting 589

Diagnostics 589

Help Menu 592

General 592

Contents 592

Technical Support 592

About Electric Truck AC Controls Program 592

524205680-0620YRM1098-(03-2010)-UK-EN 599

toc 599

AC Motor Repair 599

Safety Precautions Maintenance and Repair 600

General 603

AC Motor Repair 603

Disassemble 603

Assemble 607

Troubleshooting 609

524223768-2100YRM1139-(02-2014)-UK-EN 613

524238572-0100YRM1200-(11-2006)-UK-EN 661

toc 661

Frame 661

Safety Precautions Maintenance and Repair 662

General 665

Description 665

Overhead Guard Replacement 667

Remove 667

Install 668

Battery and Operator Restraint, Hood and Seat Brake Repair 669

Battery Restraint and Hood Repair 669

Operator Restraint System and Seat Assembly 672

Automatic Locking Retractor (ALR) 672

Emergency Locking Retractor (ELR) 672

Seat Brake Repair 673

Counterweight Replacement 673

Remove 673

Install 674

Traction Motor Repair 674

Remove 674

Install 675

Hydraulic Tank Repair 676

Inspect 676

Small Leaks, Repair 676

Large Leaks, Repair 676

Clean 676

Steam Method 677

Chemical Solution Method 677

Additional Preparations For Repair 677

Safety Label Replacement 678

Battery Specifications 680

tables 661

Table 1 Torque Values 668

Table 2 Weight of Counterweights 673

Table 3 Battery Specifications* 680

524238574-8000YRM1201-(02-2010)-UK-EN 683

toc 683

Periodic Maintenance 683

Safety Precautions Maintenance and Repair 684

General 689

How to Move Disabled Lift Truck 689

How to Tow Lift Truck 689

How to Put Lift Trucks on Blocks 690

How to Raise Drive Tires 690

How to Raise Steering Tires 690

How to Clean a Lift Truck 691

Maintenance Schedule 692

Maintenance Procedures Every 8 Hours or Daily 696

General 696

How to Make Checks With Key Switch OFF 697

Tires and Wheels 697

Forks 697

Remove 697

Inspect 697

Install 698

Adjust 698

Inspection of Mast, Mast Pivots, Header Hoses and Lift Chains 699

Safety Labels 699

Steering Column Latch 699

Operator Restraint System 700

Automatic Locking Retractor (ALR) 700

Emergency Locking Retractor (ELR) 700

Battery Restraint System 701

Battery 702

Hydraulic System 703

How to Make Checks With Key Switch ON 704

Horn, Lights, and Alarm 704

Steering System 705

Service Brakes 705

Parking Brake 705

Seat Brake 705

Control Levers and Pedals 705

Direction and Speed Control Pedals 705

Lift System Operation 705

Oil Leaks 706

First Service After First 100 Hours of Operation 706

Change Hydraulic Oil and Filter 706

Lift Truck Models ERC35-55HG (ERC70-120HH) (C839) 706

Remove 706

Install 708

Lift Truck Models ERC35-55HG (ERC70-120HH) (B839) 709

Remove 709

Install 710

Maintenance Procedures Every 500 Hours or 3 Months 711

Wheel Nuts 711

Header Hose Checks 711

Mast Lubrication 711

Integral Sideshift Carriage 714

Brake Fluid 715

Other Lubrication 715

Maintenance Procedures Every 1000 Hours or 6 Months 715

Differential and Speed Reducer 715

Lift Chains 715

Wear Check 715

Lubrication 716

Forks 716

Parking Brake 716

Brake Linkage Shafts 717

Steering Spindles and Tie Rod Ends 717

Seat Rails 717

Seat Plate Hinges 717

Electrical Inspection 718

Contactors 718

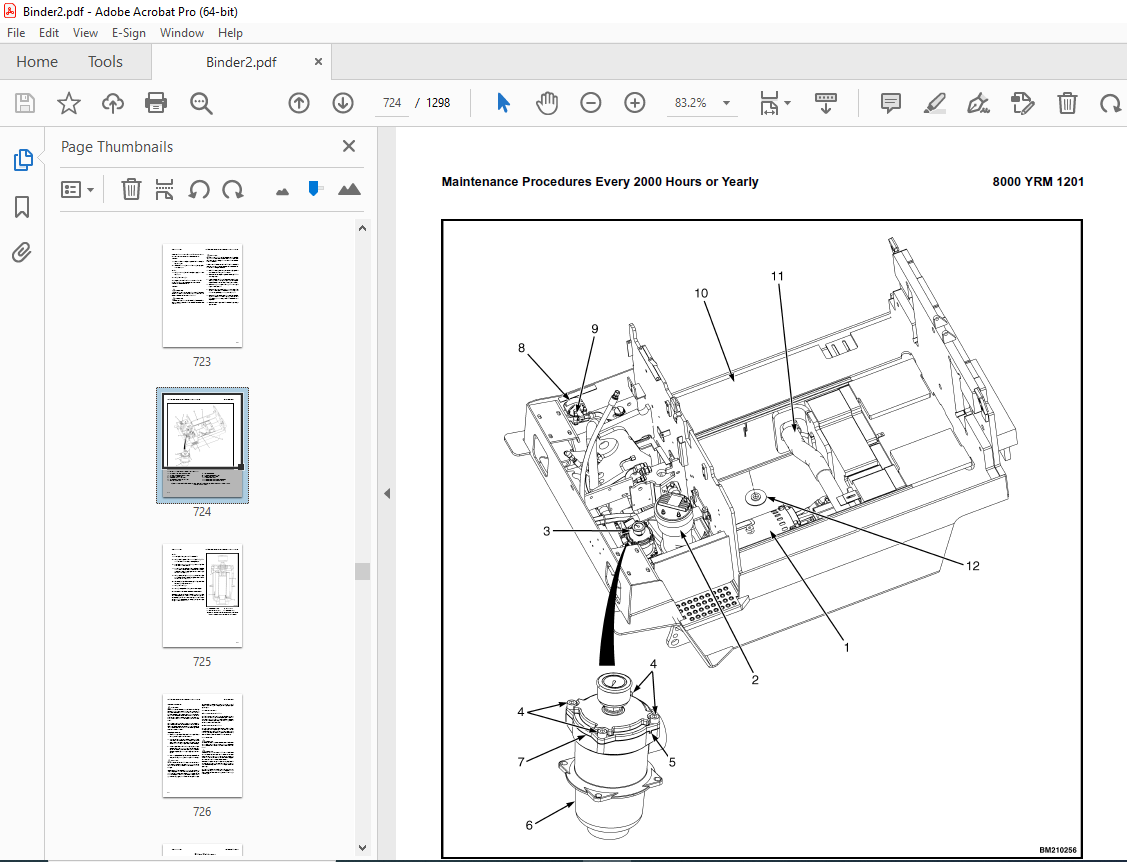

Maintenance Procedures Every 2000 Hours or Yearly 720

Brake Fluid 720

Hydraulic System 721

Hydraulic Tank Breather, Lift Truck Models ERC35-55HG (ERC70-120 721

Change Hydraulic Oil and Hydraulic Oil Filter, Lift Truck Models 721

Remove 721

Install 722

Hydraulic Tank Breather, Lift Truck Models ERC35-55HG (ERC70-120 723

Remove 723

Install 723

Change Hydraulic Oil and Hydraulic Oil Filter, Lift Truck Models 723

Remove 723

Install 725

Differential and Speed Reducer 725

Service Brakes 726

Wheel Bearings 726

Steer Wheels, Lubrication 726

Drive Wheels, Lubrication 726

Lift Chains 726

Battery Maintenance 727

How to Charge Battery 727

How to Change Battery 728

Safety Procedures When Working Near Mast 731

Lift and Tilt System Leak Check 734

Check Lift Cylinders for Leaks 734

Check Tilt Cylinders for Leaks 734

Lift Chain Adjustments 735

Welding Repairs 736

Overhead Guard Changes 737

Wheels and Tires 737

General 737

Remove Wheels From Lift Truck 737

Remove Tire From Wheel and Install Tire on Wheel 737

Remove 737

Install 737

Install Wheels 738

tables 683

Table 1 Maintenance Schedule 693

Table 2 Battery Specifications* 731

Table 3 Hook-Type Carriage Chain Adjustment 736

524238575-8000YRM1202-(11-2006)-UK-EN 741

toc 741

Capacities and Specifications 741

Safety Precautions Maintenance and Repair 742

Lift Truck Lifting Capacity 745

Counterweight Weights 745

Tire Sizes 745

Capacities 746

Hydraulic System 746

Steering System 747

Specifications 747

Turning Radius 747

Mast Speeds 748

Maximum Carriage and Tilt Creep Rates 749

Battery Specifications 749

Traction Motor Speed 750

Battery Current at Hoist Relief 750

Torque Specifications 750

Brake System 750

Differential 751

Drive Axle 751

Frame 751

Mast 751

Main Control Valve 751

Steering System 751

Tilt Cylinders 752

Hydraulic System 752

Electrical System 752

tables 741

Table 1 Manual Control Valve 746

Table 2 E-Hydraulic Control Valve 746

524238576-8000YRM1203-(02-2009)-UK-EN 755

toc 755

Diagrams 755

Safety Precautions Maintenance and Repair 756

524256687-2000YRM1224-(04-2008)-UK-EN 795

toc 795

Electro-hydraulic Control Valve 795

Safety Precautions Maintenance and Repair 796

General 799

Description 799

Electro-Hydraulic Control System 799

Electro-Hydraulic Control Valve 802

Electro-Hydraulic Valve Driver Module 818

Mini-Lever Module (MLM) 818

Joystick 819

Electro-Hydraulic Control Valve Repair 820

Remove 820

Disassemble 829

Solenoid Coil Replacement 831

Cartridge Replacement 833

Electro-Hydraulic Pressure Reducing Valve (EHPR) Replacement 834

Lift Circuit Check Valve Replacement 835

Compensator Cartridge Replacement 835

Primary and Secondary Relief Valves Replacement 835

Tilt Counterbalance Valve Replacement 836

Flow Regulator Valve Replacement 836

Assemble 836

Install 836

E-Hydraulics Calibration 845

Mini-Lever Module 847

Mini-Lever Module (MLM) 847

Remove 847

Install 847

Mini-Lever Replacement 847

Remove 847

Clean and Inspect 848

Install 848

Push Button Switch Replacement 849

Remove 849

Install 850

Test 851

Mini-levers 851

Full Stroke Test 851

Function Returns to Neutral Test 851

Push Button Switch 852

Joystick 852

Remove and Disassemble 852

Inspect 852

Assemble and Install 852

Troubleshooting 853

tables 795

Table 1 Primary and Secondary Relief Valve Values 805

Table 2 Solenoid Resistance Values 831

Table 3 Cartridge and Solenoid Coil Nut Torque for Lift truck M 834

Table 4 Cartridge and Solenoid Coil Nut Torque for Lift truck M 834

524265342-4000YRM1250-(06-2021)-UK-EN 865

Safety Procedures When Working Near Mast 871

Fork Replacement 874

Remove, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 874

Remove, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 875

Remove, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 877

Install, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 878

Install, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 879

Install, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017 GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 880

Checks, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 880

Checks, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 881

Checks, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 882

Fixed Carriage Replacement 884

Remove, Carriage With Hook Forks 884

Remove, Carriage With Pin Type Forks Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 892

Install, Carriage With Hook Forks 893

Install, Carriage With Pin Type Forks Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 893

Disconnecting Attachment Hydraulic Quick Disconnect Hoses 894

Connecting Attachment Hydraulic Quick Disconnect Hoses 894

Integral Sideshift Carriage Repair 895

Remove, for lift truck models ERC35-55HG (ERC70-120HH) (C839), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 895

Disassemble 895

Clean and Inspect 898

Assemble 898

Install, for lift truck models ERC35-55HG (ERC70-120HH) (C839), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 899

Hang On Sideshift Carriage Repair 900

Remove, Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GC/GLC/GDC60VX, GC/GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879, G879) 900

Disassemble 912

Clean and Inspect 921

Assemble 922

Install 923

Hang-On Sideshift Carriage Repair 925

Remove 925

Disassemble Carriage 927

Clean and Inspect 930

Assemble 930

Install 933

Fork Positioner 936

Two-Stage Mast With Limited Free-Lift Repair 937

Remove 937

Disassemble 940

Clean and Inspect 943

Assemble 961

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 963

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879, G879), and ERC35-55HG (ERC70-120HH) (C839) 965

Header Hose Alignment 976

Two-Stage Mast With Full Free-Lift Repair 987

Remove 987

Disassemble 989

Clean and Inspect 1000

Assemble 1001

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 1003

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and ERC35-55HG (ERC70-120HH) (C839) 1006

Header Hose Installation and Adjustment 1010

Installation 1010

Adjustment 1011

Three-Stage Mast With Full Free-Lift Repair 1012

Remove 1012

Disassemble 1014

Clean and Inspect 1044

Assemble 1046

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) and GLP/GDP60VX, GLP/GDP70VX, (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 1049

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818), GC/GLC/GDC60VX, GC/GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879, G879), and ERC35-55HG (ERC70-120HH) (C839) 1054

Header Hose Alignment for GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813), and ERC35-55HG (ERC70-120HH) (C839) 1061

Header Hose Alignment for GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GC/GLC/GDC60VX, GC/GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879, G879) 1068

Mast Operation Check 1072

Tilt Cylinder Adjustment 1073

Lift Chains Adjustment 1073

Mast Adjustments 1075

Load Roller Adjustment 1075

Mast Side Kicking Adjustment 1077

Shimming The Mast Mounting Pin, Lift Truck Models GP/GLP/GDP080, 090, 100, 110, 120VX (F813, G813, H813, K813) 1078

Carriage Adjustments 1080

Series Code / Model Designation Reference Table 1081

524265342-4000YRM1250-(09-2018)-UK-EN 1085

Safety Procedures When Working Near Mast 1091

Fork Replacement 1093

Remove, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 1093

Remove, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 1095

Remove, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 1096

Install, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 1097

Install, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 1098

Install, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017 GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 1099

Checks, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 1099

Checks, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 1101

Checks, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 1101

Fixed Carriage Replacement 1103

Remove, Carriage With Hook Forks 1103

Remove, Carriage With Pin Type Forks Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 1112

Install, Carriage With Hook Forks 1113

Install, Carriage With Pin Type Forks Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 1113

Disconnecting Attachment Hydraulic Quick Disconnect Hoses 1114

Connecting Attachment Hydraulic Quick Disconnect Hoses 1114

Integral Sideshift Carriage Repair 1115

Remove, for lift truck models ERC35-55HG (ERC70-120HH) (C839), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 1115

Disassemble 1115

Clean and Inspect 1118

Assemble 1118

Install, for lift truck models ERC35-55HG (ERC70-120HH) (C839), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 1119

Hang On Sideshift Carriage Repair 1119

Remove, Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 1119

Disassemble 1131

Clean and Inspect 1140

Assemble 1141

Install 1142

Bolzoni Hang-On Sideshift Carriage Repair 1144

Remove 1144

Disassemble Carriage 1146

Clean and Inspect 1149

Assemble 1149

Install 1152

Fork Positioner 1154

Two-Stage Mast With Limited Free-Lift Repair 1155

Remove 1155

Disassemble 1159

Clean and Inspect 1162

Assemble 1179

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 1181

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), and ERC35-55HG (ERC70-120HH) (C839) 1182

Header Hose Alignment 1194

Two-Stage Mast With Full Free-Lift Repair 1204

Remove 1204

Disassemble 1206

Clean and Inspect 1218

Assemble 1219

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 1221

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and ERC35-55HG (ERC70-120HH) (C839) 1224

Header Hose Installation and Adjustment 1228

Installation 1228

Adjustment 1228

Three-Stage Mast With Full Free-Lift Repair 1229

Remove 1229

Disassemble 1231

Clean and Inspect 1261

Assemble 1262

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) and GLP/GDP60VX, GLP/GDP70VX, (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 1266

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818), GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), and ERC35-55HG (ERC70-120HH) (C839) 1271

Header Hose Alignment for GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813), and ERC35-55HG (ERC70-120HH) (C839) 1278

Header Hose Alignment for GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 1284

Mast Operation Check 1288

Tilt Cylinder Adjustment 1288

Lift Chains Adjustment 1289

Mast Adjustments 1290

Load Roller Adjustment 1290

Mast Side Kicking Adjustment 1292

Shimming The Mast Mounting Pin, Lift Truck Models GP/GLP/GDP080, 090, 100, 110, 120VX (F813, G813, H813, K813) 1293

Carriage Adjustments 1296